Biodegradable nanofiber nonwoven fabric capable of preventing postoperative adhesion and preparation thereof

A non-woven fabric, biodegradable technology, applied in the field of medical supplies, can solve the problems of short degradation time of chitosan film and oxidized cellulose film, unable to maintain physical barrier function, unable to prevent adhesion, etc., and achieve good tissue compatibility. Compatible with blood, achieve mass production, effective anti-adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of PLLA spinning dope:

[0039] The solvent is dichloromethane, PLLA raw material (viscosity average molecular weight is 450000): dichloromethane = 5wt%: 95wt%; stir evenly at room temperature.

[0040] Electrospinning of PLLA spinning dope:

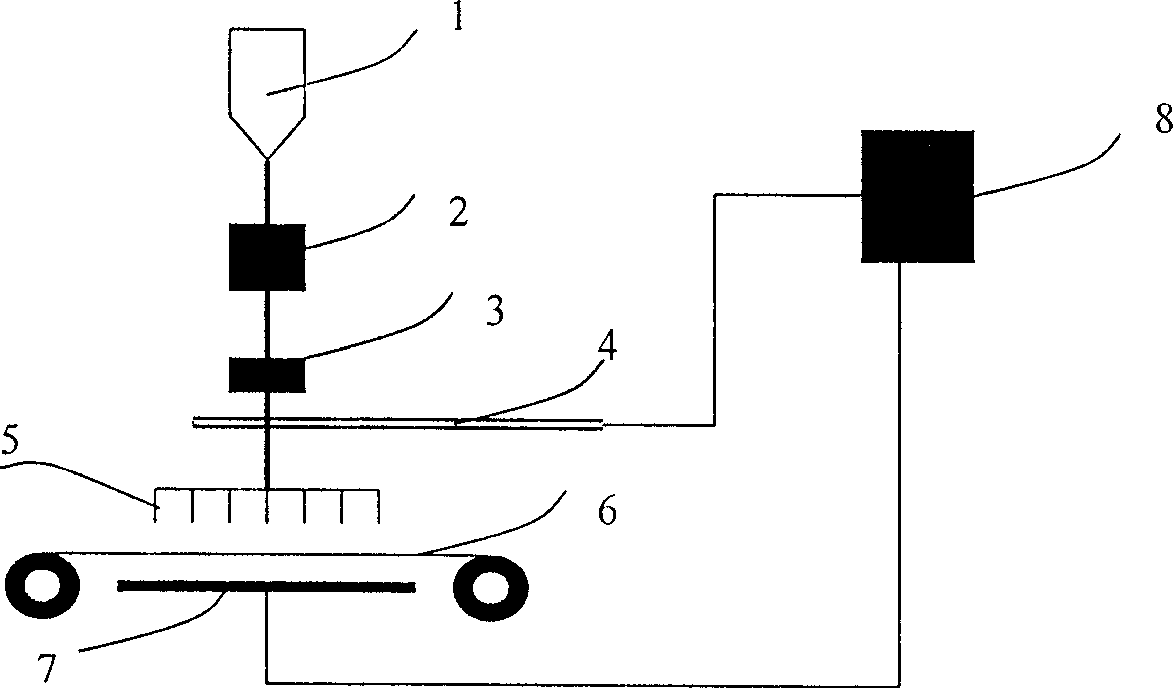

[0041] The spinning material is stored in the storage tank 1, quantitatively measured by the metering pump 2, and supplied to the spinning material gas-liquid mixing device 3, thereby intermittently changing the flow of the spinning material. After that, the spinning material was supplied to the nozzle block area 5, under a voltage of 50 kv, and spun into a fiber shape through the nozzle. The woven fibers are collected on a collecting plate 6 and produced into a nonwoven web. Each nozzle block has 400 needles and is composed of 20 nozzle blocks. Use a high voltage generator. The output rate of one needle is 0.0026 g / min, resulting in a total throughput of 20.8 g / min. One nozzle stagnation area is divided into 10, ...

Embodiment 2

[0044] Preparation of PLGA copolymer (50:50) spinning dope:

[0045] The solvent is dichloromethane, PLGA copolymer (50:50) raw material (viscosity average molecular weight: 250000): dichloromethane = 10wt%: 90wt%; stirring at normal temperature.

[0046] PLGA copolymer (50:50) spinning dope electrospinning:

[0047]The spinning material is stored in the storage tank 1, quantitatively measured by the metering pump 2, and supplied to the spinning material gas-liquid mixing device 3, thereby intermittently changing the flow of the spinning material. After that, the spinning material was supplied to the nozzle block area 5 at a voltage of 50 kV, and spun into a fiber shape through the nozzle. The woven fibers are collected on a collecting plate 6 and are ready to produce a nonwoven web. Here, each nozzle block area has 400 needles, and is composed of 20 nozzle block arrays. Use a high voltage generator. The output rate of one needle was 0.0032 g / min (1.28 g / min total injectio...

Embodiment 3

[0050] Preparation of PDLLA spinning dope:

[0051] The solvent is dichloromethane, PLLA raw material (viscosity average molecular weight is 350000): dichloromethane = 8wt%: 92wt%; stirring at normal temperature.

[0052] Electrospinning of PDLLA spinning dope:

[0053] The spinning material is stored in the storage tank 1, quantitatively measured by the metering pump 2, and supplied to the spinning material gas-liquid mixing device 3, thereby intermittently changing the flow of the spinning material. Then the spinning material is supplied to the nozzle block zone 5, under the voltage of 50kv, and spun into the shape of fibers through the nozzle. The woven fibers are collected on a collecting plate 6 and produced into a nonwoven web. Each nozzle block area has 400 needles and is composed of 20 nozzle block arrays. Use a high voltage generator. The output rate of one needle is 0.0026 g / min, resulting in a total throughput of 20.8 g / min. A nozzle blocking area is divided in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com