Metal surface constructional gradient biological layer and its preparation and usage

A bio-coating and structural gradient technology, applied in the fields of coating, electrolytic inorganic material coating, medical science, etc., can solve problems such as the inability to effectively prevent the dissolution of harmful metal ions, so as to facilitate cell proliferation, improve adhesion, and improve biological active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

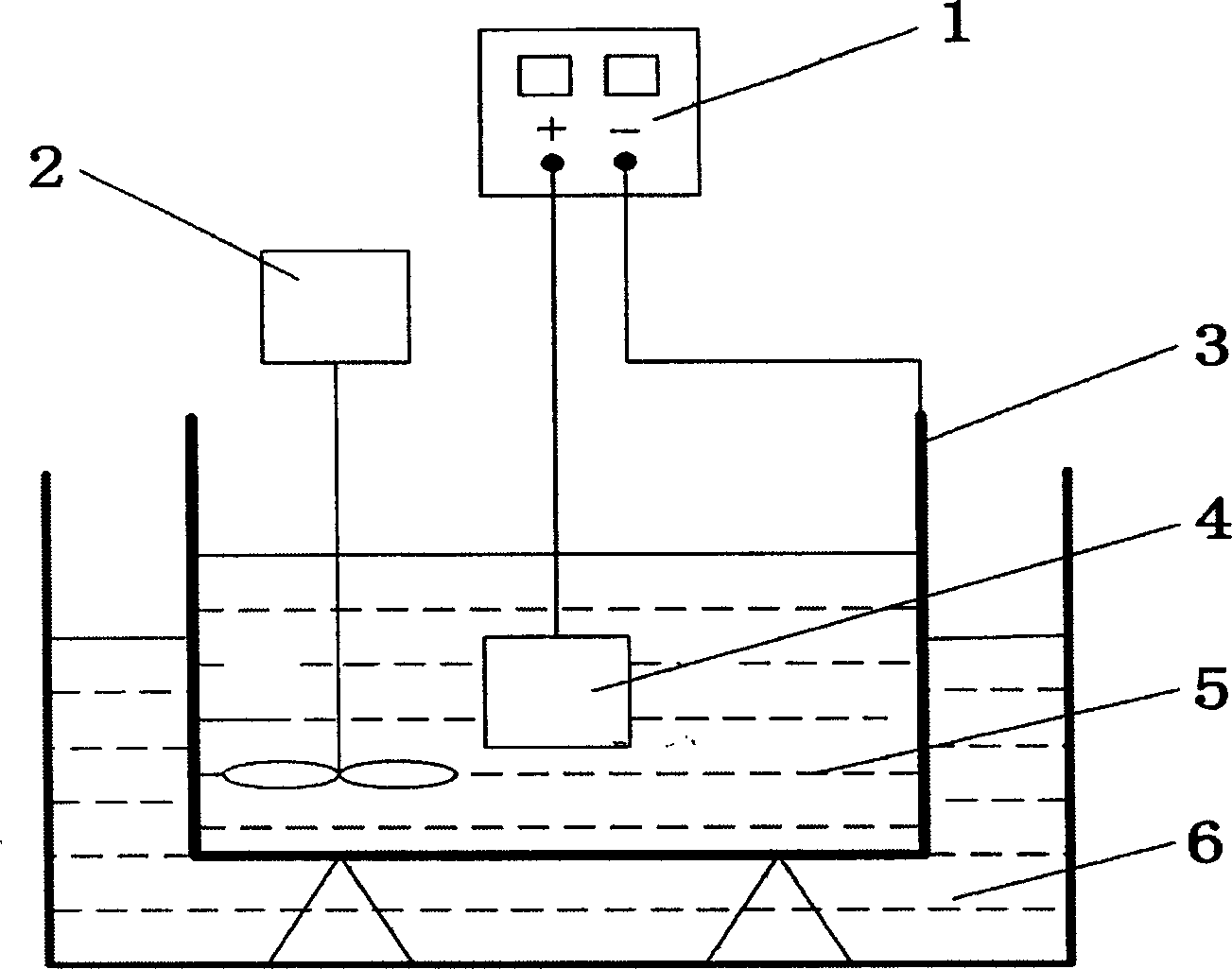

[0028] 1) With pure titanium as the substrate, first anodize the pure titanium: use 0.5M / L oxalic acid solution as the electrolyte, and use pure titanium as the anode, stainless steel electrolytic cell as the cathode, and use DC power supply with voltages of 100V and 200V respectively , 300V, the range of current density is 300~50mA / cm 2 , the oxidation time is 2min, 10min, 30min respectively, and the anodic oxidation is carried out on the pure titanium specimen.

[0029]2) Prepare the electrolyte solution so that it contains 0.5 mol / L of calcium acetate and 0.05 mol / L of β-sodium glycerophosphate. With the anodized test piece as the anode and the stainless steel electrolytic cell as the cathode, the current density is 5-100mA / cm when the DC high voltage is 150, 300V and 600V respectively. 2 , the oxidation time is 5min, 30min, 60min respectively.

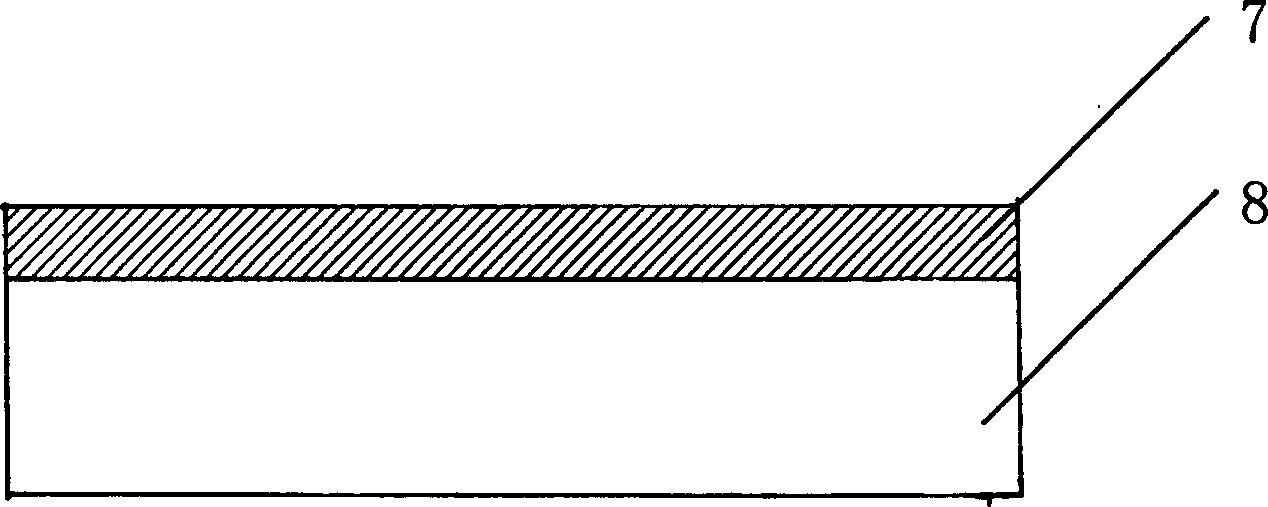

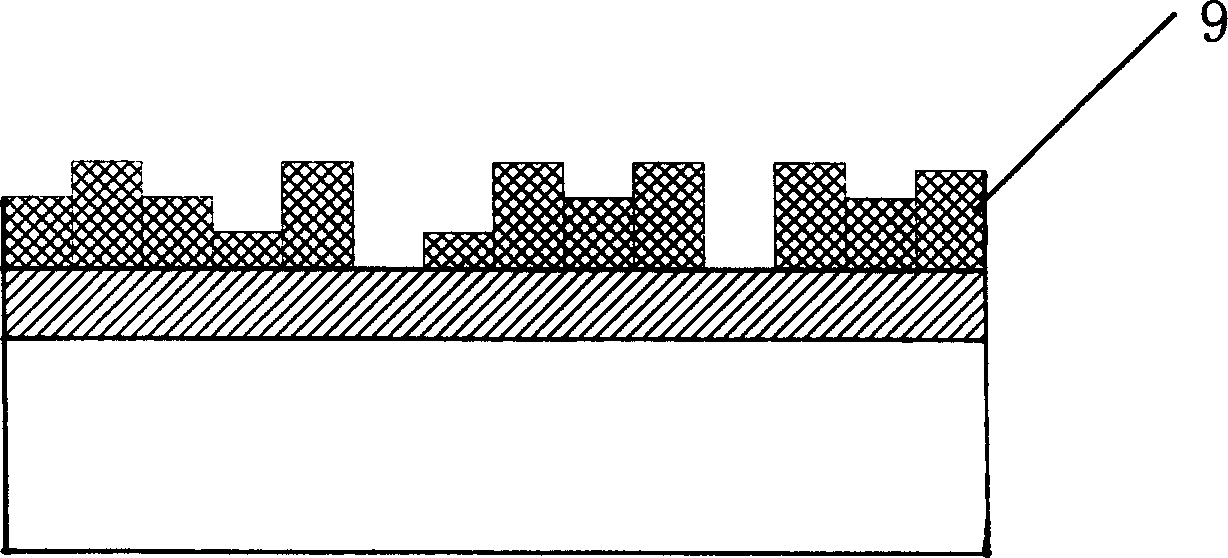

[0030] The titanium dioxide coating with structural gradient prepared by this group of processes is composed of dense inner lay...

Embodiment 2

[0032] 1)) With Ti6Al4V as the substrate, first anodize Ti6Al4V: use 0.5M / L phosphoric acid solution as electrolyte, pure titanium as anode, stainless steel electrolytic cell as cathode, DC power supply, voltage respectively 100V, 200V, 300V, the range of current density is 300~180mA / cm 2 , the oxidation time is 2min, 10min, 30min, anodizing the pure titanium specimen.

[0033] 2) Prepare the electrolyte solution so that it contains 0.05mol / L of calcium ions and 0.001mol / L of phosphate ions, with the anodized specimen as the anode and the stainless steel electrolytic cell as the cathode, and the current density is 20mA / cm 2 , 60mA / cm 2 , 100mA / cm 2 , the voltage is 200-420V, and the oxidation time is 5min, 10min, 30min.

[0034] The biological coating with structural gradient prepared by this group of processes is composed of a dense inner layer (1.2-5 μm in thickness) and porous titanium dioxide (1.7-20.0 μm in thickness) in the outer layer. The thickness of the inner lay...

Embodiment 3

[0036] 1) First, anodize Ti6Al7Nb: use 0.05M / L oxalic acid solution as electrolyte, titanium alloy as anode, stainless steel electrolytic cell as cathode, use DC power supply at constant voltage 125V, current density variation range is 300-180mA / cm 2 , the oxidation time is 30min, anodize the pure titanium specimen.

[0037] 2) Prepare the electrolyte solution so that it contains 0.01mol / L calcium ion and 0.001mol / L phosphate ion, take the anodized test piece as the anode and the stainless steel electrolytic cell as the cathode, adopt a DC high voltage power supply, and take the current density 40mA / cm 2 , the oxidation time is 5-40min, and the voltage is 200-430V.

[0038] The titanium dioxide coating with structural gradient prepared by this group of processes is composed of dense inner layer (0.7 μm in thickness) and porous titanium dioxide (2-15.0 μm in thickness) in the outer layer. The thickness of the inner layer can reach 2μm; the hardness can reach HV 200g 270; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com