Rare-earth yttrium-aluminium garnet luminous material and its gas-phase preparing method

A technology of yttrium aluminum garnet and luminescent material, applied in the field of luminescent material, can solve the problems of unequal size, hollow shape and high energy consumption, and achieve the effects of stable temperature characteristics, uniform size and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

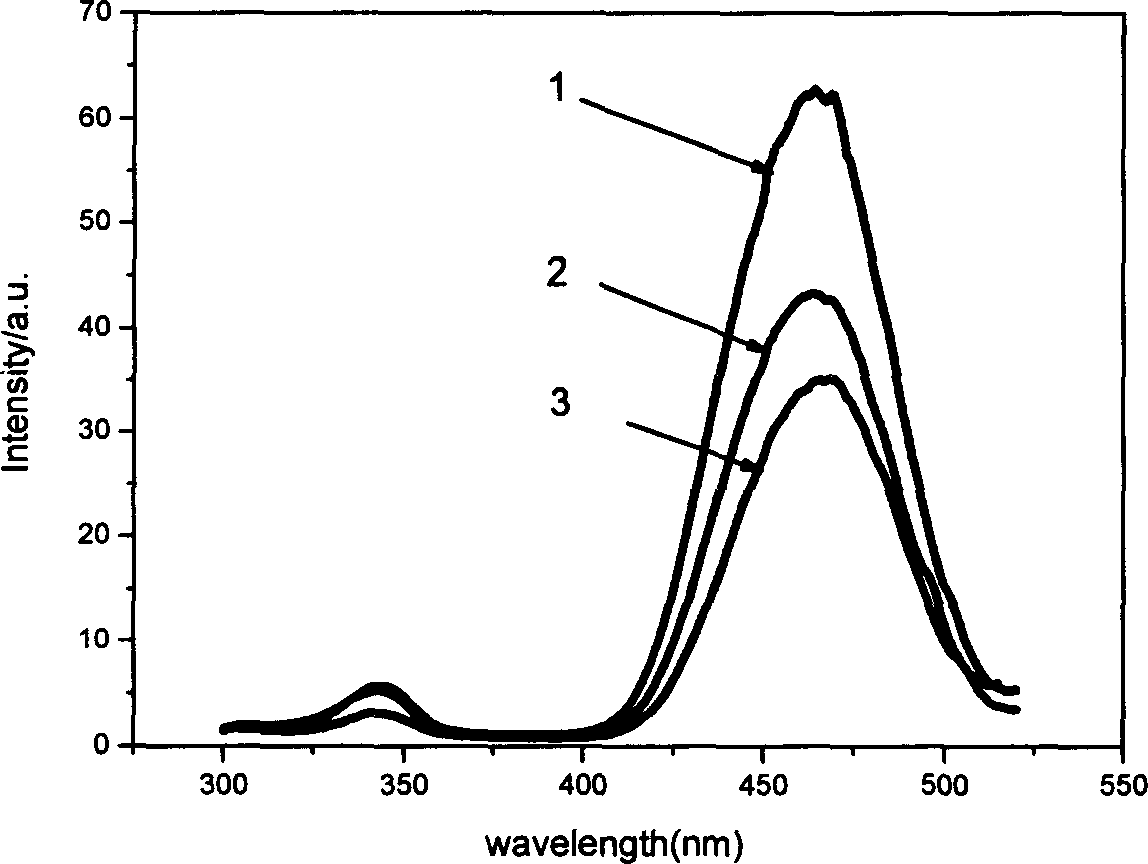

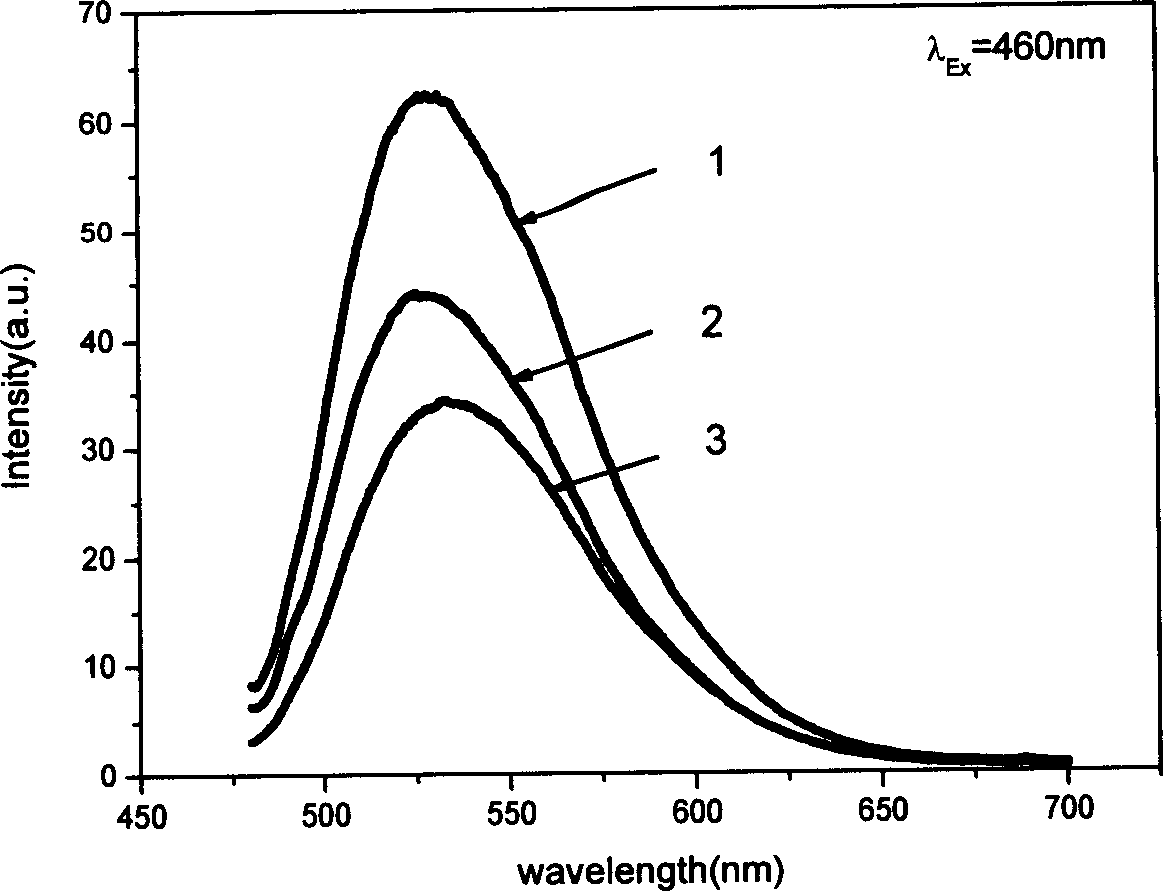

[0024] According to pseudo-boehmite: water=5:95 (percent weight ratio), the pseudo-boehmite is dissolved in deionized water, and the acidity is adjusted to pH=2 with a nitric acid solution with a percentage concentration of 30%. After dispersion, a stable colloid is obtained, and the seed crystal is about 5 nanometers; according to the chemical formula, it is Y 3-m Al 5-n R n o 15 : Ce m , wherein the number of atomic moles m=0.02, n=1, R=Ga, and B are added at the same time, and the number of atomic moles is 0.5 each. Add yttrium nitrate, cerium nitrate, gallium nitrate and boric acid, and perform mechanical stirring to form a doped sol, and the sol is left to stand for 24 hours; set the atomization parameters as follows: inlet temperature 250°C, dry air volume 100m 3 / h, the material flow is 2L / h, and the atomized particles are obtained; 2 +H 2 After the mixed gas is fired at 1200°C for 2 hours, a pure YAG phase product with a yellow body color is obtained, and the ave...

example 2

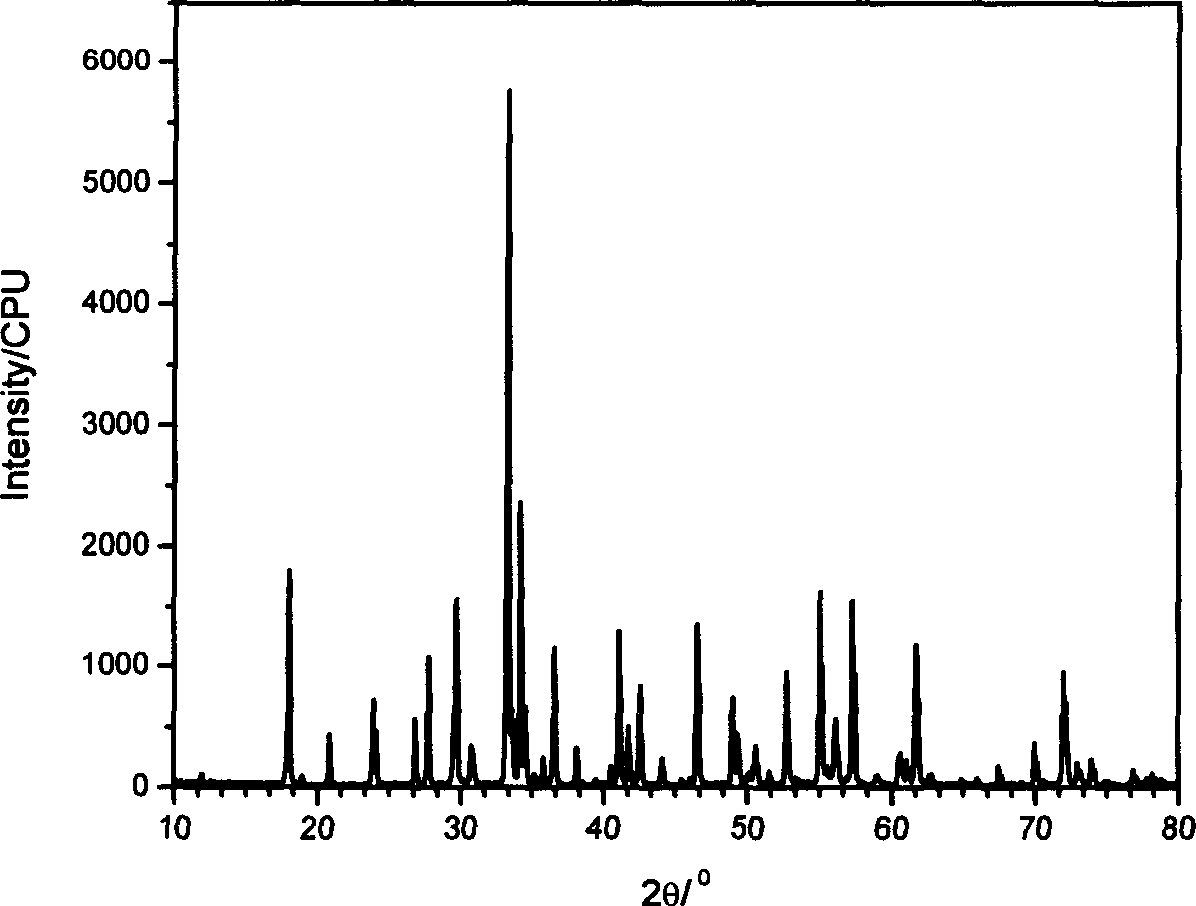

[0027] According to pseudo-boehmite: water=10:90 (percent weight ratio), the pseudo-boehmite is dissolved in deionized water, and the acidity is adjusted to pH=4 by a hydrochloric acid solution with a percentage concentration of 30%. After dispersion, a stable colloid is obtained, and the seed crystal is about 20 nanometers; press Y 3-m Al 5-n B n o 15 : Ce m , m=0.05, n=3, add yttrium nitrate, cerium nitrate, magnesium nitrate and boric acid, and perform mechanical stirring to form a doped sol, and the sol stands still for 24 hours; set the atomization parameters as follows: inlet temperature 1500°C, dry air volume 200m 3 / h, the material flow is 1L / h, to obtain atomized particles; use activated carbon in the lifting furnace to obtain a weak reducing atmosphere, and after firing at 1300°C for 3 hours, a pure YAG phase product with a yellow body color is obtained, and the particle average The particle size is 1 micron, spherical and solid. The XRD collection of luminescent...

example 3

[0029] According to pseudo-boehmite: water=15:85 (percent weight ratio), the pseudo-boehmite is dissolved in deionized water, and the acidity is adjusted to pH=6 with a hydrochloric acid solution with a percentage concentration of 30%. A stable colloid is obtained after dispersion, and the seed crystal is about 40 nanometers; press Y 3-m al 5-n B n o 15 : Ce m , m=0.01, n=1 Add yttrium nitrate, cerium nitrate and boric acid, carry out ultrasonic dispersion, form doped sol, sol stand still for 24 hours; set atomization parameters as: inlet temperature 110 ℃, dry air volume 300m 3 / h, the material flow is 1.5L / h, to obtain atomized particles; use the ammonolysis furnace to obtain a weak reducing atmosphere, and after firing at 1600°C for 5 hours, a pure YAG phase product with a yellow body color and an average particle size of 5 microns, spherical solid. The XRD collection of luminescent materials is the same as example 1, and the excitation and emission spectra are shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com