Cordycepin food and cordycepin substrate and preparing process thereof

A technology of Cordyceps militaris and matrix, applied in the direction of fungi, etc., can solve the problems of complex production and processing technology, complex processing technology, large investment in production equipment, etc., and achieve the effect of simplifying the production process, simplifying the process and saving capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

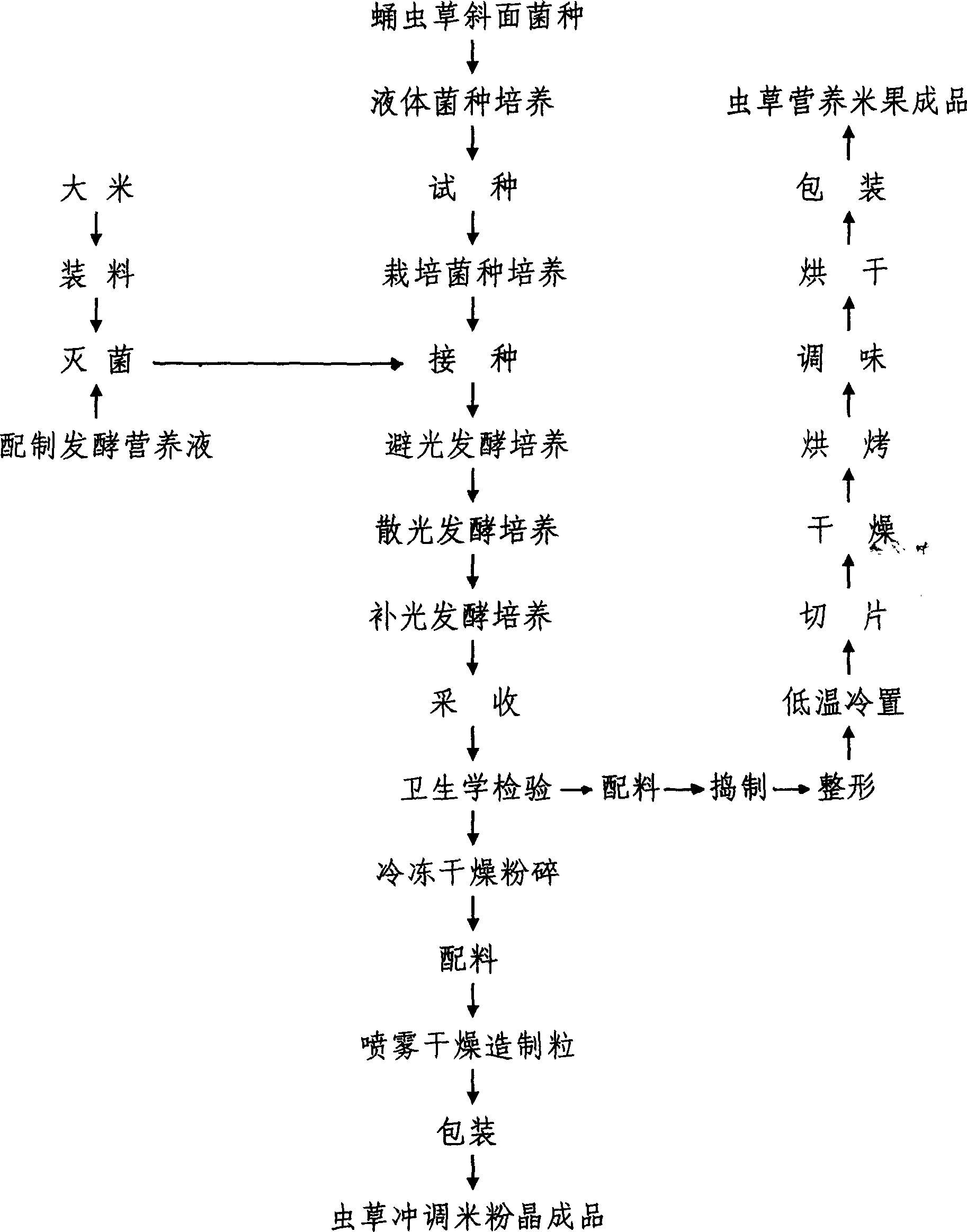

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Preparation of Cordyceps militaris matrix

[0035] a. Purchase and test Cordyceps militaris strains, and purchase Paecilomycesmilitaris (Kob.) Brown et Smith strains. If the mycelium is formed after the trial planting, the color change is normal, and the stroma can be formed in about 15 days , can be confirmed as excellent strains.

[0036] b. Prepare culture medium, choose high-quality Northeast rice, potatoes, and carrots, boil the peeled and sliced potatoes and carrot slices in 1300ml water for 20-30 minutes, squeeze the potato slices with a little force to crush them, filter the residue, take the juice, and take the juice The amount is 1000-1200ml, and the insufficient part is made up with water. The ratio of water, potatoes, and carrots is 1000-1200ml:150-170g:50-70g. ratio, put it into a wide-mouth bottle, and then seal the material bottle filled with the culture medium with a polypropylene film, autoclave for 35 minutes, and cool it for later use...

Embodiment 2

[0044] a, prepare the liquid strain of Cordyceps militaris,

[0045] The first step is to weigh the peeled potatoes, slice them into the pot, add water, cook for 25 minutes, remove the residue and get the filtered juice (if insufficient, add water); add 1500ml of potatoes and water into the pot according to the ratio of 100g, and the filtered juice is 1000ml .

[0046] In the second step, in every 1000ml of potato juice, add: 2.5g of potassium dihydrogen phosphate, 1.5g of magnesium sulfate, 1.5g of yeast extract, 5g of peptone, 15g of glucose, and 15g of white sugar, and divide the prepared liquid into glass In culture flasks (100ml per bottle).

[0047] In the third step, the prepared liquid culture bottle is autoclaved for 45 minutes, and cooled for later use.

[0048] The fourth step is to pick out the Cordyceps militaris bacteria stored in the inclined tube, about the size of rice grains, and put them into the sterilized culture bottle, and keep it in the dark for 72 ho...

Embodiment 3

[0049] Embodiment 3: Preparation of Cordyceps brewed rice flour crystals

[0050] Main ingredients: Freeze-dried and superfinely pulverized culture substrate powder. The particle size is above 200 mesh.

[0051] Ingredients: freeze-dried base powder 100g, cooked rice flour 100kg (grain size 200 mesh), xylose 20kg, lecithin 200g, vegetable oil 4kg, citric acid 200g, sodium bicarbonate 200g, vanillin 200g.

[0052] Operation method: Process the prepared raw materials according to the spray-drying granulation process. Packing method and packing material: 40g small bag, vacuum packed with nitrogen, 18 small bags per big bag, net weight 720g. The packaging material is aluminum floating film plastic.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com