Production method of low molecular weight tetrafluoro ethylene resin

A polytetrafluoroethylene, production method technology, applied in the field of warm polymerization, can solve problems such as high viscosity, large dispersion, and large environmental pollution, and achieve the effect of fine and uniform particles and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

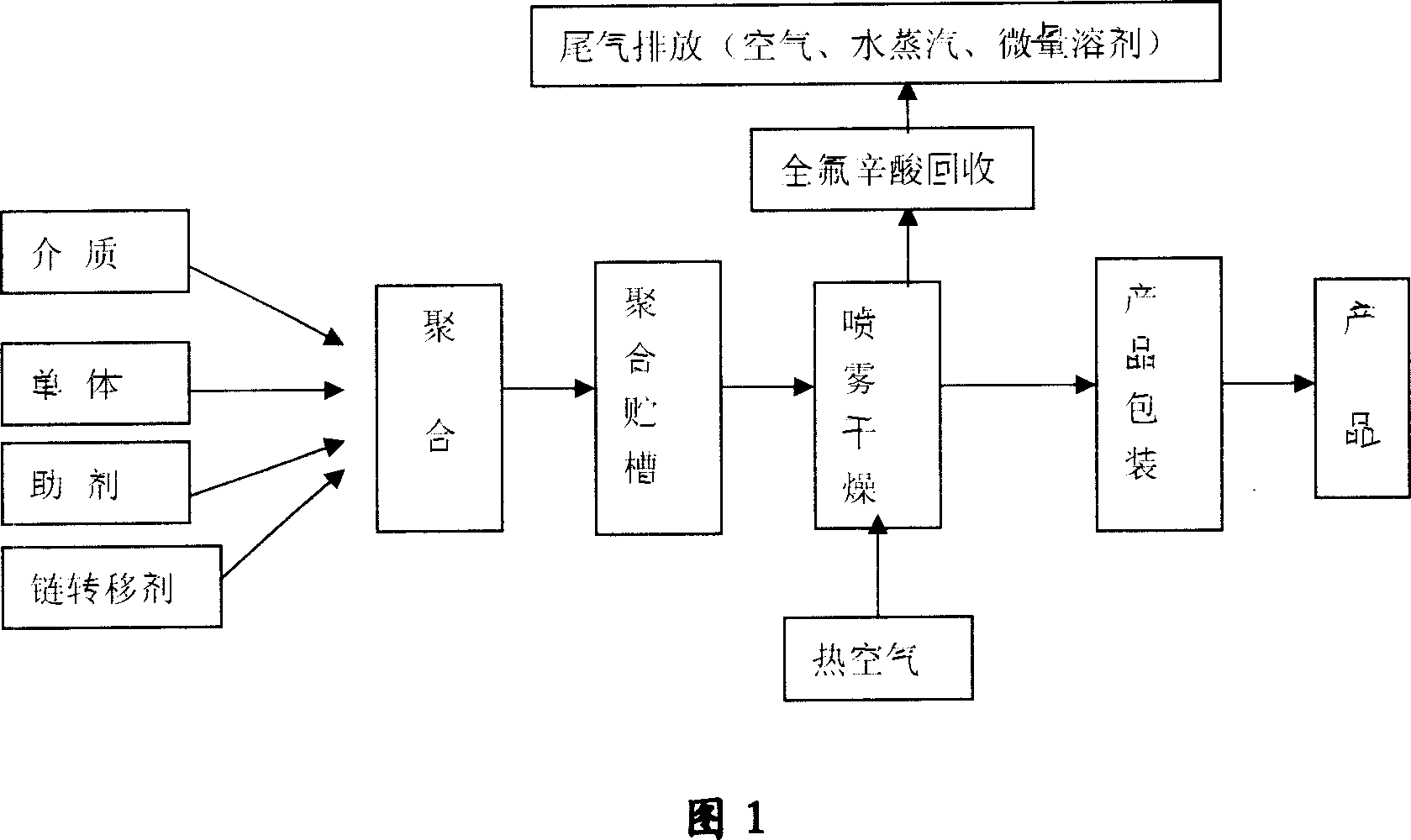

Method used

Image

Examples

Embodiment 1

[0020]Embodiment 1: 1. Polymerization: Select 1000L stainless steel jacketed reactor, which has the advantages of rapid temperature rise, heat transfer and excellent effect. After washing, add deionized water, ammonium persulfate, and ammonium perfluorooctanoate solution according to the formula, and seal the reactor body, evacuate, replace with inert gas, analyze the oxygen content in the kettle, if the oxygen content is less than 30ppm, it is qualified, fill with tetrafluoroethylene gas phase monomer and methylene chloride liquid, at this time, the pressure in the kettle is 0.5-0.8MPa, and the temperature in the kettle rises to 70 At this time, the polymerization reaction proceeds, and the pressure in the kettle drops. The whole polymerization process is controlled at a stable pressure of 0.8±0.05MPa, and the reaction temperature is controlled at 100-75℃. When the pressure in the kettle drops, add tetrafluoroethylene gas phase single body, when the reaction rate drops in the ...

Embodiment 2

[0025] Embodiment 2: 1. Polymerization: select 1000L stainless steel jacketed reactor, rapid temperature rise, heat transfer and excellent effect of the reactor, after washing, add deionized water, ammonium persulfate, ammonium perfluorooctanoate solution according to the formula, and seal the reactor body, evacuate, replace with inert gas, analyze the oxygen content, the oxygen content is less than 30ppm is qualified, fill the tetrafluoroethylene gas phase and dichloromethane liquid, at this time the pressure in the kettle is 0.1 ~ 1.0MPa, the temperature in the kettle rises to 70 ℃, at this time The polymerization reaction proceeds, the pressure in the kettle drops, and the whole polymerization process is controlled at a stable pressure of 0.8±0.05MPa, and the reaction temperature is controlled at 100-75°C. When the pressure in the kettle drops, tetrafluoroethylene gas phase monomer is added. When the reaction rate drops, ammonium persulfate is allowed to be added. The whole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com