Reversably removal lithium embedded material for cathode of lithium ion battery and its preparation

A lithium-ion battery, intercalation technology, applied in the direction of electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of cycle performance degradation, poor anti-overcharge ability, high price, etc., and achieve a wide charging and discharging voltage window, The effect of easy control and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]Weigh 100mg of lithium tablets, in N 2 Under the protection of the atmosphere, heat treatment at 100°C for 15 hours. When the metallic white lithium flakes were completely transformed into dark red, they were taken out and placed in a glove box. Grind it with an agate mortar and sieve it through a 200-mesh sieve to prepare Li 3x SiO 2 N x Required Li 3 N powder precursor.

[0027] In a glove box filled with Ar gas, weigh an appropriate amount of Li at a molar ratio of 5:3 3 N and Si powders (5 SiN y (where 0<Y<1.67).

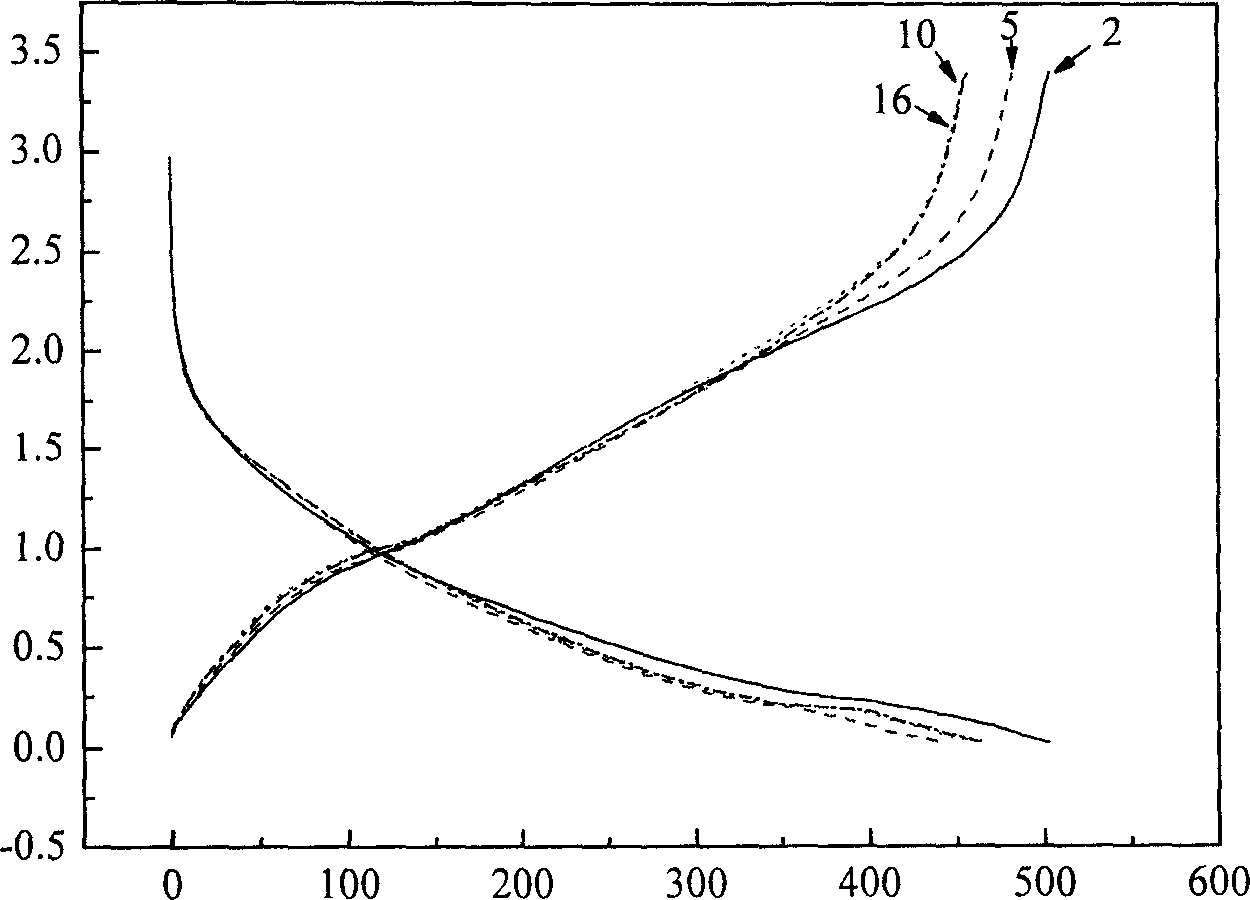

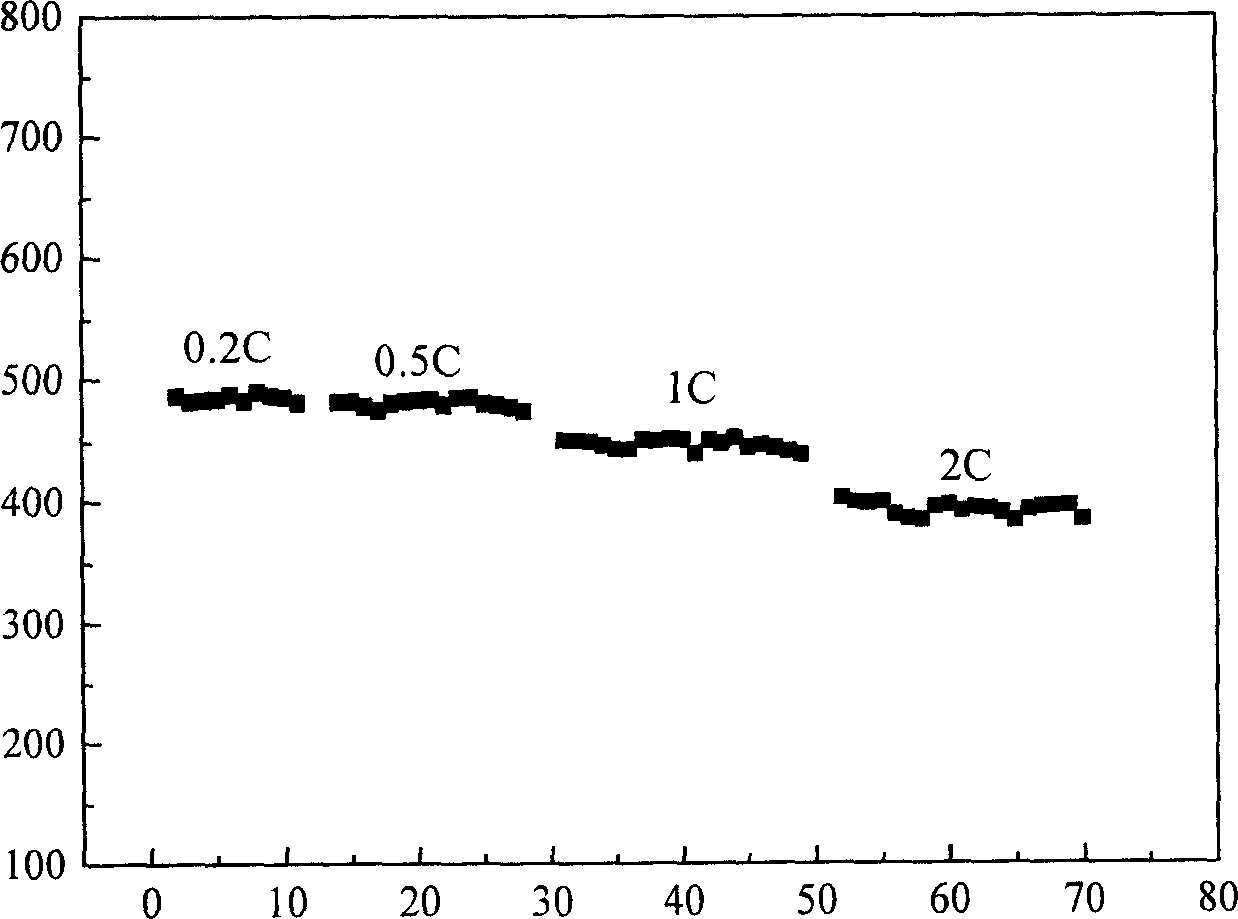

[0028] The product after the reaction is made into an electrode sheet according to the electrode sheet preparation process, and is used as a counter electrode with metal Li to make a button battery, and the electrolyte is LiPF 6 / EC: DMC (1:1, Vol). The test charge and discharge current density is 0.24mA / cm 2 , Cut-off charge and discharge voltage 0 ~ 3V. The first reversible capacity of the prepared material reaches more than 400mAh / g, and the f...

Embodiment 2

[0030] Li 3 The preparation of N powder is the same as in Example 1.

[0031] In a glove box filled with Ar gas, weigh an appropriate amount of Li at a molar ratio of 5:3 3 N and nano-silicon powder, mixed evenly, and placed in a stainless steel ball mill jar, sealed. And fill the ball mill with pure N 2 , when it is determined that the tank is completely filled with nitrogen, seal the ball mill tank. At room temperature, the ball mill was milled at a frequency of 450 rpm for 20 hours. To obtain the desired product, its chemical formula is Li 5 SiN y (wherein 1.67<Y<3). For the reacted product, the cut-off charge and discharge voltage of the electrochemical test process is 0-3.4V, and the rest are the same as in Example 1. The first reversible capacity of the prepared composite negative electrode material reaches more than 480mAh / g, the first charge and discharge efficiency is more than 80%, and after 16 cycles, the capacity retention rate is more than 90%.

Embodiment 3

[0033] Li 3 The preparation of N powder is the same as in Example 1.

[0034] In a glove box filled with Ar gas, weigh an appropriate amount of Li at a molar ratio of 3:1 3 N and SiO 2 Powder, mixed evenly, and placed in a stainless steel ball mill jar, sealed, at this time the ball mill jar was full of Ar gas. At room temperature, the ball mill was milled at a frequency of 600 rpm for 10 hours. The desired product Li 9 SiO 2 N 3 . The reaction product, the electrochemical test process is the same as in Example 1. The prepared composite anode material has a reversible capacity of more than 600mAh / g for the first time, and after 10 cycles, the capacity has almost no fading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com