Prepn of oxygen-sensing sensor

A sensor and oxygen-sensing technology, applied in the direction of material electrochemical variables, material resistance, etc., can solve the problems of narrow oxygen-sensitivity range, different preparation methods, high working temperature, etc., and achieve the effects of fast response, broad application prospects and low working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

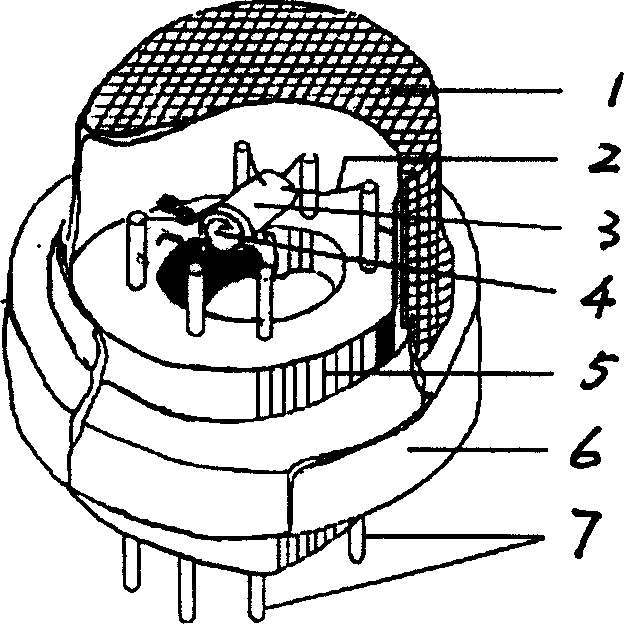

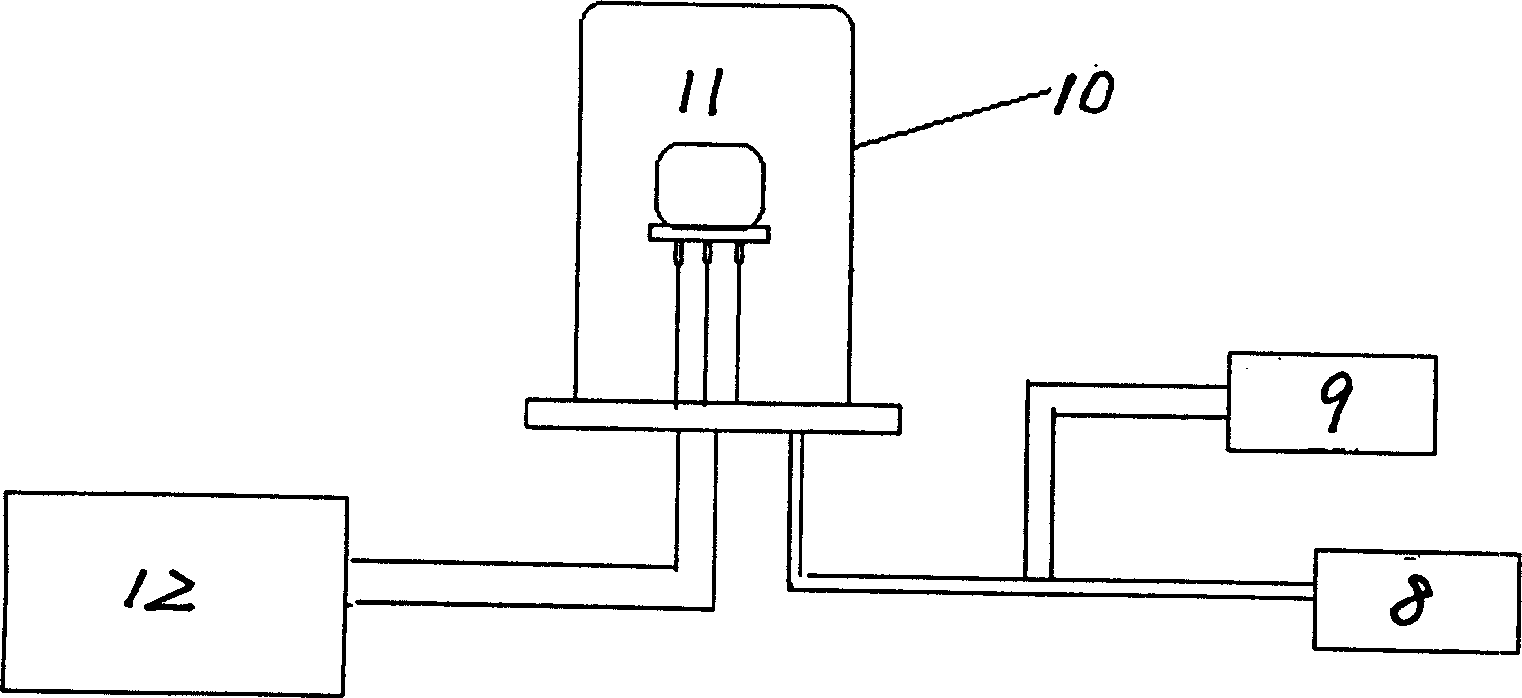

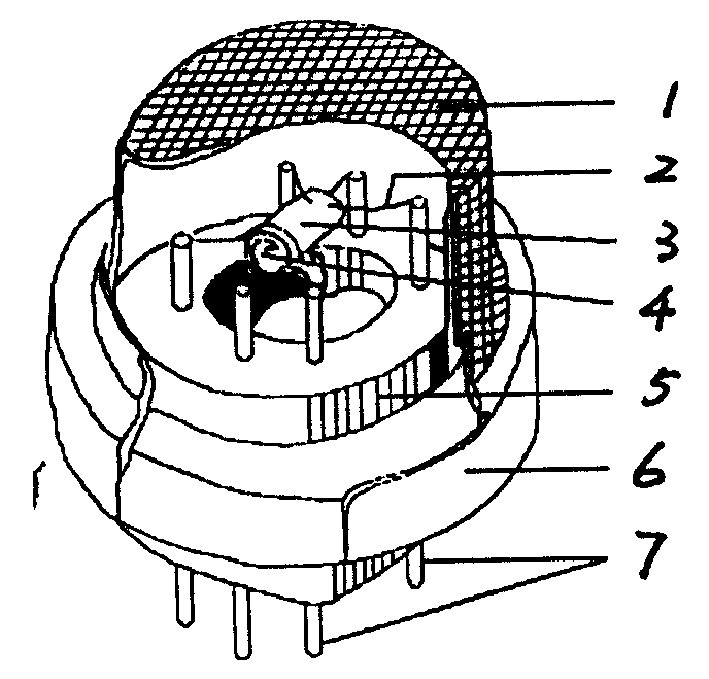

Method used

Image

Examples

Embodiment 1

[0036] (1) Using titanium trichloride (TiCl 3 ) (15% dissolved in HCl solution) and doped NbCl 5 When the source material is Nb:Ti=11:89 (molar ratio) (the above are analytically pure), fully stir in a 60°C water bath.

[0037] (2) add an appropriate amount of hydrogen peroxide (H 2 o 2 ) strong oxidant and DBS surface coating agent, stirred in a water bath at 60°C until a gel is formed, and kept warm for 3-5 hours.

[0038] (3) Prepare the gel in a vacuum oven at 80° C. and dry it for 12 hours.

[0039] (4) Grinding for 2 hours to make nanopowder. Pre-fire at 350°C for 1 hour to remove related organic matter.

[0040] (5) Prepare the above nano-powder with terpineol, and evenly spread it on the porcelain tube with the brush electrode to form a thick-film semiconductor element.

[0041] (6) Thick-film components are placed in a muffle furnace and sintered at 400°C for 1 hour. Its structure is determined by X-ray powder diffraction to be pure rutile phase, the grain size i...

Embodiment 2

[0044] (1) Using titanium trichloride (TiCl 3 ) (content 15% dissolved in HCl solution) and

[0045] doped TaCl 5 When Ta:Ti=4:96 (molar ratio) as the source material (the above are analytically pure), fully stir in a 60°C water bath.

[0046] (2) add an appropriate amount of hydrogen peroxide (H 2 o 2 ) strong oxidant and DBS surface coating agent, stirred in a water bath at 60°C until a gel is formed, and kept warm for 3-5 hours.

[0047] (3) Prepare the gel in a vacuum oven at 80° C. and dry it for 12 hours.

[0048] (4) Grinding for 2 hours to make nanopowder. Pre-fire at 350°C for 1 hour to remove related organic matter.

[0049] (5) Prepare the above nano-powder with terpineol, and evenly spread it on the porcelain tube with the brush electrode to form a thick-film semiconductor element.

[0050] (6) Thick-film components are placed in a muffle furnace and sintered at 400°C for 1 hour. Its structure is determined by X-ray powder diffraction to be pure rutile phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com