Adsorbing material for removing cadmium in water and production thereof

A composite adsorption material, water removal technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the process of cadmium removal that has no practical application, does not attract enough attention, and the effect is not ideal, etc. problems, to achieve the effect of low preparation cost, low cost and high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

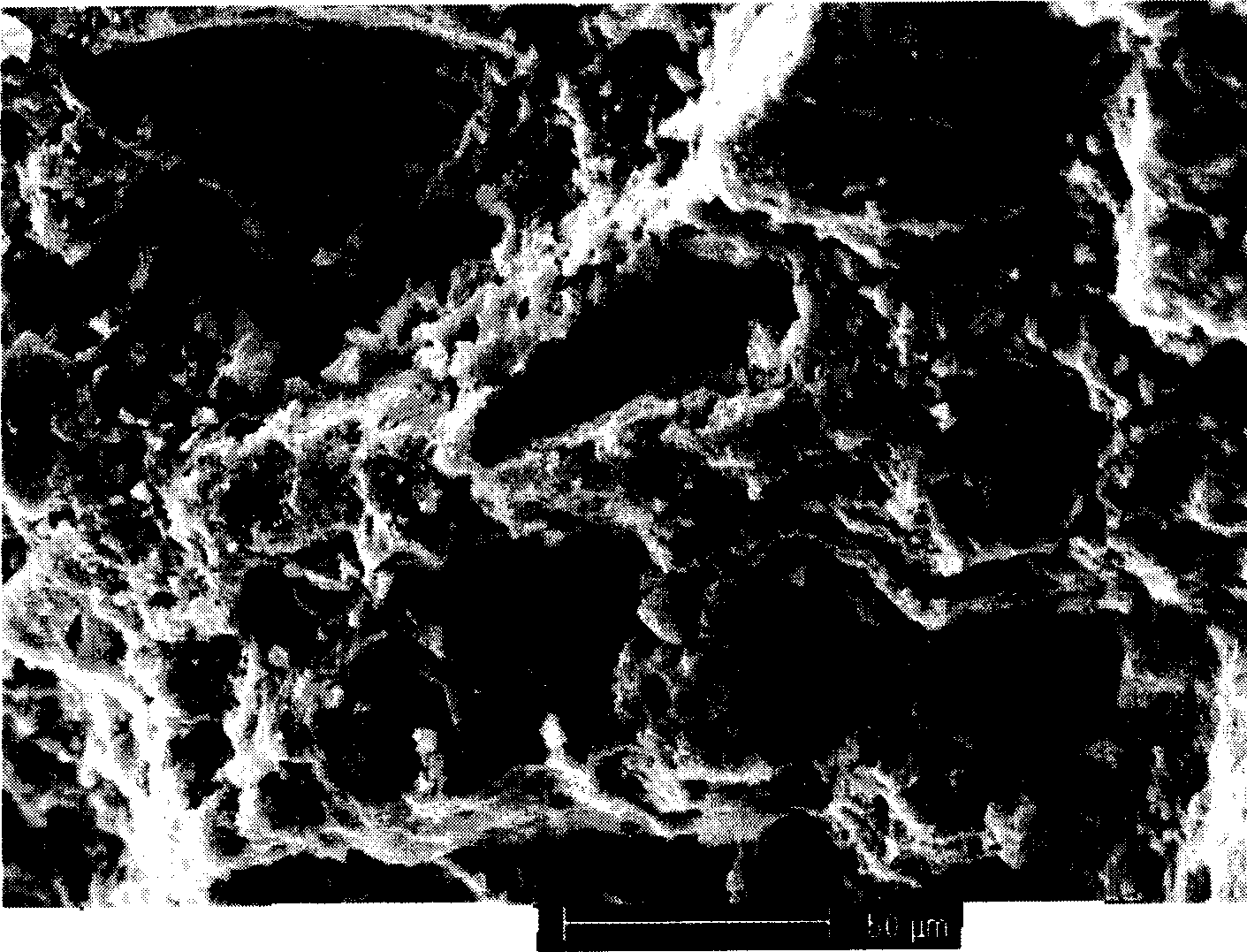

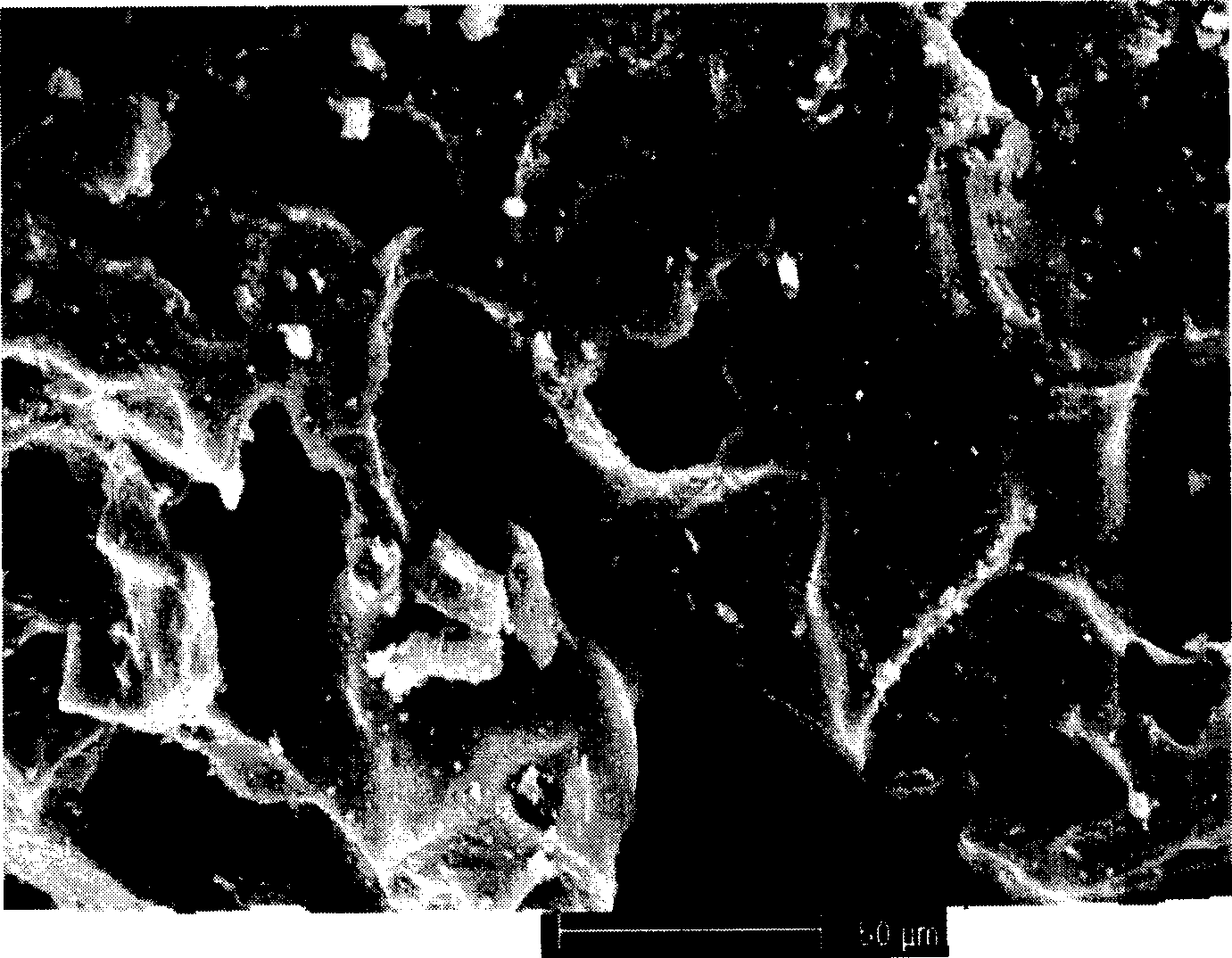

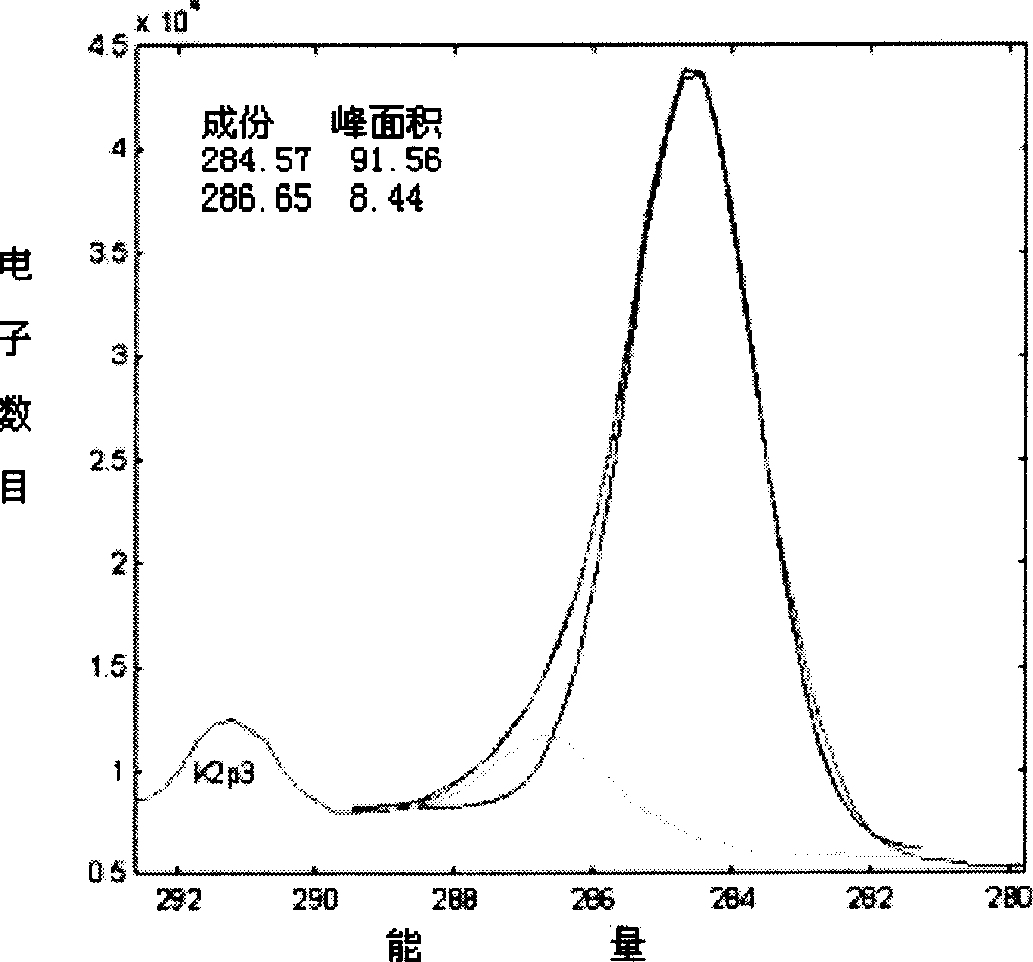

[0023] The present invention selects coal-based granular activated carbon (AC12X40) produced by Calgon Carbon (Tianjin) Co., Ltd. for use. 480 g / l with a particle size distribution ranging from less than 1.7mm diameter (less than 12 mesh US sieve, less than 1.8% of total weight) to greater than 0.425mm diameter (greater than 40 mesh US sieve, less than 1.9% of total weight). The chemicals used are all analytically pure. Prepare a solution of the test reagent by diluting cadmium nitrate with distilled water. The pH of the test solution was adjusted with 1M sodium hydroxide and 1M hydrochloric acid. A pH meter (model PHS-3C, produced in Shanghai) was used for the measurement of pH value. The metal concentration of the sample was measured using an inductively coupled plasma ICP (Perkin-Elmer, produced in the United States) with a wavelength of 228.8 nm. The porosity and bulk weight of the adsorbent were measured using a mercury porosimeter and a dedicated gravity bottle, respe...

Embodiment 2

[0030]Embodiment 2, the method for adsorbing and removing cadmium by the adsorption material prepared by the present invention is as follows:

[0031] With Cd(NO 3 ) 2 4H 2 O preparation concentration is each 200ml of cadmium-containing solution of 67.4mg / l, puts into respectively in the shaker adsorption bottle of 250ml, weighs each 3g of pure gac and the adsorption material prepared by the present invention. Put it into a shaker at 25°C with a rotation speed of 160 rpm for 24 hours and take it out, take the supernatant and filter it with a filter membrane with a diameter of 0.45 nm, and analyze its remaining concentration by ICP. The results are respectively: the concentration of the saturated residual liquid of activated carbon is 52.27 mg / l, the concentration of the saturated residual liquid of the adsorbent material of the present invention is 2.902 mg / l, and the adsorption effect of the adsorbent material of the present invention is 18 times that of activated carbon ....

Embodiment 3

[0032] Embodiment 3, the method for the adsorption of cadmium of the adsorption material prepared by the present invention is as follows:

[0033] Take by weighing activated carbon and each 3g of the adsorption material prepared by the present invention, a total of 12 parts, respectively prepare 2 groups of different cadmium-containing initial concentrations of 58.6ug / l, 87.1ug / l, 117.2ug / l, 146.5ug / l, 178.5ug / l and 234.4ug / l, each take 200ml and put it into a shaker bottle. Weigh 3g of the adsorbent material into a shaker bottle, put it in a shaker with a speed of 160 rpm at 25°C and shake for 24 hours, take it out, take the supernatant and filter it with a filter membrane with a diameter of 0.45 nm, and use ICP Analyze its remaining concentration.

[0034] According to the initial concentration and the adsorption equilibrium concentration, the adsorption saturation amount was calculated, and the adsorption equilibrium isotherm curve was drawn.

[0035] The adsorption equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com