A nonaqueous electrolyte for lithium secondary battery

A non-aqueous electrolyte and lithium secondary battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of lower solvent ignition point, lower battery safety, high melting point, etc., to inhibit further decomposition and improve charge and discharge efficiency , Improve the effect of cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

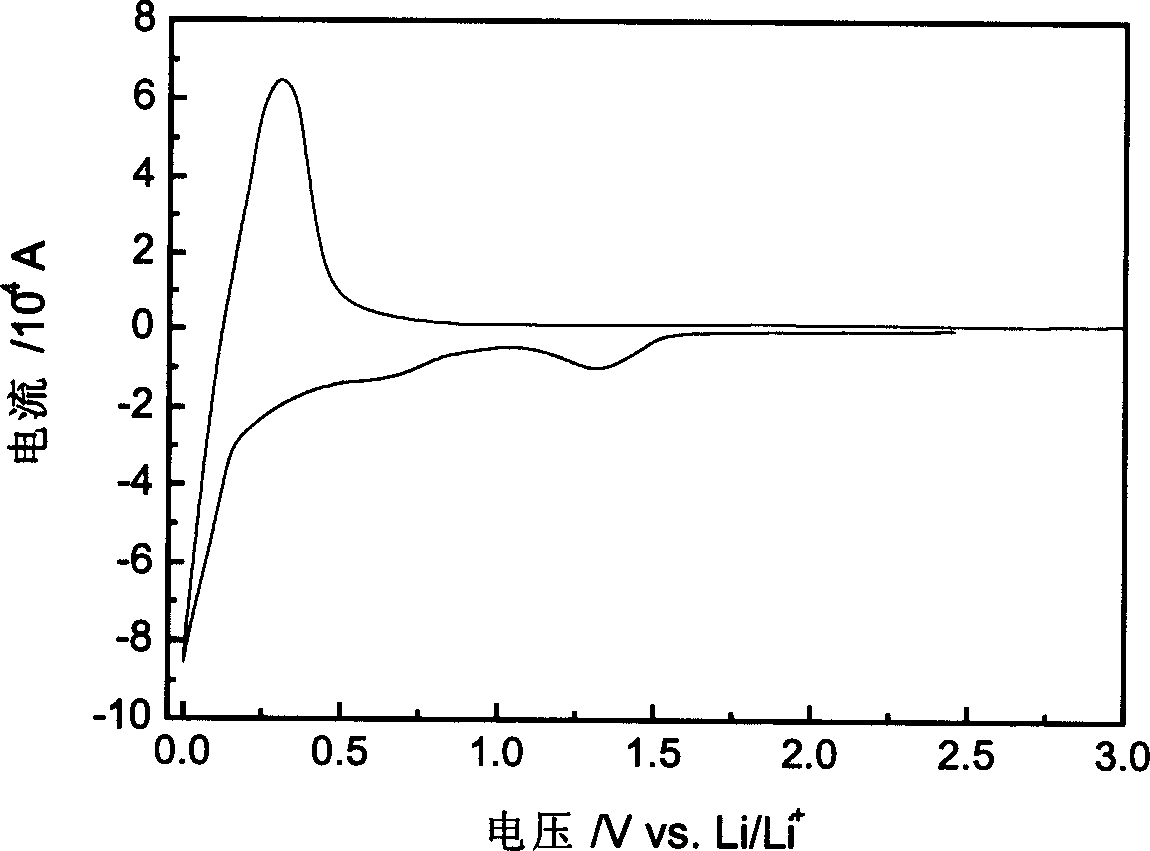

[0027] Embodiment 1, preparation contains the non-aqueous electrolyte of 0.1wt% tetrachlorethylene and simulation battery 1

[0028] In an argon atmosphere glove box with a water content of 6 Dissolved therein at an amount of 1 mol / L to prepare a non-aqueous electrolyte containing 0.1 wt % tetrachlorethylene.

[0029] The natural graphite powder of 90 parts by weight is mixed with the N-methylpyrrolidone binder solution of 10 parts by weight of PVDF (polyvinylidene fluoride) to form a uniform slurry, and evenly coated on the thickness of the negative electrode current collector On the 12μm copper foil, vacuum-dried at 120°C for 8 hours, cut into electrode sheets of a certain size, used as the cathode, and the lithium foil as the anode, with a separator impregnated with the prepared non-aqueous electrolyte in between to form a simulated battery 1 .

Embodiment 2~4

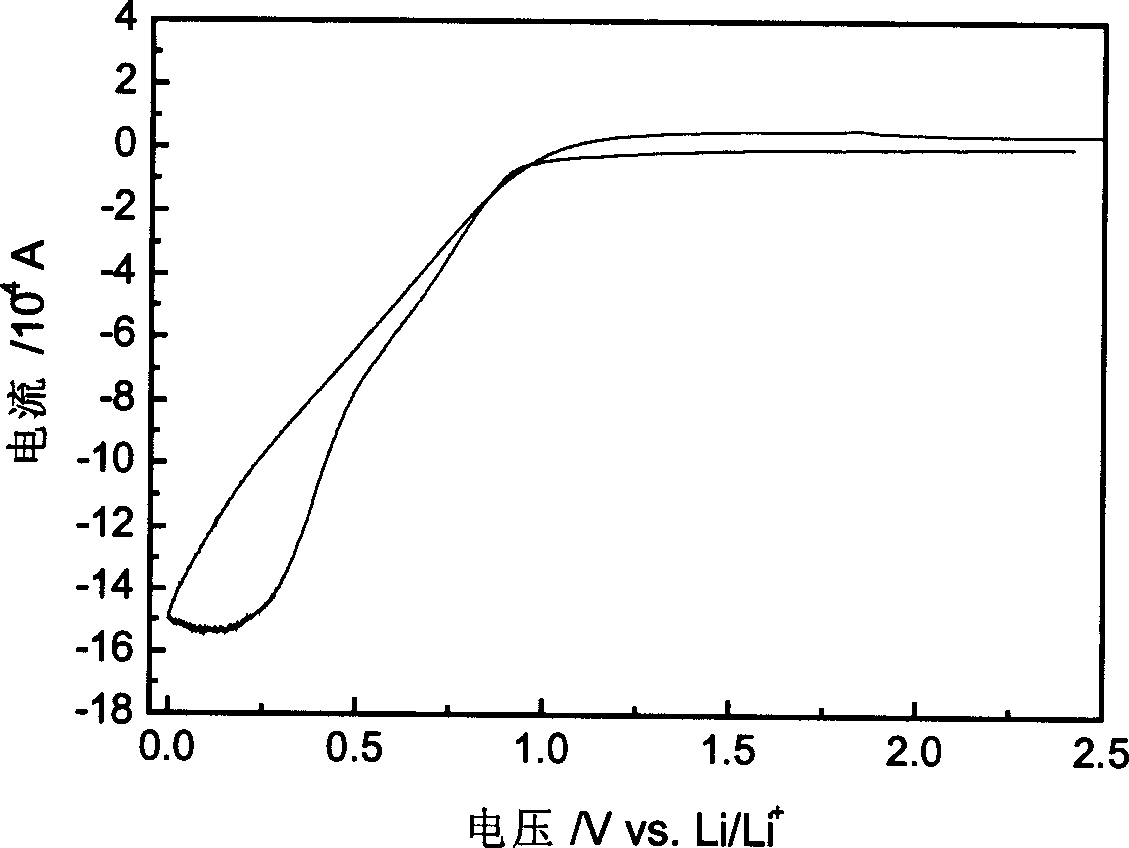

[0030] Embodiment 2~4, preparation contains the non-aqueous electrolyte of 3wt%, 5wt% and 10wt% perchlorethylene and simulation battery 2~4

[0031] According to the method of Example 1, 3wt%, 5wt% and 10wt% tetrachlorethylene were dissolved in propylene carbonate and LiPF respectively 6 Among them, non-aqueous electrolytes containing 3wt%, 5wt% and 10wt% tetrachlorethylene were prepared.

[0032] According to the method in Example 1, simulated batteries 2-4 were constructed.

Embodiment 5~8

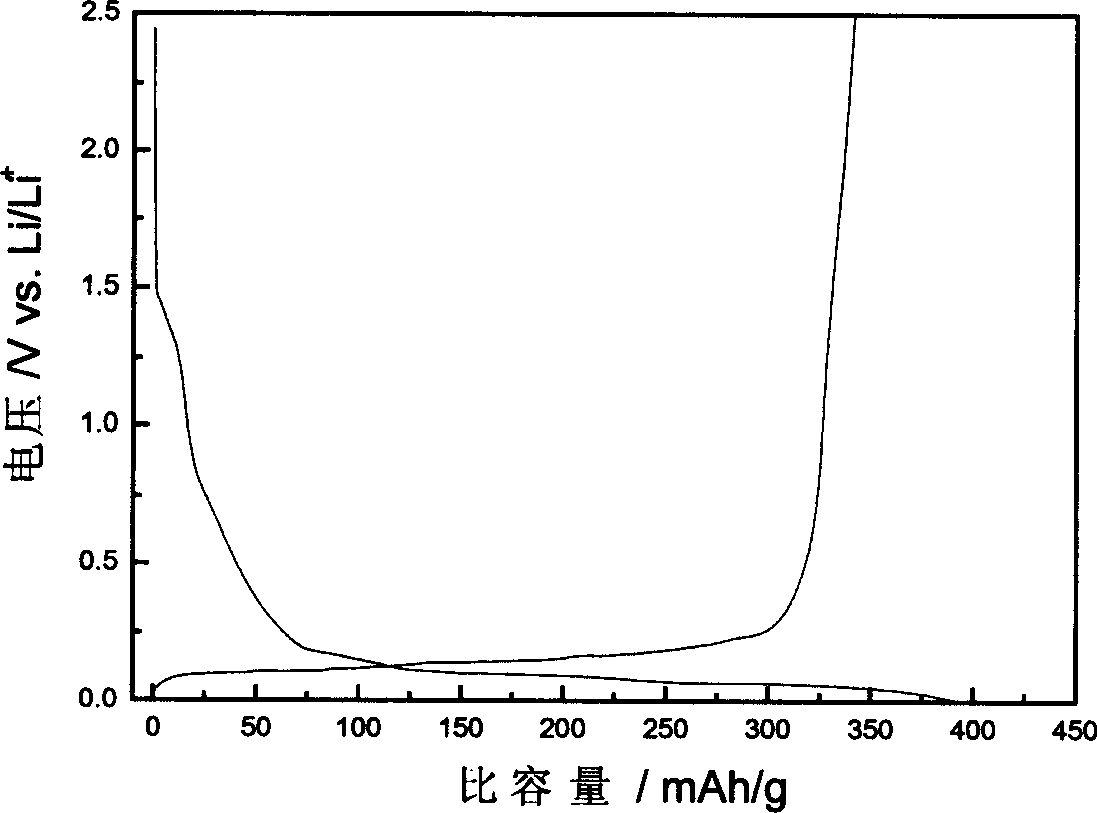

[0033] Examples 5-8, preparation of non-aqueous electrolytes and simulated batteries containing 0.1wt%, 3wt%, 5wt% and 10wt% tetrafluoroethylene 5-8

[0034] According to the method of Example 1, 0.1wt%, 3wt%, 5wt% and 10wt% tetrafluoroethylene were dissolved in propylene carbonate and LiPF respectively 6 Among them, non-aqueous electrolytes containing 0.1wt%, 3wt%, 5wt% and 10wt% tetrafluoroethylene were prepared.

[0035] According to the method in Example 1, simulated batteries 5-8 were constructed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com