Nano Pd catalyst and its preparation and application

A catalyst and nano-palladium technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as increased equipment investment and operating costs, health hazards for workers, and difficult product purification, etc., to achieve omission Solvent recovery, elimination of potential safety hazards, and the effect of eradicating organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] (1), preparation of catalyst

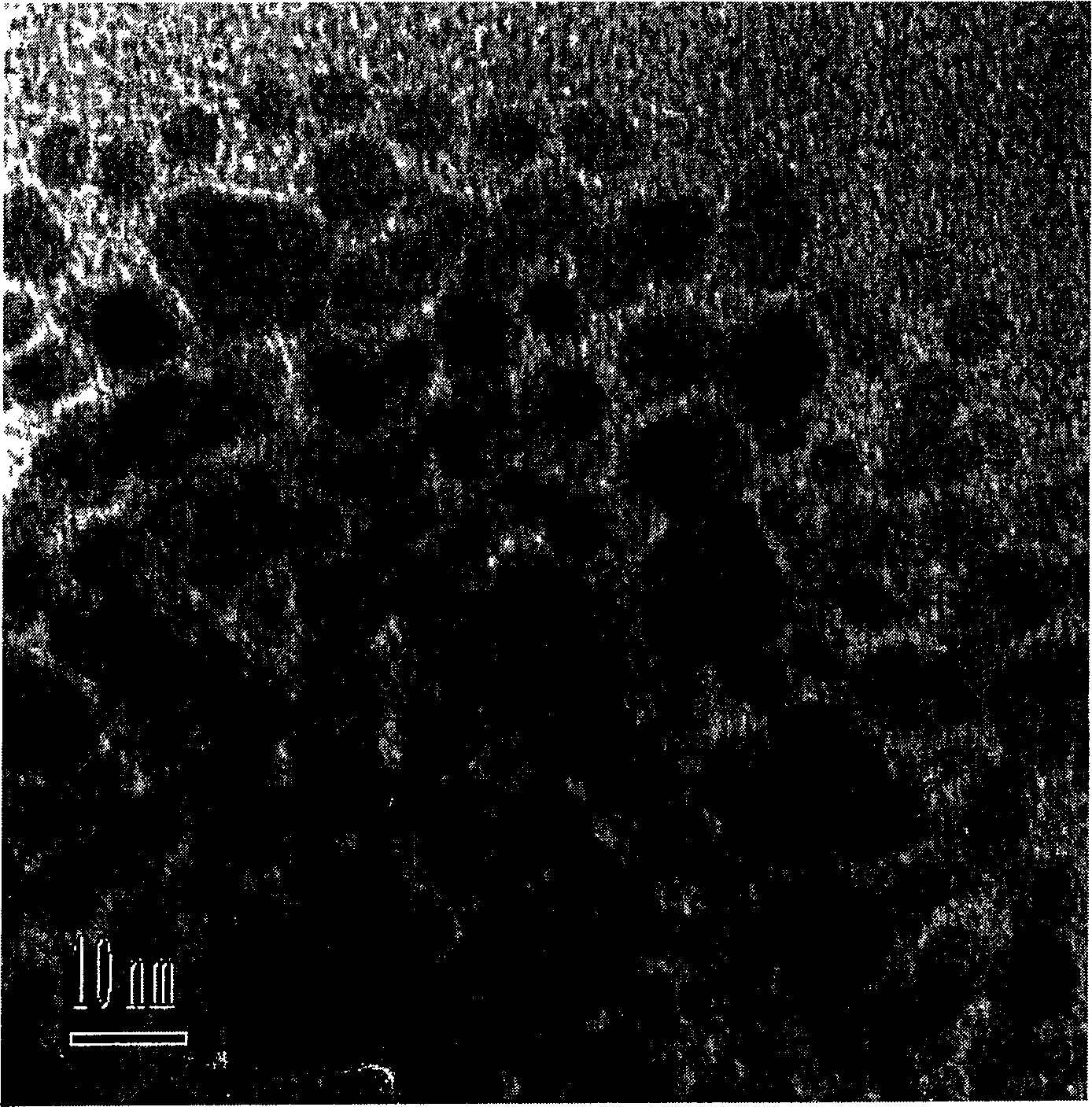

[0015] 1. Take 300-500ml of ethanol and add it to the reaction flask with a reflux condenser, add 17.7g of palladium chloride and 32.3g of polyvinyl alcohol under stirring, heat up after dissolving, react at 80°C for 2 hours, and the new ecological black nano palladium powder (average particle size 5nm) precipitated out and attached to polyvinyl alcohol. After the reaction is finished, the ethanol is evaporated to obtain the polyvinyl alcohol-supported nano-palladium catalyst.

[0016] 2. Take 300-500ml of ethylene glycol, 23g of palladium nitrate, 37g of sodium alginate, 75°C for 3 hours, and other operations are the same

Embodiment 1

[0018] 3. Take 300-500 ml of ethanol and propanol mixed alcohol, 22.4 g of palladium acetate, and 32.6 g of carboxymethyl cellulose, at 85° C. for 2 hours, and other operations are the same as in Example 1.

[0019] 4. Take 300-500 ml of propanol, 17.7 g of palladium chloride, and 32.3 g of polyethylene oxide, at 80° C. for 2 hours, and other operations are the same as in Example 1.

[0020] (2), the preparation of biphenyl compound

[0021] Now taking the preparation of p-toluene as an example, non-limiting examples are described as follows:

[0022] 5. Put 6L of tap water into the reaction kettle, add 50g of this catalyst (containing 10.6g, 0.1mol of palladium black) and equimolar (20ml) of iodobenzene, p-tolueneboronic acid and potassium carbonate under stirring, heat up, and react at 80°C for 3~ 4 hours. After the reaction is finished, cool down, let stand at room temperature and separate the layers, separate the water phase, and recycle it for reuse. The organic phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com