Patents

Literature

59 results about "Data entry error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A transcription error is a specific type of data entry error that is commonly made by human operators or by optical character recognition programs (OCR).

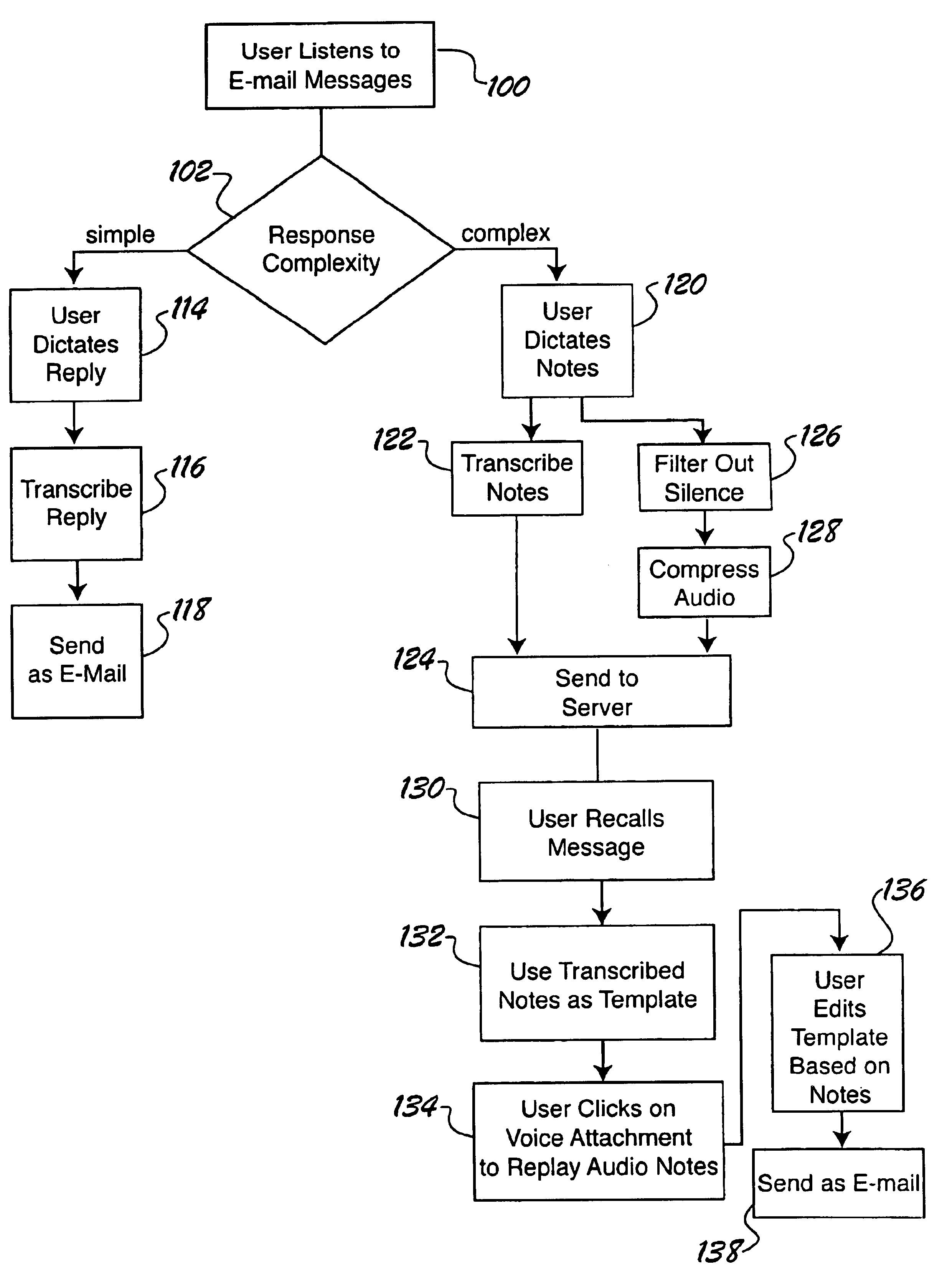

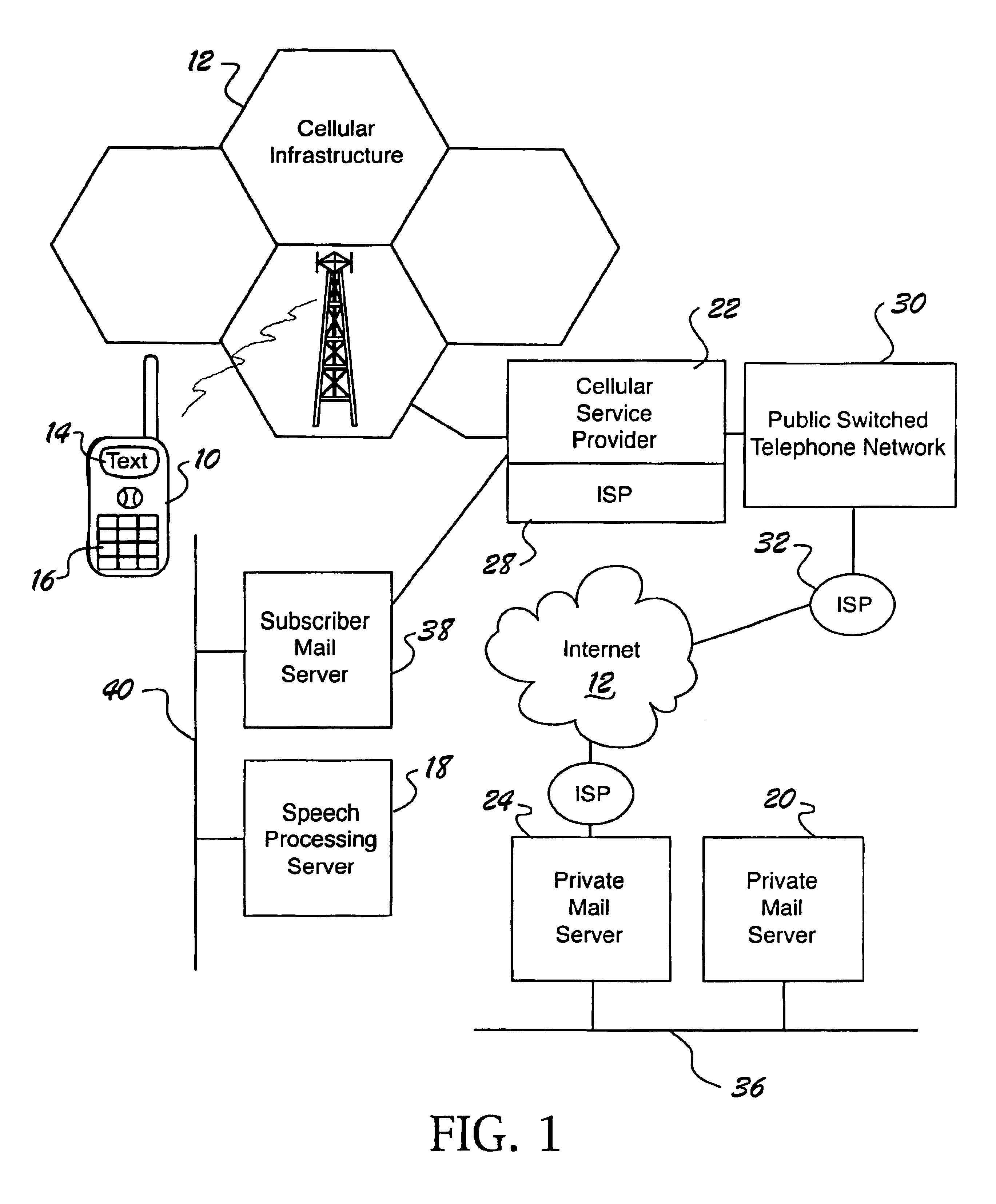

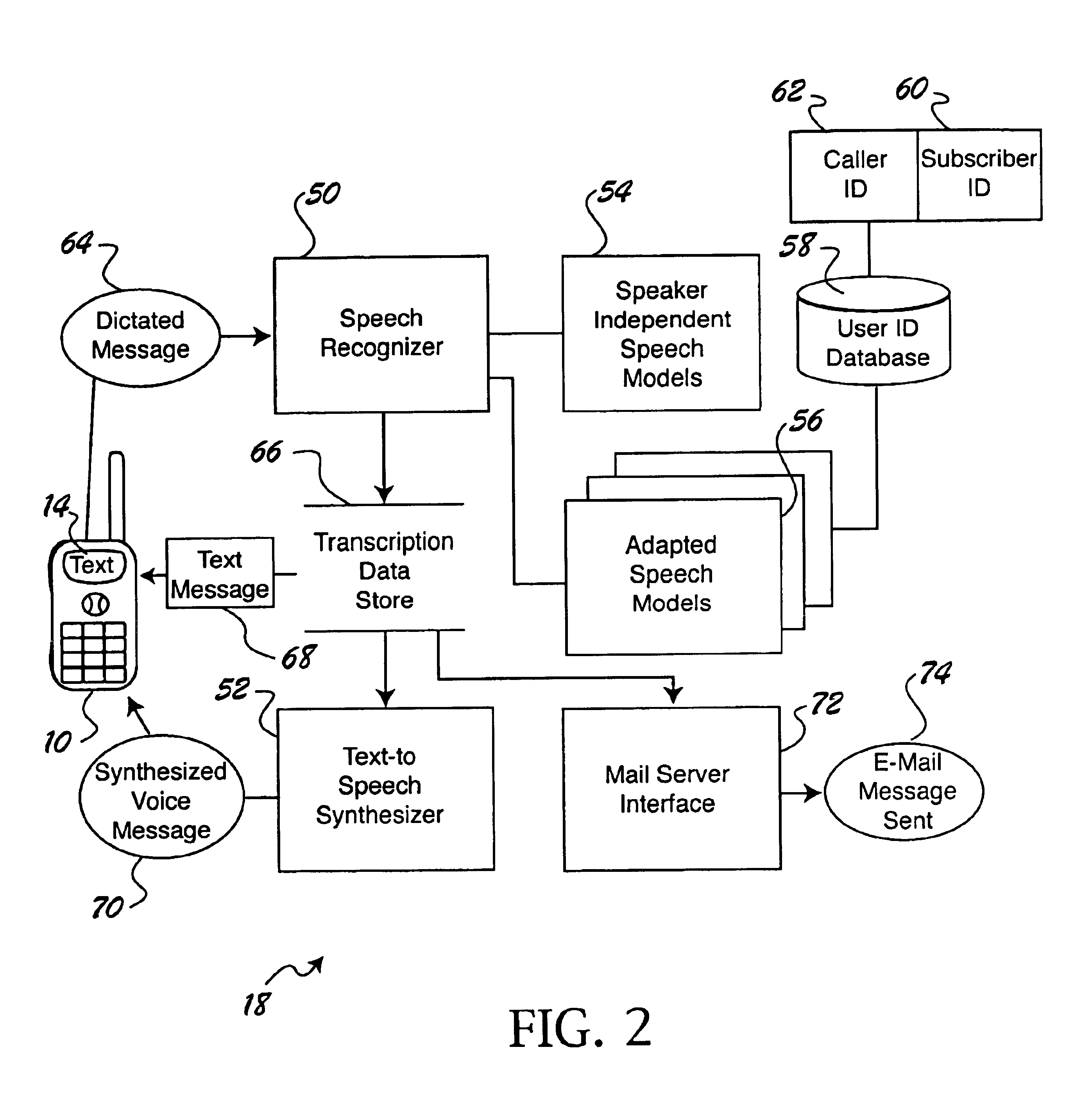

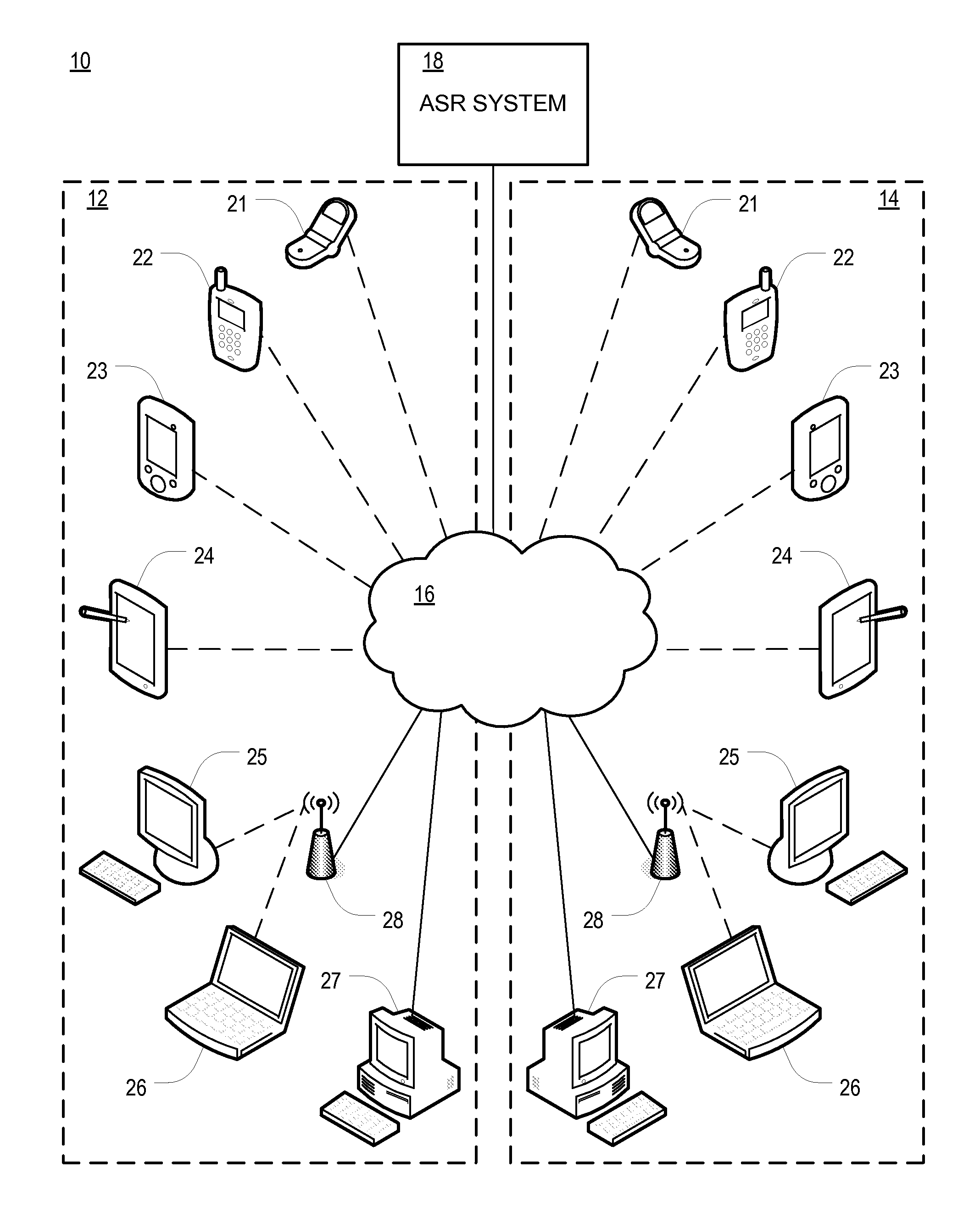

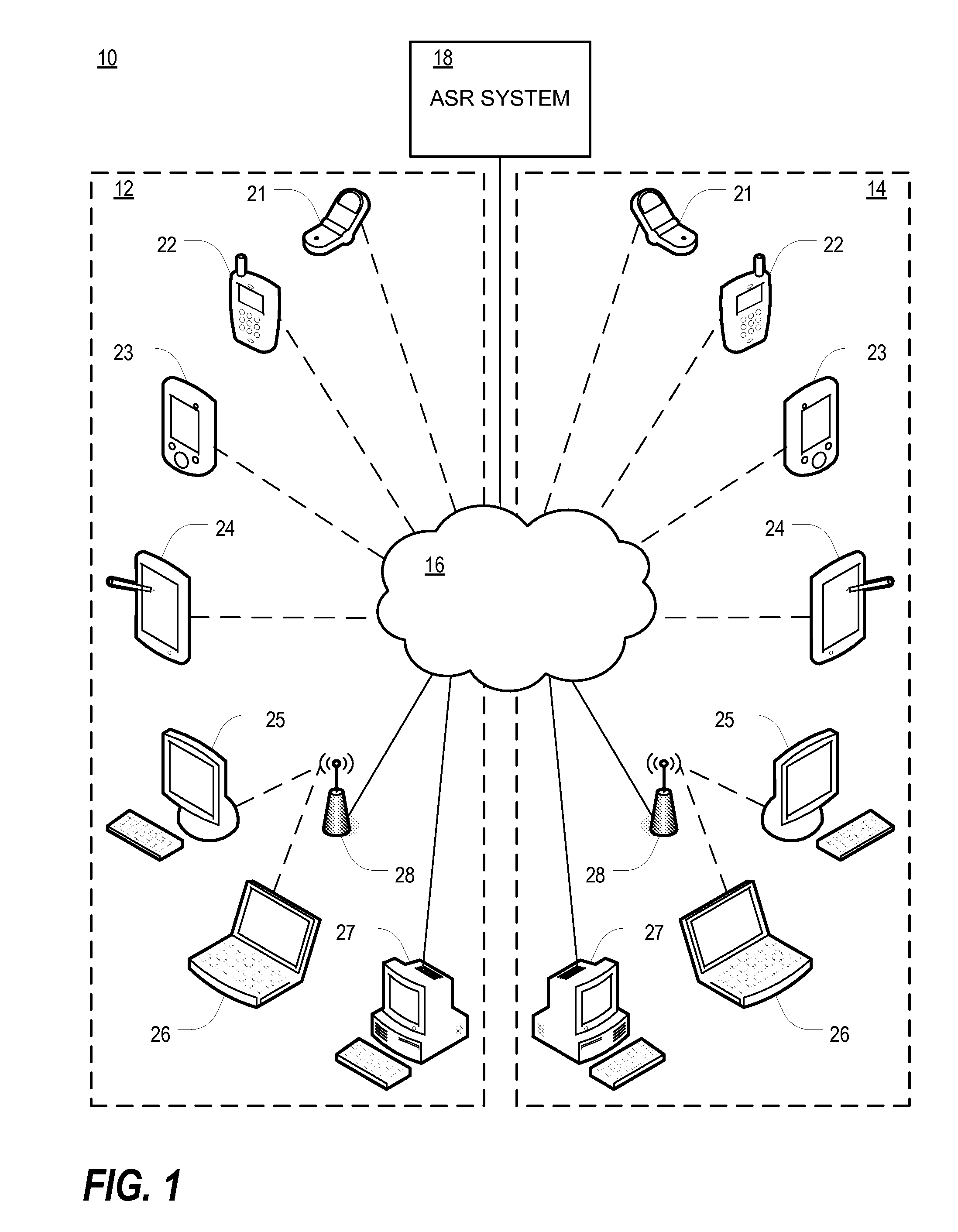

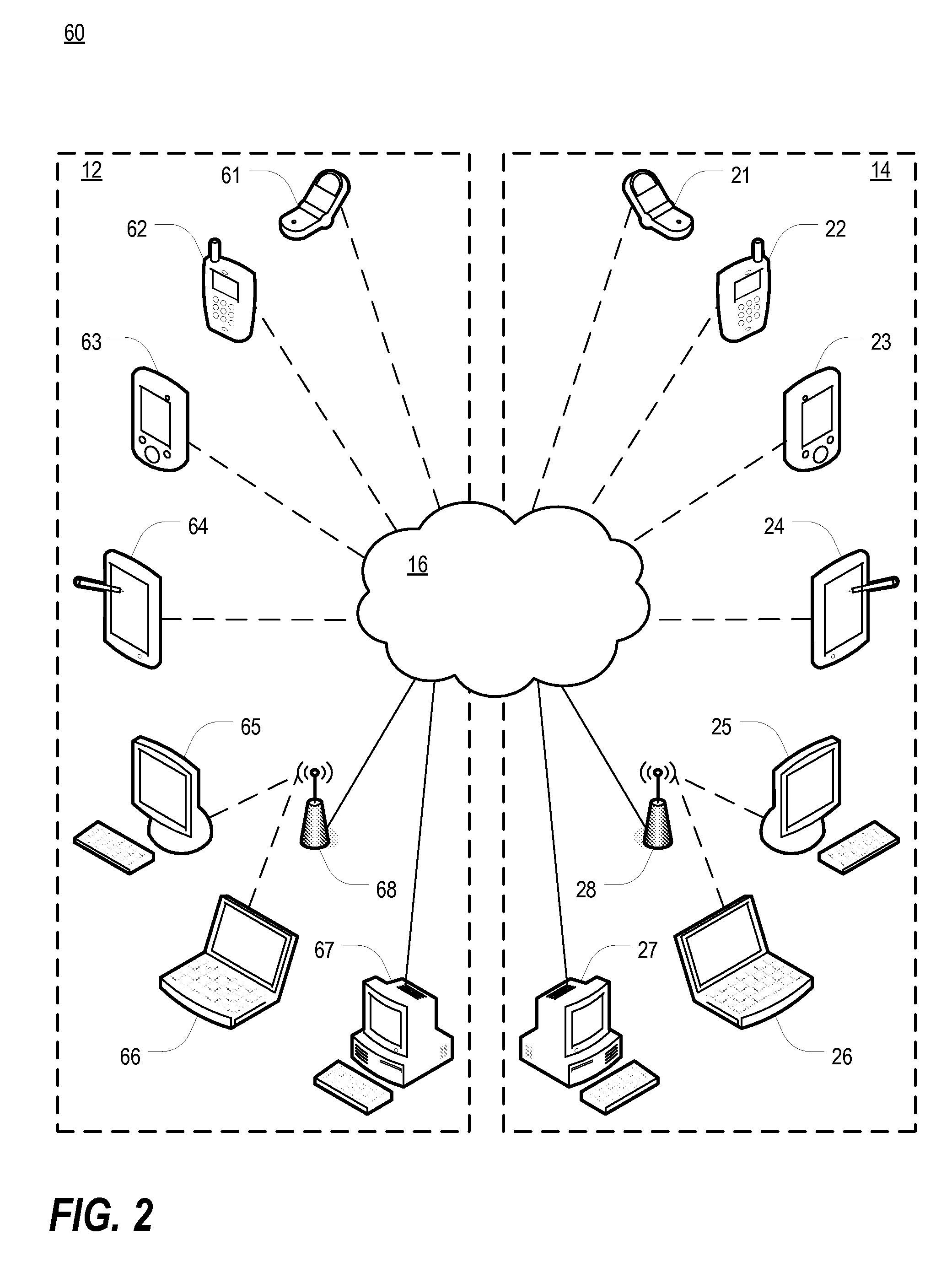

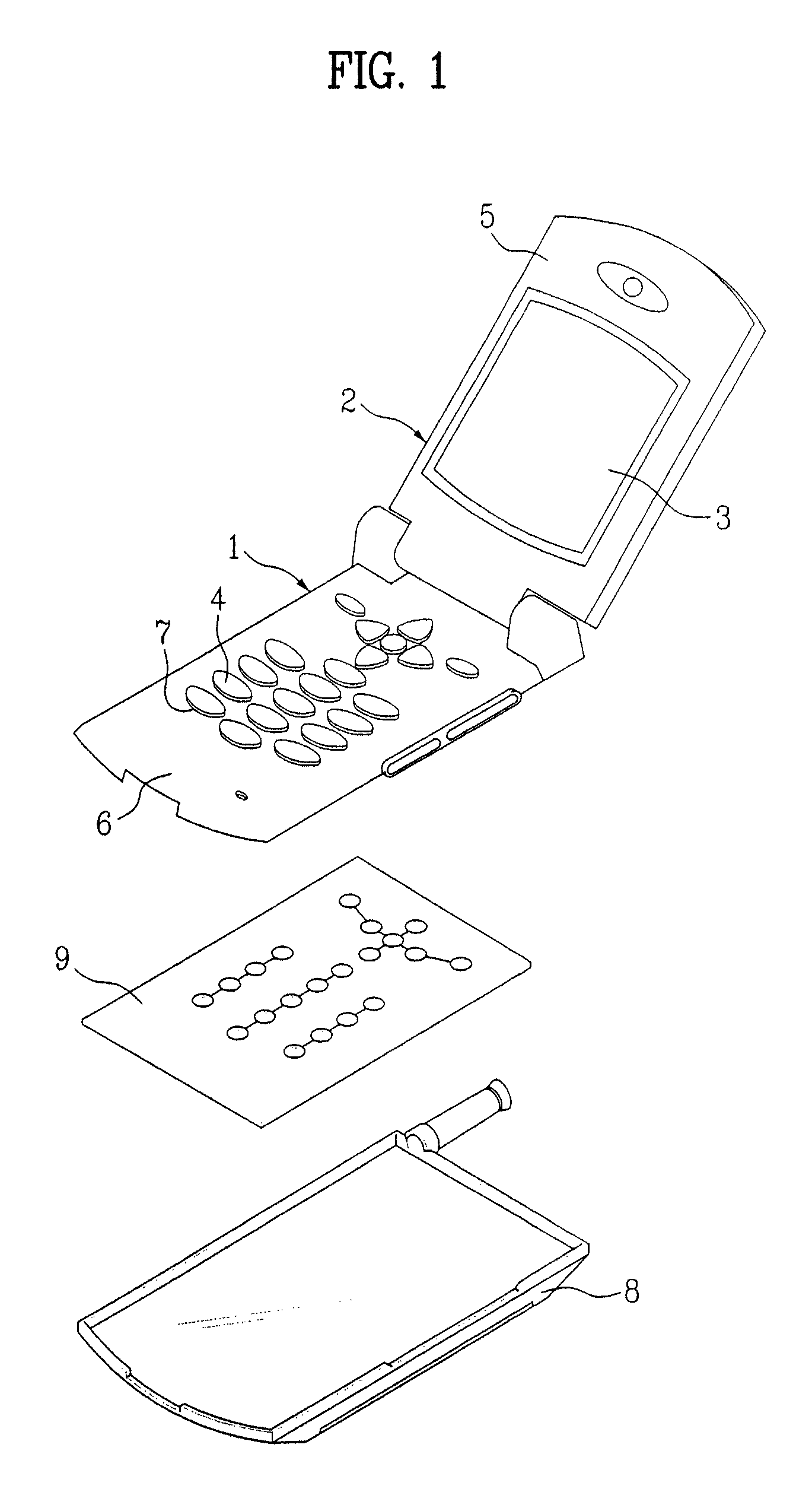

Personalized agent for portable devices and cellular phone

InactiveUS6895257B2Overcomes shortcomingImproving text and audio messaging featureCordless telephonesDevices with voice recognitionPersonalizationSpeech synthesis

Personalized agent services are provided in a personal messaging device, such as a cellular telephone or personal digital assistant, through services of a speech recognizer that converts speech into text and a text-to-speech synthesizer that converts text to speech. Both recognizer and synthesizer may be server-based or locally deployed within the device. The user dictates an e-mail message which is converted to text and stored. The stored text is sent back to the user as text or as synthesized speech, to allow the user to edit the message and correct transcription errors before sending as e-mail. The system includes a summarization module that prepares short summaries of incoming e-mail and voice mail. The user may access these summaries, and retrieve and organize email and voice mail using speech commands.

Owner:SOVEREIGN PEAK VENTURES LLC

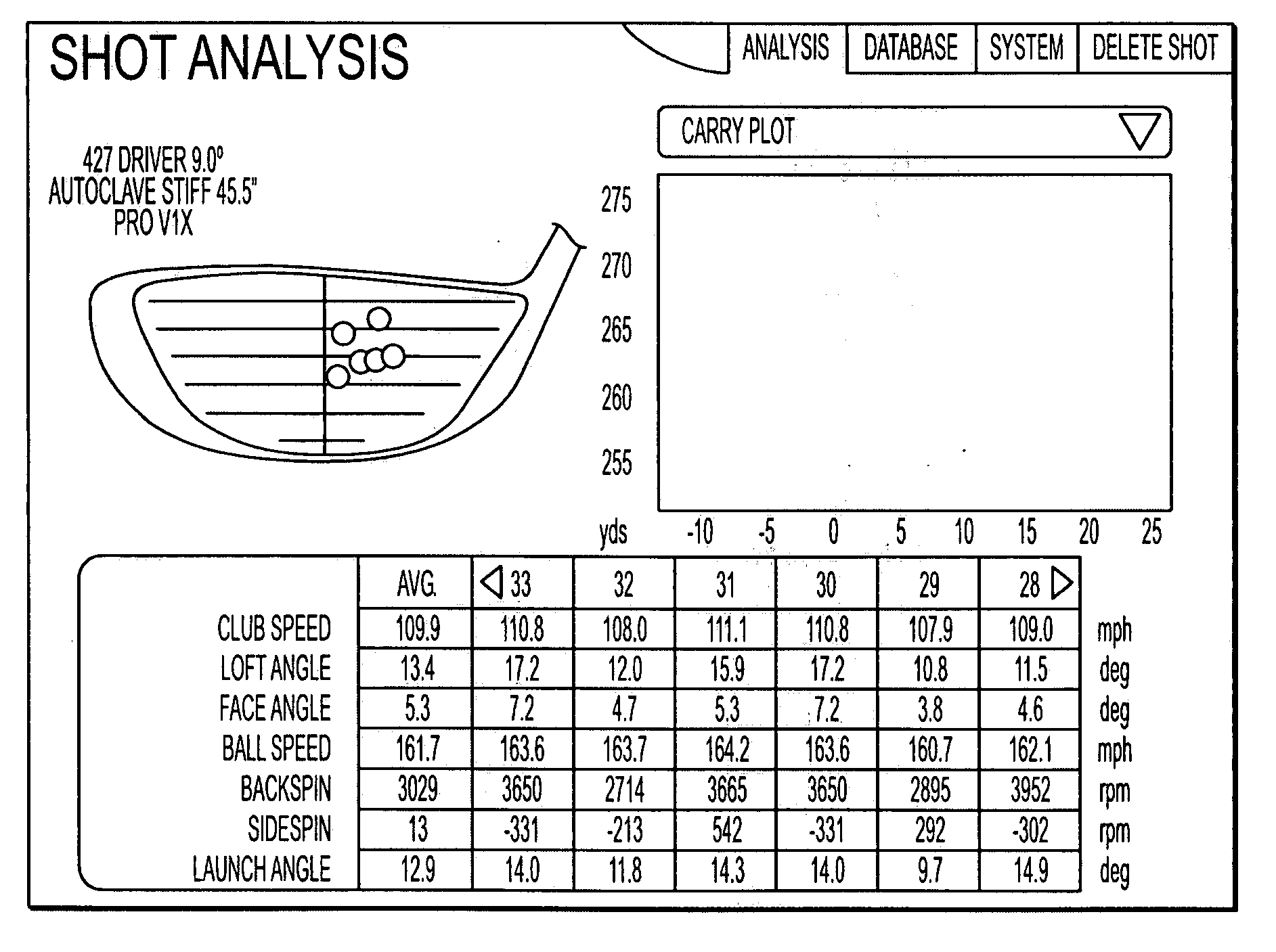

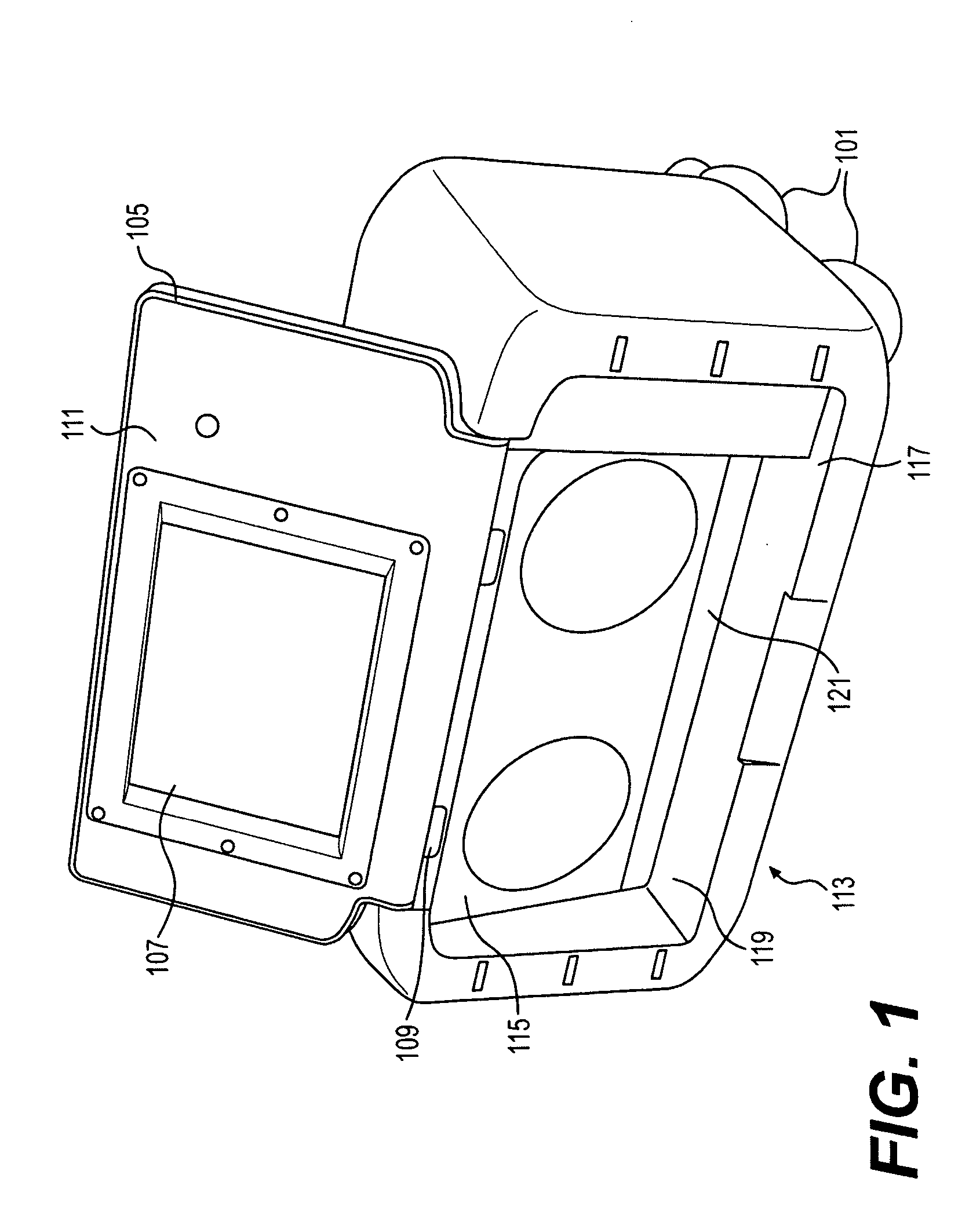

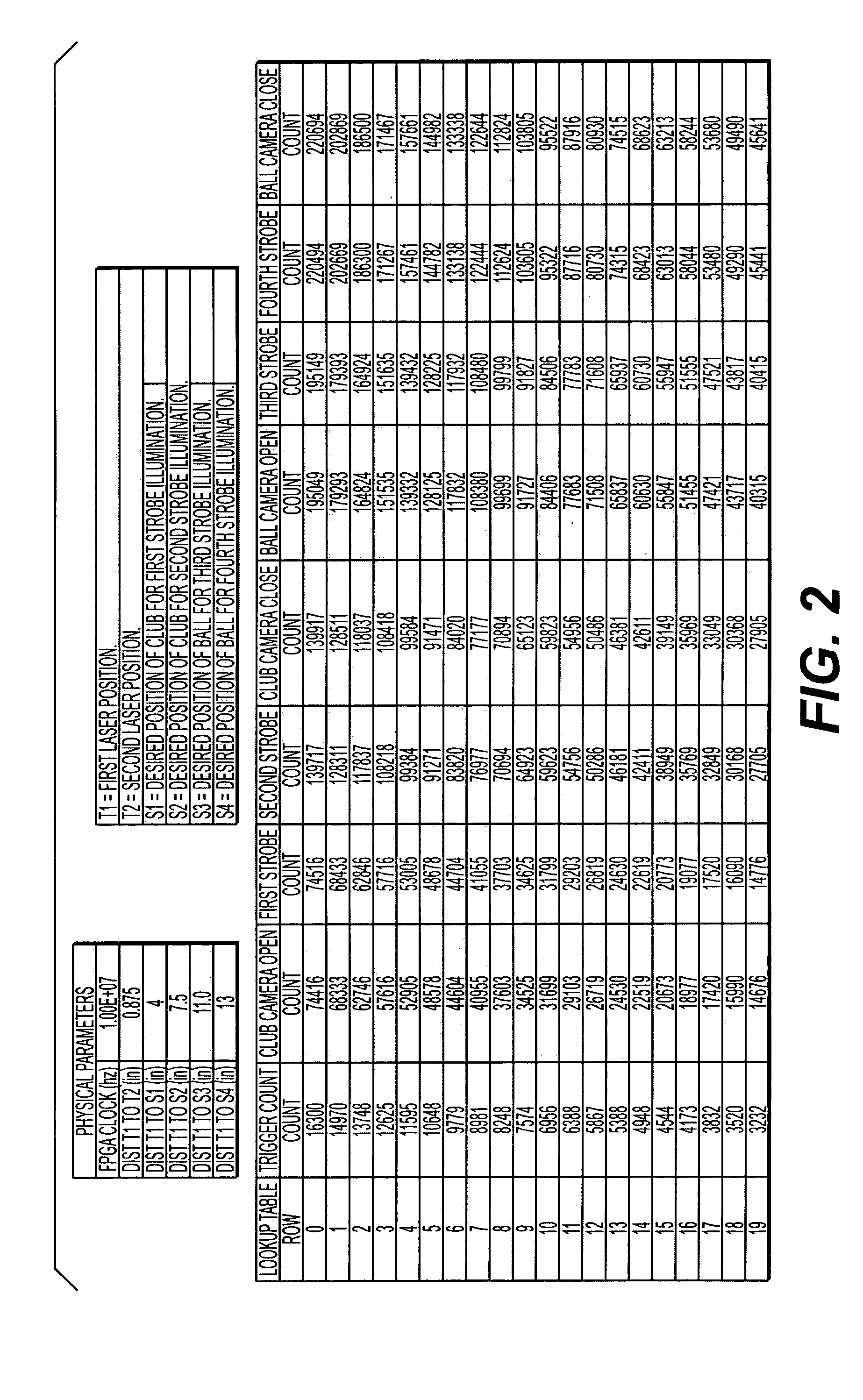

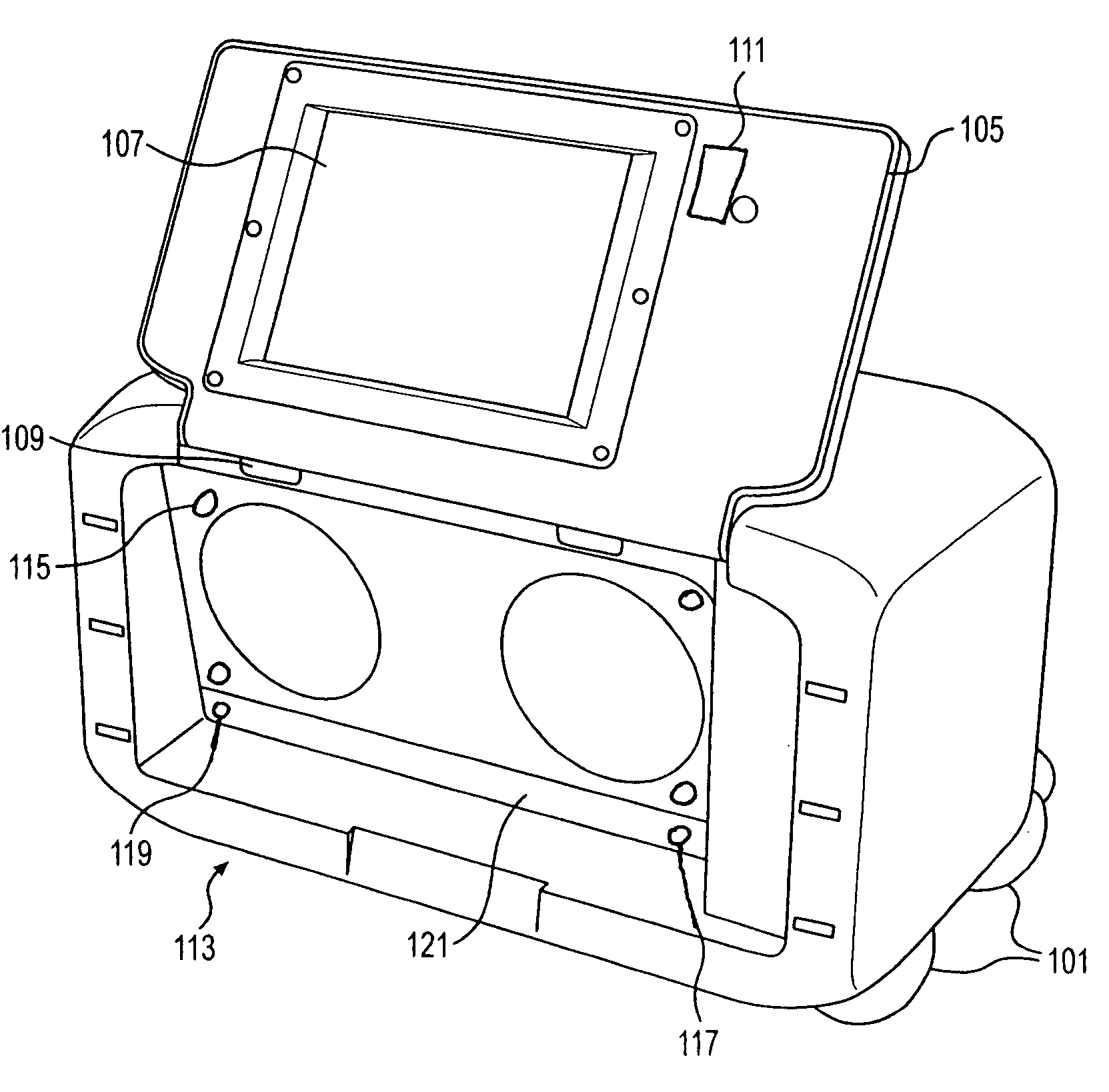

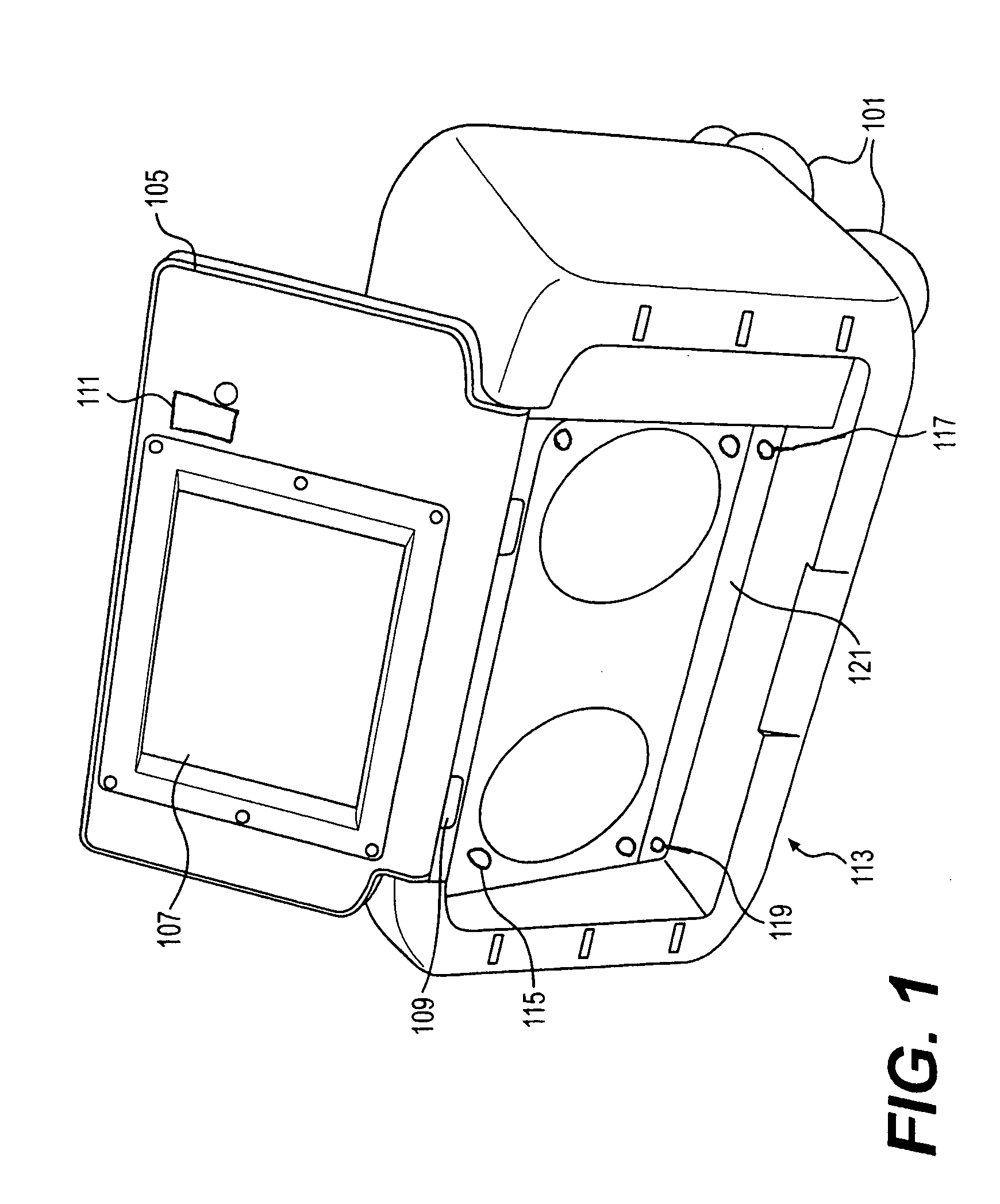

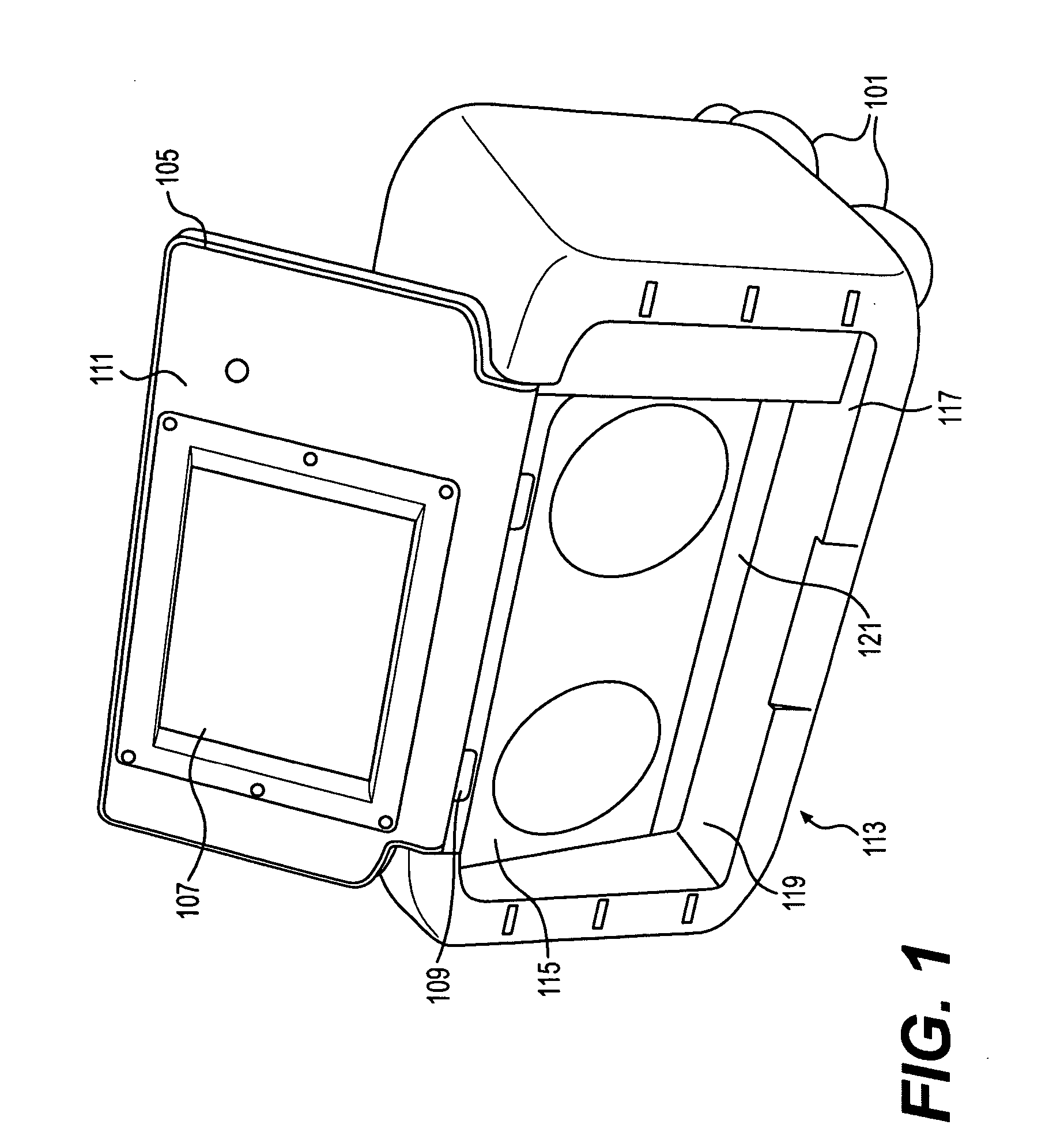

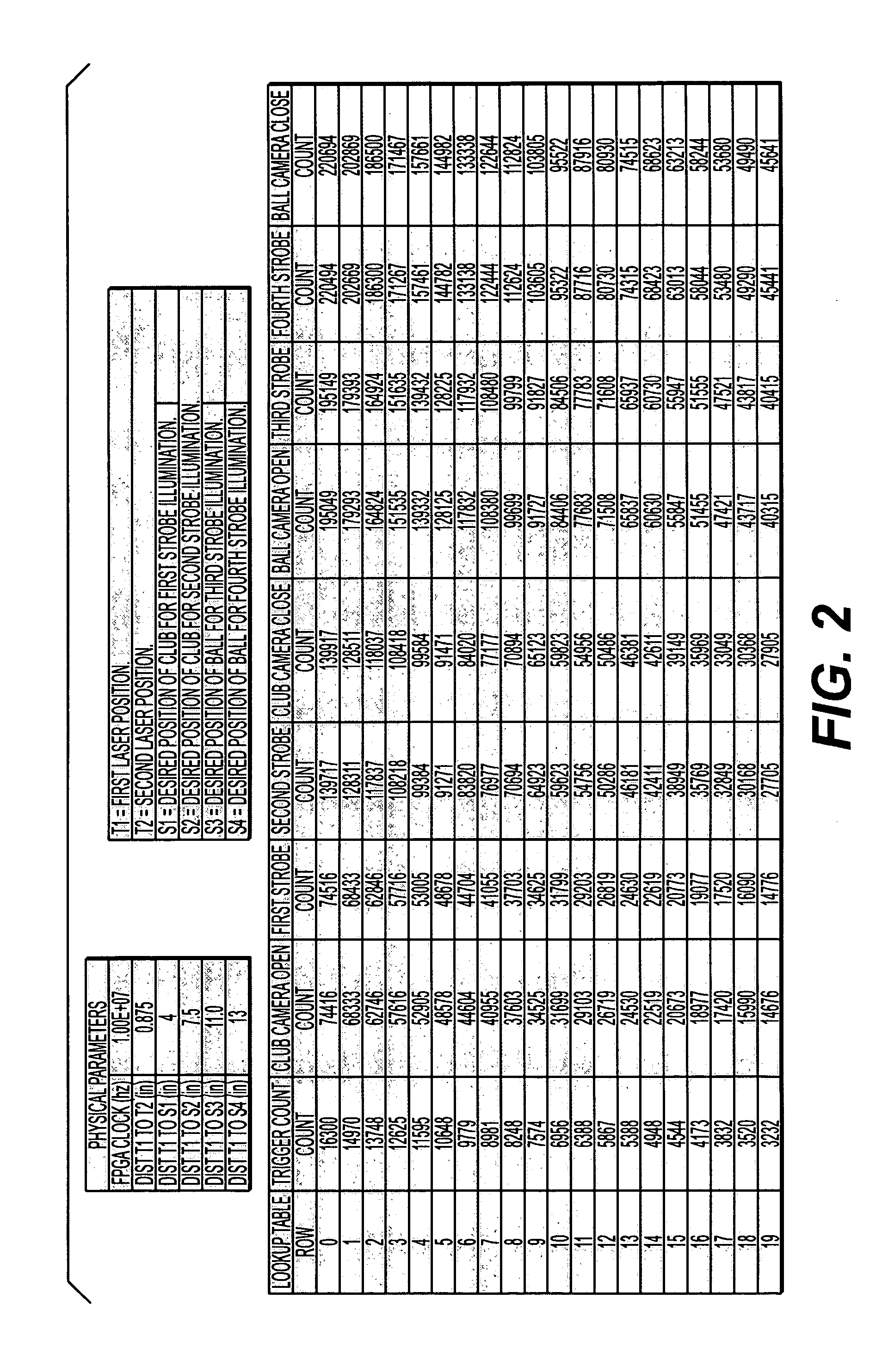

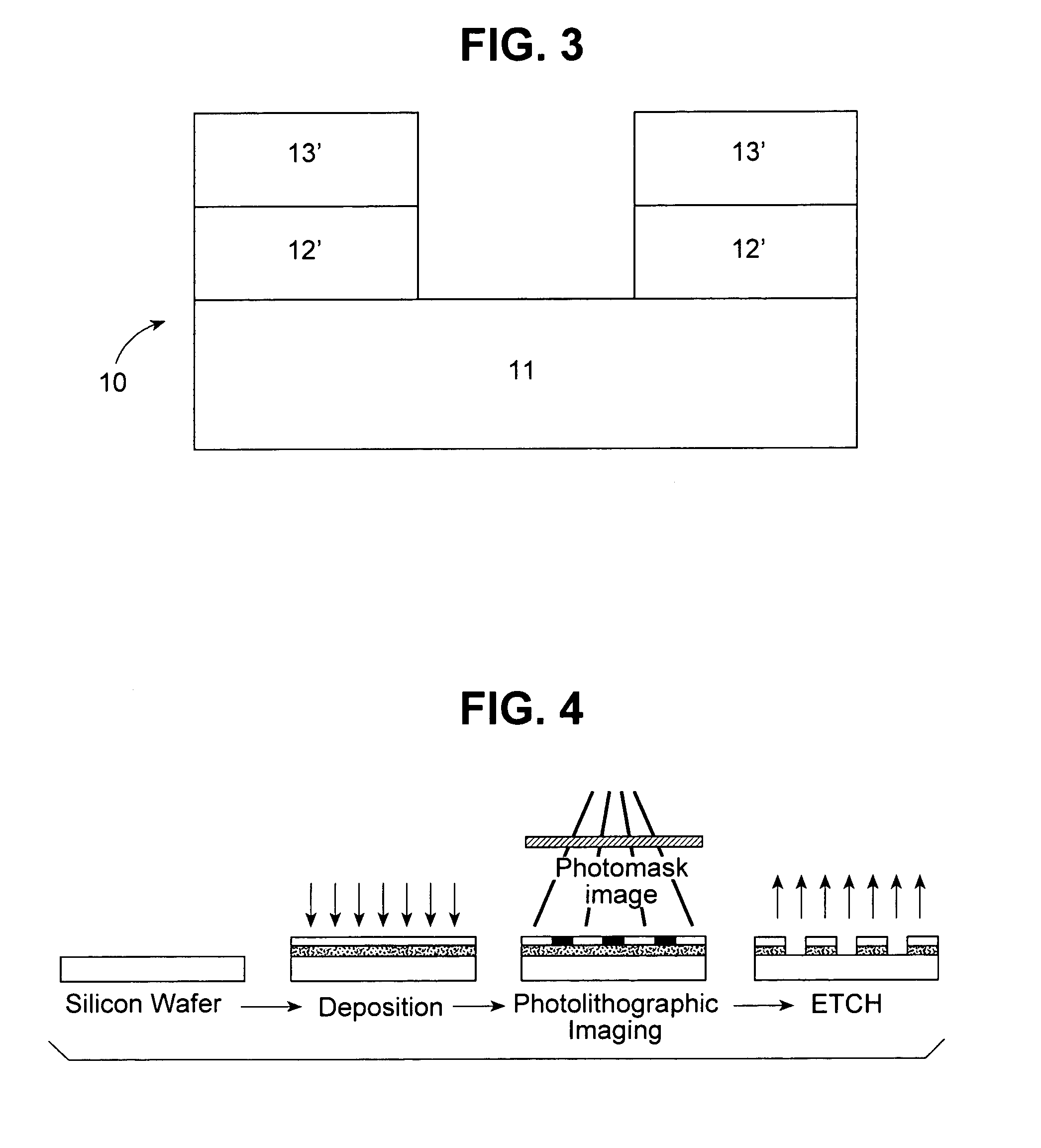

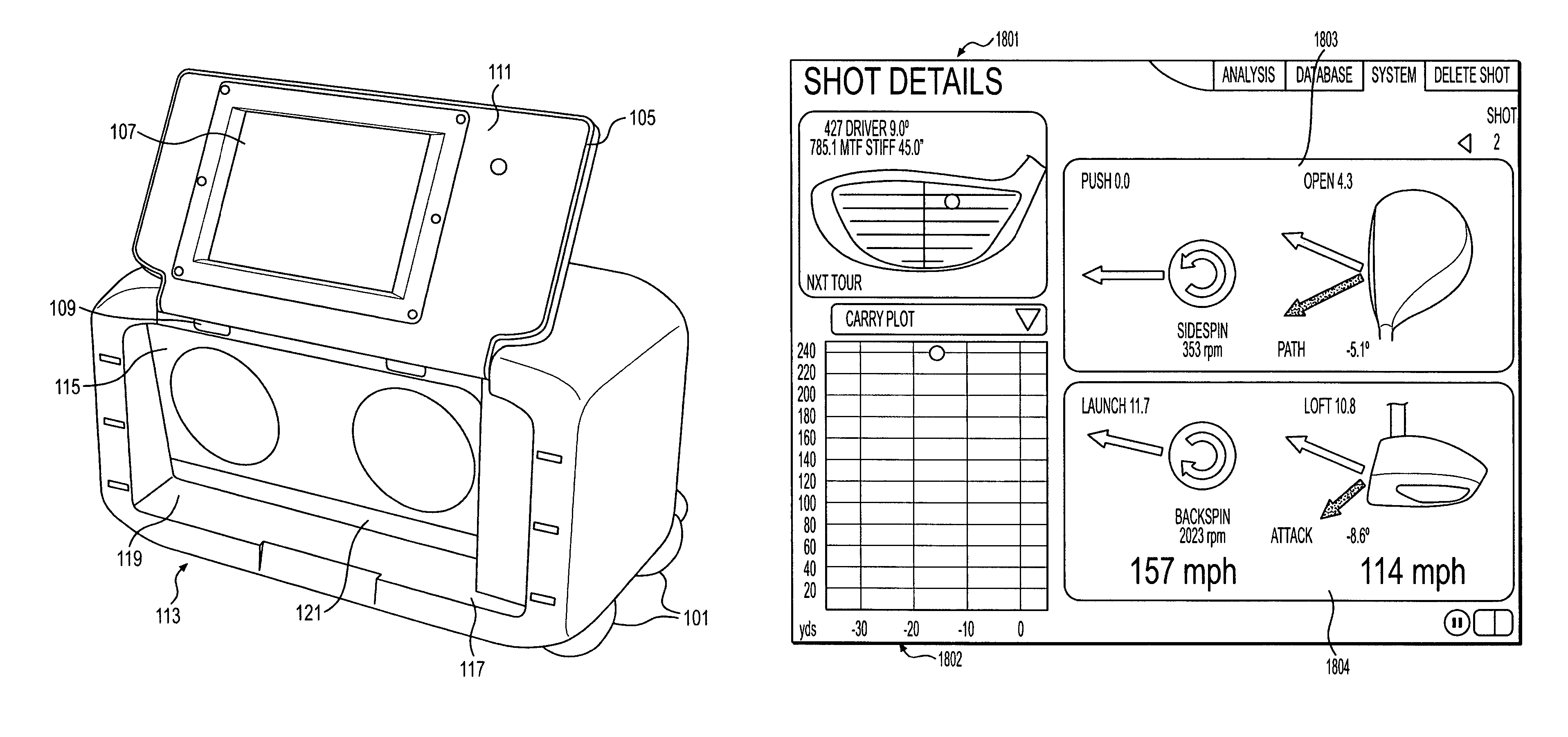

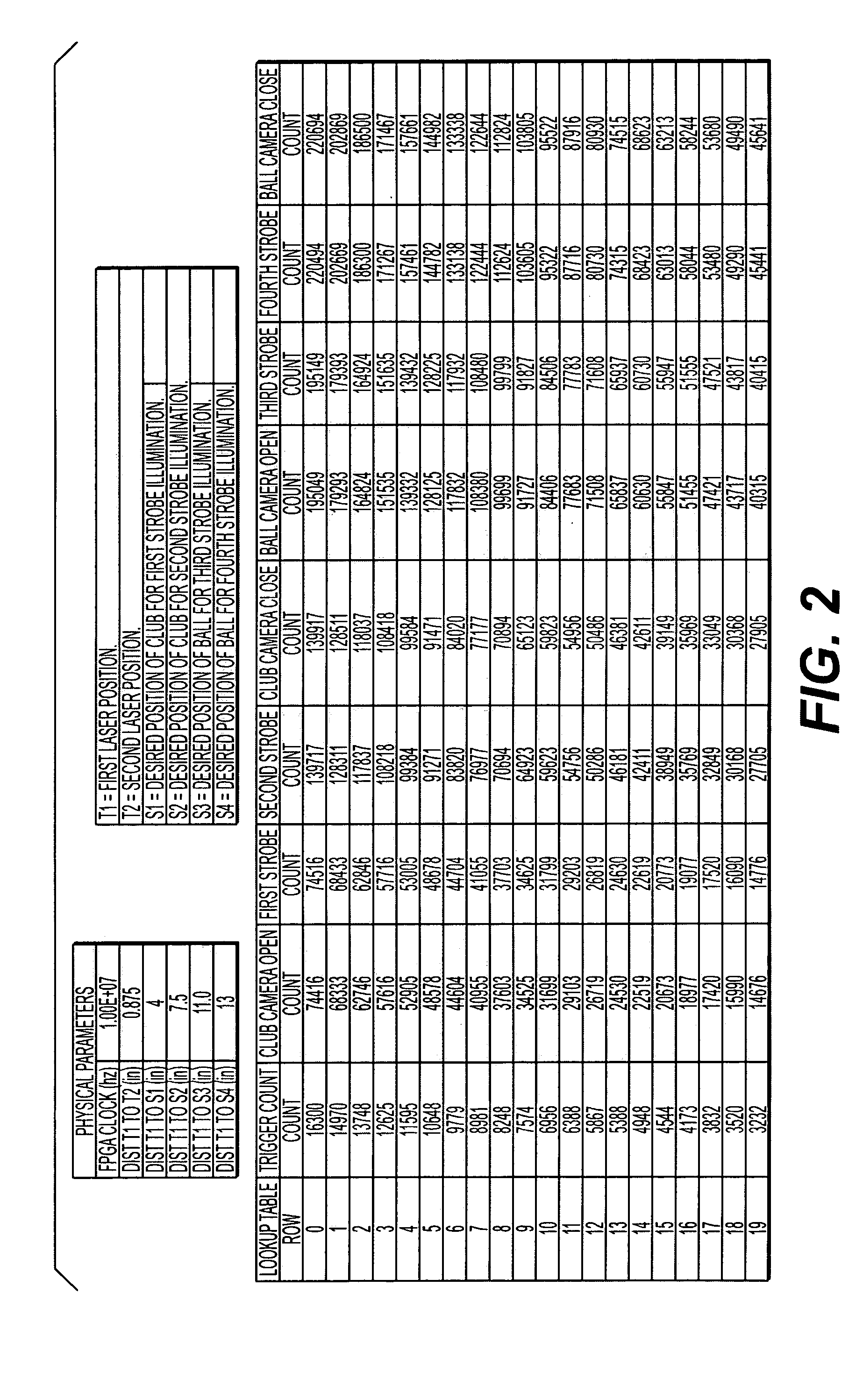

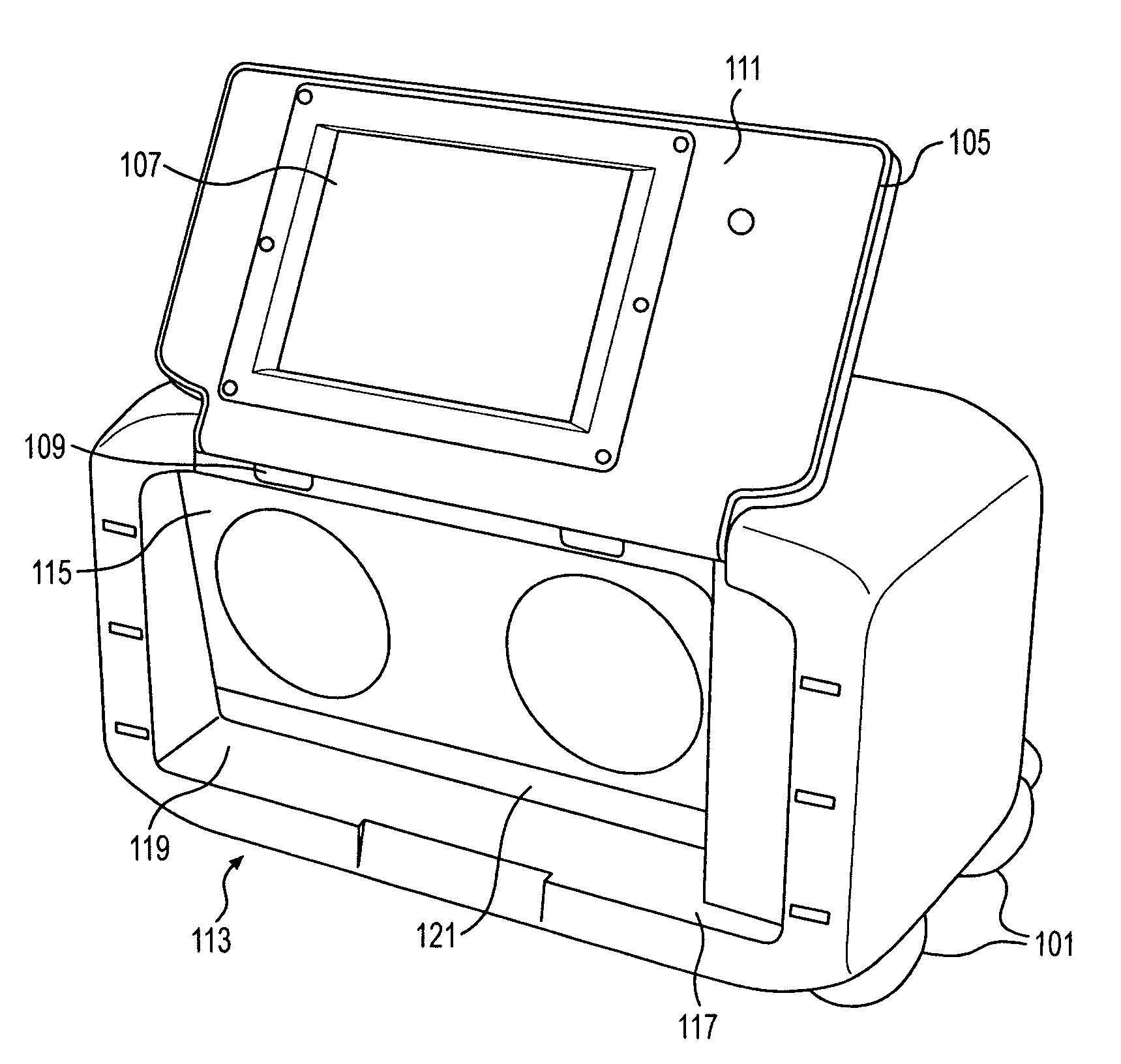

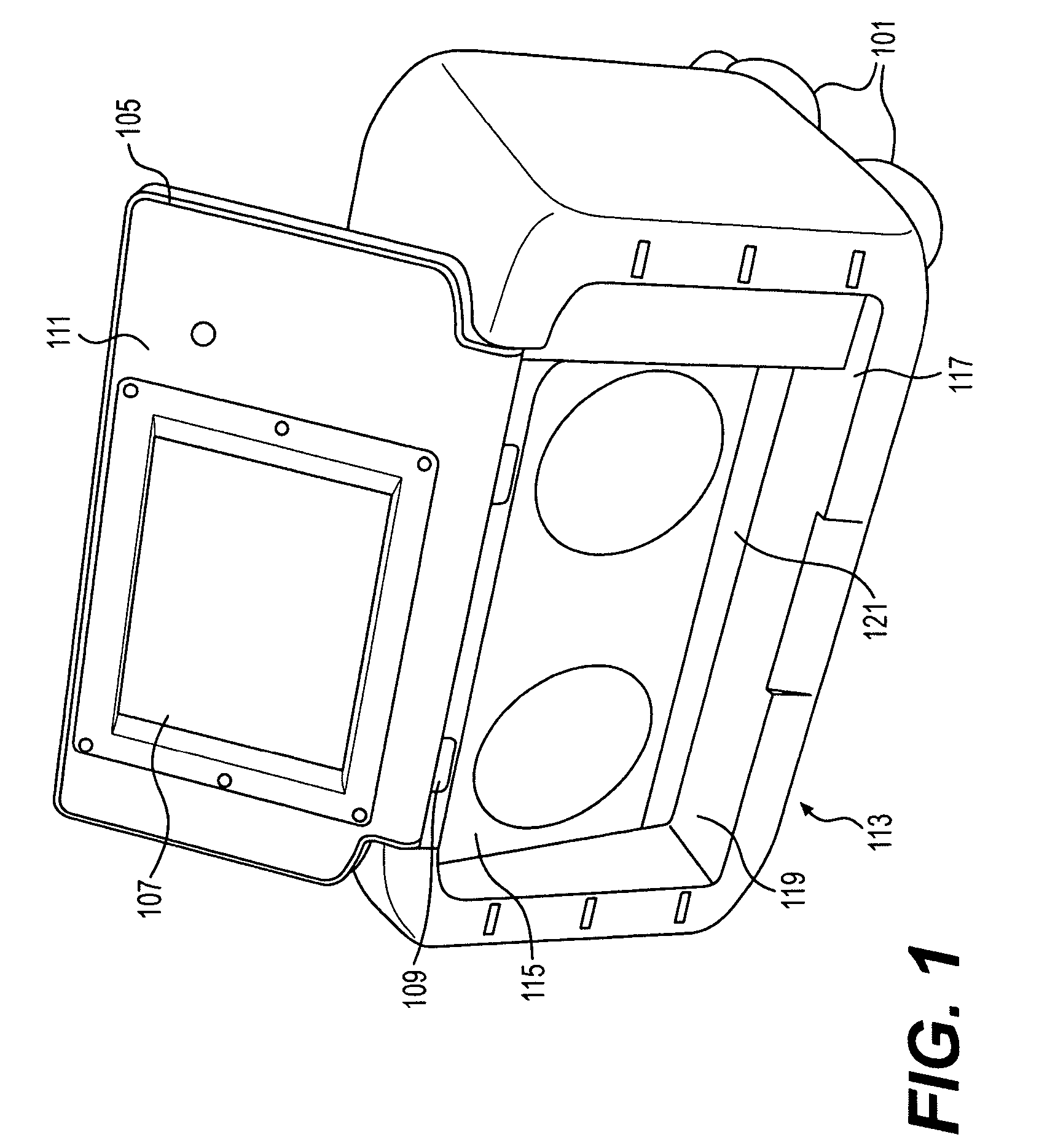

Launch monitor

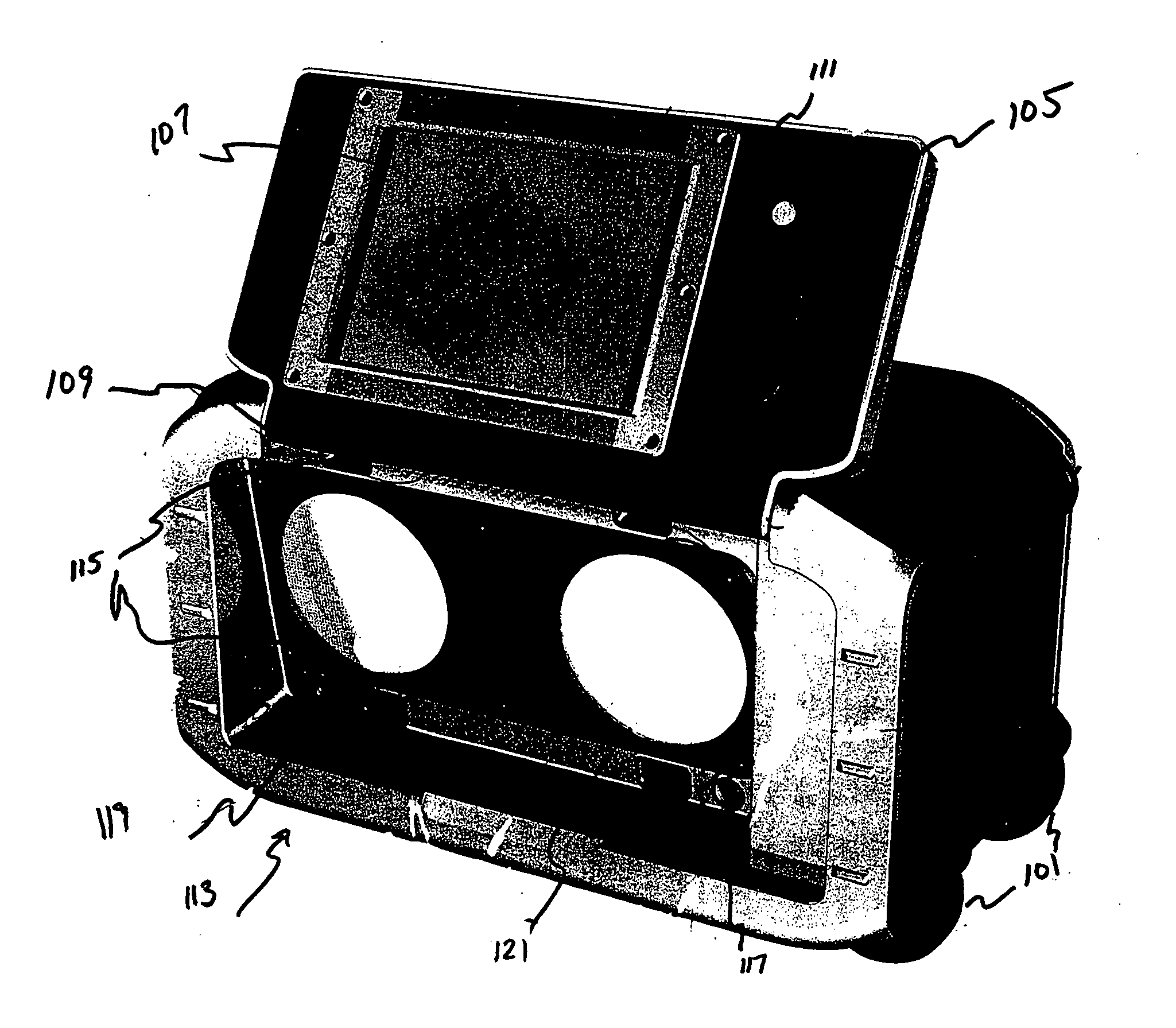

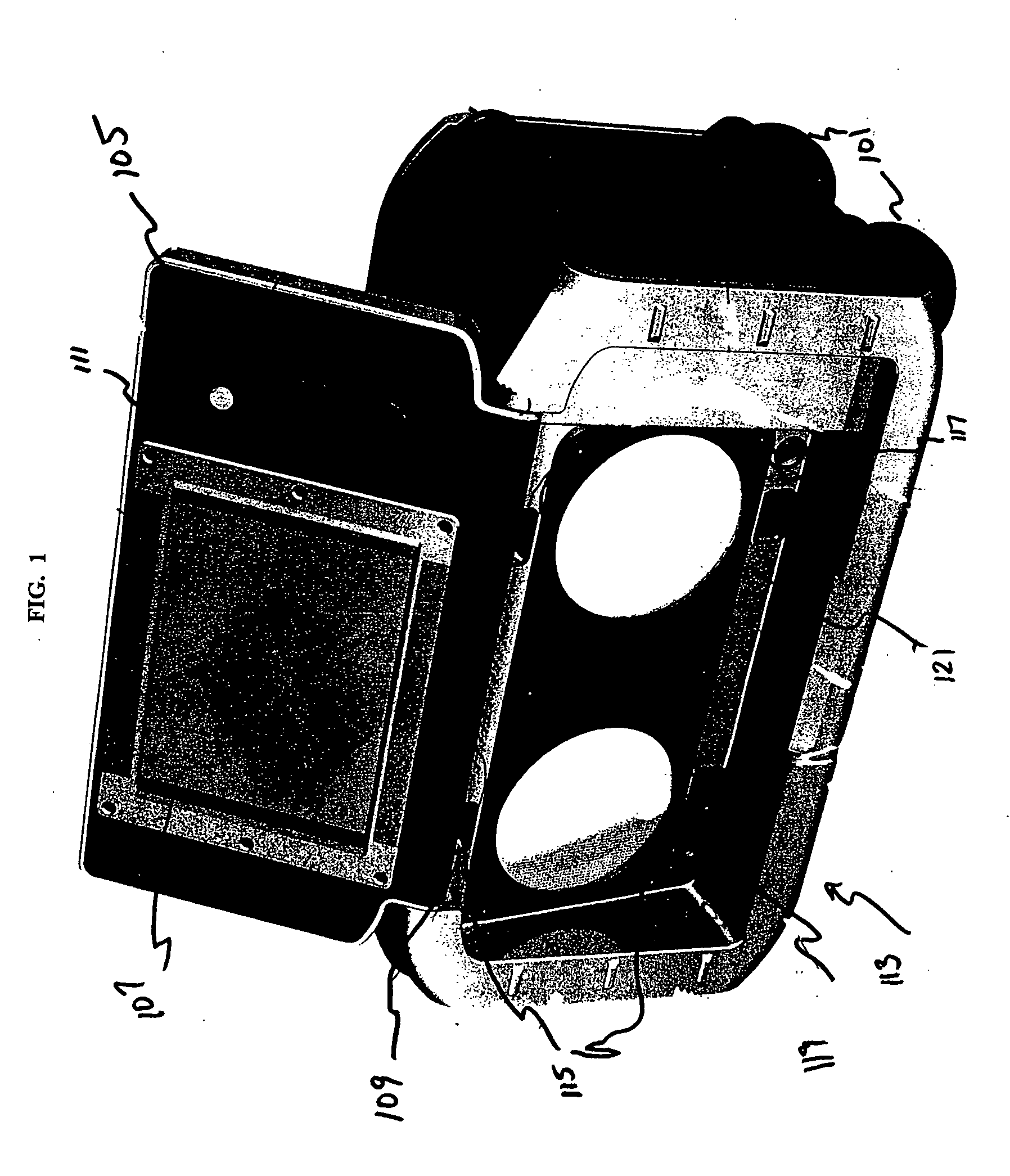

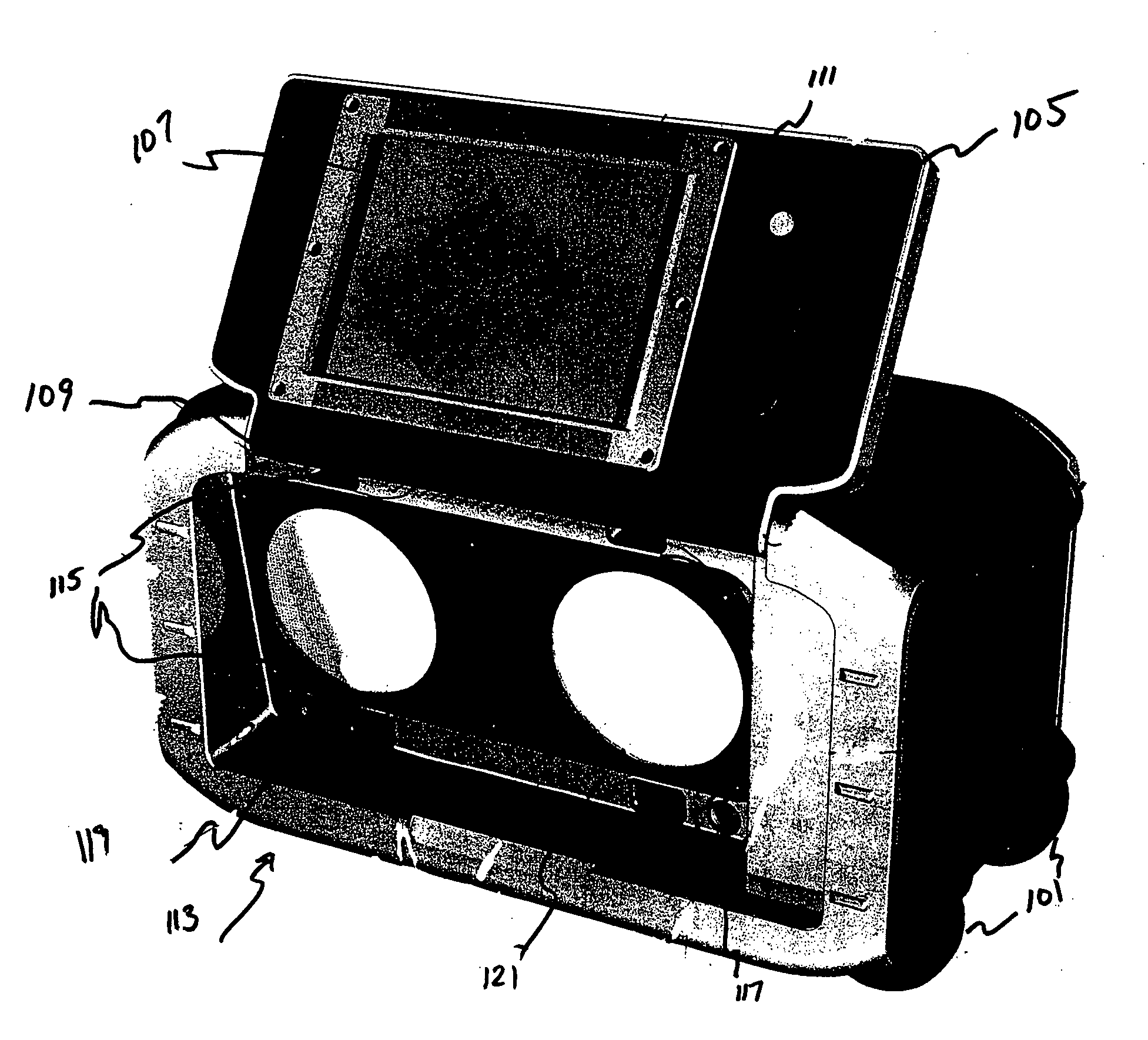

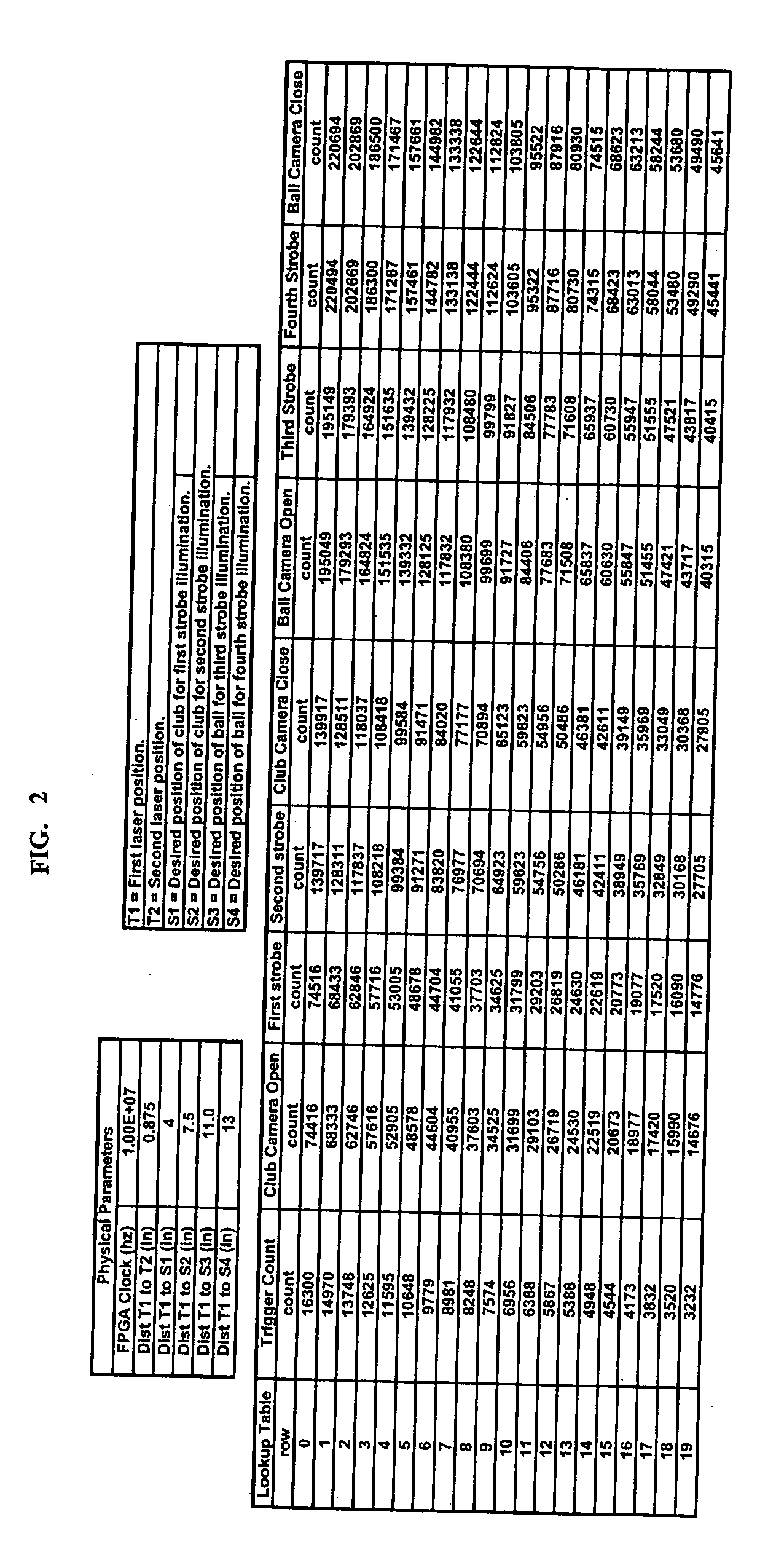

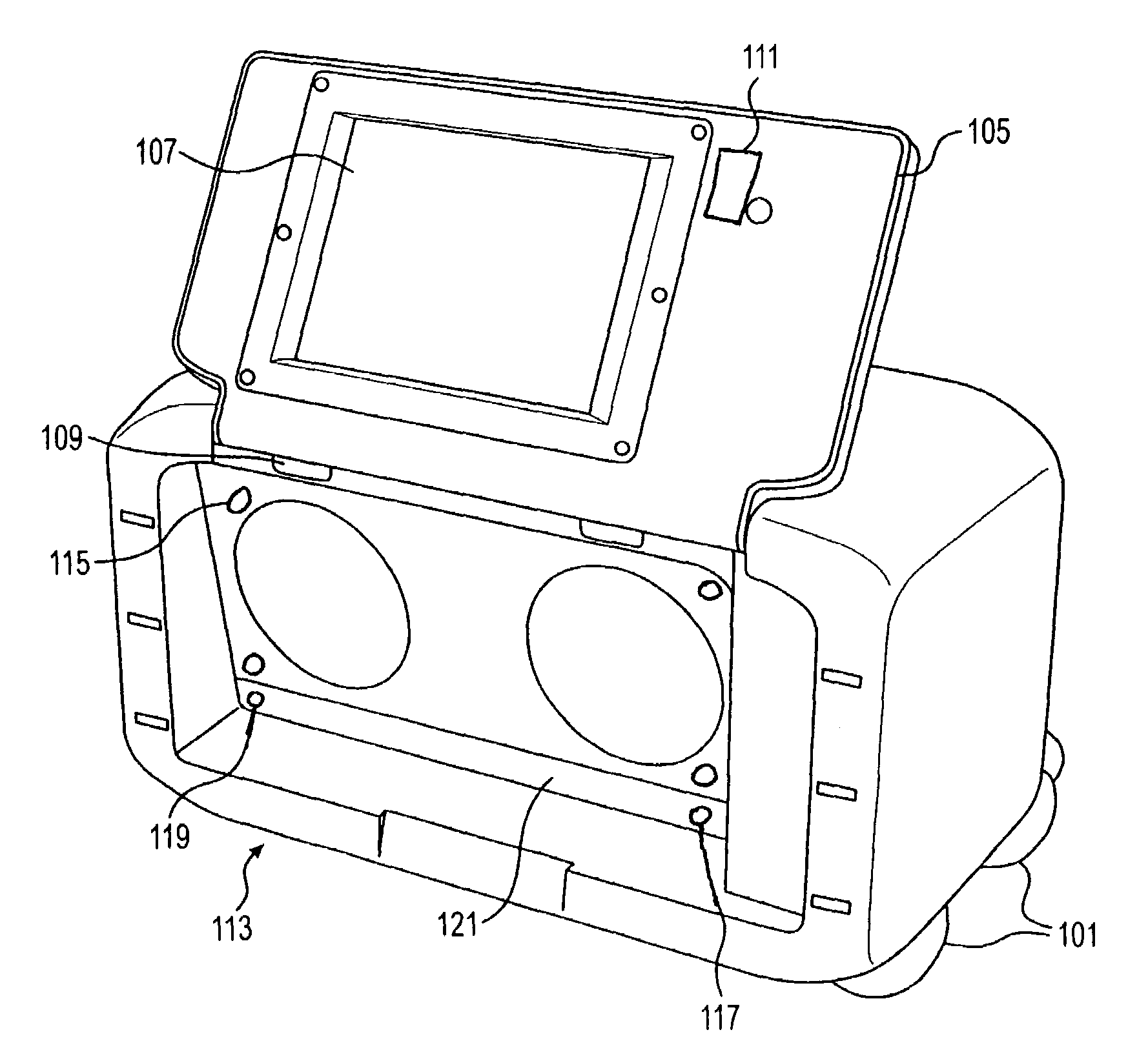

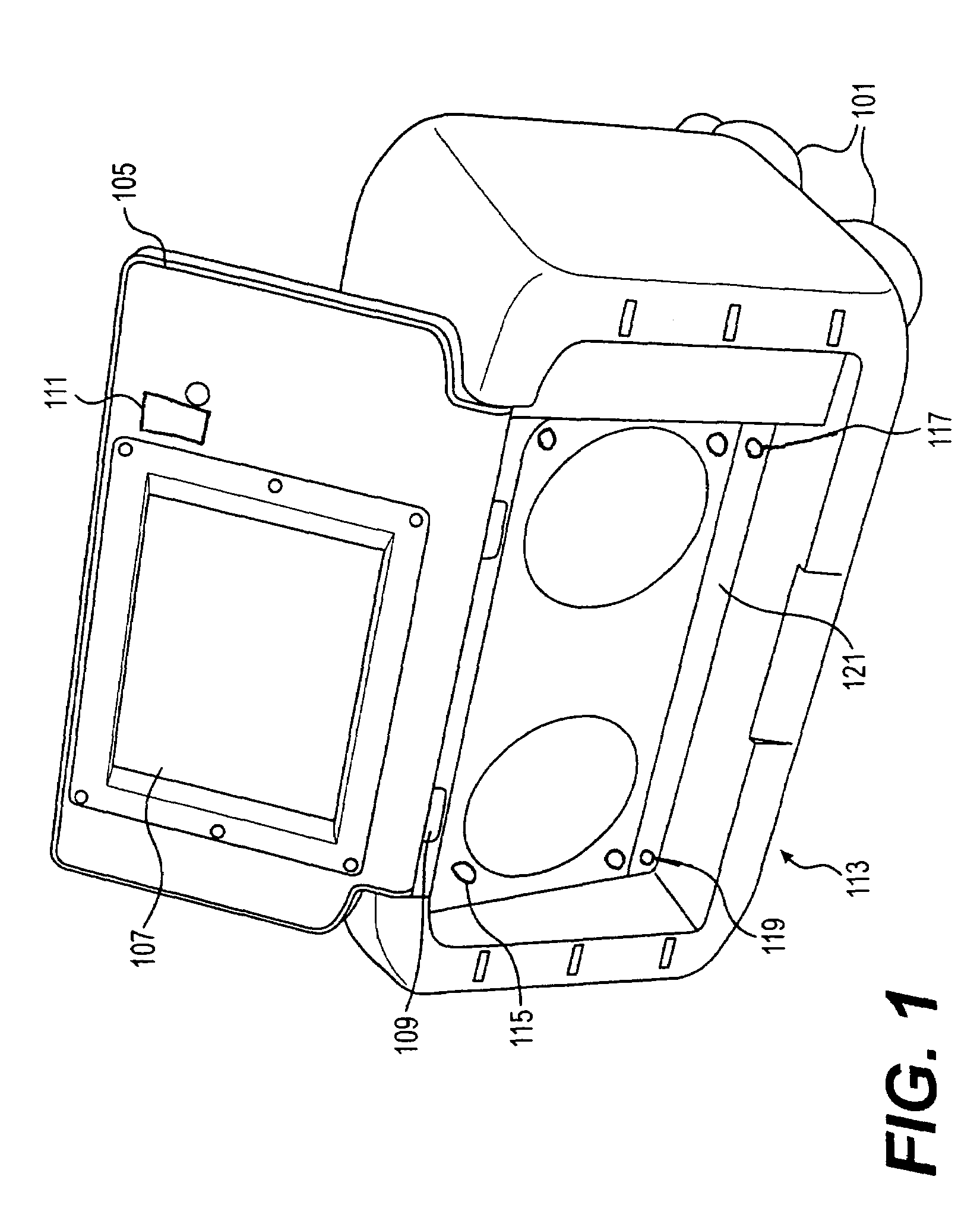

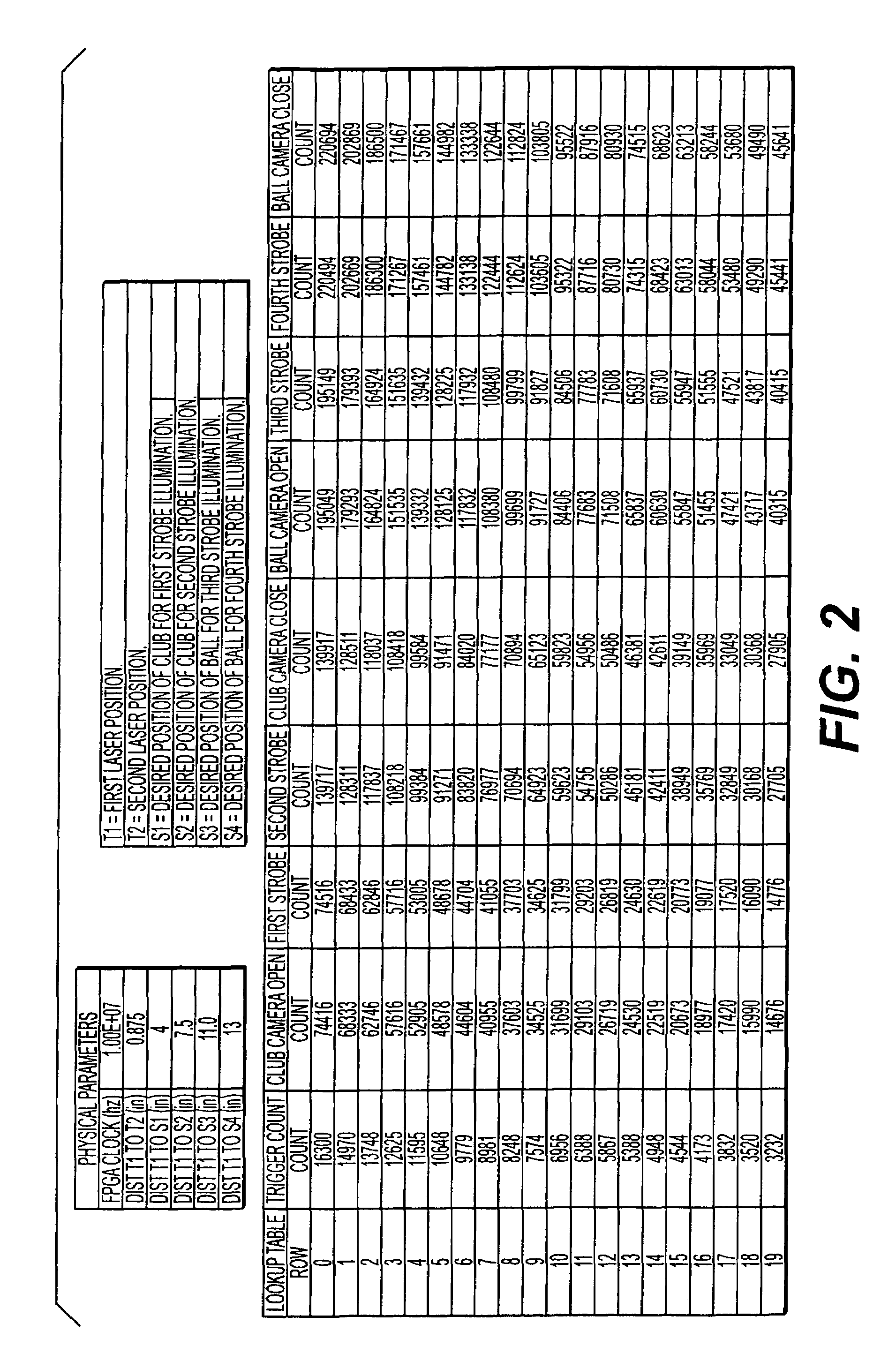

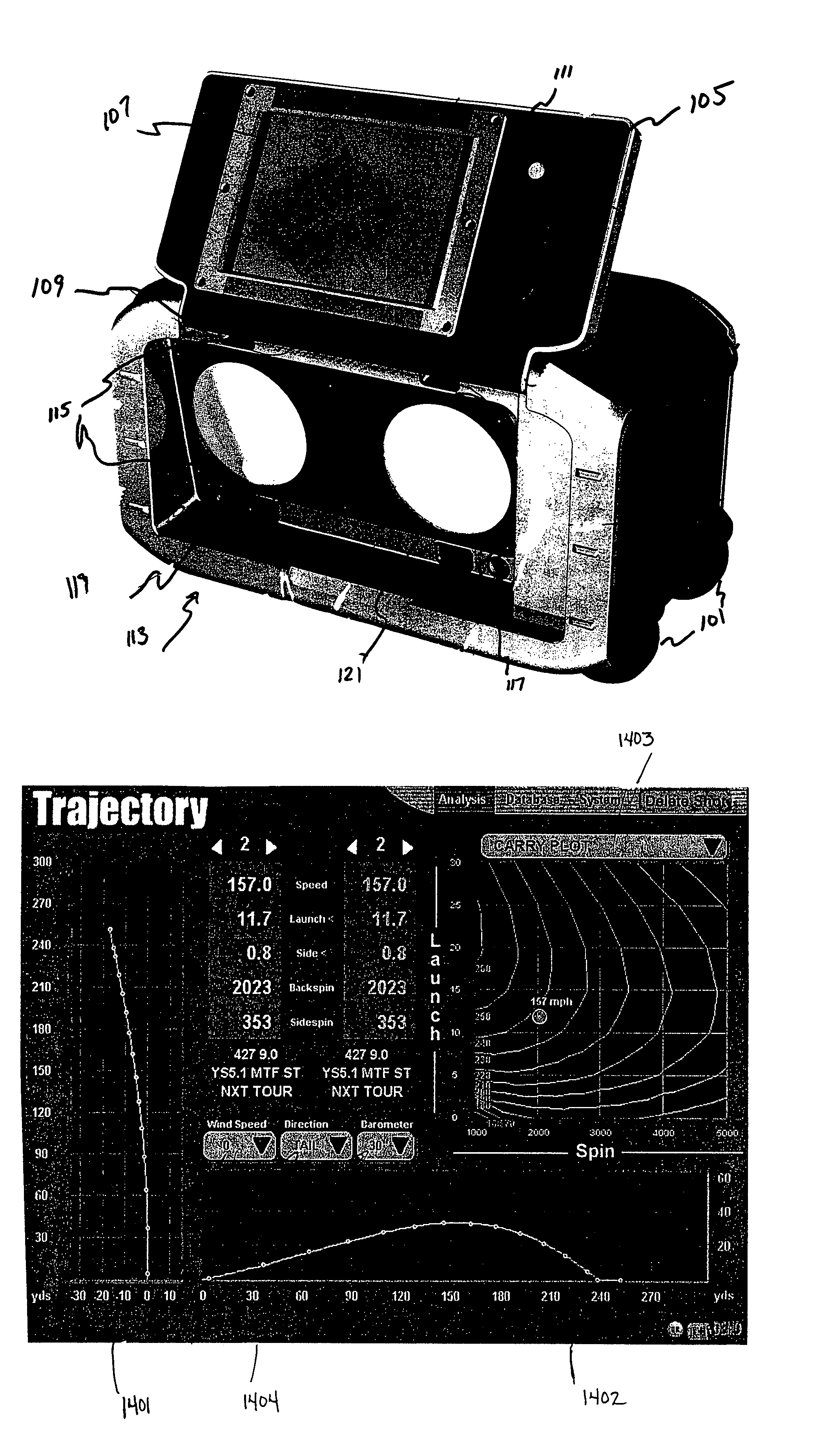

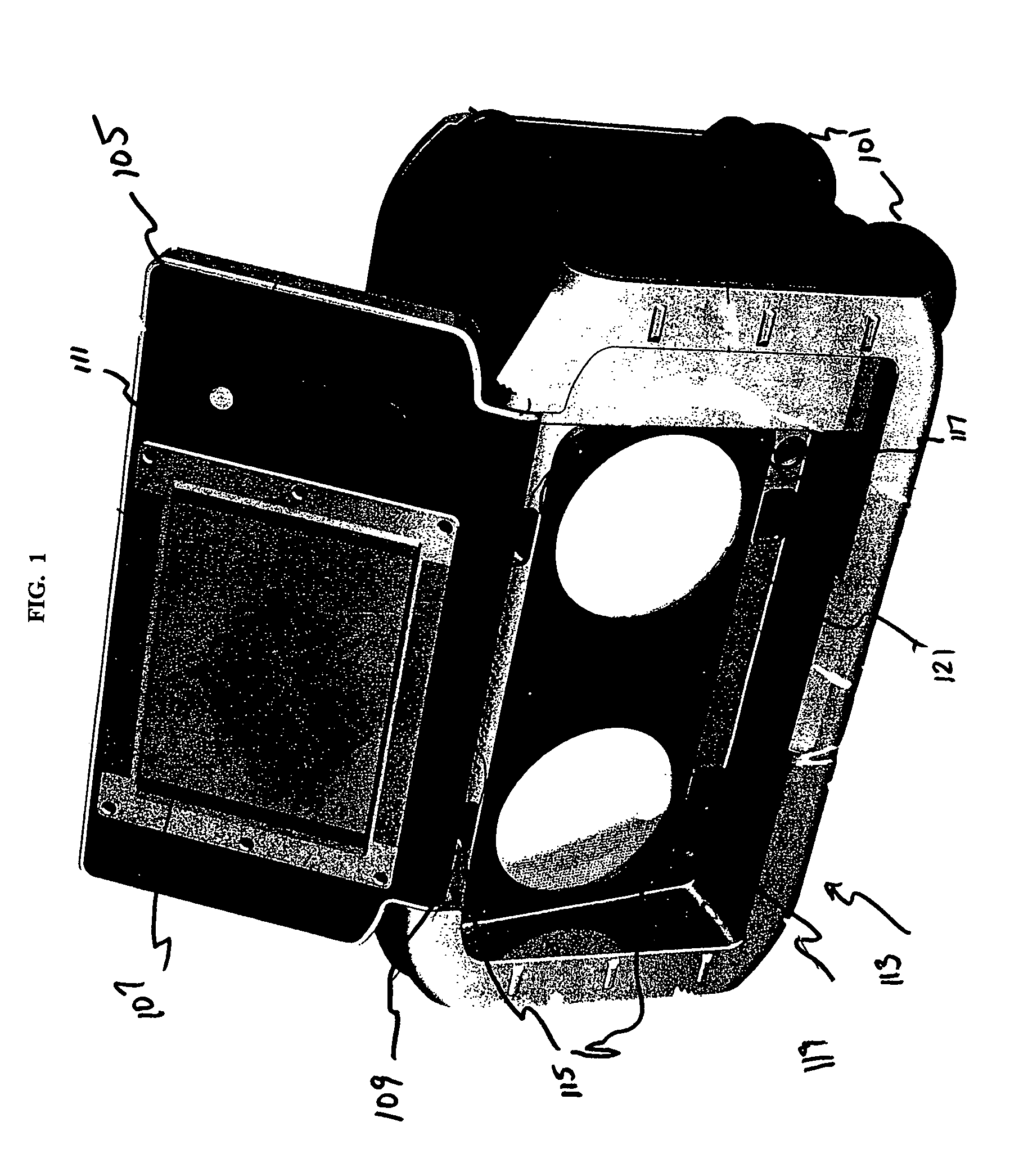

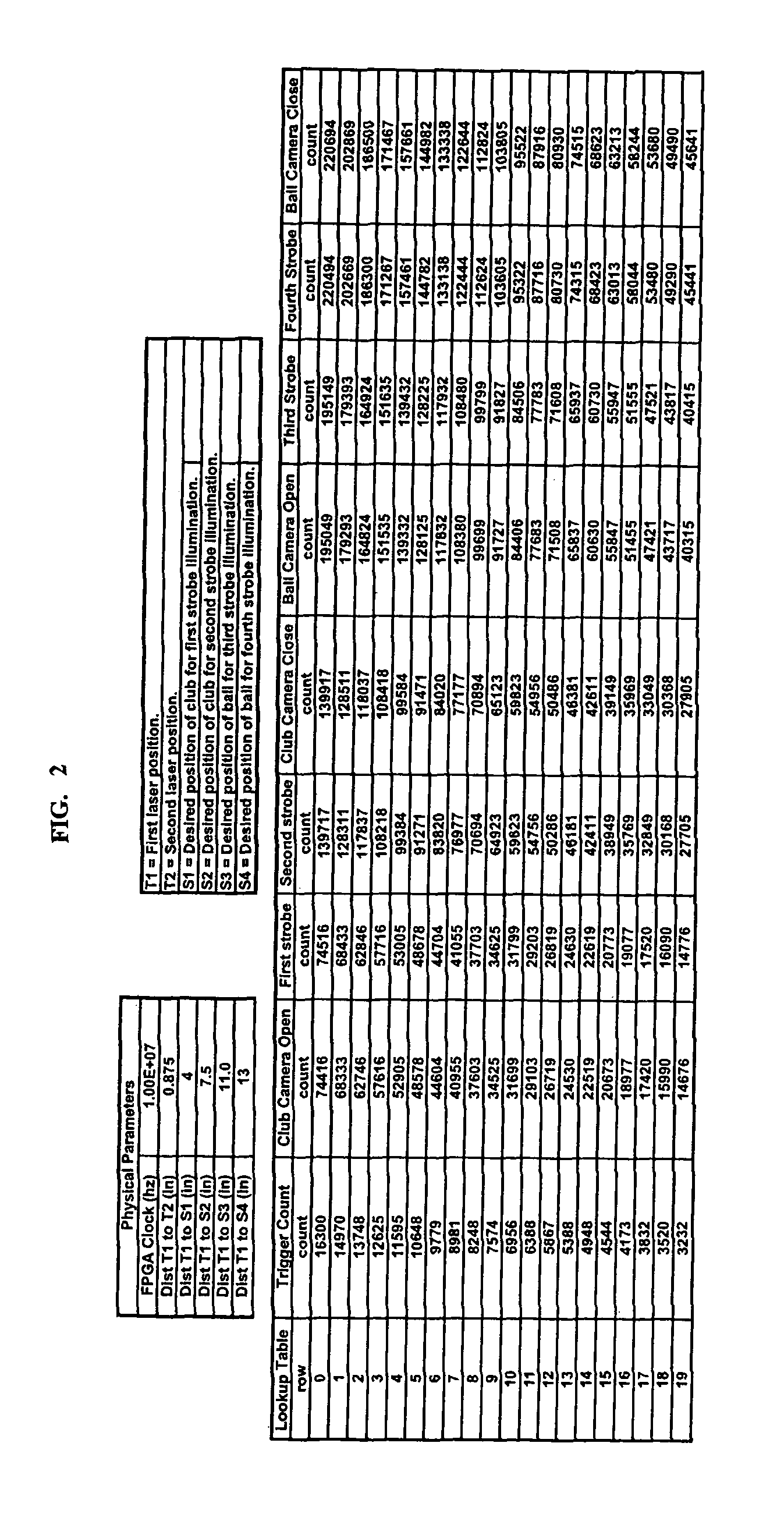

A launch monitor that includes substantially all of its functional components on or within a housing is disclosed. In one embodiment, the launch monitor is capable of being transported and used in any desired location. One or more camera's, flashes, and triggers may be used to acquire images of a golf club and golf ball. The launch monitor is preferably capable of receiving and transmitting data over a wireless network. Acquired images and other data may be analyzed by a processor, and then displayed using an LED, LCD or other type of display or printer. The launch monitor may “recognize” a plurality of golf clubs and golf balls based on an optical fingerprint. The optical fingerprints, which are preferably stored in a memory, allow the launch monitor to identify a golf club and / or ball substantially soon after they are placed in the field of view of the monitor Optical fingerprinting enables automatic record keeping, and storing performance data and equipment used simultaneously. This feature eliminates tedious record keeping, eliminates data entry errors, and enables rapid equipment optimization.

Owner:ACUSHNET CO

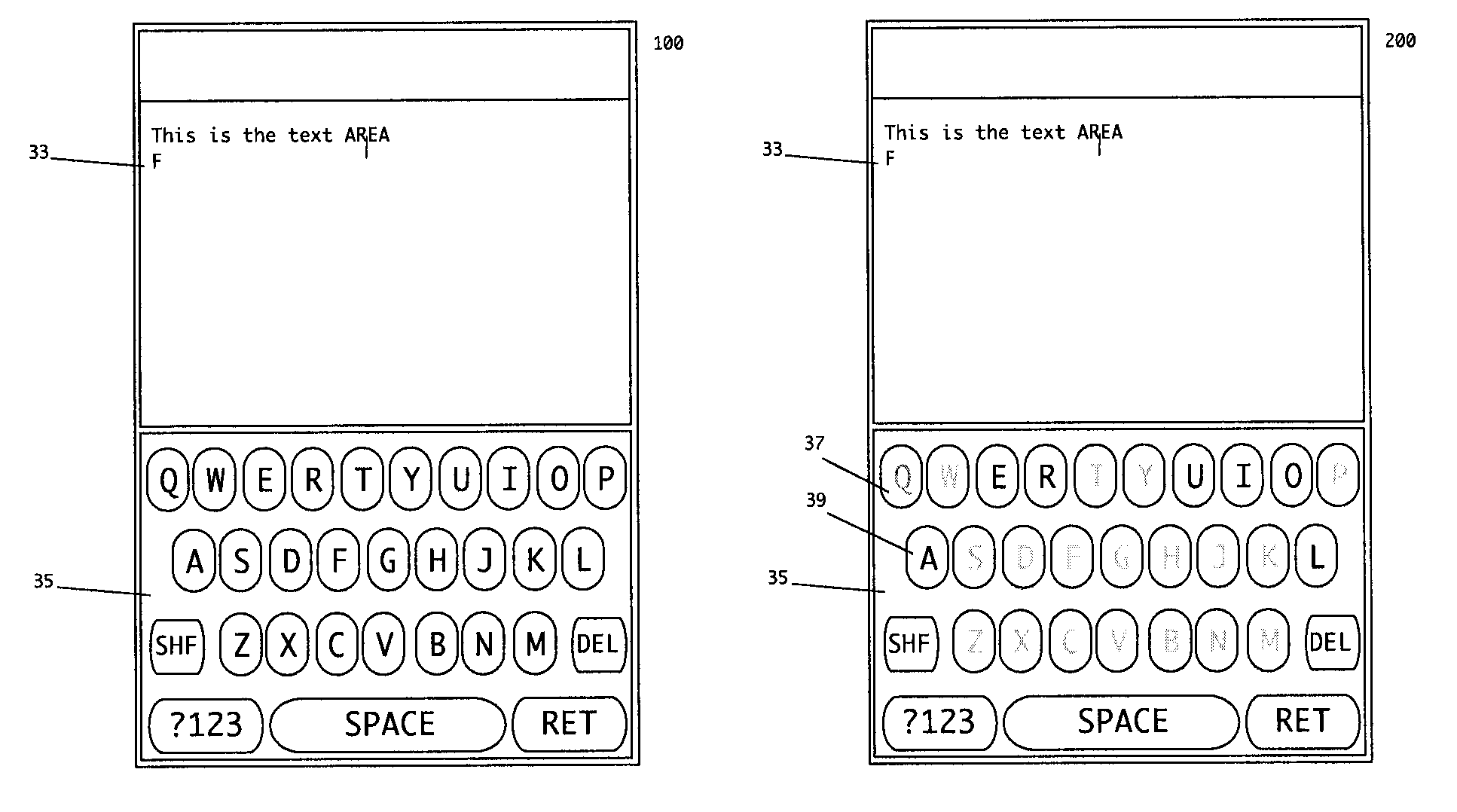

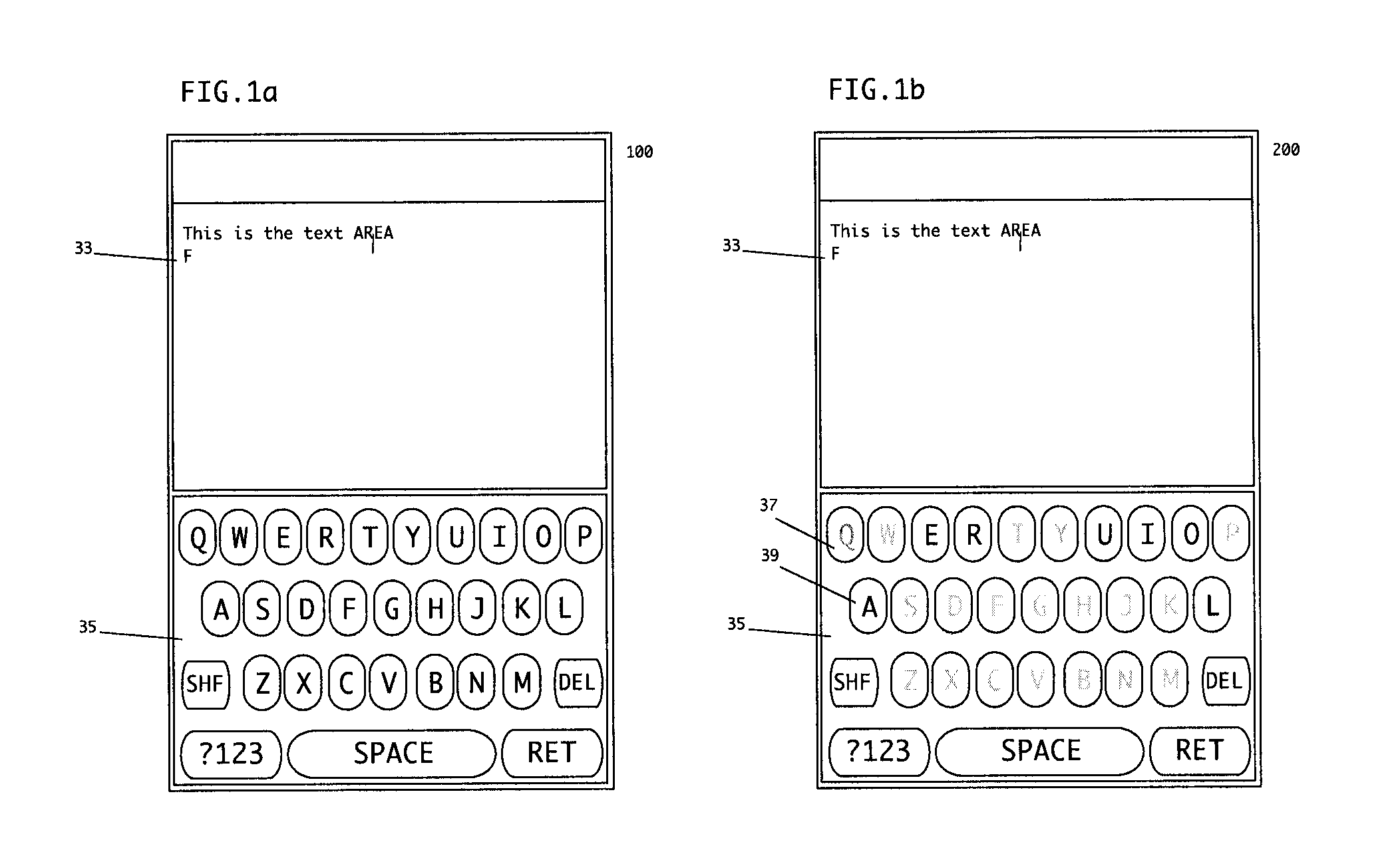

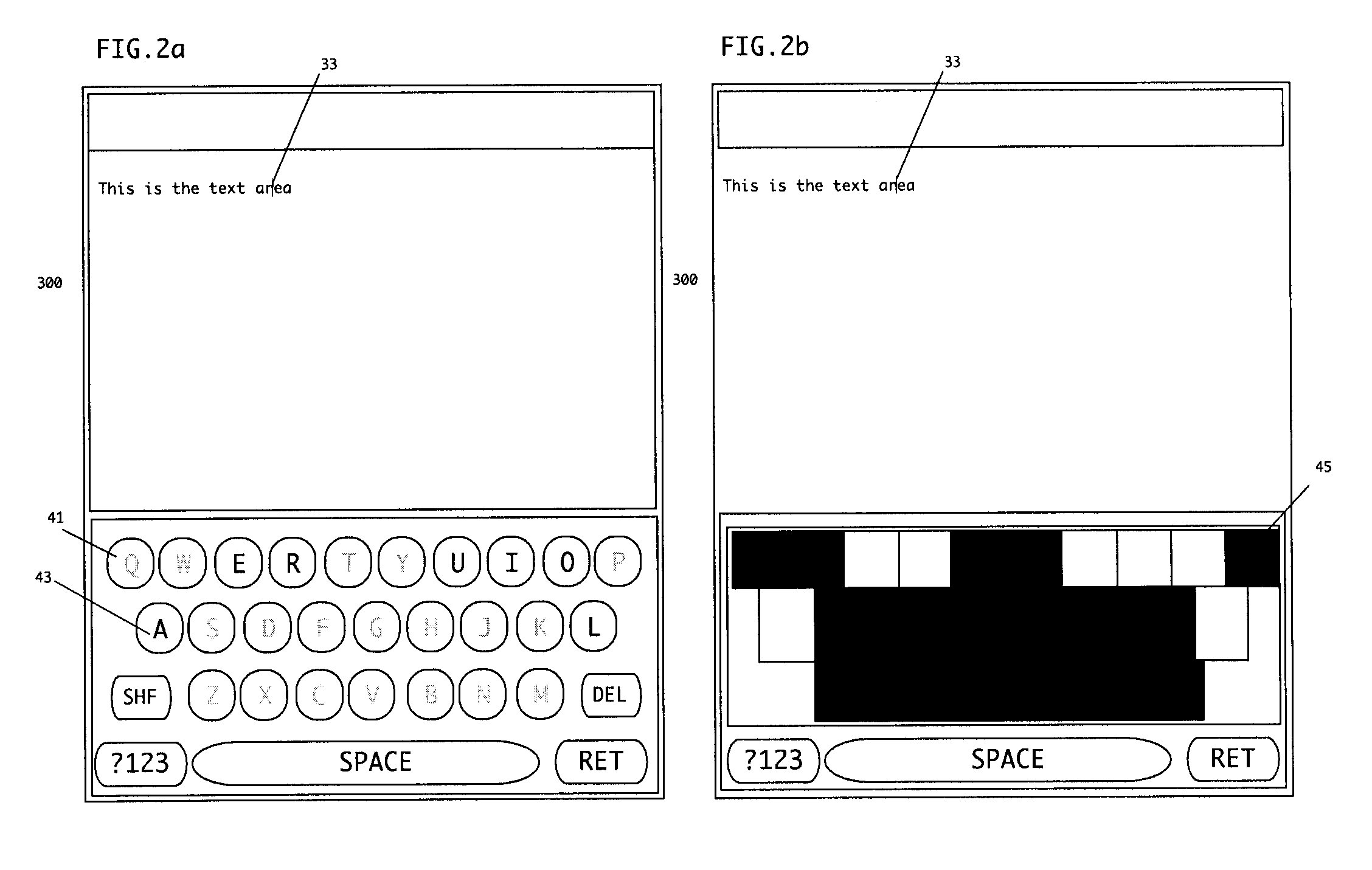

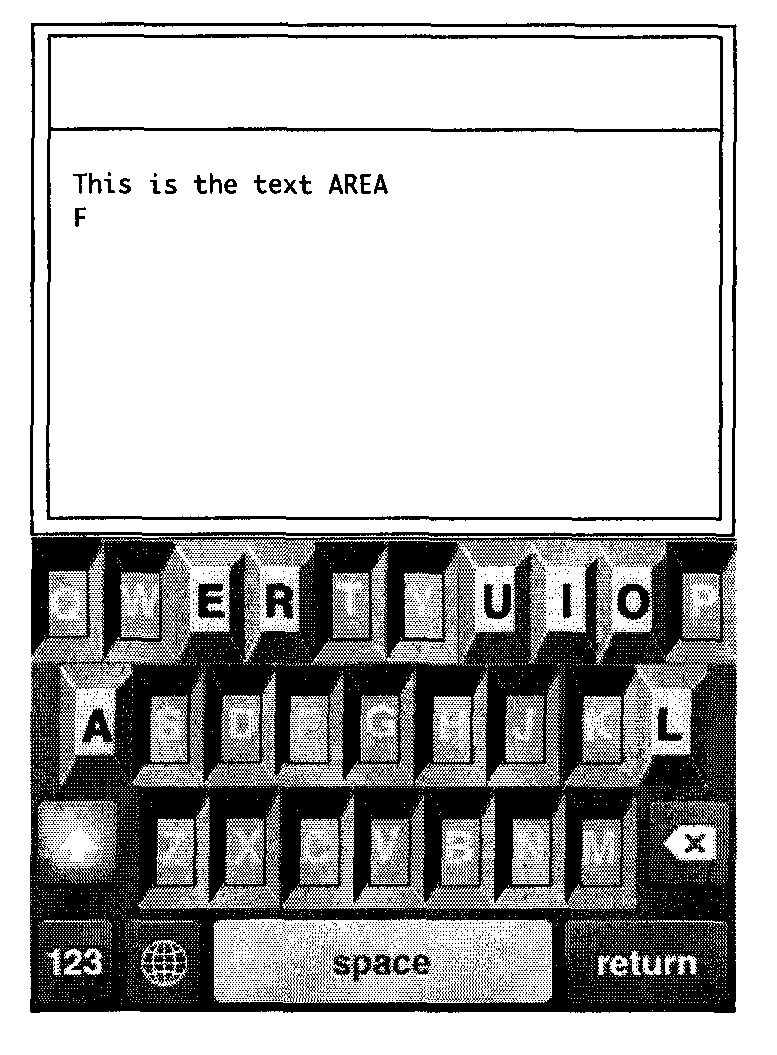

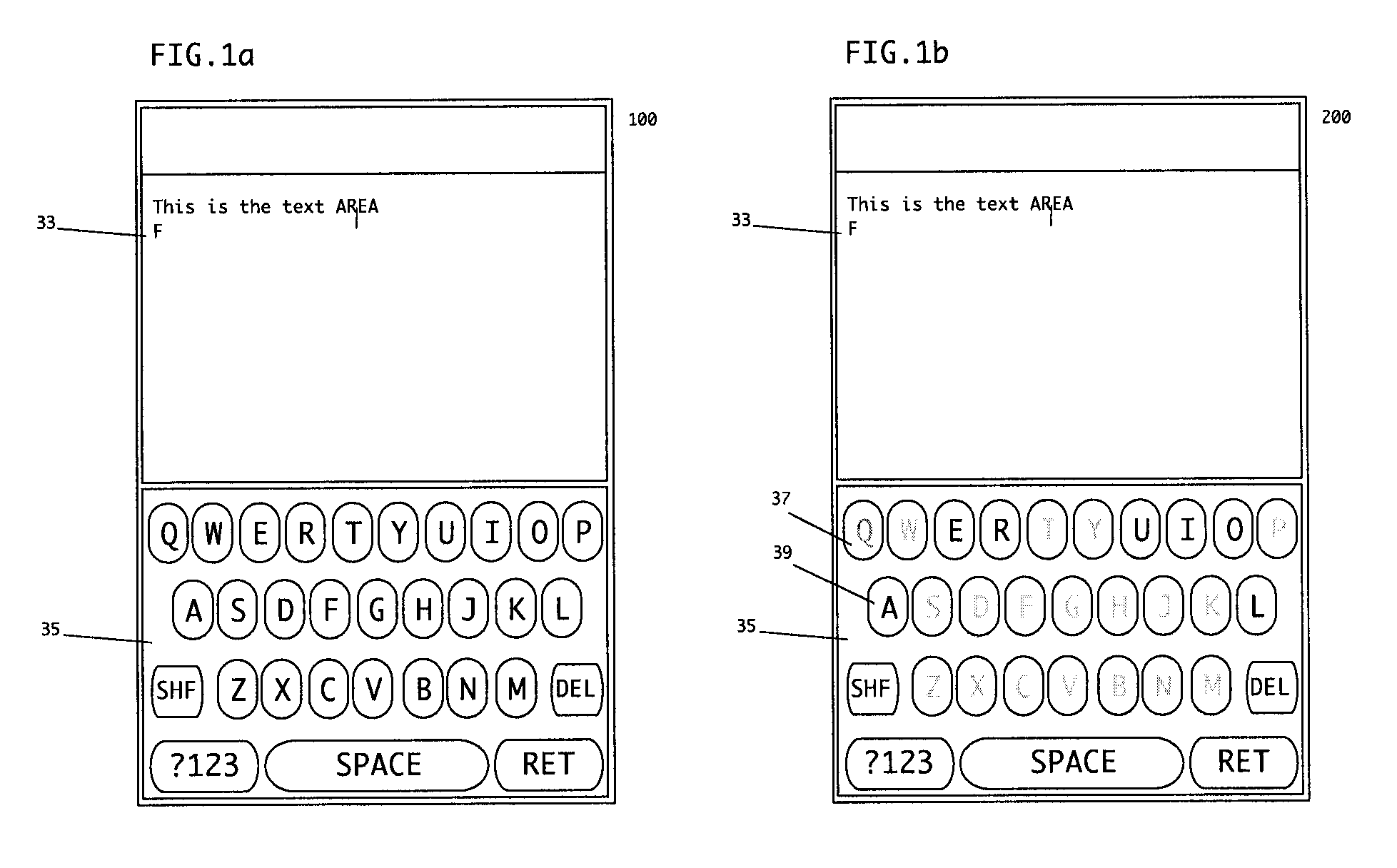

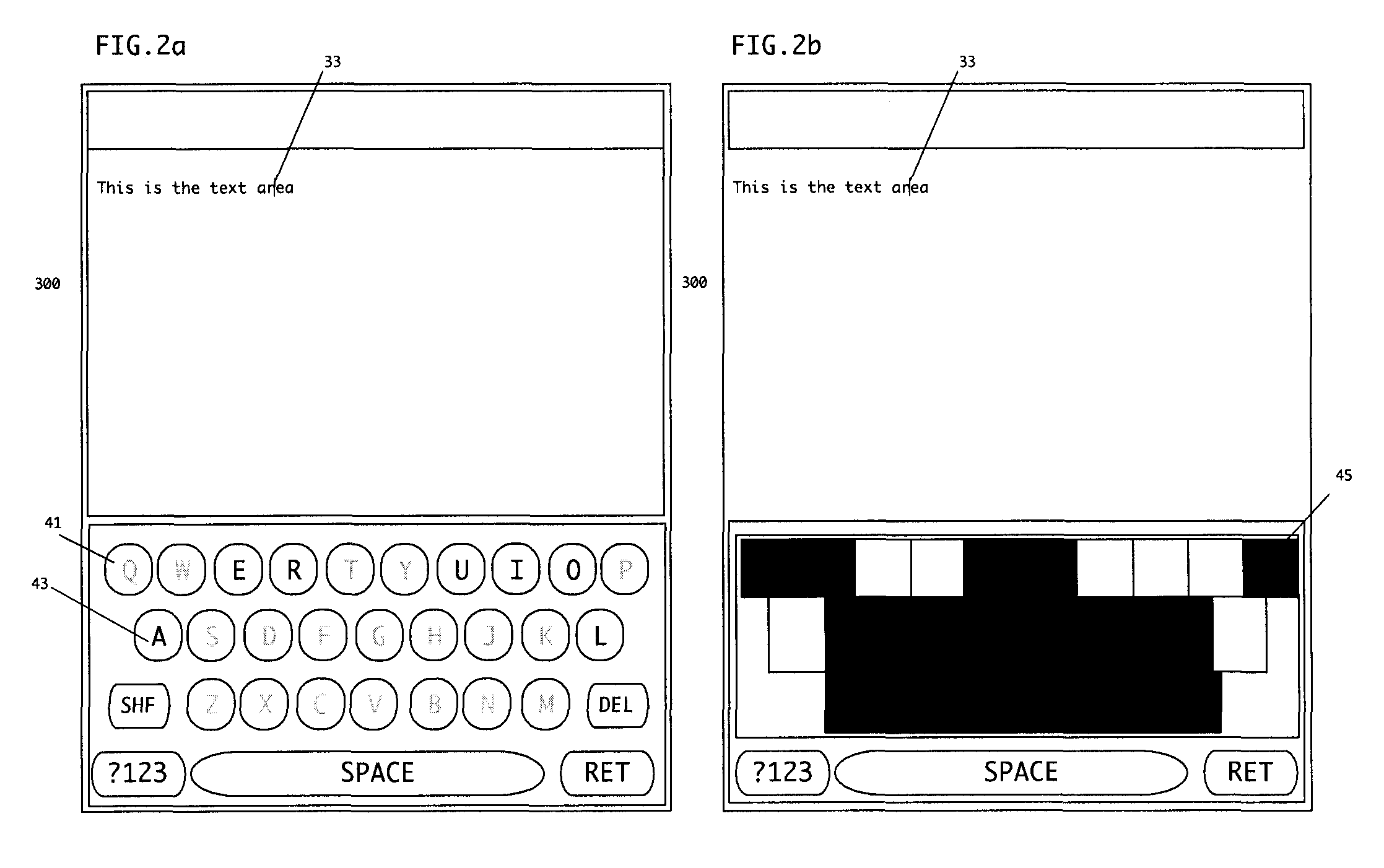

Methods of and systems for reducing keyboard data entry errors

InactiveUS20120062465A1Minimization requirementsEasy accessInput/output for user-computer interactionCathode-ray tube indicatorsSoft keyDisplay device

Method of and system for reducing data entry errors that ascertains a subset of keys that can be selected by a user based upon the respective likelihood that each key follows a previously selected key within a predetermined language, corpus, or subset thereof, and controls the display of the keys within an input device so that the keys within the ascertained subset are displayed in a visually distinguishable manner from the keys that not within the ascertained subset. In a touch screen device, the keys that are displayed are part of the soft keys displayed on the screen. In a system that includes an actual physical keyboard, the appearance of select keys of the keyboard can be modified in various manners, including the use of an LCD display or other controllable lighting mechanism disposed within the keyboard. Multiple additional techniques for reducing data entry also are disclosed.

Owner:SIEGEL ABBY L

Launch monitor

A launch monitor that includes substantially all of its functional components on or within a housing is disclosed. In one embodiment, the launch monitor is capable of being transported and used in any desired location. One or more camera's, flashes, and triggers may be used to acquire images of a golf club and golf ball. The launch monitor is preferably capable of receiving and transmitting data over a wireless network. Acquired images and other data may be analyzed by a processor, and then displayed using an LED, LCD or other type of display or printer. The launch monitor may “recognize” a plurality of golf clubs and golf balls based on an optical fingerprint. The optical fingerprints, which are preferably stored in a memory, allow the launch monitor to identify a golf club and / or ball substantially soon after they are placed in the field of view of the monitor Optical fingerprinting enables automatic record keeping, and storing performance data and equipment used simultaneously. This feature eliminates tedious record keeping, eliminates data entry errors, and enables rapid equipment optimization.

Owner:ACUSHNET CO

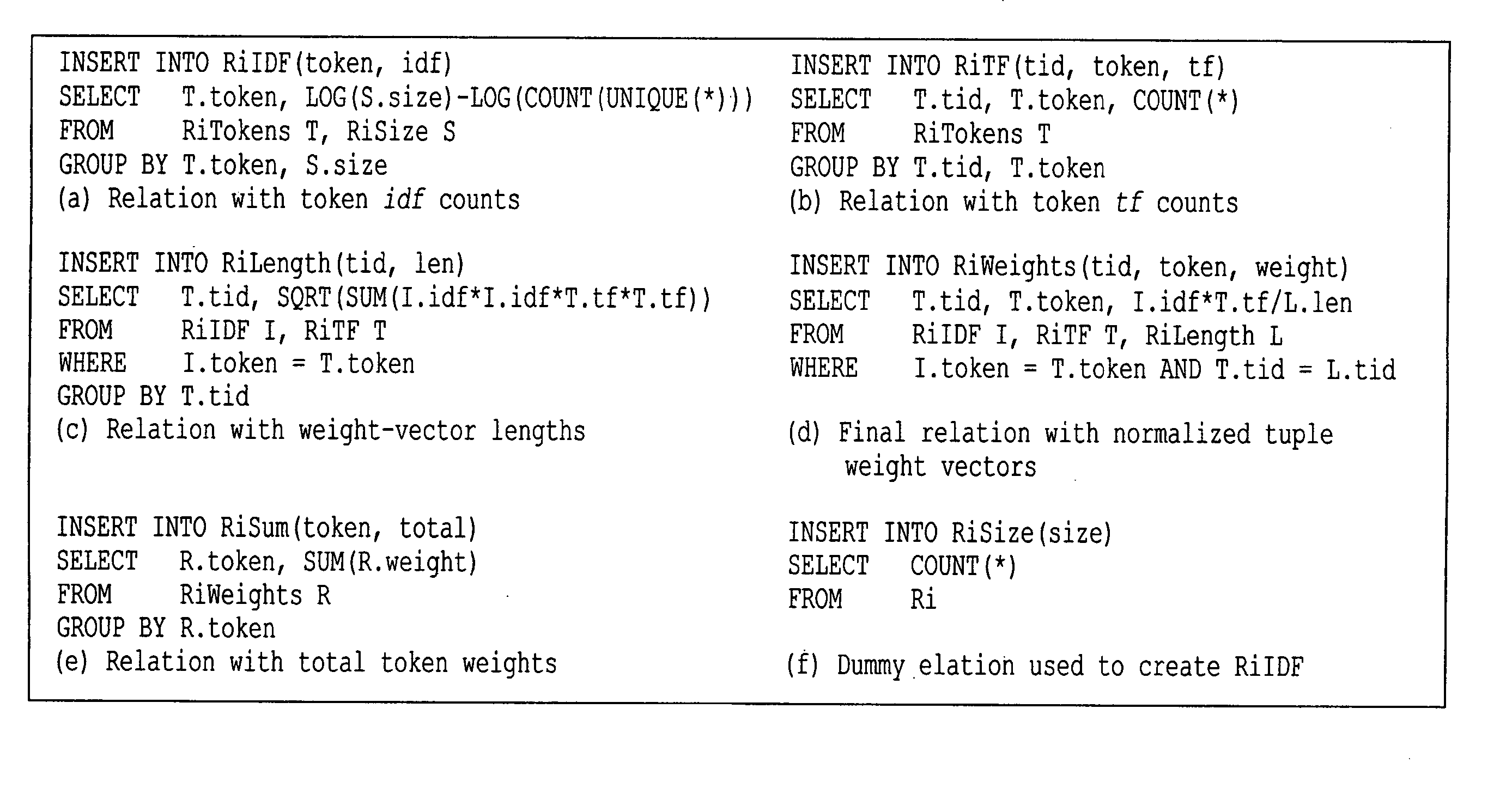

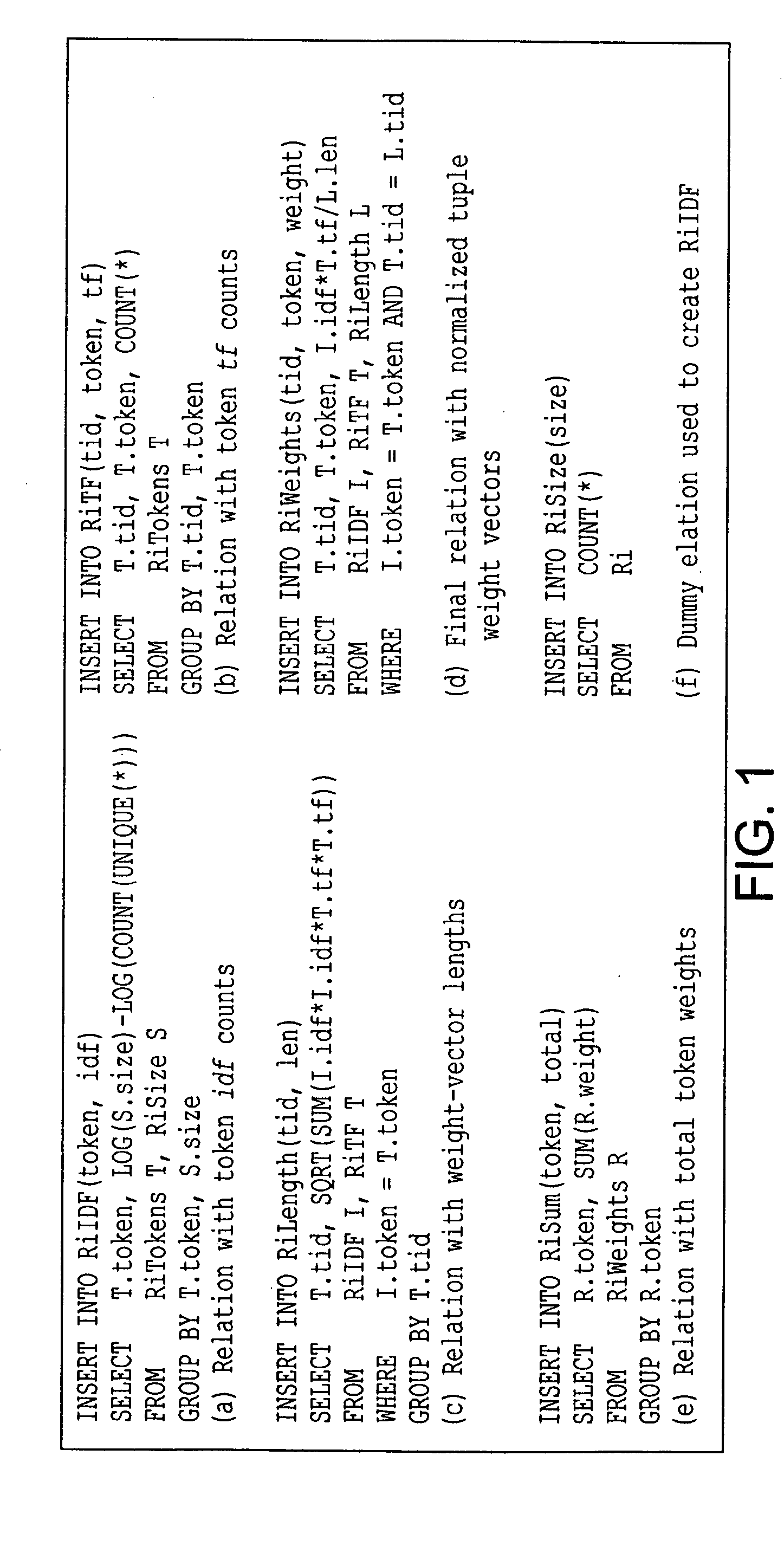

Text joins for data cleansing and integration in a relational database management system

InactiveUS20050027717A1Relational databasesComparison of digital valuesCosine similarityRelational database management system

Owner:AMERICAN TELEPHONE & TELEGRAPH CO +1

Launch monitor

A launch monitor that includes substantially all of its functional components on or within a housing is disclosed. In one embodiment, the launch monitor is capable of being transported and used in any desired location. One or more camera's, flashes, and triggers may be used to acquire images of a golf club and golf ball. The launch monitor is preferably capable of receiving and transmitting data over a wireless network. Acquired images and other data may be analyzed by a processor, and then displayed using an LED, LCD or other type of display or printer. The launch monitor may “recognize” a plurality of golf clubs and golf balls based on an optical fingerprint. The optical fingerprints, which are preferably stored in a memory, allow the launch monitor to identify a golf club and / or ball substantially soon after they are placed in the field of view of the monitor Optical fingerprinting enables automatic record keeping, and storing performance data and equipment used simultaneously. This feature eliminates tedious record keeping, eliminates data entry errors, and enables rapid equipment optimization.

Owner:ACUSHNET CO

Method of detecting data entry errors by sorting amounts and verifying amount order

InactiveUS6055327AReduction of correction keying laborLabor for correctingCharacter and pattern recognitionPattern recognitionAmbiguity

An improved method and system for verifying the correctness of data entered from document images. Images are sorted according to their entered values, and are then presented to an adjudication operator, who verifies that the values shown in the images are correctly ordered. Images violating the sorted order are marked for correction. The marking of images is ergonomically advantageous in requiring only a simple pointing device used infrequently. Input can be by voice command. In one preferred embodiment, images are presented in rows and columns upon a video screen, and the operator uses controls similar to the "forward" and "back" buttons of a web browser to navigate through a set of images. In another preferred embodiment, images scroll automatically upwards through an attention zone, within which the operator verifies correct pairwise ordering. The adjudication method can operate with or without information used in previous systems, such as target values, recognition confidence, balancing information, and the like. Variants are described using such information to disambiguate mis-ordered pairs of images; to select images to participate in amount order adjudication; to determine when to accept a second-choice recognition result; and to bypass initial data entry altogether. The method provides for non-intrusive monitoring of its own performance and of the accuracy of the initial data entry module, by measuring results on items whose ordering has been intentionally manipulated.

Owner:ARAGON DAVID BRADBURN

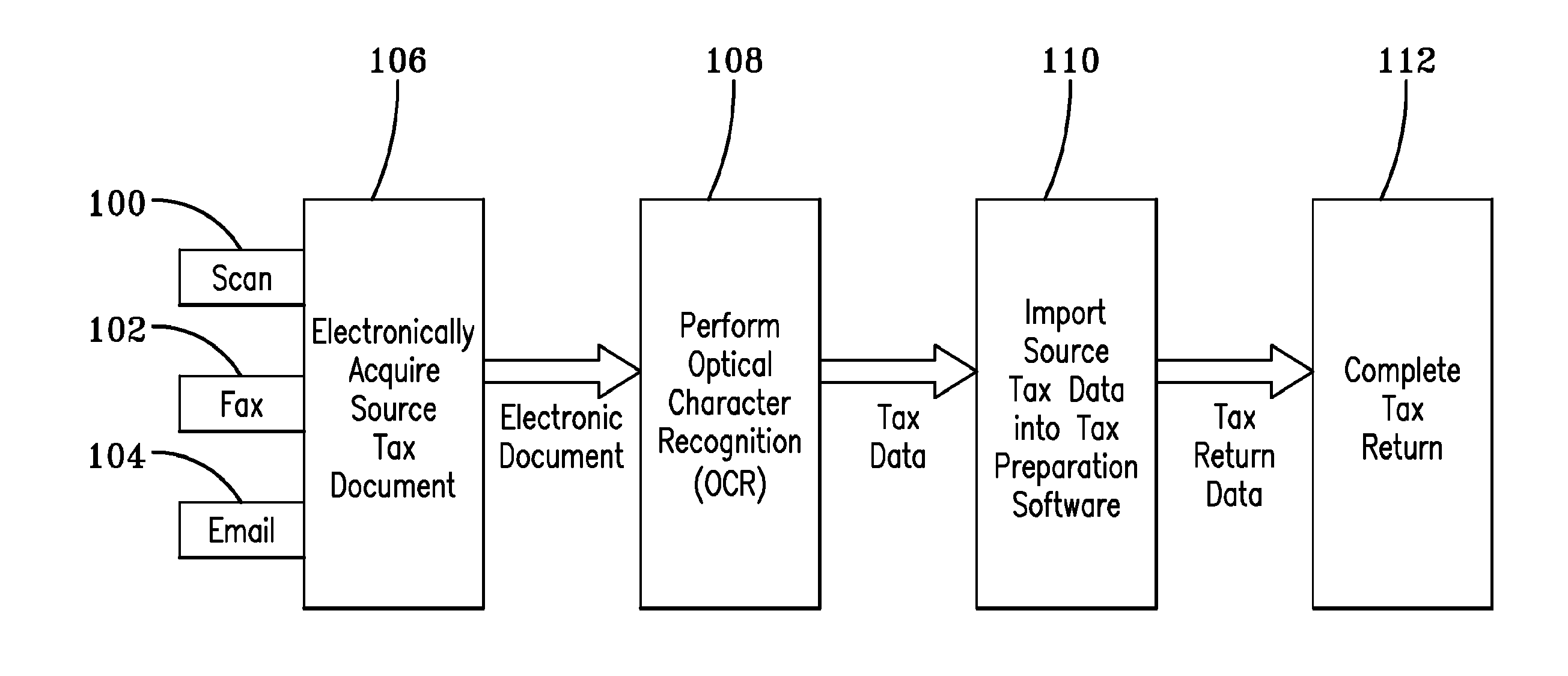

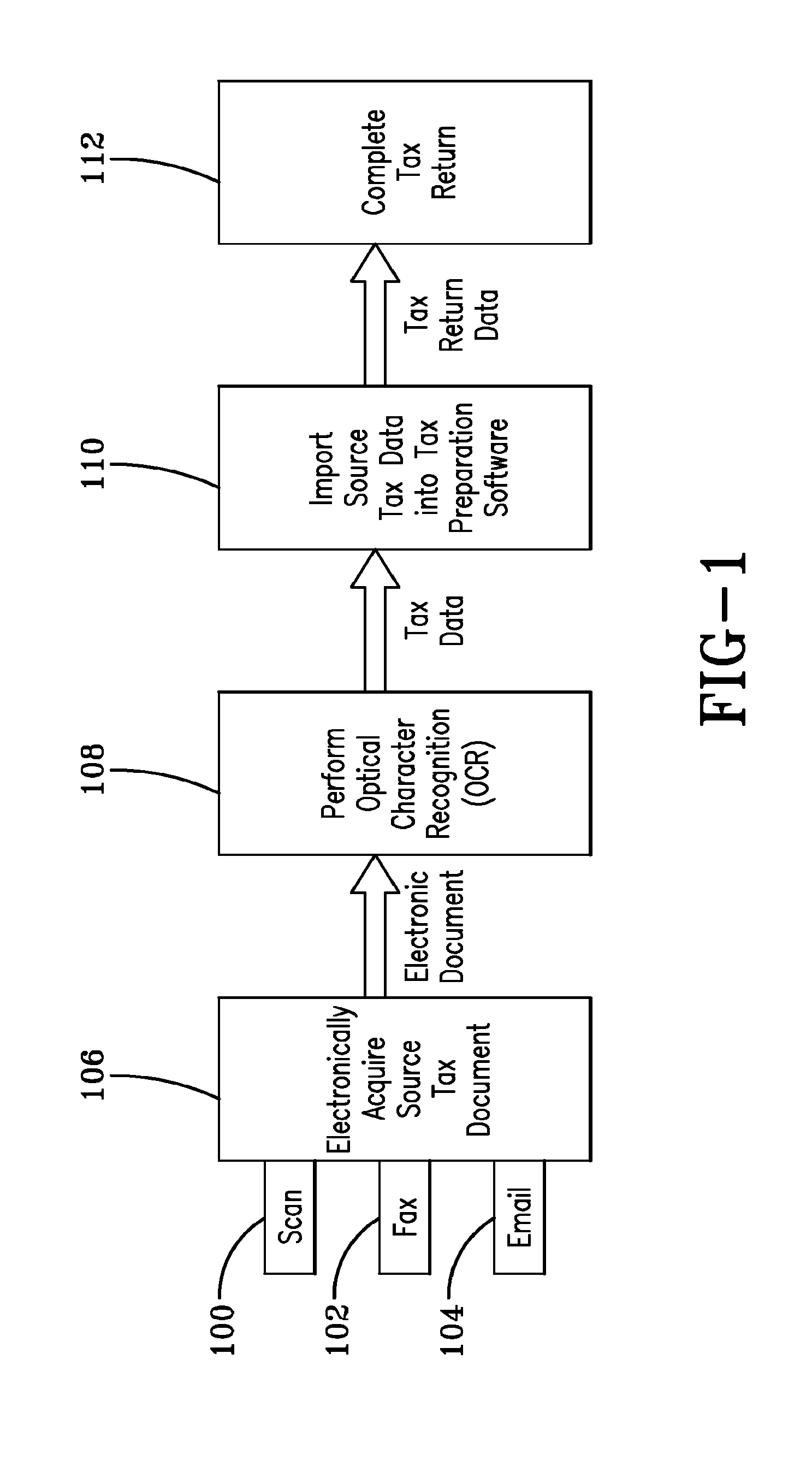

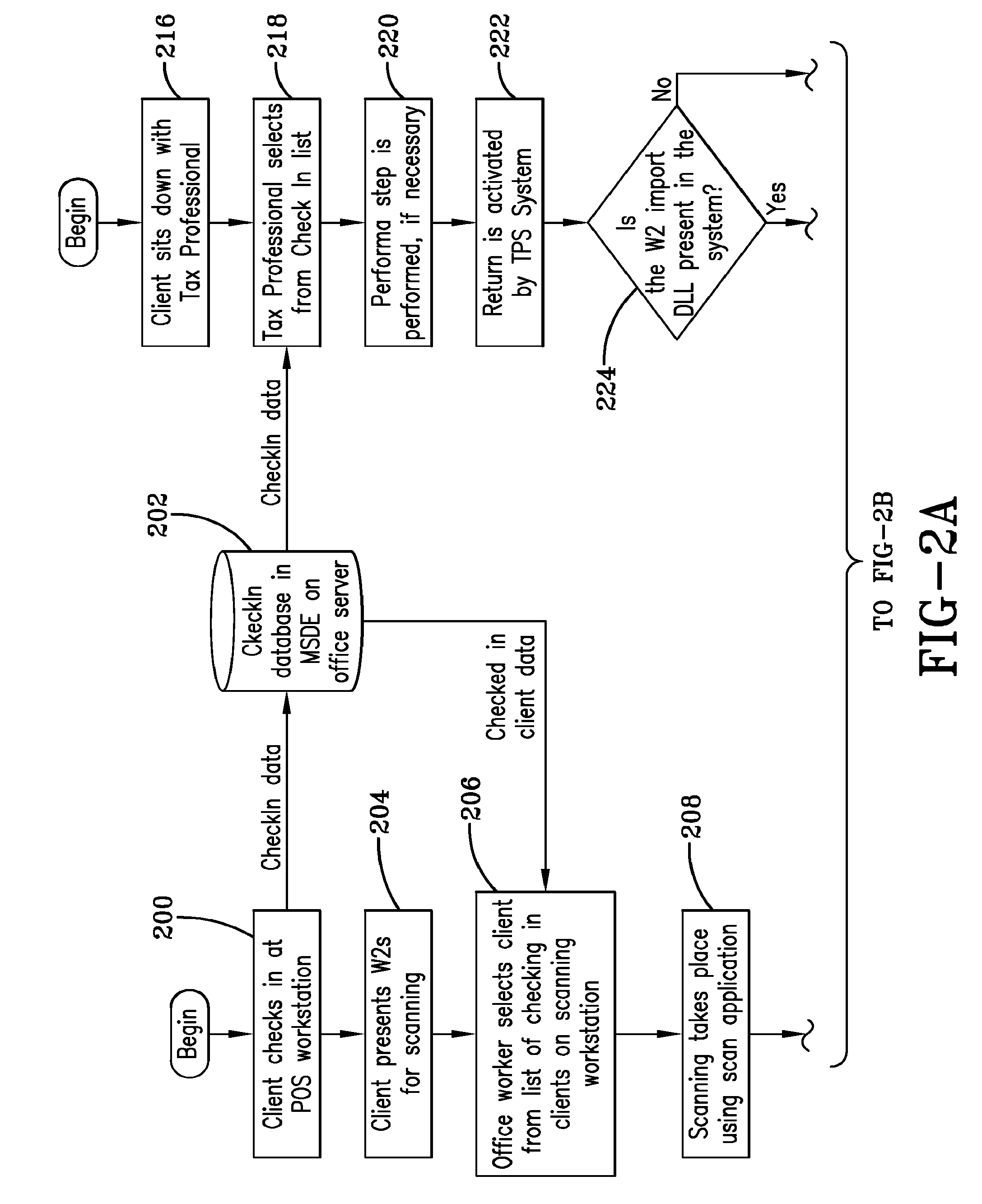

System and method for acquiring tax data for use in tax preparation software

InactiveUS20140172656A1Easy to operateMany timesComplete banking machinesFinanceElectronic formData acquisition

An automated system and method for acquiring tax data and importing it into tax preparation software. Tax documents are acquired electronically in a tax data acquisition process by scanning, faxing, or emailing them. Once a tax document is in electronic form, an optical character recognition (OCR) software process obtains tax data from the electronic tax document. Each piece of tax data that is obtained from the OCR software process is then imported into tax preparation software. Once the tax data has been imported into tax preparation software, the software may be used to complete a tax return. An important step in the tax return preparation process is automated so the need for tax professionals to spend time entering tax data into tax preparation software is reduced and data entry errors are reduced. Tax professionals may devote more time to preparing tax returns and less time to data entry.

Owner:HRB TAX GROUP

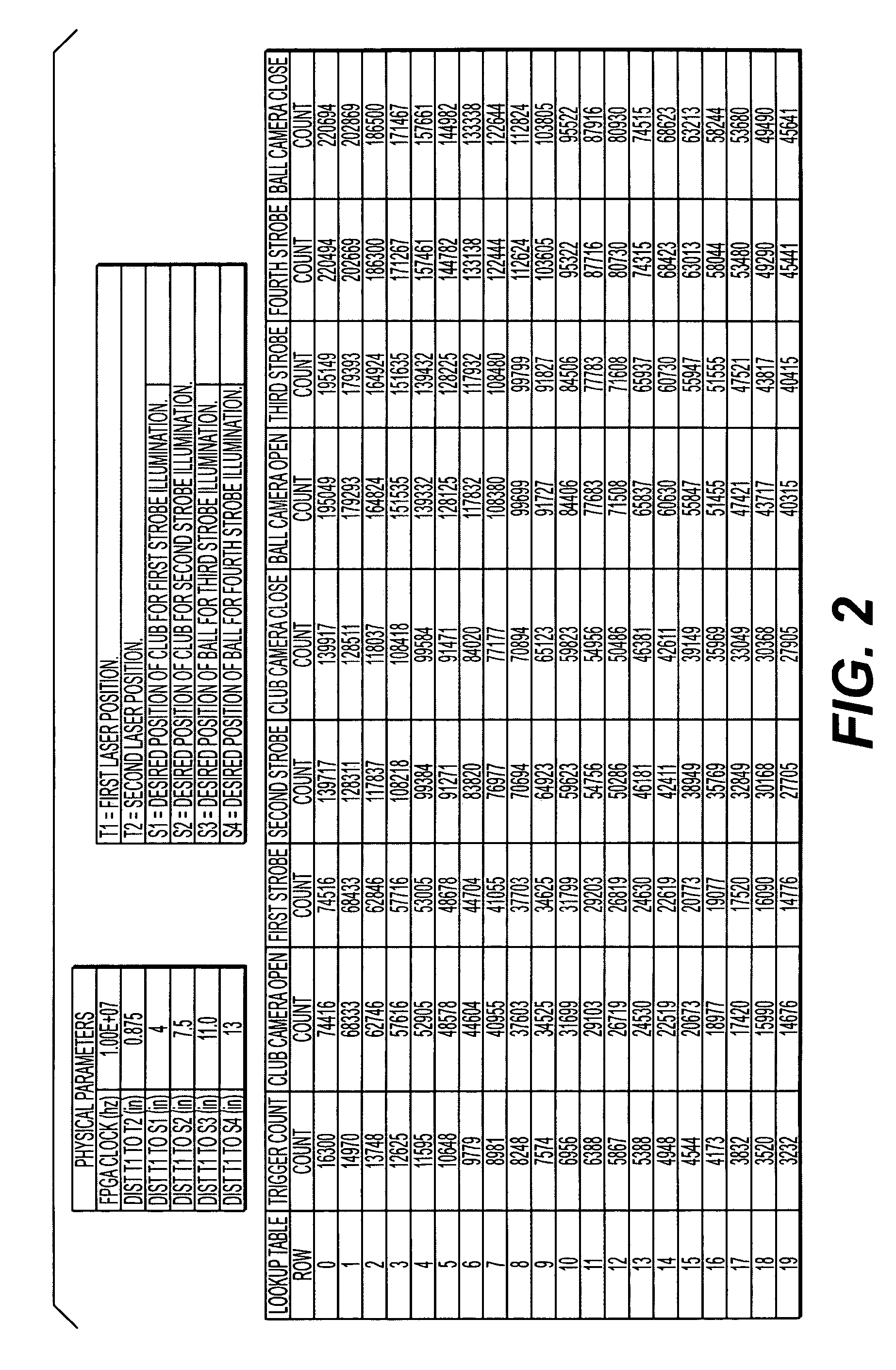

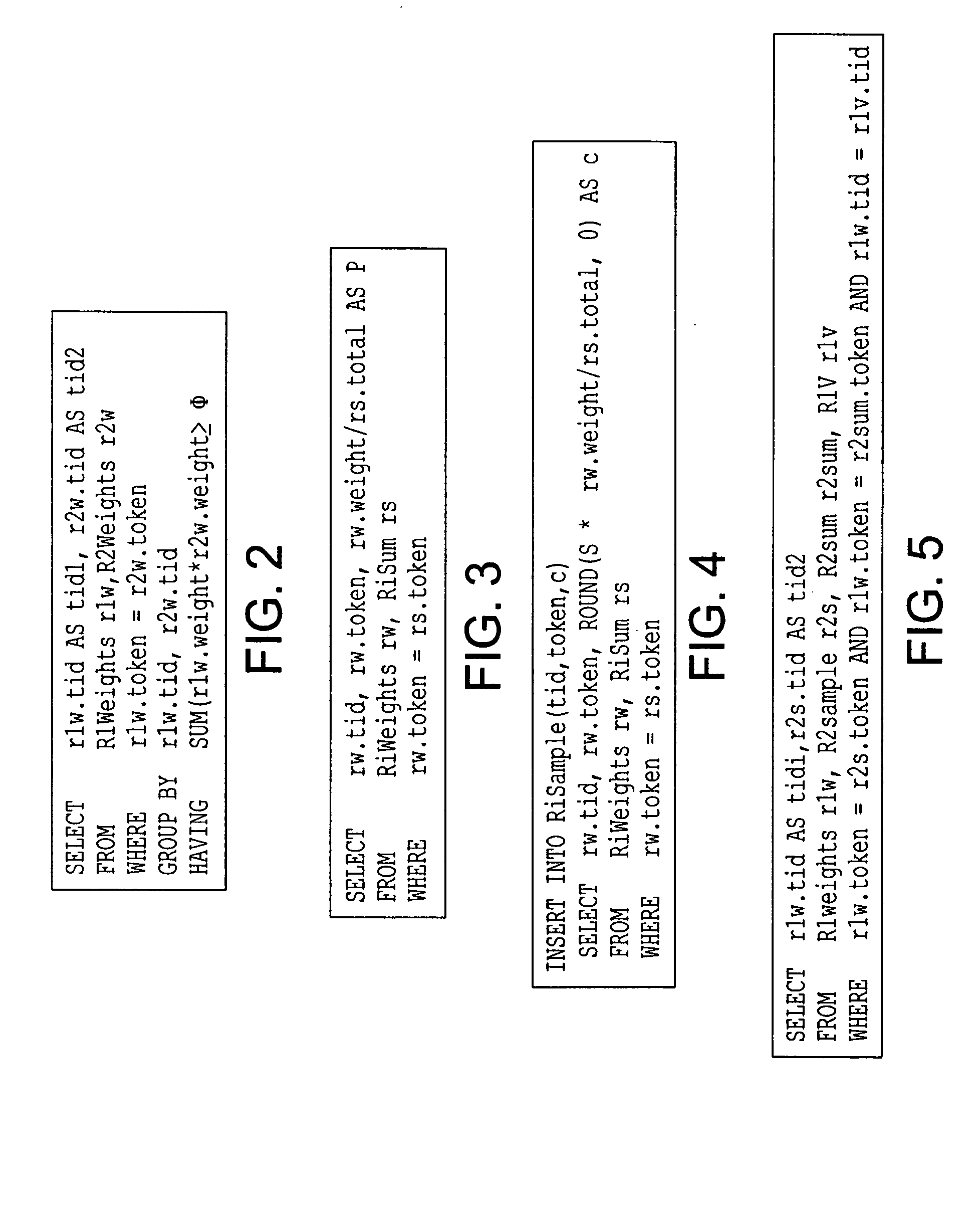

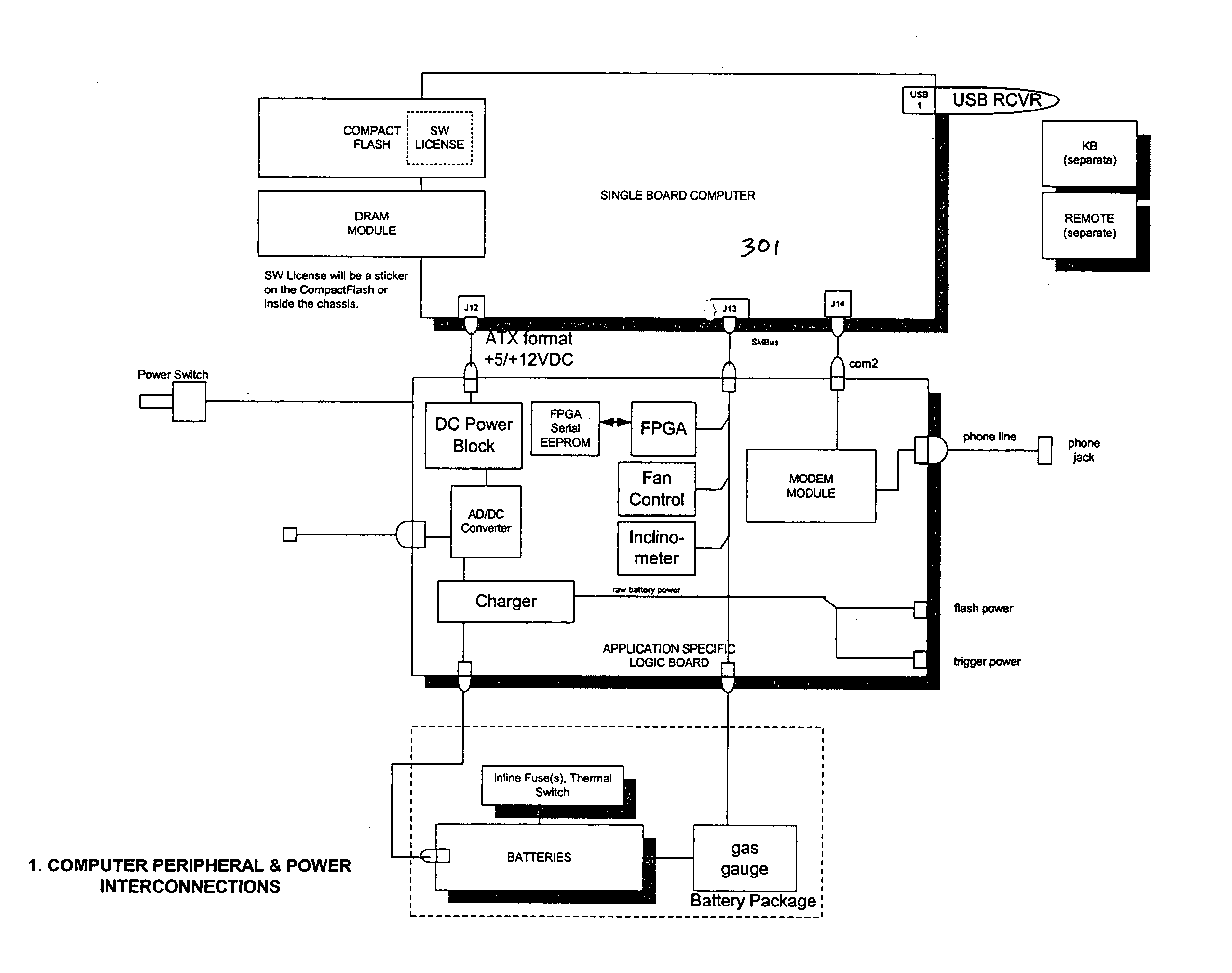

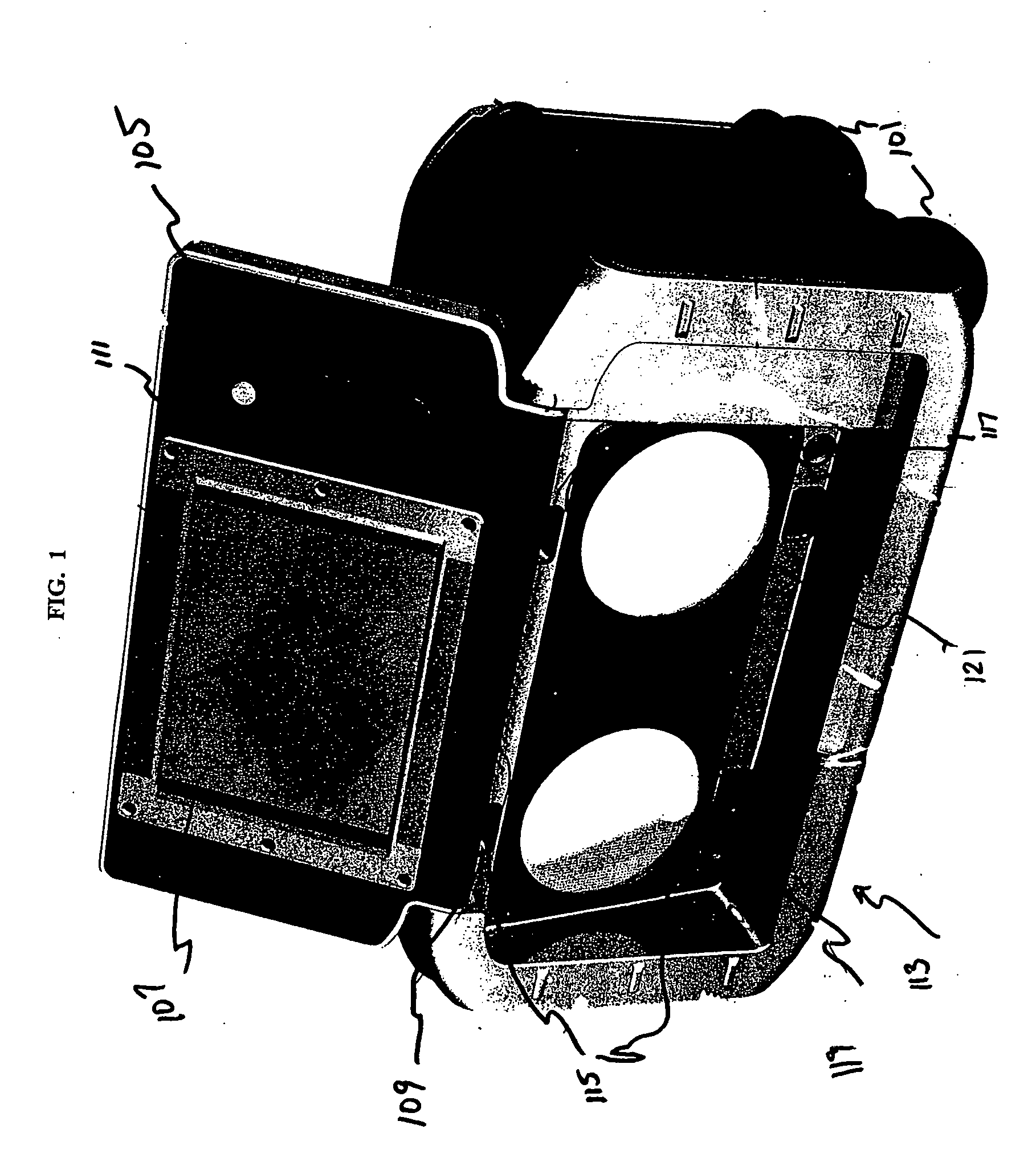

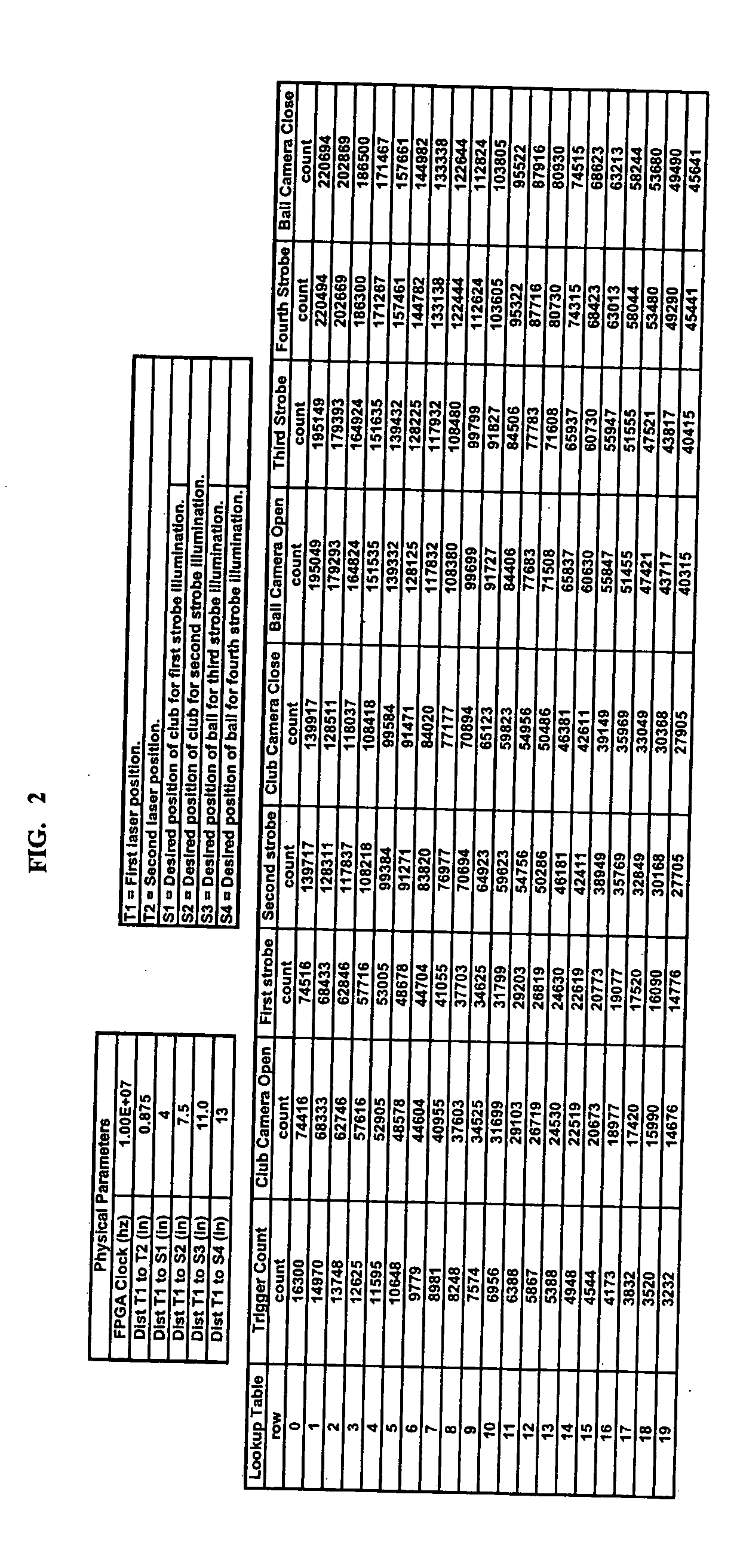

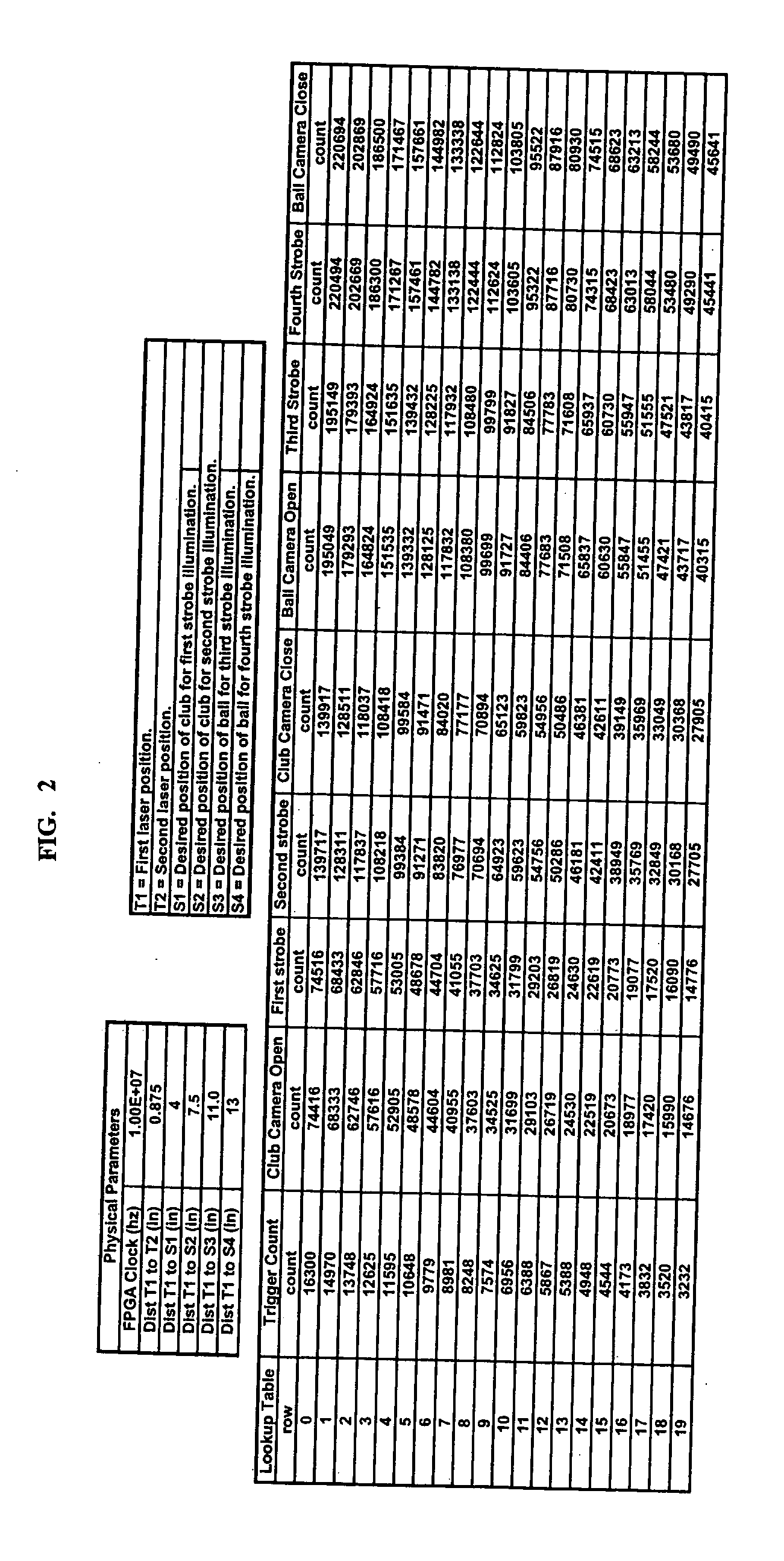

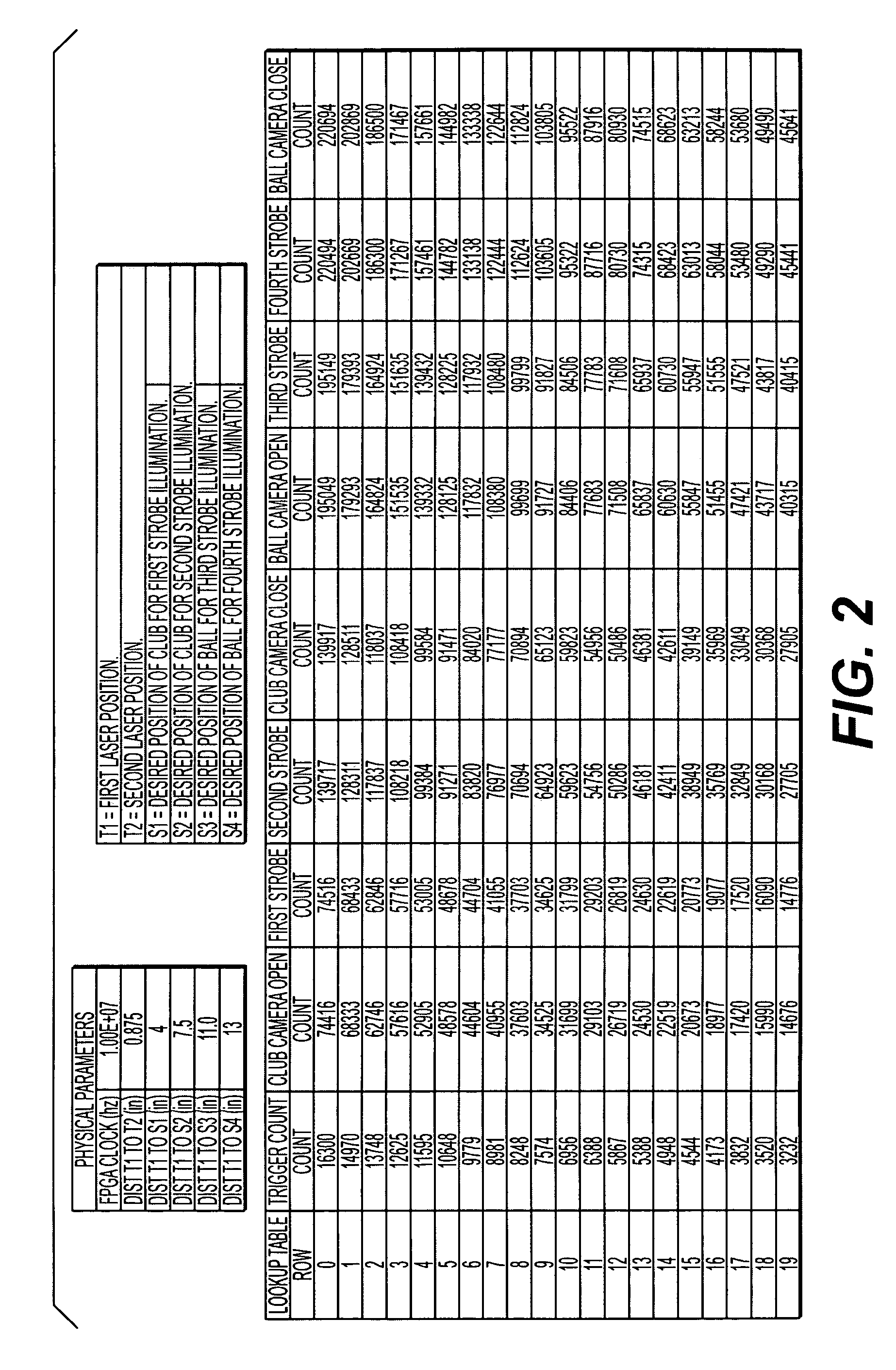

Launch monitor

ActiveUS20050272513A1Provide powerGymnastic exercisingCharacter and pattern recognitionDisplay deviceEngineering

A launch monitor that includes substantially all of its functional components on or within a housing is disclosed. In one embodiment, the launch monitor is capable of being transported and used in any desired location. One or more camera's, flashes, and triggers may be used to acquire images of a golf club and golf ball. The launch monitor is preferably capable of receiving and transmitting data over a wireless network. Acquired images and other data may be analyzed by a processor, and then displayed using an LED, LCD or other type of display or printer. The launch monitor may “recognize” a plurality of golf clubs and golf balls based on an optical fingerprint. The optical fingerprints, which are preferably stored in a memory, allow the launch monitor to identify a golf club and / or ball substantially soon after they are placed in the field of view of the monitor Optical fingerprinting enables automatic record keeping, and storing performance data and equipment used simultaneously. This feature eliminates tedious record keeping, eliminates data entry errors, and enables rapid equipment optimization.

Owner:ACUSHNET CO

Launch monitor

A launch monitor that includes substantially all of its functional components on or within a housing is disclosed. In one embodiment, the launch monitor is capable of being transported and used in any desired location. One or more camera's, flashes, and triggers may be used to acquire images of a golf club and golf ball. The launch monitor is preferably capable of receiving and transmitting data over a wireless network. Acquired images and other data may be analyzed by a processor, and then displayed using an LED, LCD or other type of display or printer. The launch monitor may “recognize” a plurality of golf clubs and golf balls based on an optical fingerprint. The optical fingerprints, which are preferably stored in a memory, allow the launch monitor to identify a golf club and / or ball substantially soon after they are placed in the field of view of the monitor Optical fingerprinting enables automatic record keeping, and storing performance data and equipment used simultaneously. This feature eliminates tedious record keeping, eliminates data entry errors, and enables rapid equipment optimization.

Owner:ACUSHNET CO

Launch monitor

A launch monitor that includes substantially all of its functional components on or within a housing is disclosed. In one embodiment, the launch monitor is capable of being transported and used in any desired location. One or more camera's, flashes, and triggers may be used to acquire images of a golf club and golf ball. The launch monitor is preferably capable of receiving and transmitting data over a wireless network. Acquired images and other data may be analyzed by a processor, and then displayed using an LED, LCD or other type of display or printer. The launch monitor may “recognize” a plurality of golf clubs and golf balls based on an optical fingerprint. The optical fingerprints, which are preferably stored in a memory, allow the launch monitor to identify a golf club and / or ball substantially soon after they are placed in the field of view of the monitor Optical fingerprinting enables automatic record keeping, and storing performance data and equipment used simultaneously. This feature eliminates tedious record keeping, eliminates data entry errors, and enables rapid equipment optimization.

Owner:ACUSHNET CO

Launch monitor

A launch monitor that includes substantially all of its functional components on or within a housing is disclosed. In one embodiment, the launch monitor is capable of being transported and used in any desired location. One or more camera's, flashes, and triggers may be used to acquire images of a golf club and golf ball. The launch monitor is preferably capable of receiving and transmitting data over a wireless network. Acquired images and other data may be analyzed by a processor, and then displayed using an LED, LCD or other type of display or printer. The launch monitor may “recognize” a plurality of golf clubs and golf balls based on an optical fingerprint. The optical fingerprints, which are preferably stored in a memory, allow the launch monitor to identify a golf club and / or ball substantially soon after they are placed in the field of view of the monitor Optical fingerprinting enables automatic record keeping, and storing performance data and equipment used simultaneously. This feature eliminates tedious record keeping, eliminates data entry errors, and enables rapid equipment optimization.

Owner:ACUSHNET CO

Launch monitor

A launch monitor that includes substantially all of its functional components on or within a housing is disclosed. In one embodiment, the launch monitor is capable of being transported and used in any desired location. One or more camera's, flashes, and triggers may be used to acquire images of a golf club and golf ball. The launch monitor is preferably capable of receiving and transmitting data over a wireless network. Acquired images and other data may be analyzed by a processor, and then displayed using an LED, LCD or other type of display or printer. The launch monitor may “recognize” a plurality of golf clubs and golf balls based on an optical fingerprint. The optical fingerprints, which are preferably stored in a memory, allow the launch monitor to identify a golf club and / or ball substantially soon after they are placed in the field of view of the monitor Optical fingerprinting enables automatic record keeping, and storing performance data and equipment used simultaneously. This feature eliminates tedious record keeping, eliminates data entry errors, and enables rapid equipment optimization.

Owner:ACUSHNET CO

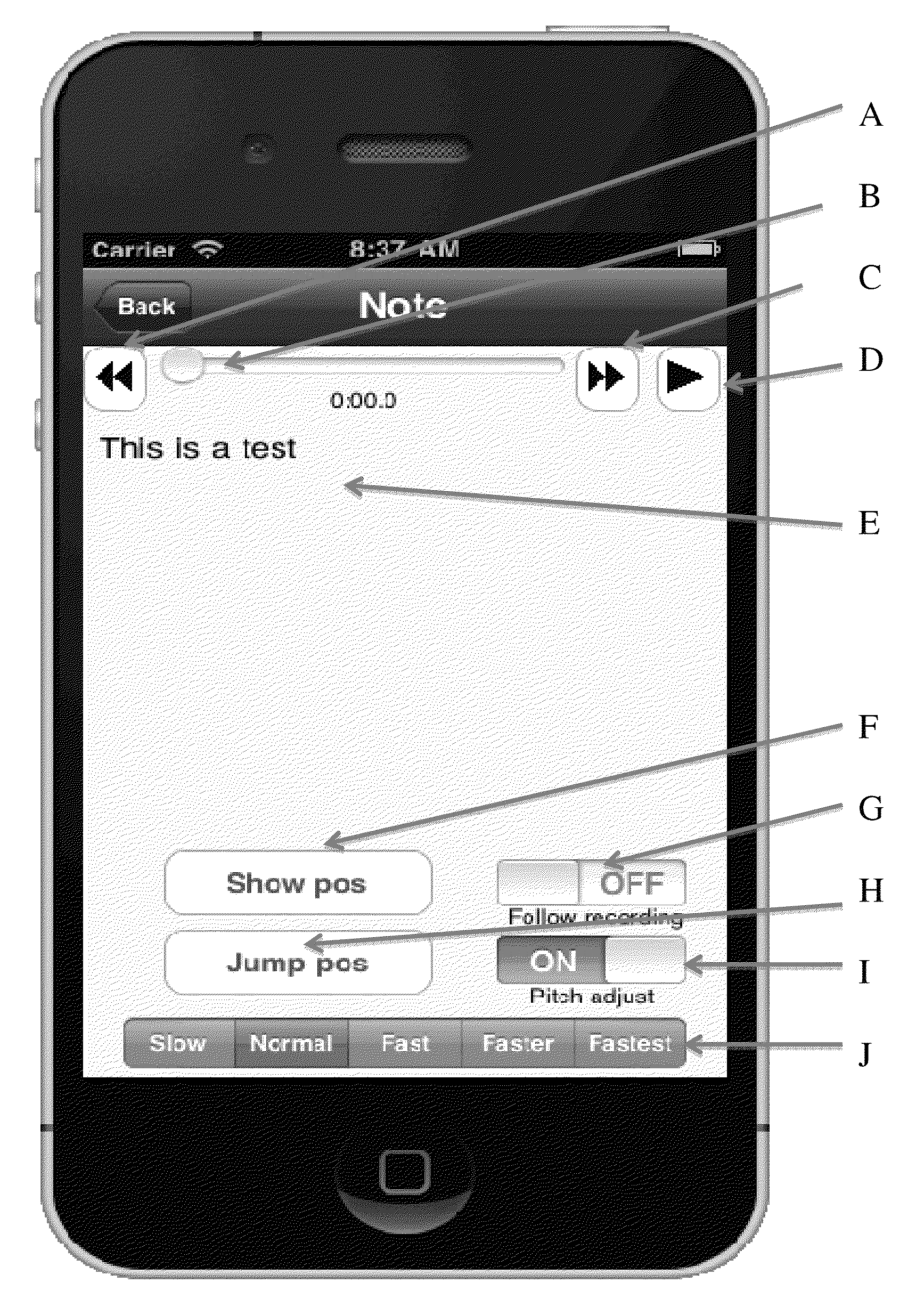

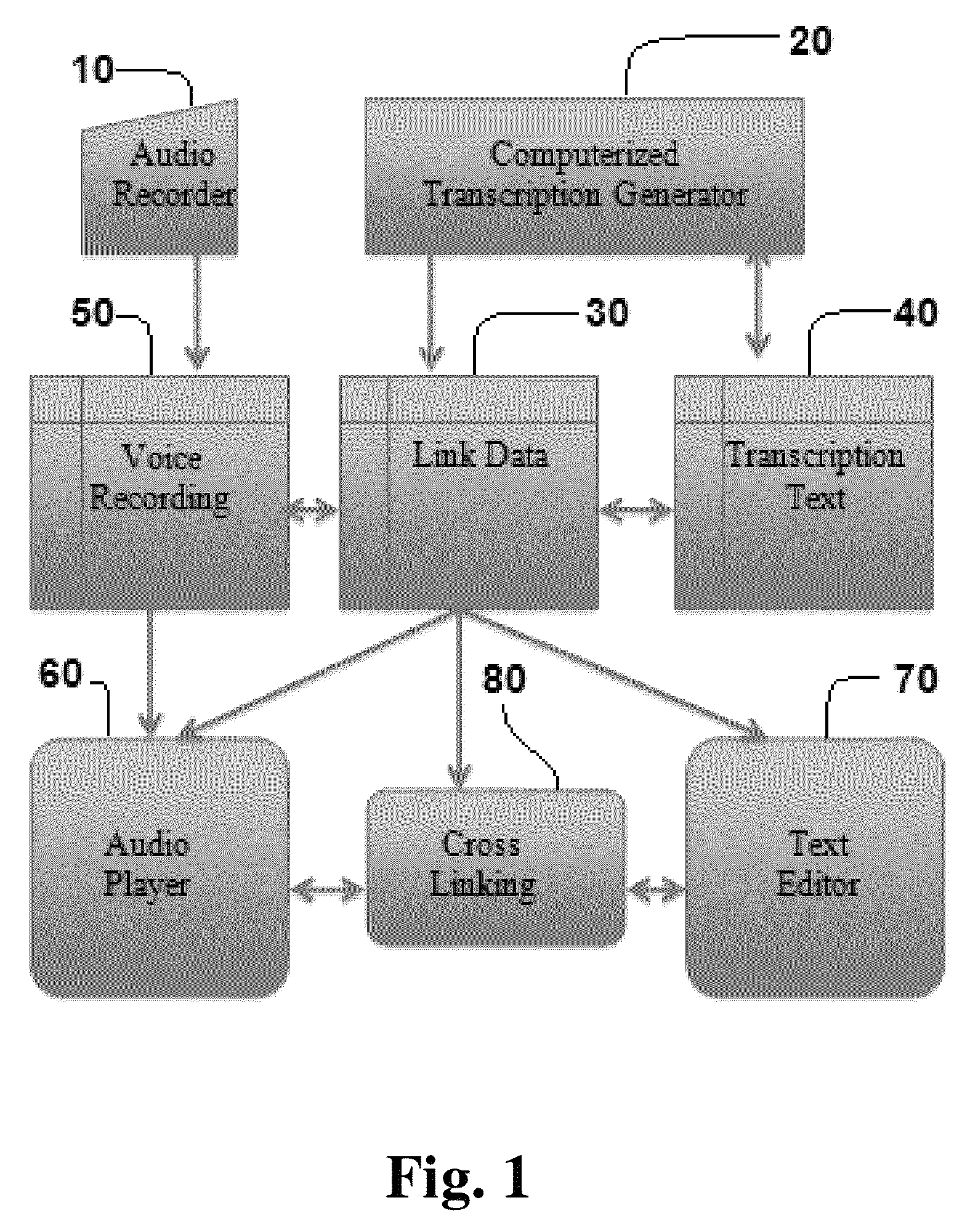

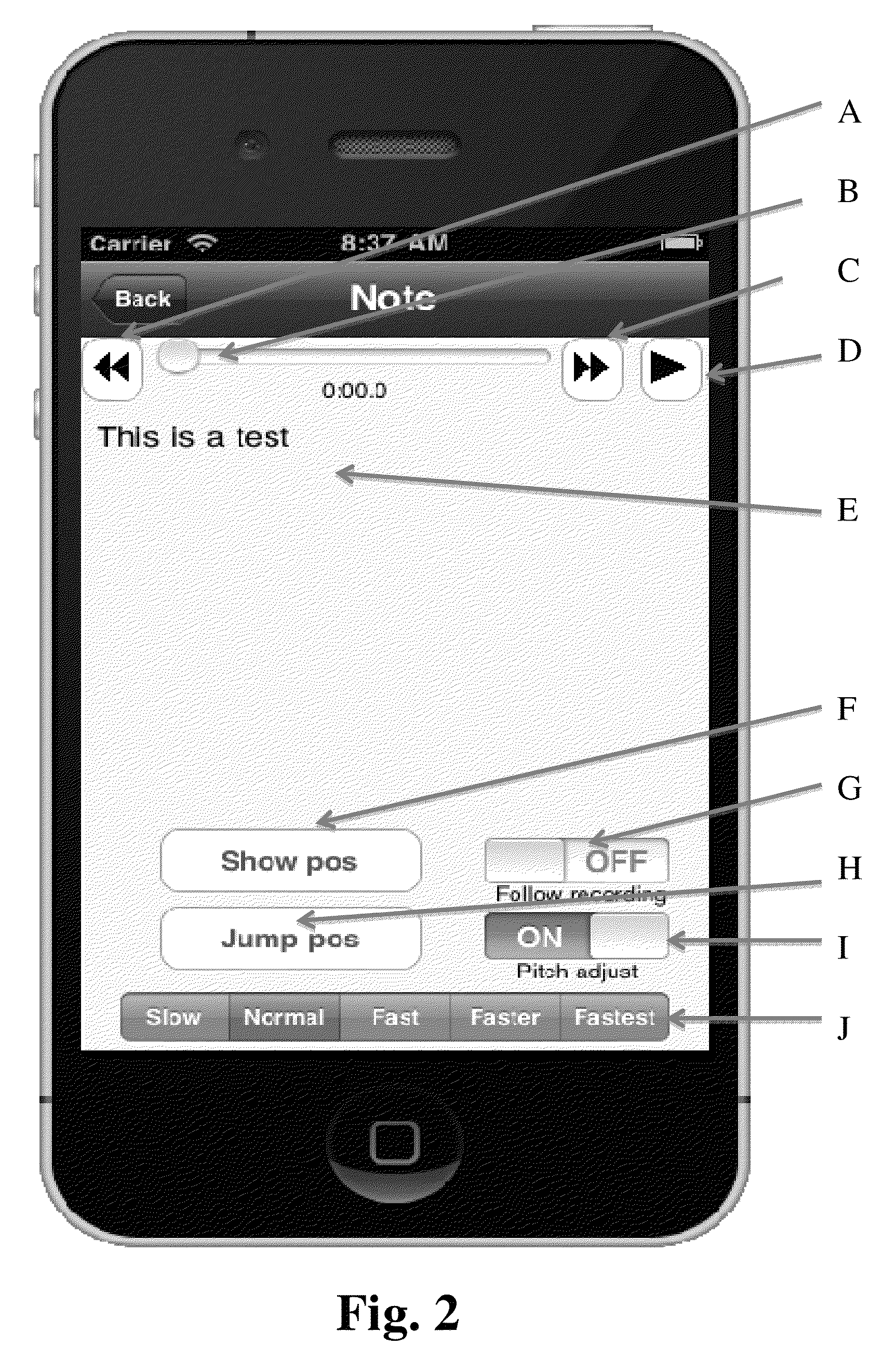

Audio transcription generator and editor

A system for correcting errors in automatically generated audio transcriptions includes an audio recorder, a computerized transcription generator, a voice recording, a collection of link data, transcription text, an audio player, a system of cross linking, and a text editor including a text display with a cursor. The system permits a user to correct transcription errors using techniques of jump to position; show position; and track playback.

Owner:ROE MOBILE DEV

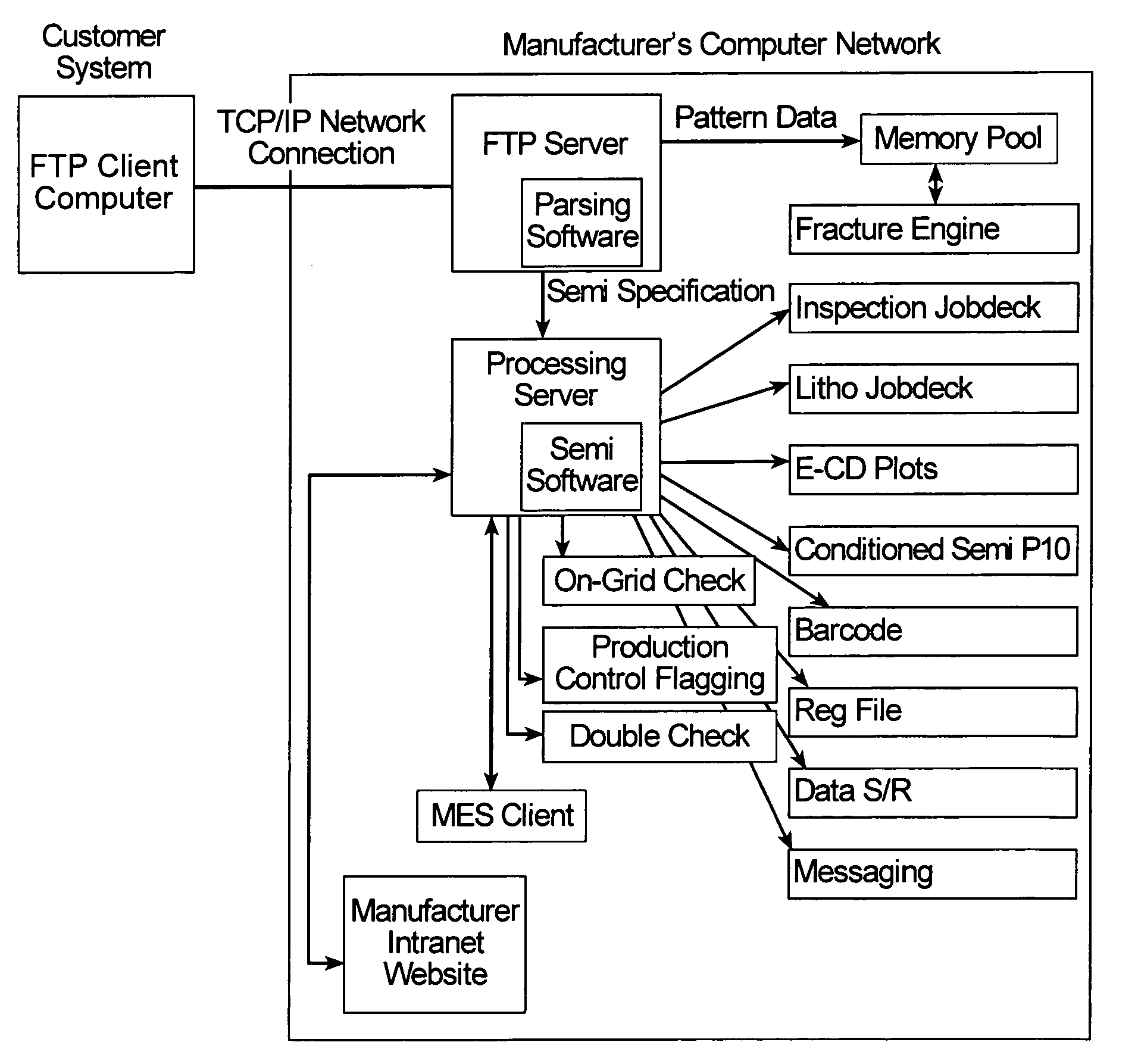

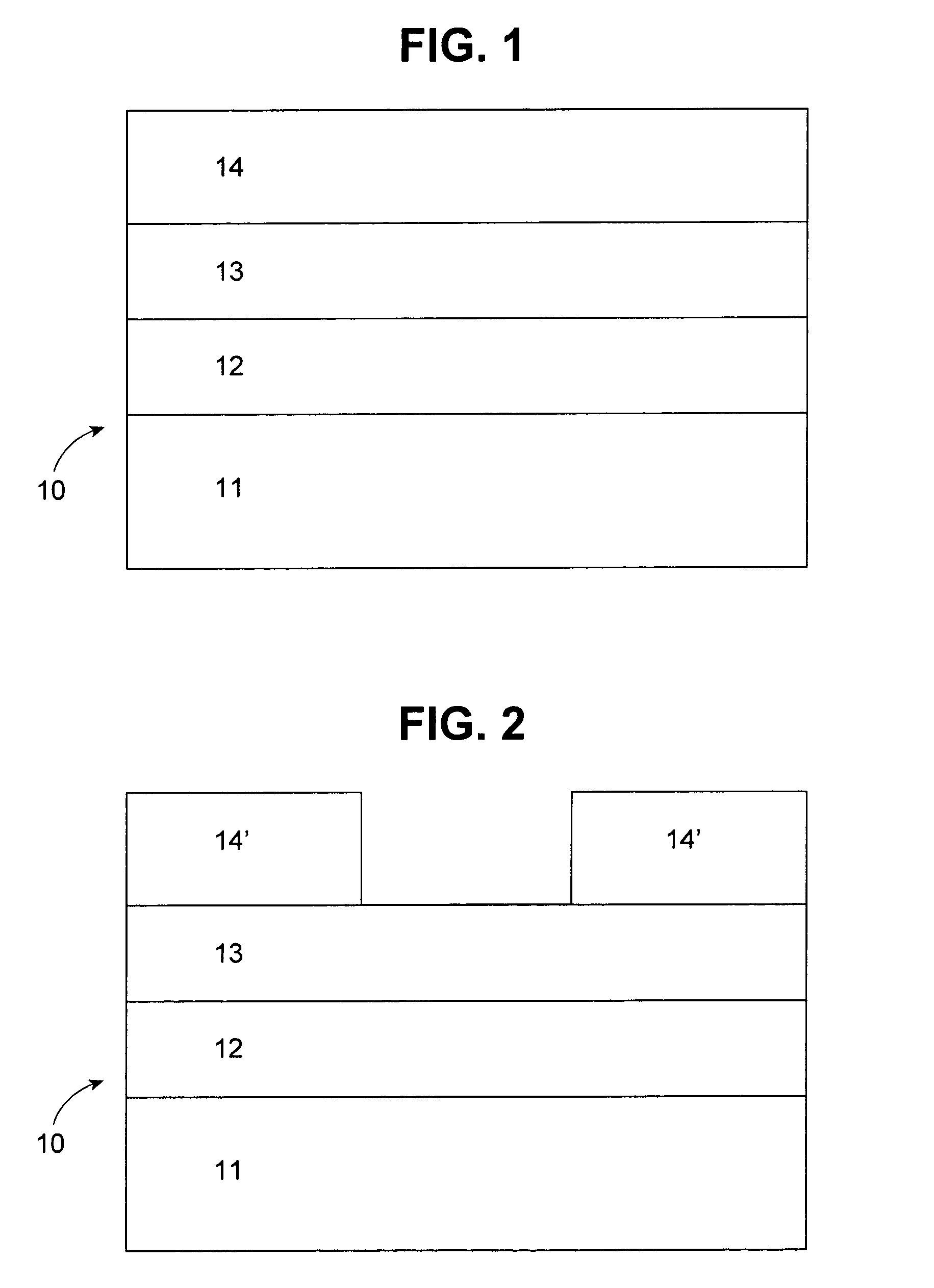

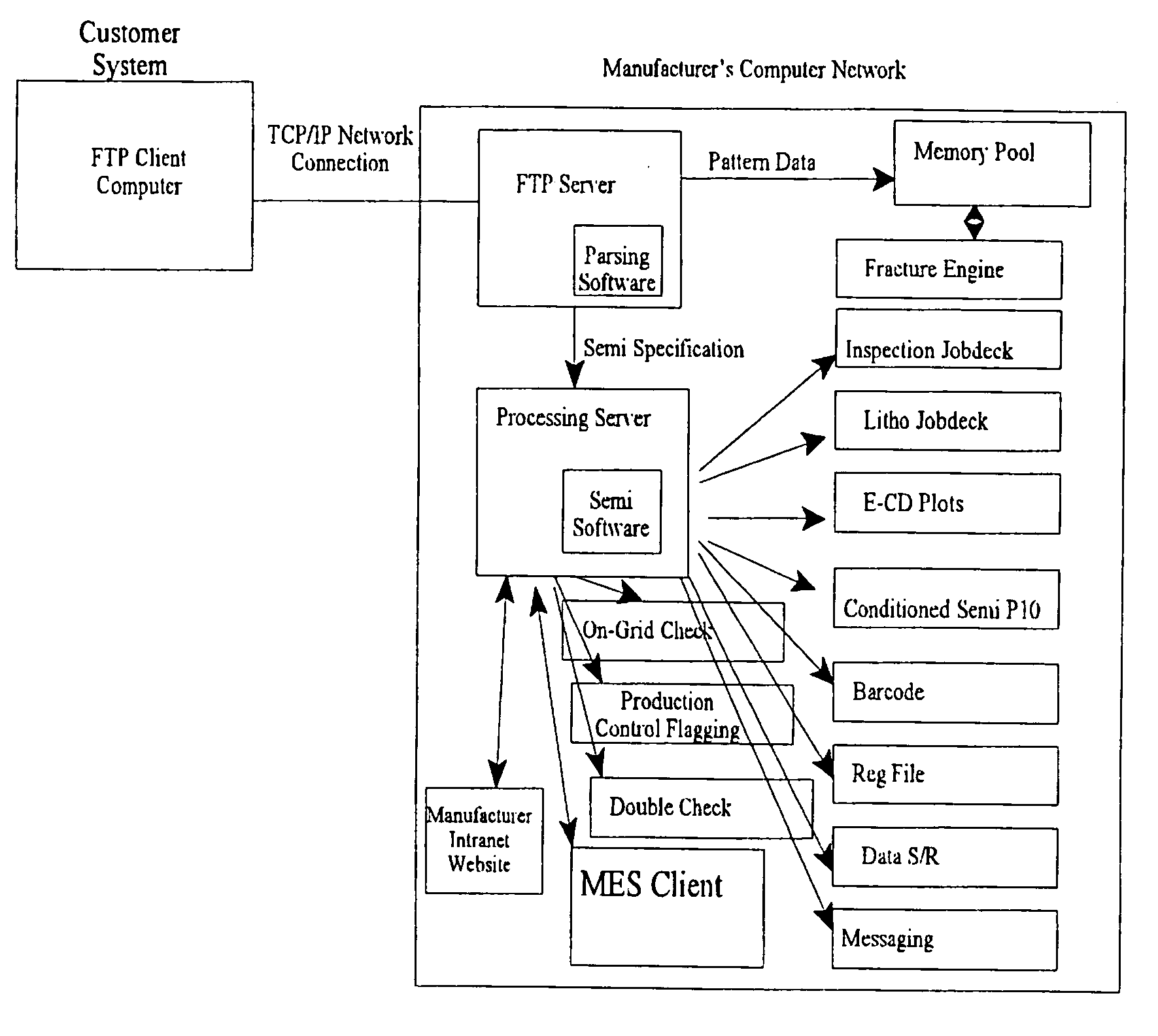

Automated manufacturing system and method for processing photomasks

InactiveUS6996450B2Costly delayCostly errorElectric controllersIgnition automatic controlNetwork connectionMonitoring system

The present invention relates generally to an automated manufacturing system and method for manufacturing photomasks wherein information provided by a customer at a remote location is interfaced, via a network, to a photomask manufacturer's computer system and automatically processes data for manufacturing a photomask and automatically formats and routes data to processing equipment. The present invention reduces the need for manual intervention, thereby avoiding costly delays and transcription errors associated therewith. The software of the present invention provides for automatic generation of data arrays, which can be used to process and monitor the status of a photomask during manufacture. Further, the software is capable of automatically modifying design data provided by a photomask user. Additionally, the software of the present invention includes an automatic messaging system which can notify users of the system, of status and errors in manufacture of photomasks. The present invention also includes a real time monitoring system capable of notifying users of the status and errors in the processing of the photomask during manufacture.

Owner:PHOTRONICS INC

Launch monitor

A launch monitor that includes substantially all of its functional components on or within a housing is disclosed. In one embodiment, the launch monitor is capable of being transported and used in any desired location. One or more camera's, flashes, and triggers may be used to acquire images of a golf club and golf ball. The launch monitor is preferably capable of receiving and transmitting data over a wireless network. Acquired images and other data may be analyzed by a processor, and then displayed using an LED, LCD or other type of display or printer. The launch monitor may “recognize” a plurality of golf clubs and golf balls based on an optical fingerprint. The optical fingerprints, which are preferably stored in a memory, allow the launch monitor to identify a golf club and / or ball substantially soon after they are placed in the field of view of the monitor Optical fingerprinting enables automatic record keeping, and storing performance data and equipment used simultaneously. This feature eliminates tedious record keeping, eliminates data entry errors, and enables rapid equipment optimization.

Owner:ACUSHNET CO

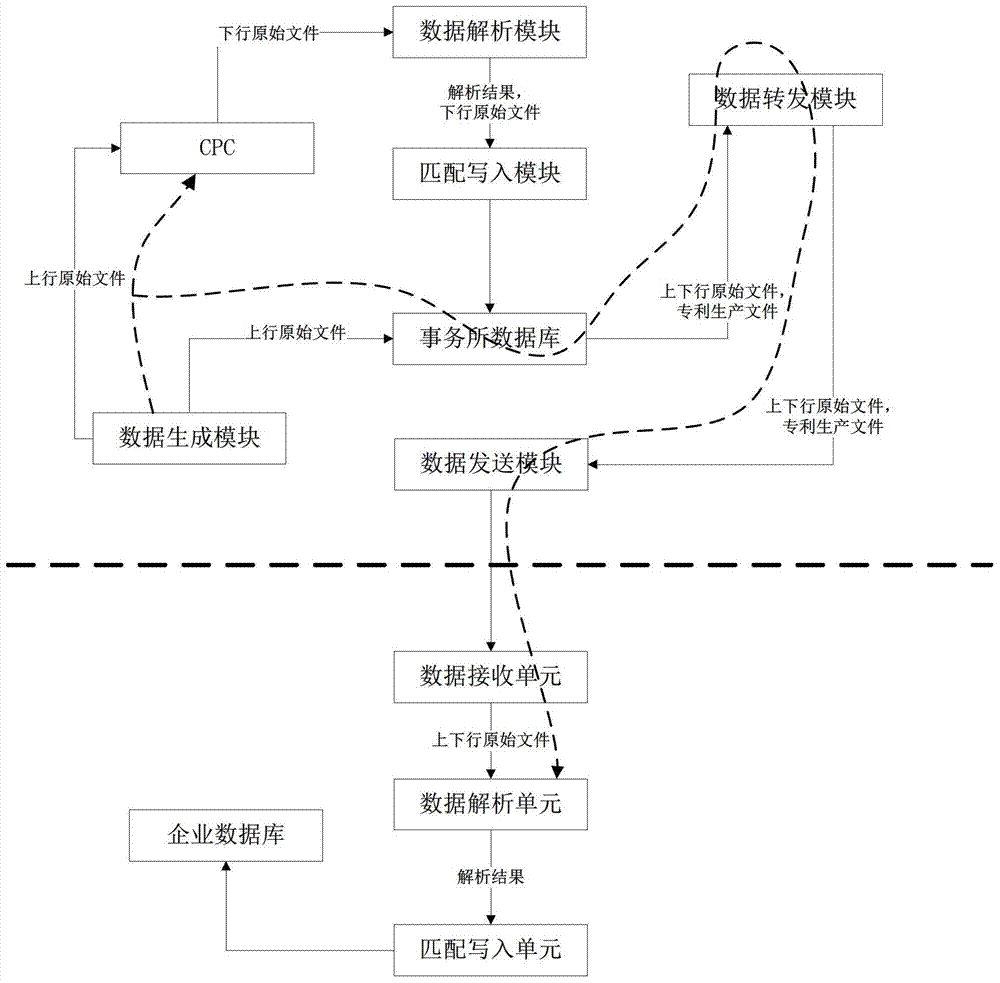

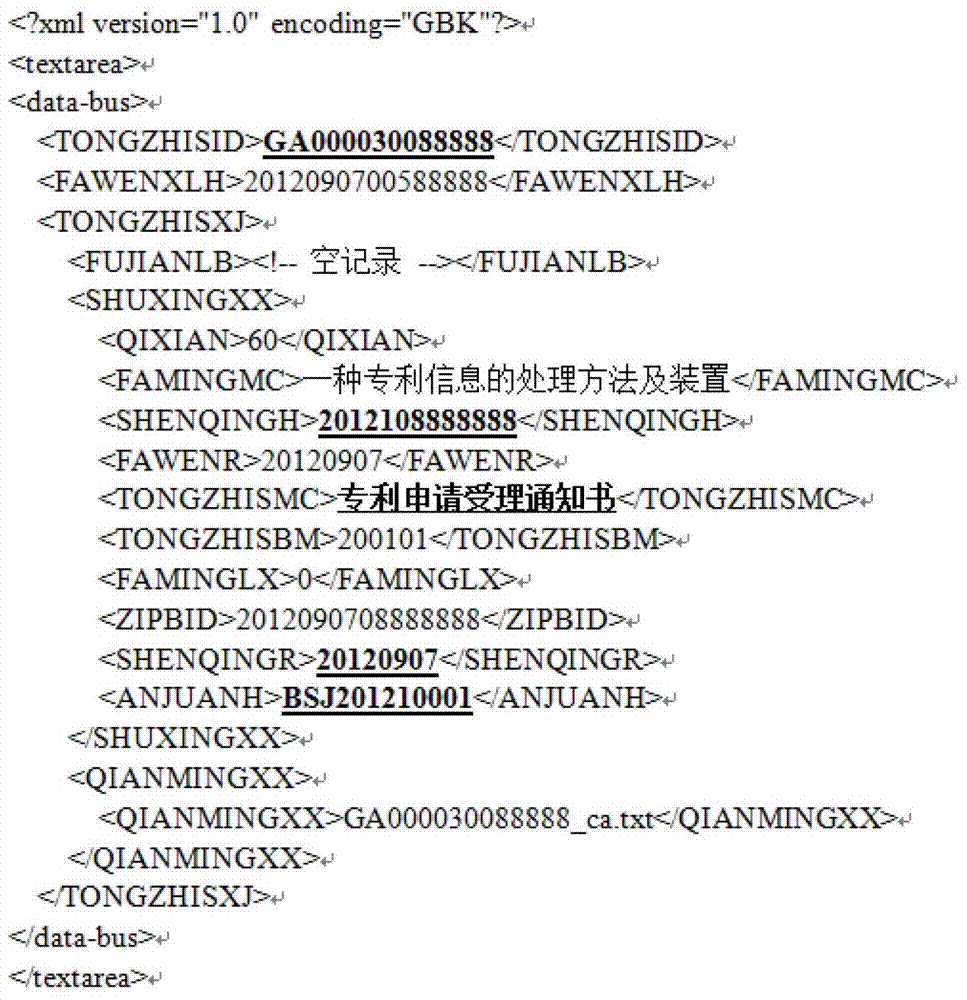

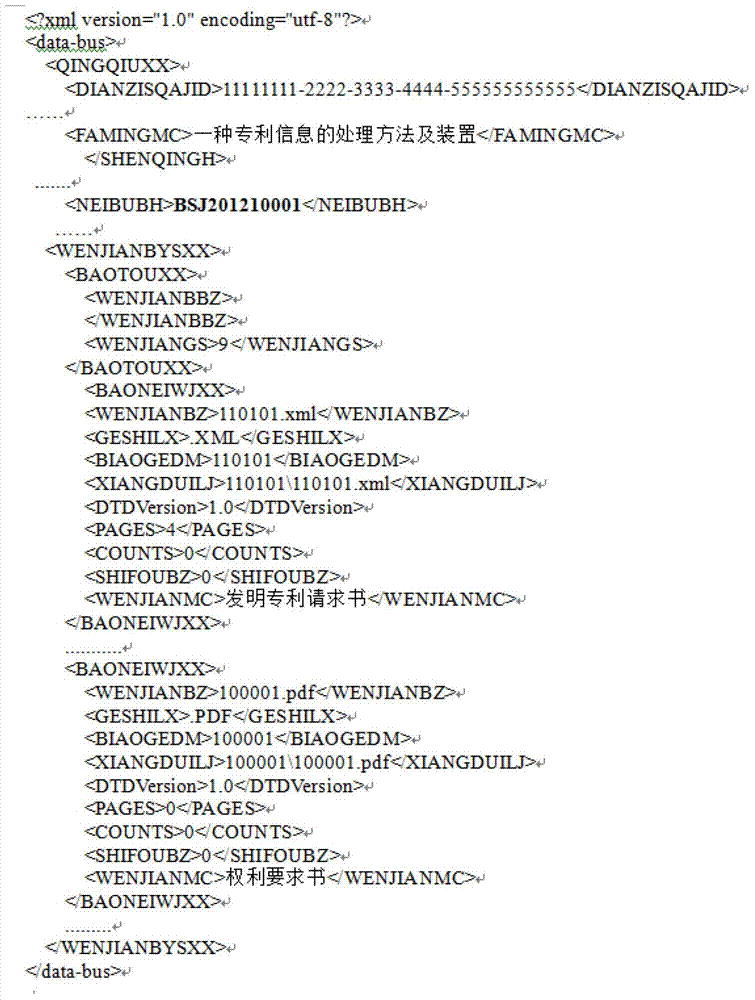

Patent management devices for applicants and firms

InactiveCN103714107AData processing applicationsSpecial data processing applicationsOriginal dataData mining

The invention provides a patent management device for applicants. The device comprises a data receiving unit, a data analyzing unit and a match writing unit. The data receiving unit is used for receiving original data from a firm through a predetermined data path, and the original data at least includes parts of data consistent with electronic application interface specification. The data analyzing unit is used for analyzing the original data according to the electronic application interface specification and acquiring at least one item of patent attribute information from the original information, and the patent attribute information includes at least one predetermined patent application identifier. The match writing unit is used for finding corresponding patent table entries in a database according to the patent application identifier, and storing the patent attribute information into the patent table entries. The invention further provides a corresponding patent management device for firms. The patent management devices for applicants and firms are matched to realize that data can be stored in an enterprise database automatically, procedure labor investment is reduced greatly, and meanwhile, the problem that manual data entry error probability is high is avoided.

Owner:BEIJING CHUANGZHI ANKANG INTPROP CONSULTING

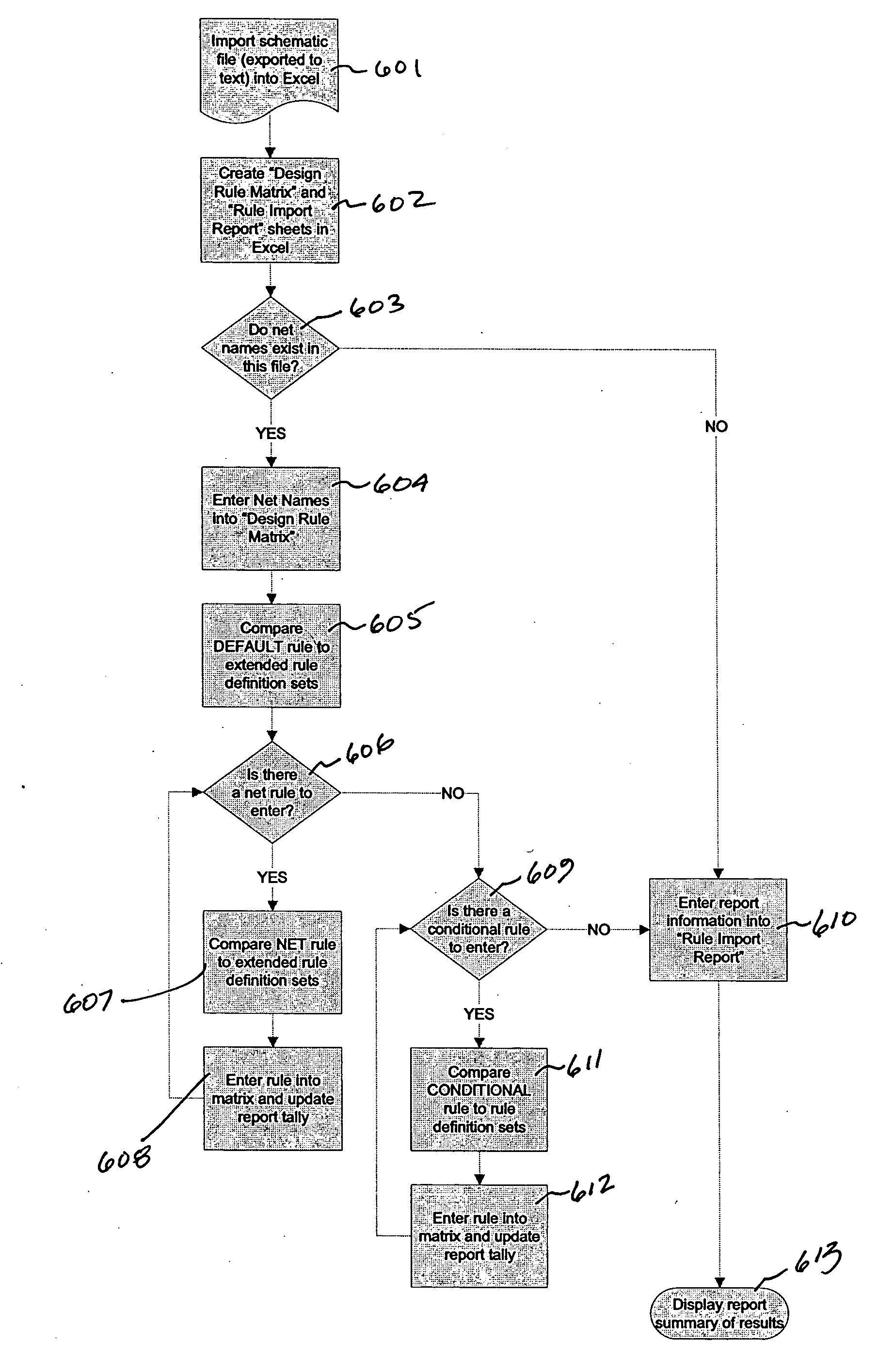

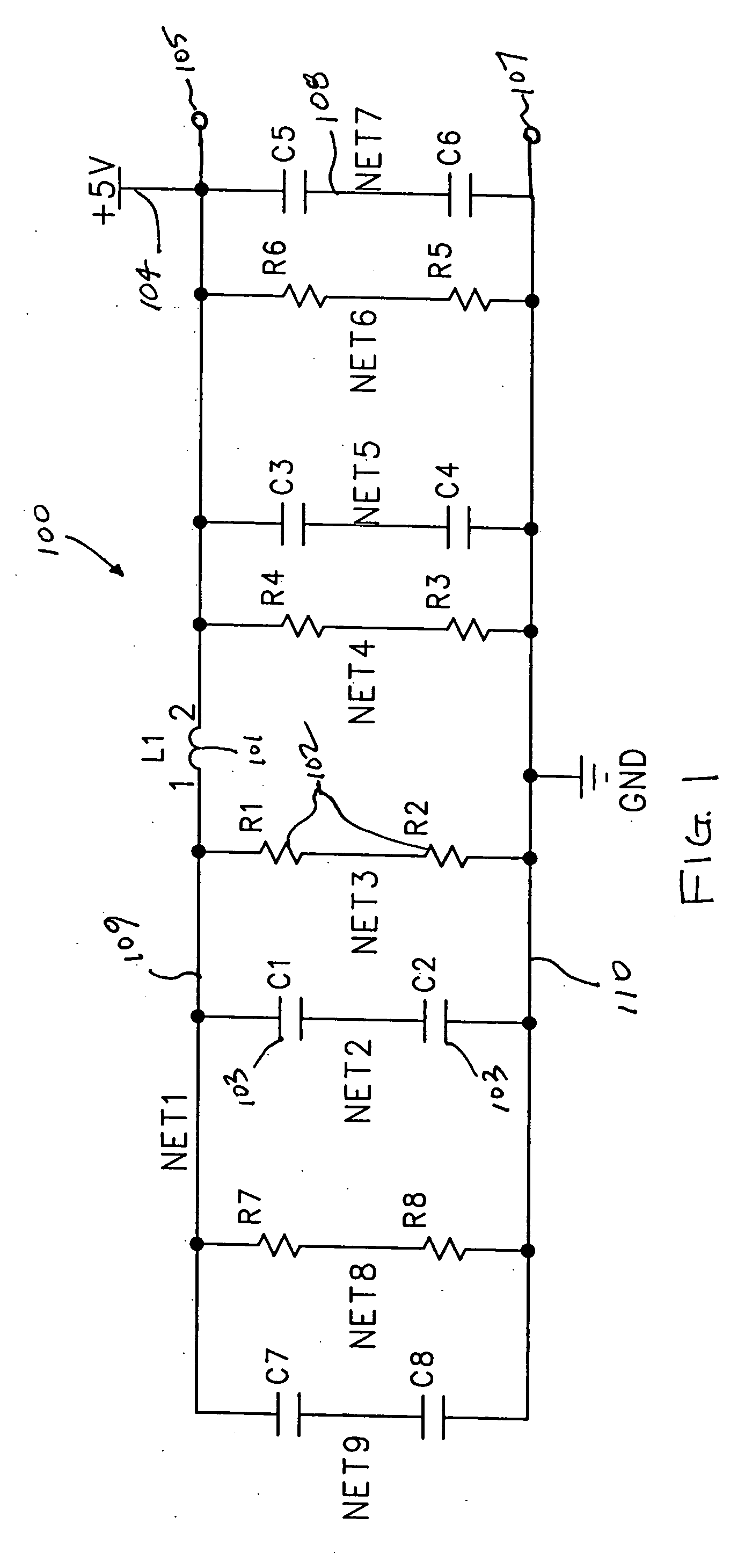

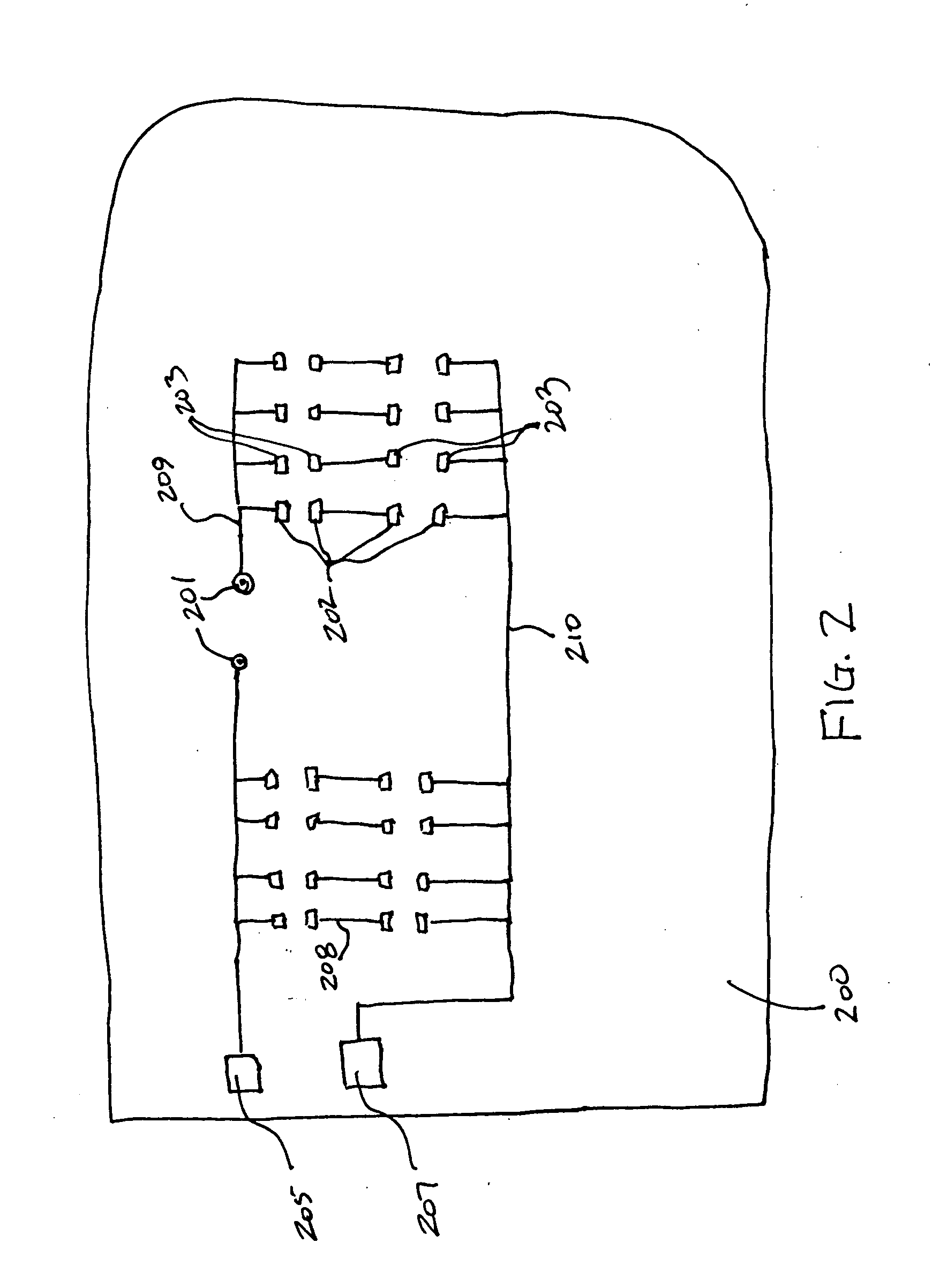

Design rule report utility

InactiveUS20060218516A1Cathode-ray tube indicatorsComputer programmed simultaneously with data introductionGraphicsComputer Aided Design

This invention provides a graphical tool by which a designer or engineer may quickly, accurately and efficiently check the relational information between elements of a computer model. By way of example, in one embodiment, the invention may be used to quickly validate the design rules, like minimum spacing requirements for instance, between the connections (or nets) in a schematic that exists in a computer aided design package. Since a designer must enter such design rules for each net, the invention first imports these design rules from the computer model. The invention then imports a standard set of design rules. After comparing the standard set of design rules to the standard set of design rules, the invention presents a graphical display to a user indicating where the model rules matched the standard set and, correspondingly, where they did not match. In one embodiment, a matrix grid is displayed with the model elements listed in an index row and column. Matches are then displayed as coefficients within the matrix, while mismatches are displayed as an alternate coefficient. The invention allows a designer to quickly identify data entry errors that may have occurred in the creation of the model.

Owner:MOTOROLA SOLUTIONS INC

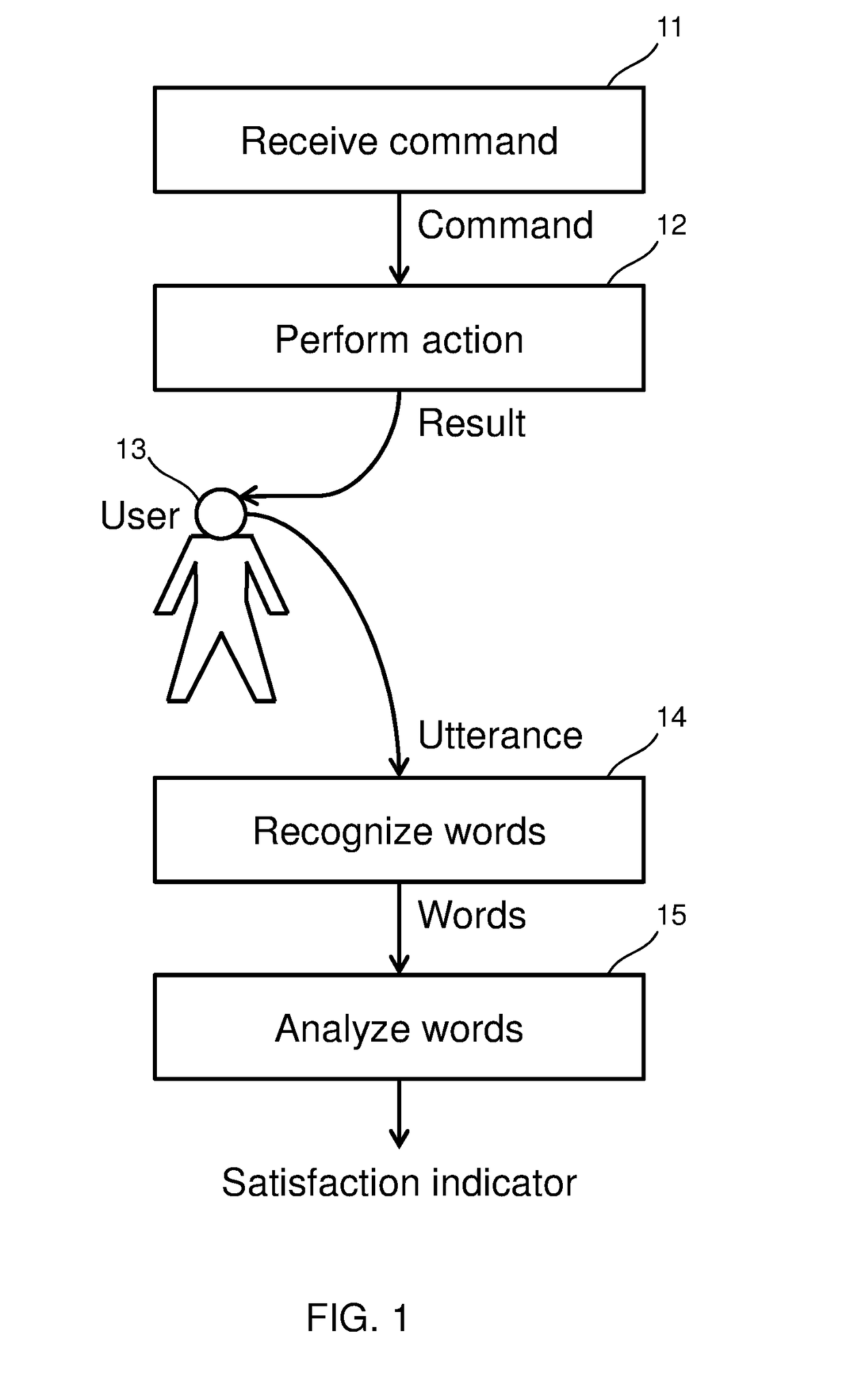

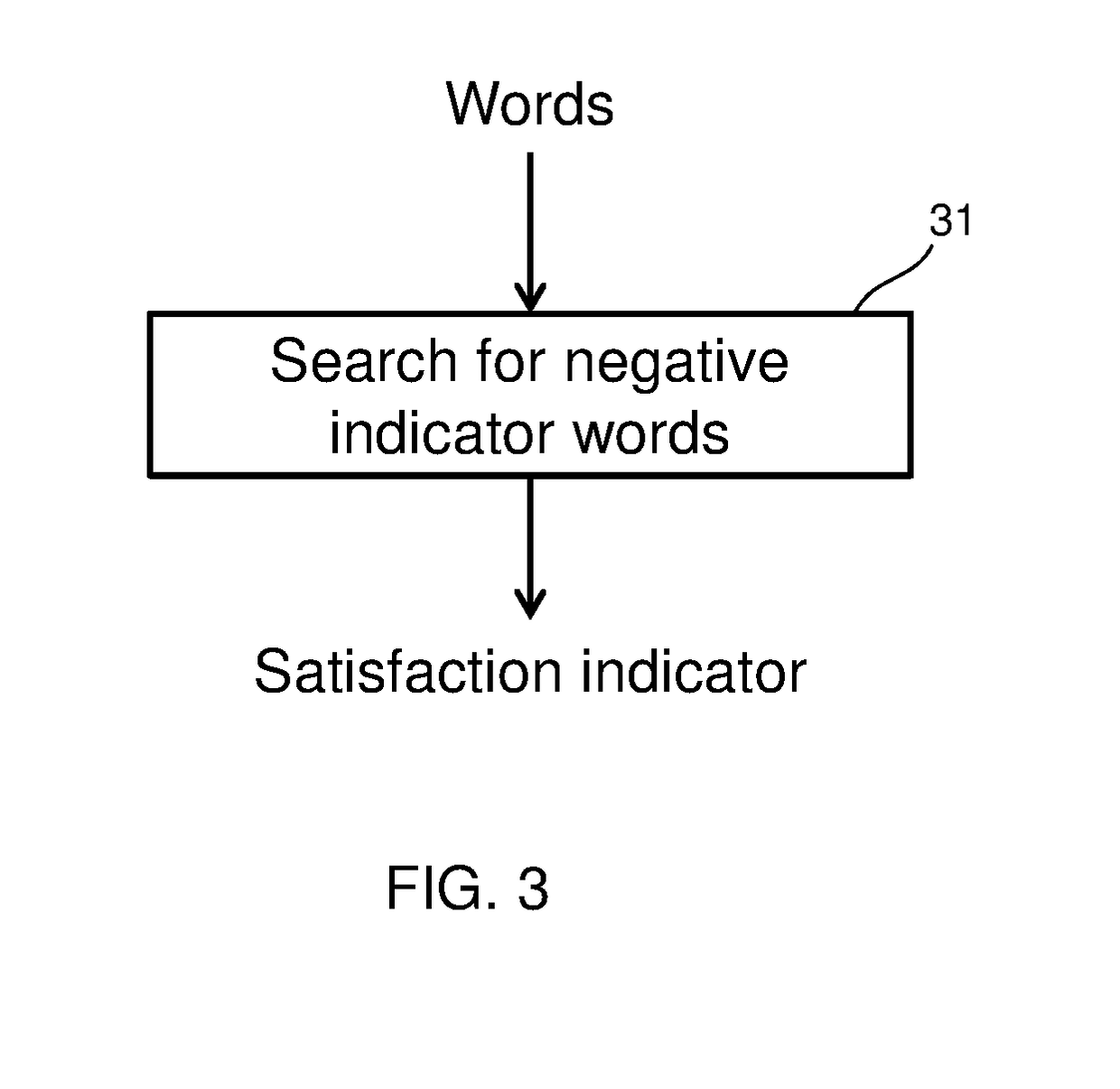

User-provided transcription feedback and correction

A system, method, and non-transitory computer readable medium provide for a visual display of a user interface for a voice-based virtual assistant system. After displaying a transcription of user speech and performing requested actions, the system allows the user to provide, by speech or manual input, an indication of satisfaction or dissatisfaction. For transcription errors, the user is presented an opportunity to correct the transcription text. The system can present several transcription hypotheses to the user, and allow the user to choose among them, or to edit one of them, as the intended transcription. A back-end server system uses the corrected transcription to train a machine learning model to perform more accurate speech recognition or provide more useful actions for future users. A system can save one or more speech recognition transcription hypotheses and check corrected results against the other transcriptions to further improve models.

Owner:SOUNDHOUND AI IP LLC

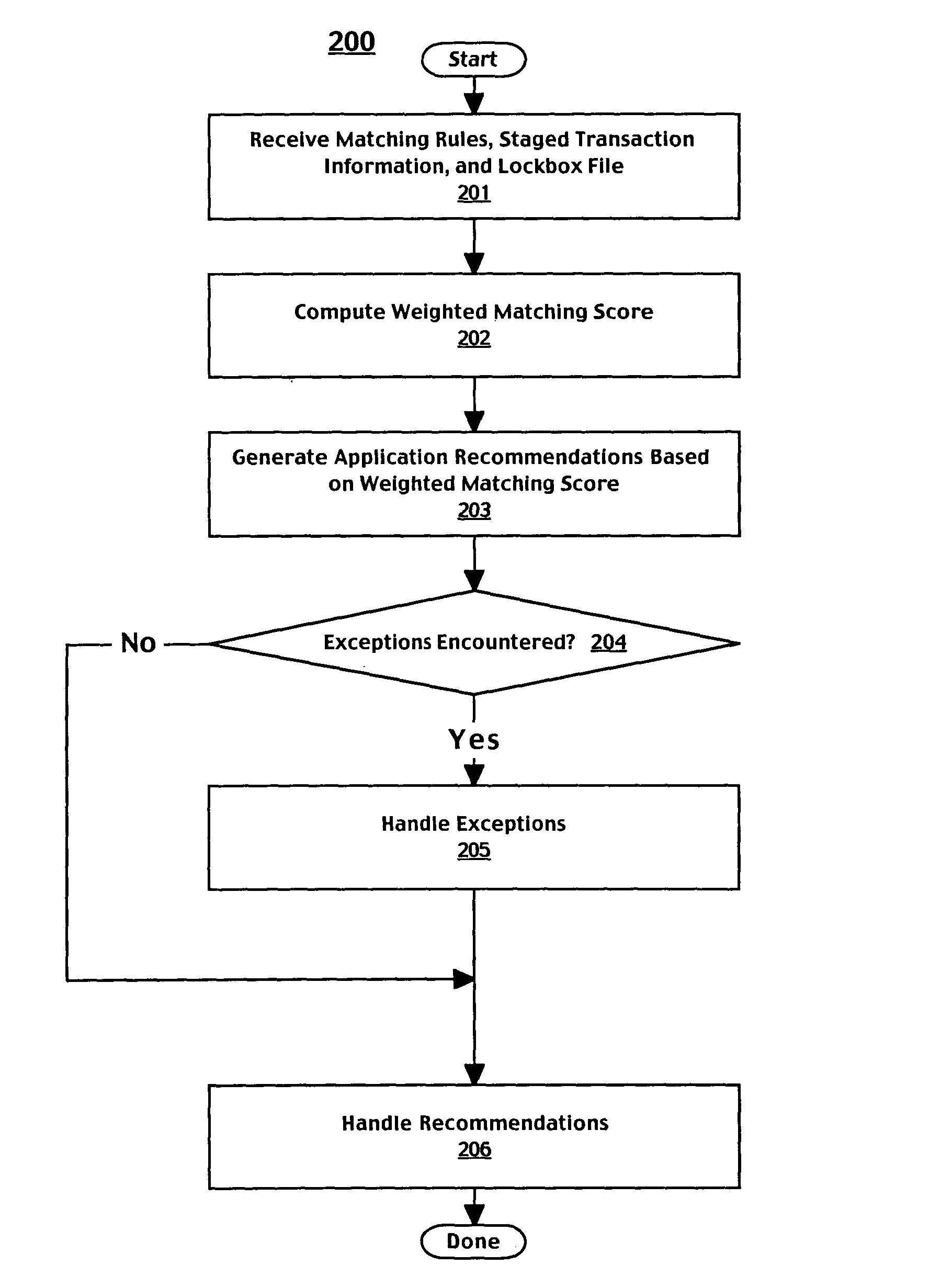

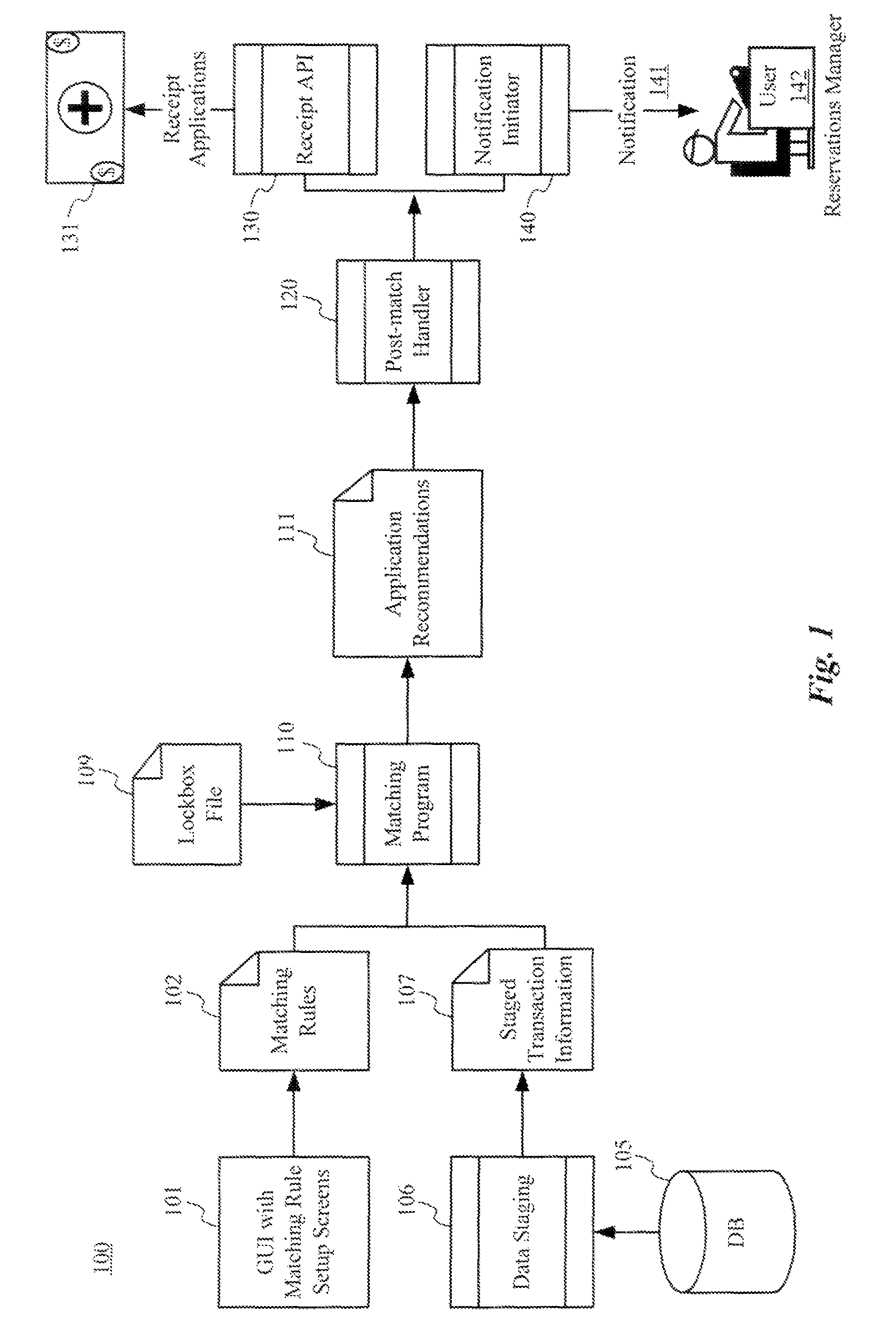

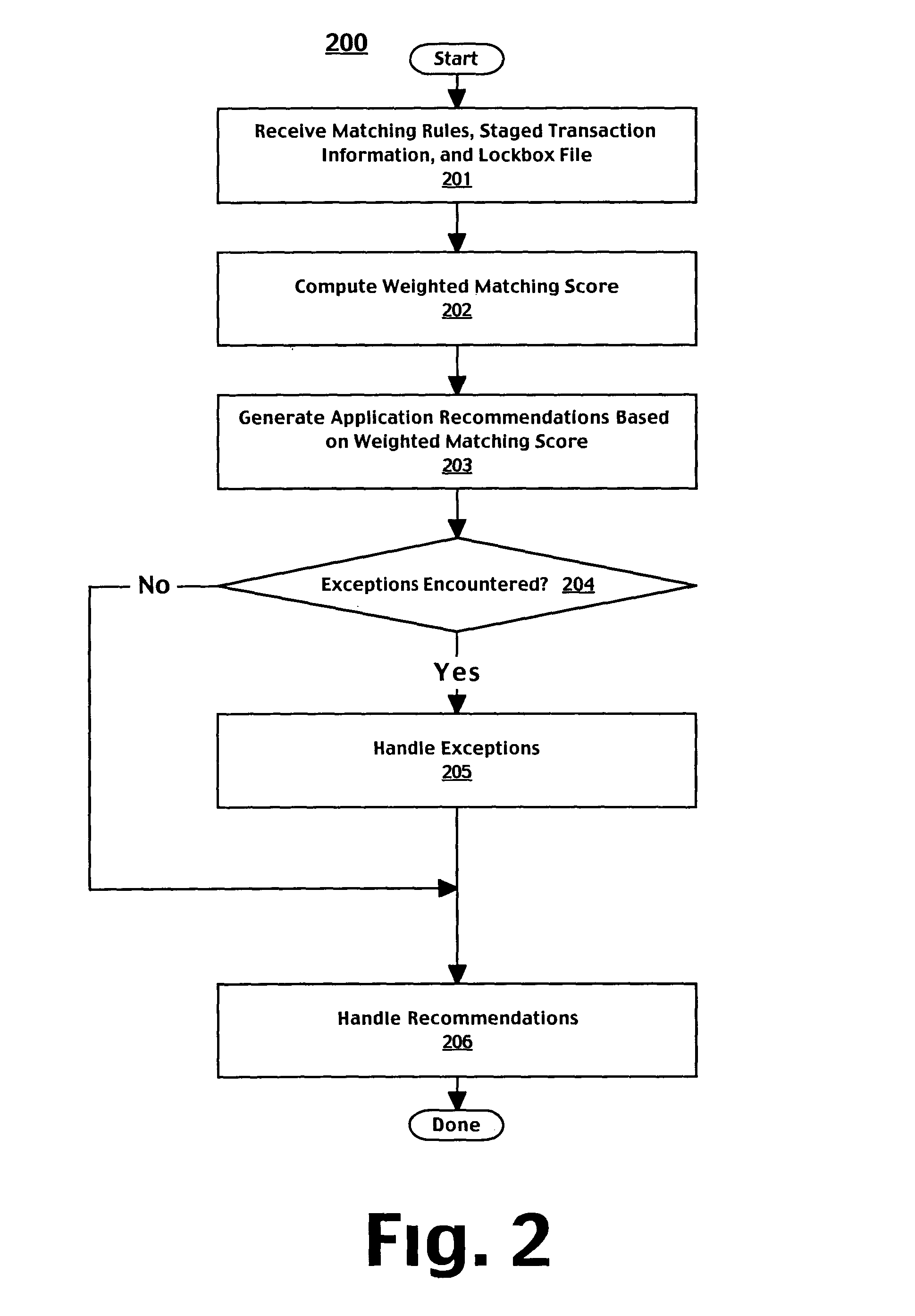

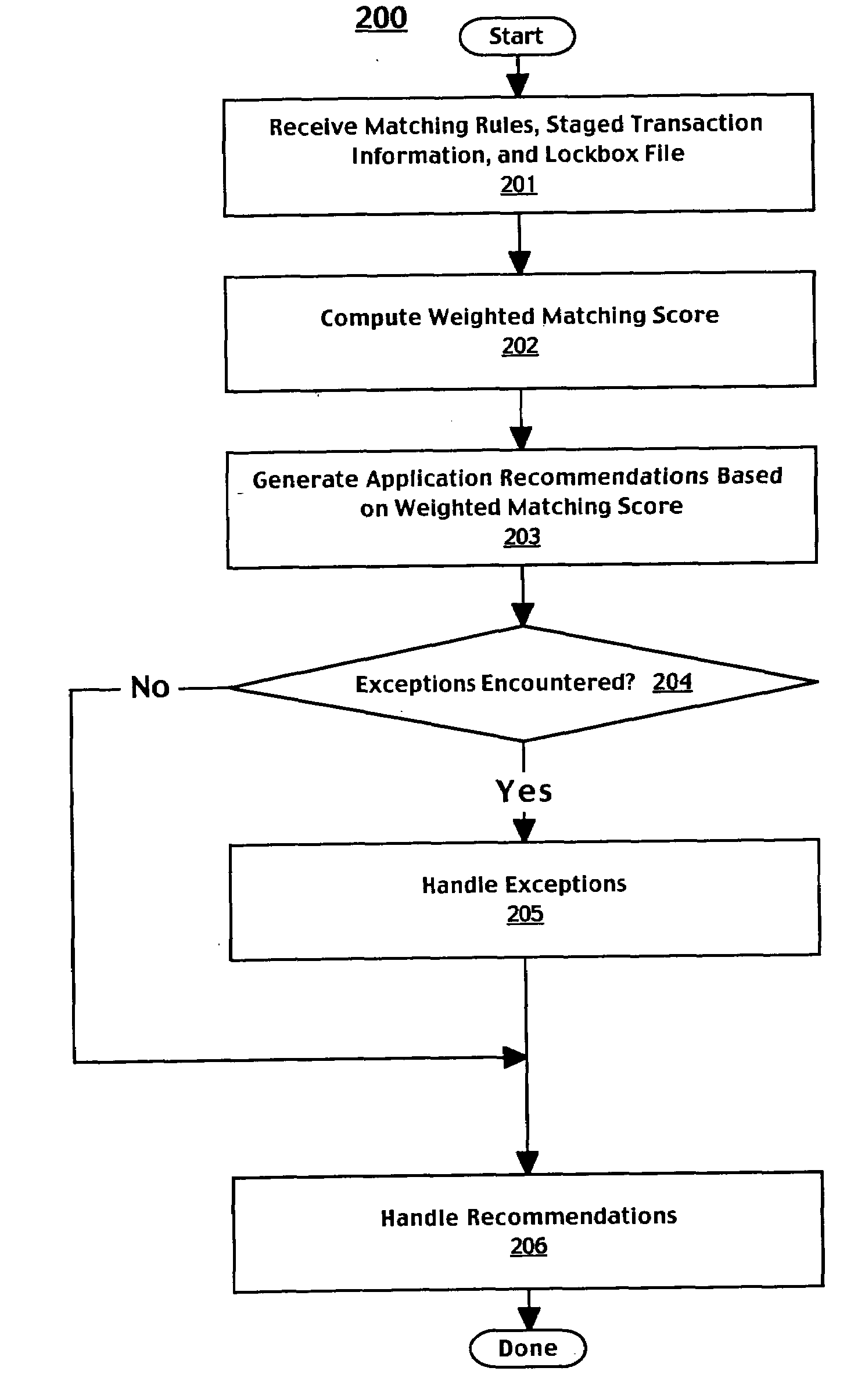

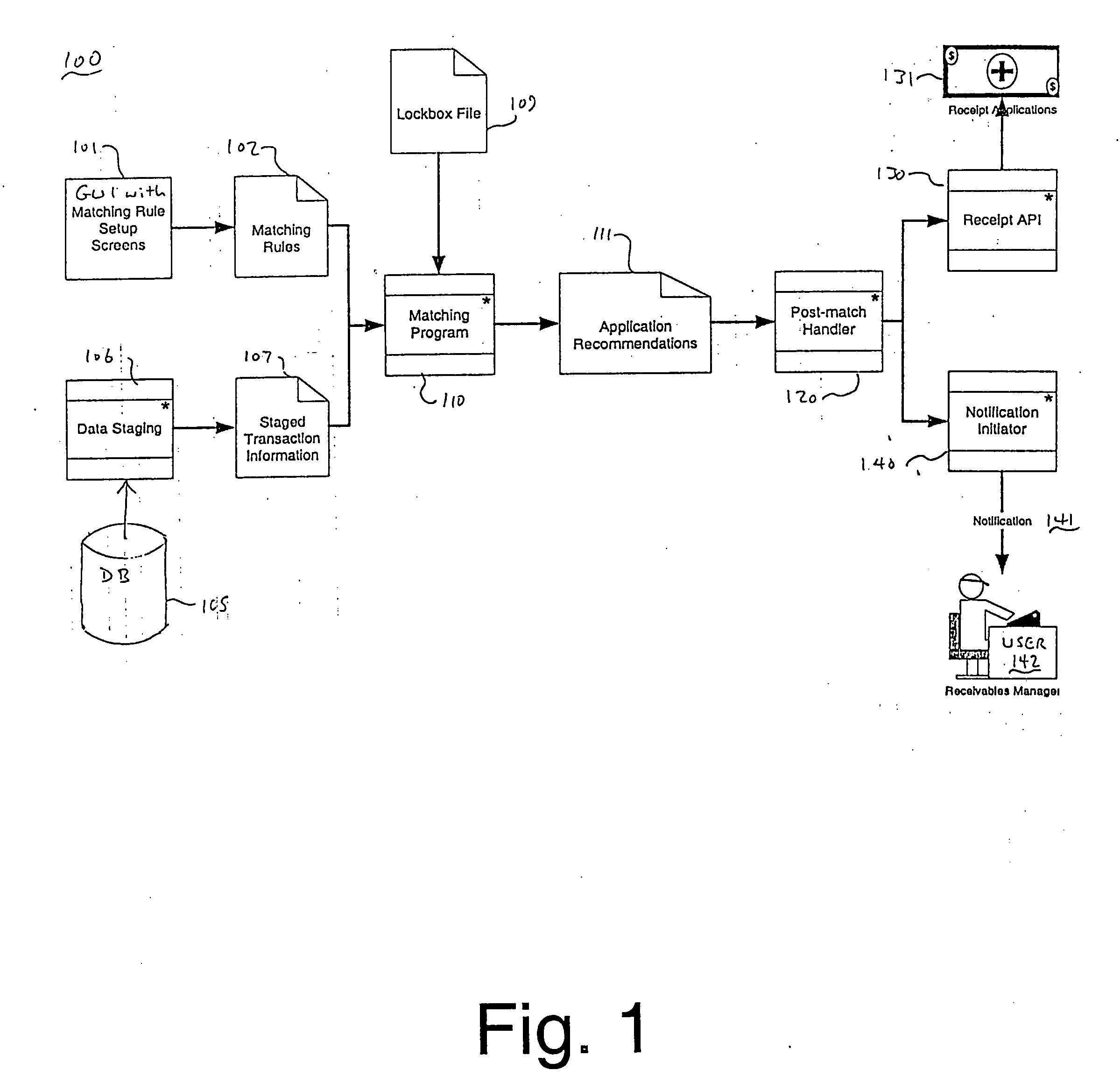

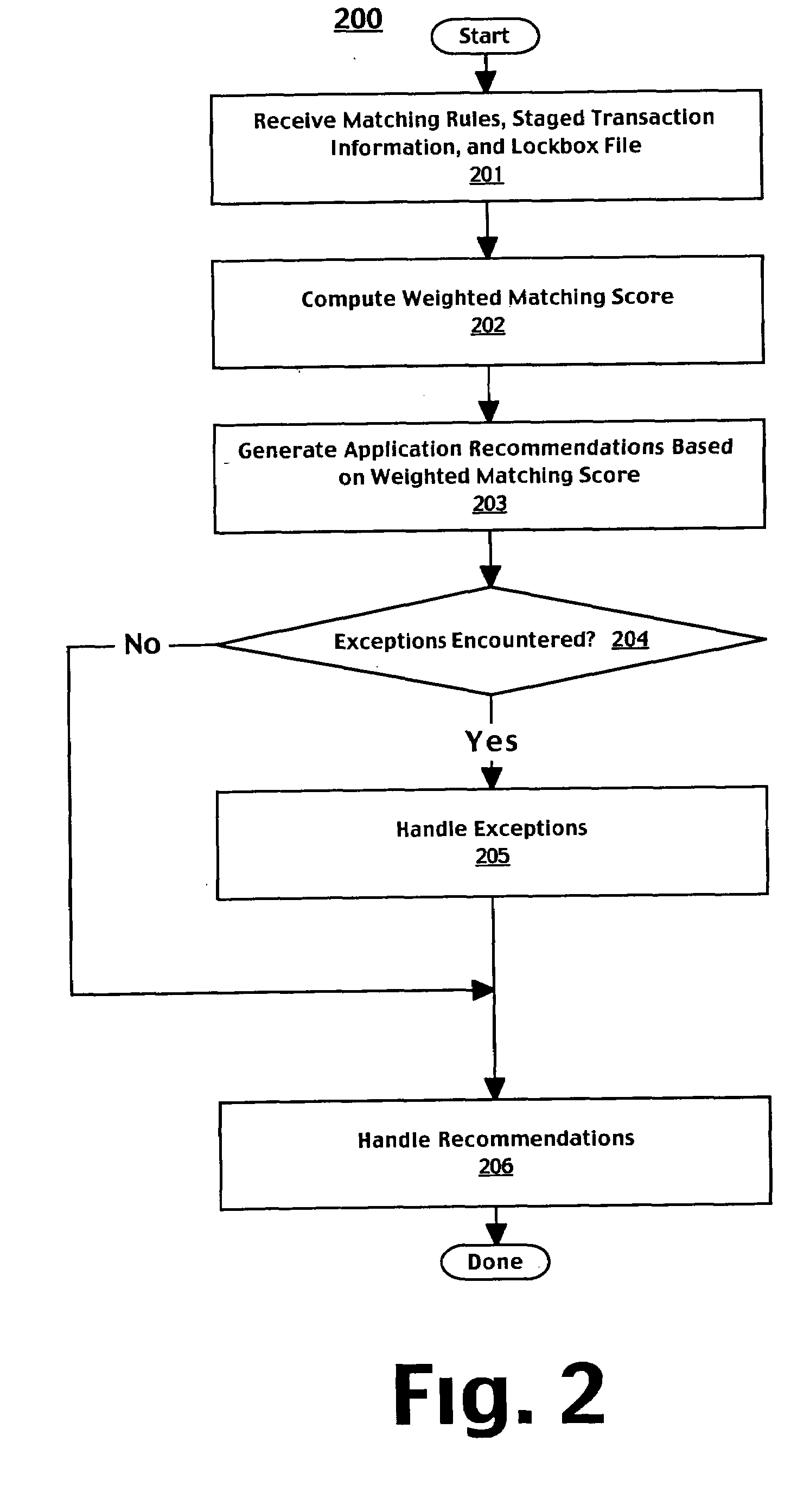

Method and system for matching remittances to transactions based on weighted scoring and fuzzy logic

A method for matching remittances to transactions is disclosed. The method for matching remittances to transactions uses a processing paradigm based on weighted scoring and fuzzy logic that is easy to maintain and fosters the use of logic based on the summarization of payments. The system and method also matches remittances to particular transactions with relaxed sensitivity to where identifying markers may be placed on a remittance and is resistant to typographical data entry errors. Further, the system and method is flexible with regards to handling various kinds of information that can result in accurate, precise matching without discarding or overlooking such information.

Owner:ORACLE INT CORP

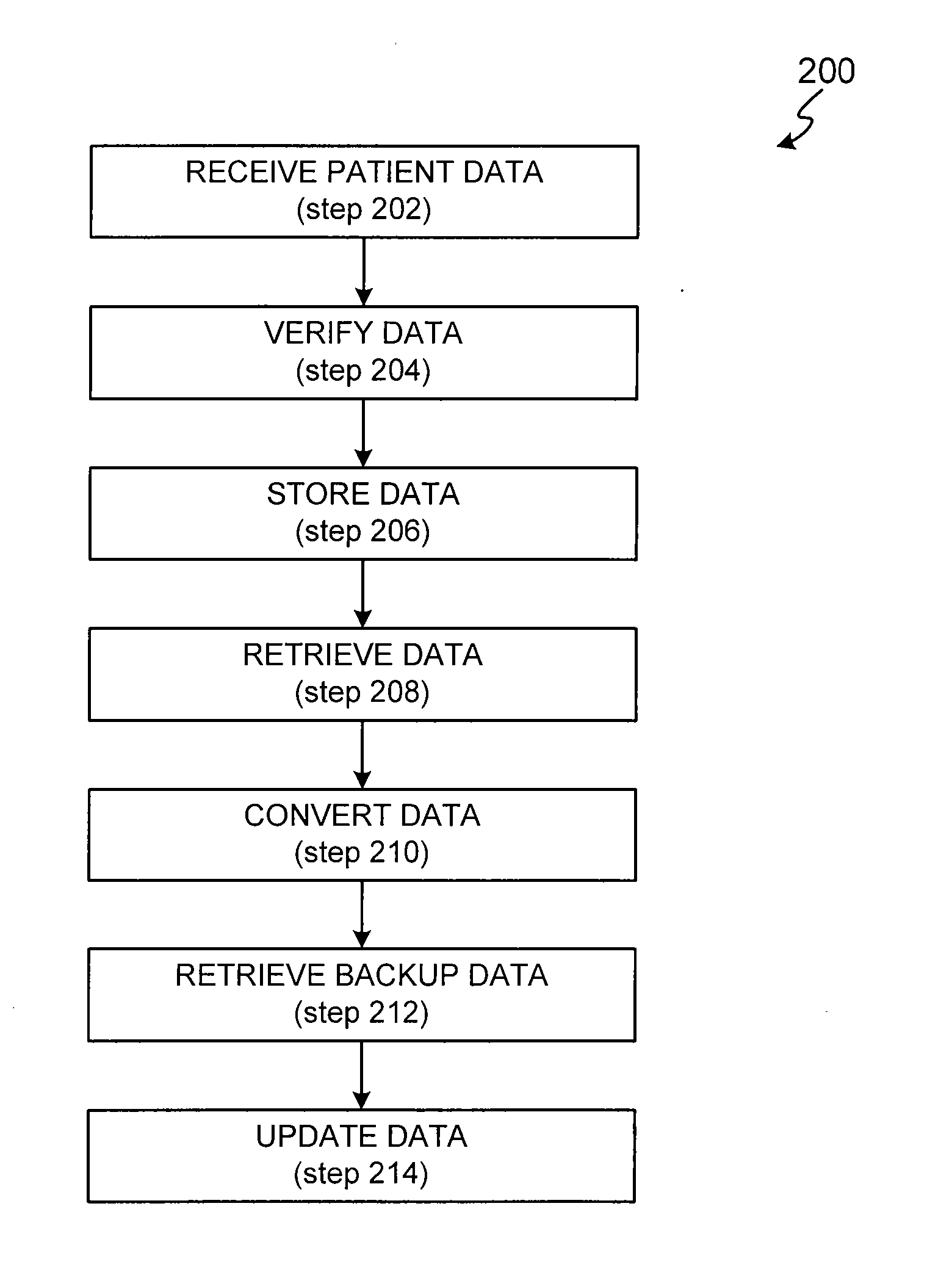

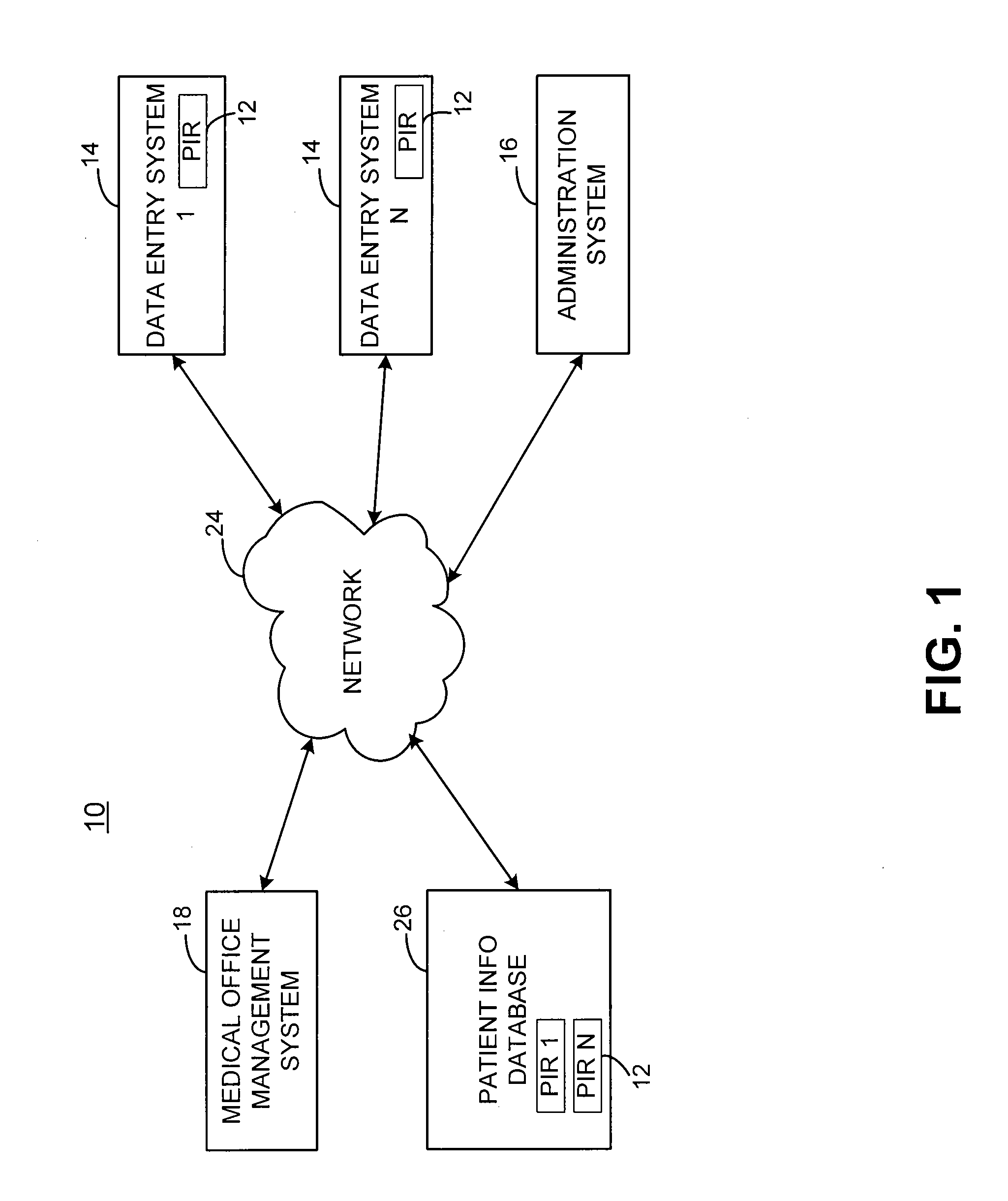

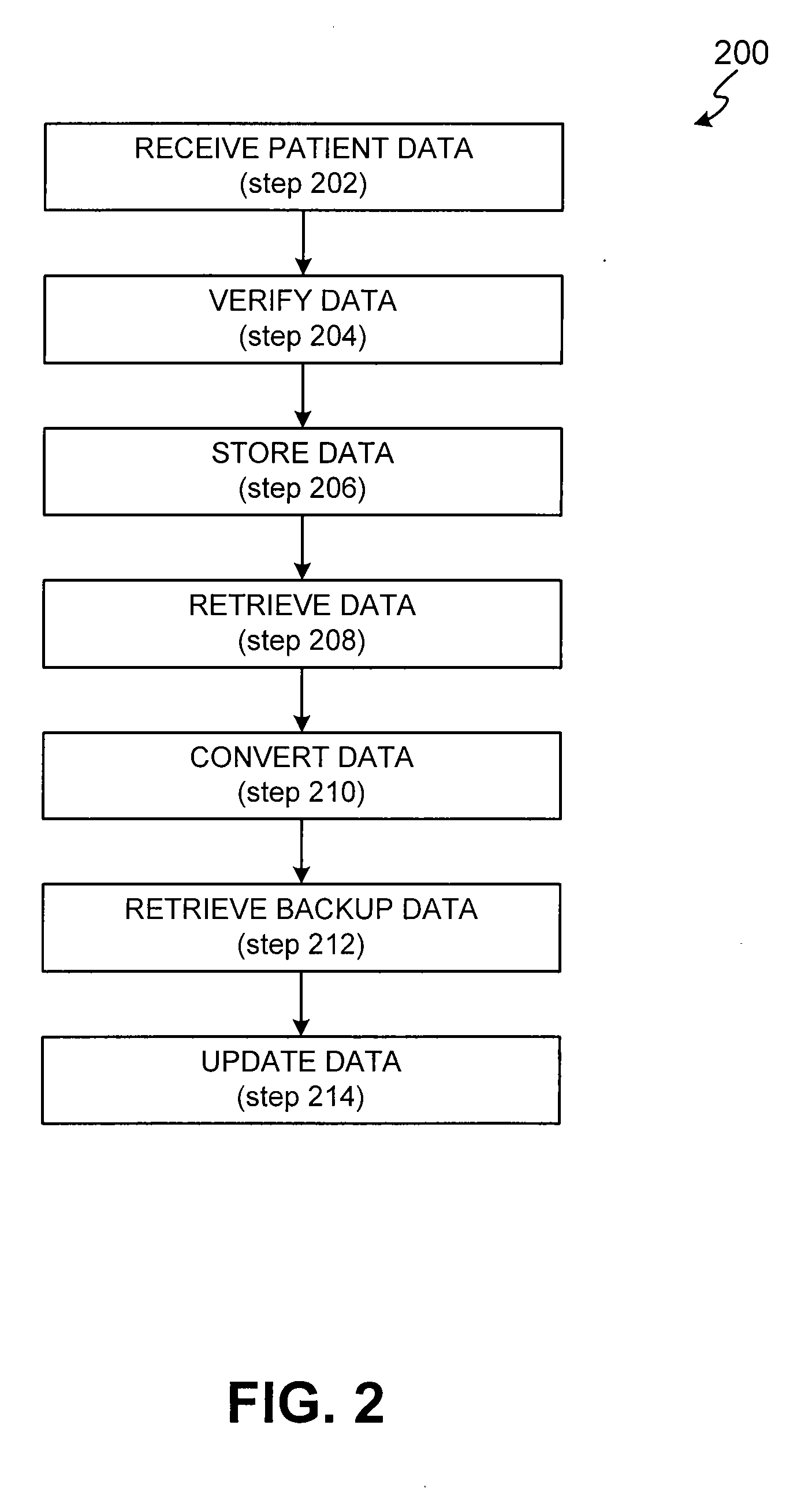

Methods and apparatus for a medical data entry system

InactiveUS20070129969A1Avoid mistakesImprove staff efficiencyData processing applicationsComputer-assisted medical data acquisitionOffice managementThe Internet

An efficient system for entry of patient information for use by a medical office, the system including a patient data entry system and an administration system for converting the patient information for use in medical office management systems. Patient data entry may also be performed remotely over the Internet. By accepting direct electronic data input from patients through an in-office data entry system or through a web-based data entry system, transcription errors are prevented and office staff efficiency is increased.

Owner:MIDMARK

Filtering transcriptions of utterances using received information to correct transcription errors

Various embodiments include methods, systems, and non-transitory computer-readable media for generating a transcription of audio data using automatic speech recognition and applying a transcription filter to a character string in the transcription (e.g., a transcribed character string) to replace the transcribed character string with another character string (e.g., a replacement character string). In some embodiments, the transcription filter applied to the transcribed character string may be ordered first in a plurality of transcription filters. In some embodiments, the transcription filter may include a finite grammar that is applied to the transcribed character string to generate the replacement character string. In some embodiments, the transcription filter may include a plurality of known character strings, and the replacement character string may be a known character string that is determined to be associated with the transcribed character filter.

Owner:AMAZON TECH INC

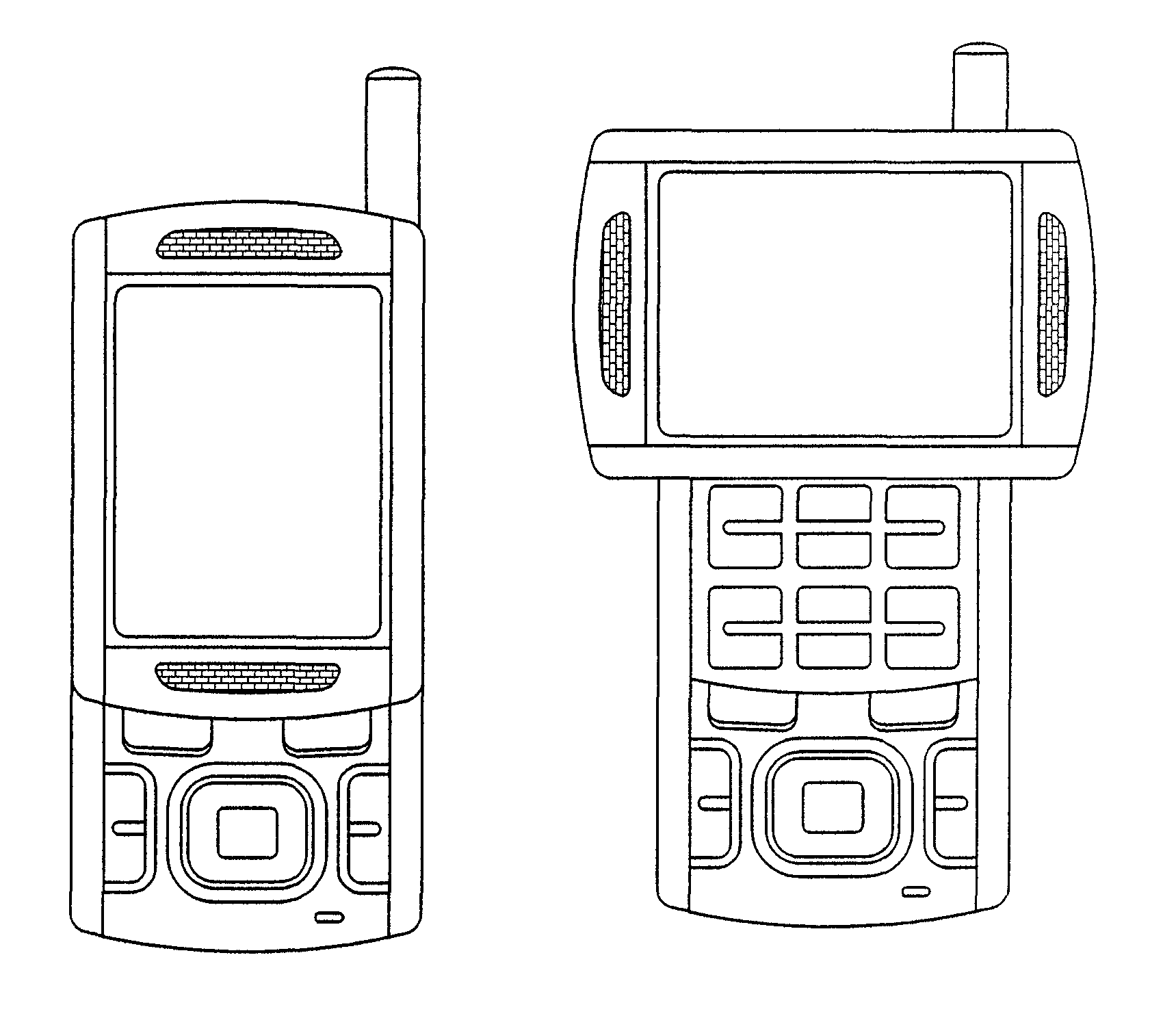

Communication terminal

InactiveUS7930003B2Sufficient structureMinimize data inputDevices with multiple keyboard unitsUnauthorised/fraudulent call preventionMiniaturizationComputer science

Disclosed herein is a communication terminal which has an adequate structure for keys so as to sufficiently fulfill various communication services, to thereby make the communication terminal compact, and can control operation of the keys so as to minimize a data input error of the keys. The communication terminal includes a first housing, a second housing which is oppositely coupled to the first housing, and a control unit which interrupts operation of a data input part provided at either the first housing or the second housing according to movement of the second housing with respect to the first housing.

Owner:LG ELECTRONICS INC

Method and system for matching remittances to transactions based on weighted scoring and fuzzy logic

ActiveUS20090094154A1Easy maintenanceData entry errorComplete banking machinesFinanceData miningData entry error

A method for matching remittances to transactions is disclosed. The method for matching remittances to transactions uses a processing paradigm based on weighted scoring and fuzzy logic that is easy to maintain and fosters the use of logic based on the summarization of payments. The system and method also matches remittances to particular transactions with relaxed sensitivity to where identifying markers may be placed on a remittance and is resistant to typographical data entry errors. Further, the system and method is flexible with regards to handling various kinds of information that can result in accurate, precise matching without discarding or overlooking such information.

Owner:ORACLE INT CORP

Launch monitor

A launch monitor that includes substantially all of its functional components on or within a housing is disclosed. In one embodiment, the launch monitor is capable of being transported and used in any desired location. One or more camera's, flashes, and triggers may be used to acquire images of a golf club and golf ball. The launch monitor is preferably capable of receiving and transmitting data over a wireless network. Acquired images and other data may be analyzed by a processor, and then displayed using an LED, LCD or other type of display or printer. The launch monitor may “recognize” a plurality of golf clubs and golf balls based on an optical fingerprint. The optical fingerprints, which are preferably stored in a memory, allow the launch monitor to identify a golf club and / or ball substantially soon after they are placed in the field of view of the monitor Optical fingerprinting enables automatic record keeping, and storing performance data and equipment used simultaneously. This feature eliminates tedious record keeping, eliminates data entry errors, and enables rapid equipment optimization.

Owner:ACUSHNET CO

Automated manufacturing system and method for processing photomasks

InactiveUS20050246049A1Costly delayCostly errorPhotomechanical treatmentResourcesMonitoring systemComputer science

The present invention relates generally to an automated manufacturing system and method for manufacturing photomasks wherein information provided by a customer at a remote location is interfaced, via a network, to a photomask manufacturer's computer system and automatically processes data for manufacturing a photomask and automatically formats and routes data to processing equipment. The present invention reduces the need for manual intervention, thereby avoiding costly delays and transcription errors associated therewith. The software of the present invention provides for automatic generation of data arrays, which can be used to process and monitor the status of a photomask during manufacture. Further, the software is capable of automatically modifying design data provided by a photomask user. Additionally, the software of the present invention includes an automatic messaging system which can notify users of the system, of status and errors in manufacture of photomasks. The present invention also includes a real time monitoring system capable of notifying users of the status and errors in the processing of the photomask during manufacture.

Owner:PHOTRONICS INC

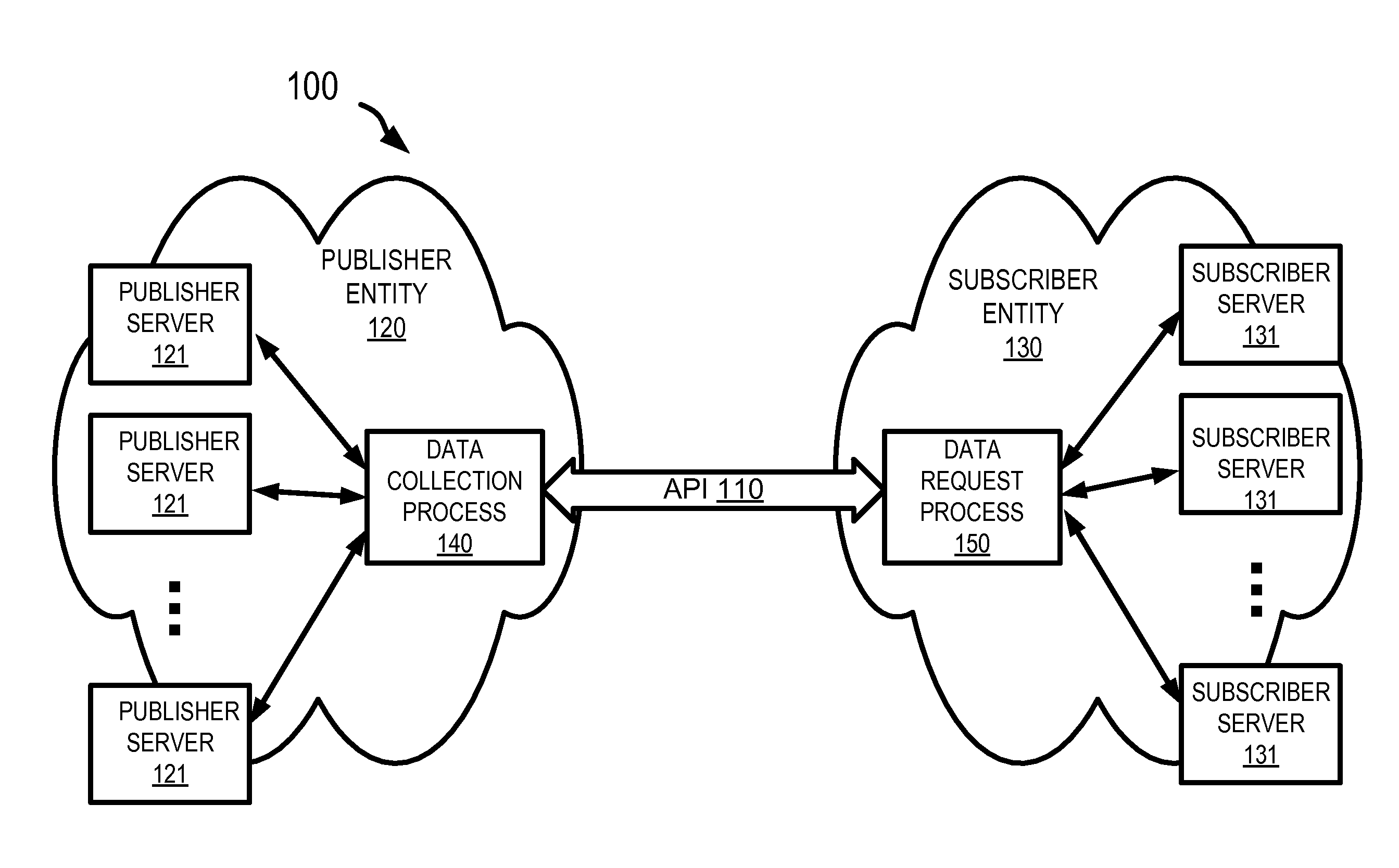

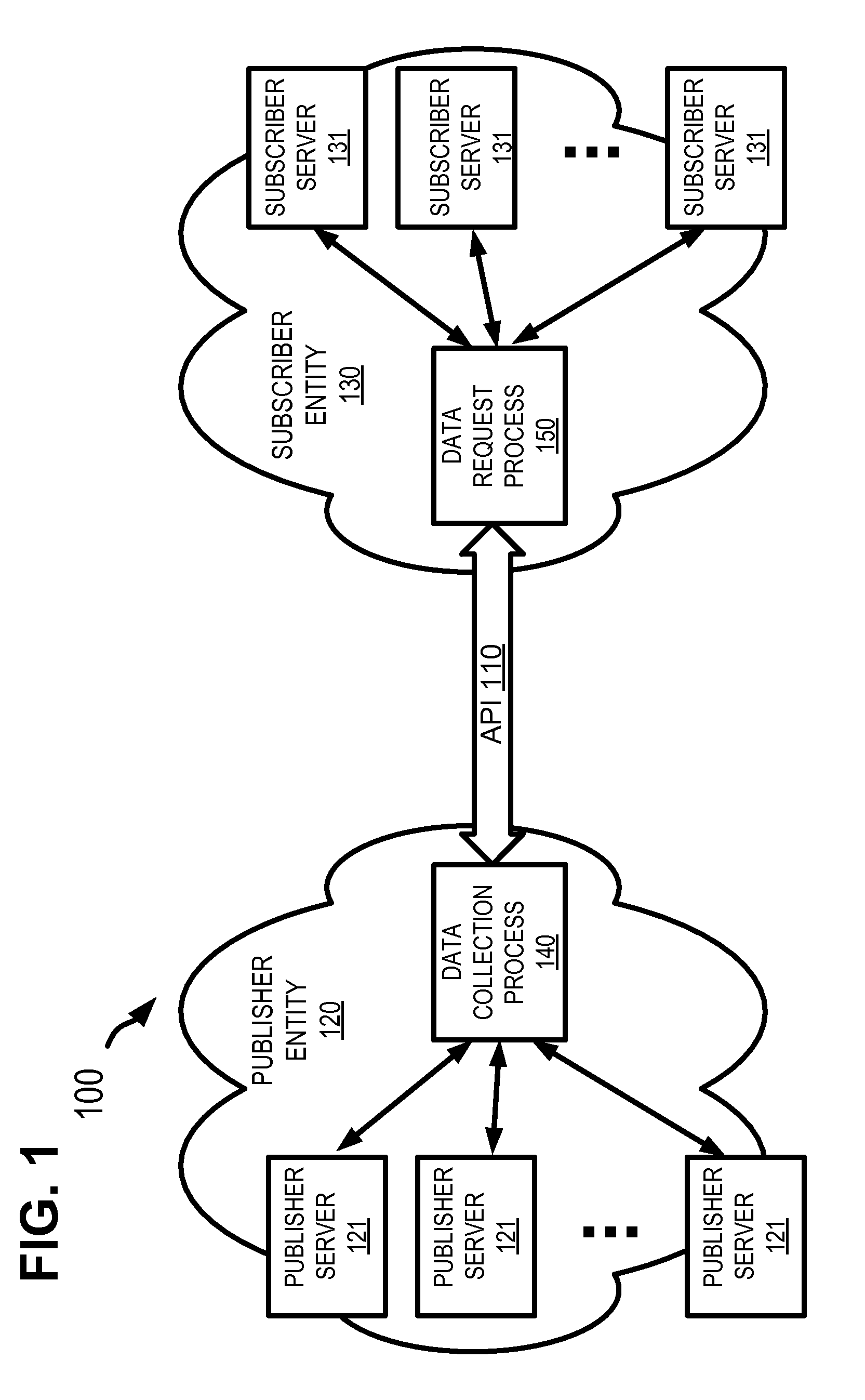

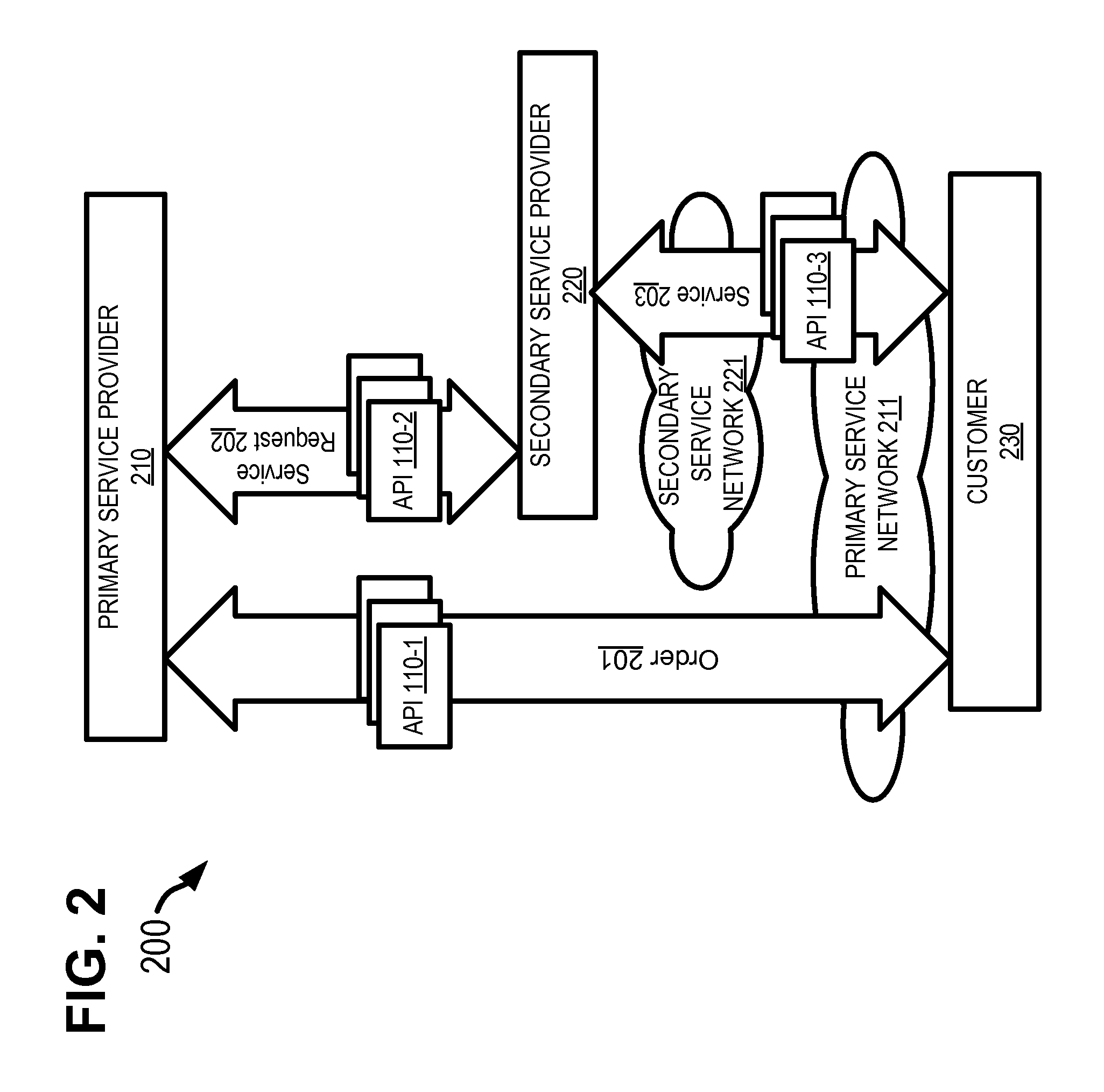

GLOBAL ENTITY-TO-ENTITY INTEGRATION PLATFORM USING STANDARDS-BASED APPLICATION PROGRAM INTERFACES (APIs)

InactiveUS20160119405A1Multiple digital computer combinationsResourcesApplication programming interfaceData exchange

A system and method may provide standardized application programming interfaces that enable global entity-to-entity communications, such as to enable a process associated with one entity to access multiple systems at another entity. Some benefits of a global, standardized API-based entity-to-entity data exchange and integration platform include reduced cycle times by accelerating service delivery through automated and streamed data collection processes and an improved overall interface experience by embedding data collection processes into existing tools and improving accuracy by reducing manual data entry errors. For example, the standardized APIs may be used to generate a service request sent from a first service provider to a second service provider to ask the second service provider to provision a service to a customer of the first service provider.

Owner:VERIZON PATENT & LICENSING INC

Methods of and systems for reducing keyboard data entry errors

InactiveUS9122318B2Minimization requirementsEasy accessInput/output for user-computer interactionCathode-ray tube indicatorsSoft keyDisplay device

Method of and system for reducing data entry errors that ascertains a subset of keys that can be selected by a user based upon the respective likelihood that each key follows a previously selected key within a predetermined language, corpus, or subset thereof, and controls the display of the keys within an input device so that the keys within the ascertained subset are displayed in a visually distinguishable manner from the keys that not within the ascertained subset. In a touch screen device, the keys that are displayed are part of the soft keys displayed on the screen. In a system that includes an actual physical keyboard, the appearance of select keys of the keyboard can be modified in various manners, including the use of an LCD display or other controllable lighting mechanism disposed within the keyboard. Multiple additional techniques for reducing data entry also are disclosed.

Owner:SIEGEL ABBY L

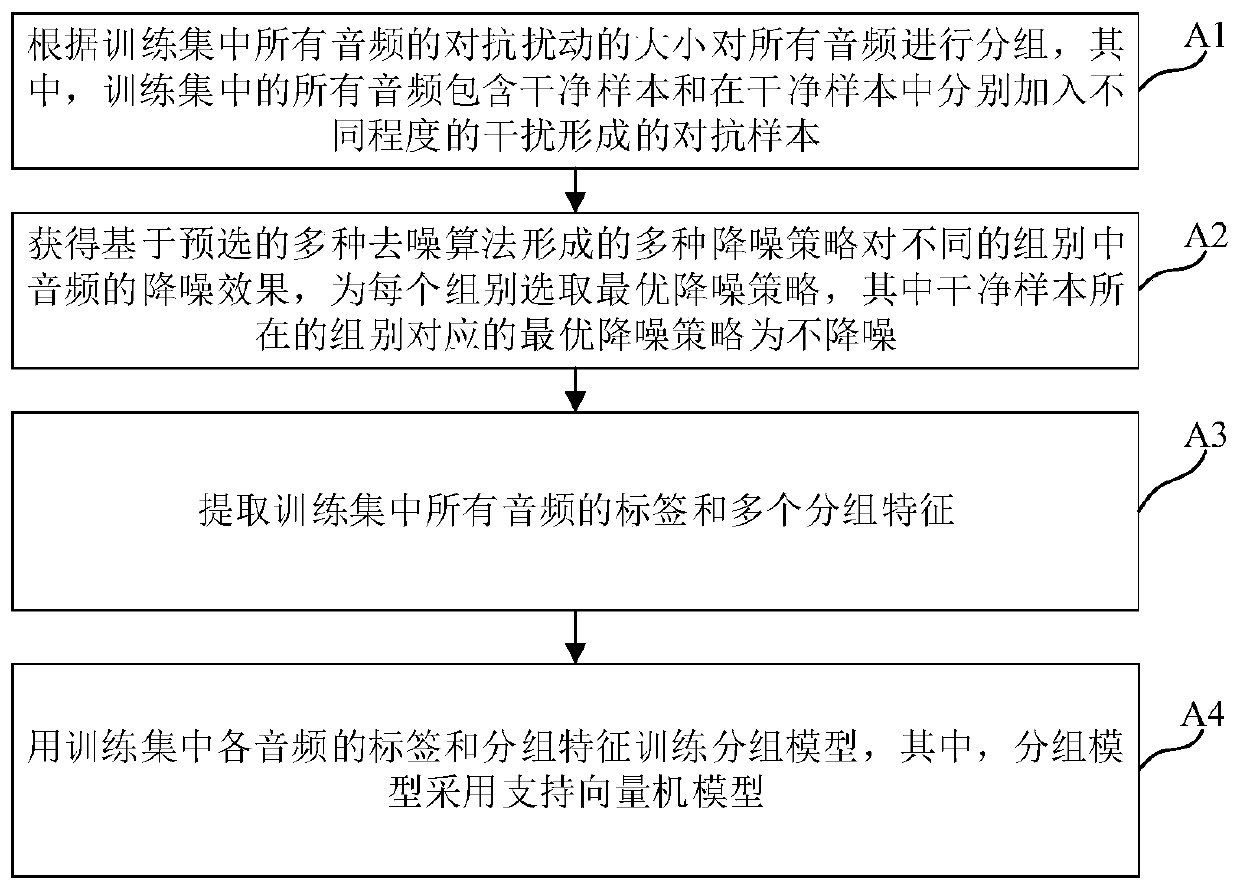

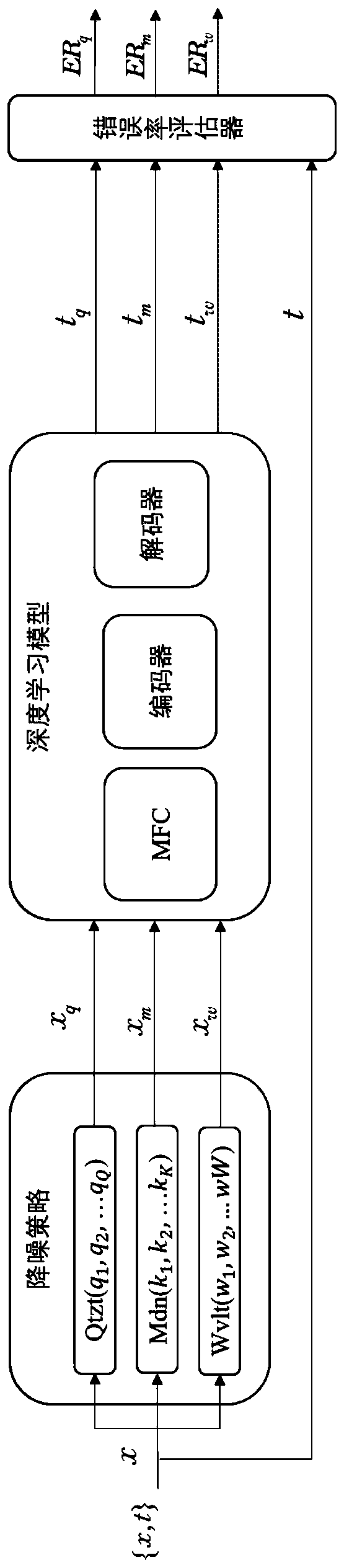

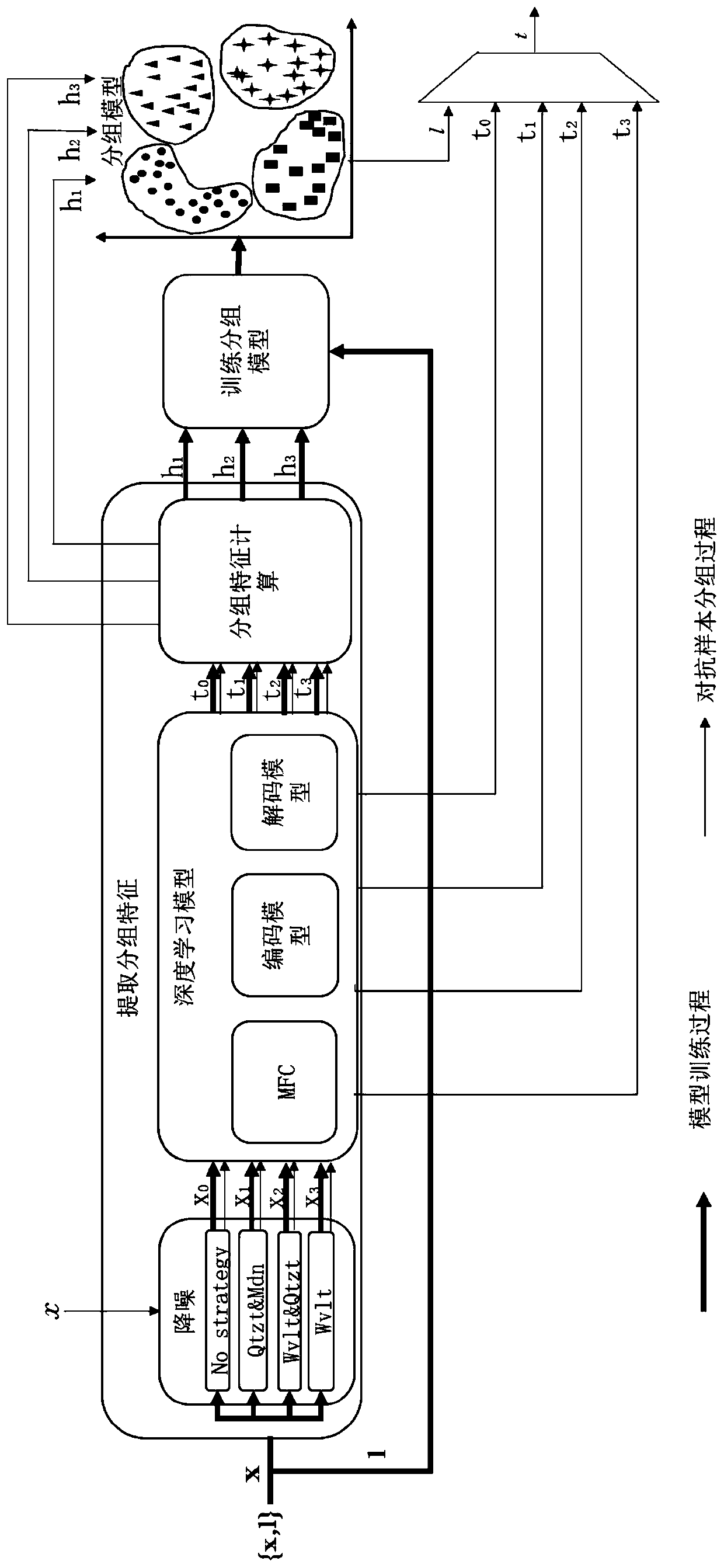

Method of training grouping model for voice grouping, and voice noise reduction method

ActiveCN111462737ADoes not affect transcription qualityReduce error rateSpeech recognitionSpeech soundAudio frequency

The embodiment of the invention provides a method for training a grouping model for voice grouping, and a voice noise reduction method. The voice noise reduction method comprises the steps: B1, obtaining an input audio, and extracting the grouping features of the input audio; B2, inputting the grouping features of the input audio into a grouping model, and predictively outputting the label of theinput audio; and B3, according to the label of the input audio, taking the transcription text obtained by the audio processed by the optimal noise reduction strategy of the group corresponding to thelabel as the transcription text of the input audio. According to the technical scheme provided by the embodiment of the invention, the group to which the input audio belongs can be predicted accordingto the anti-disturbance of the input audio, and the noise reduction strategy suitable for the group is selected for noise reduction, so that the transcription error rate can be reduced, and the transcription quality of a clean sample cannot be influenced while the anti-transcription is recovered to the original transcription.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

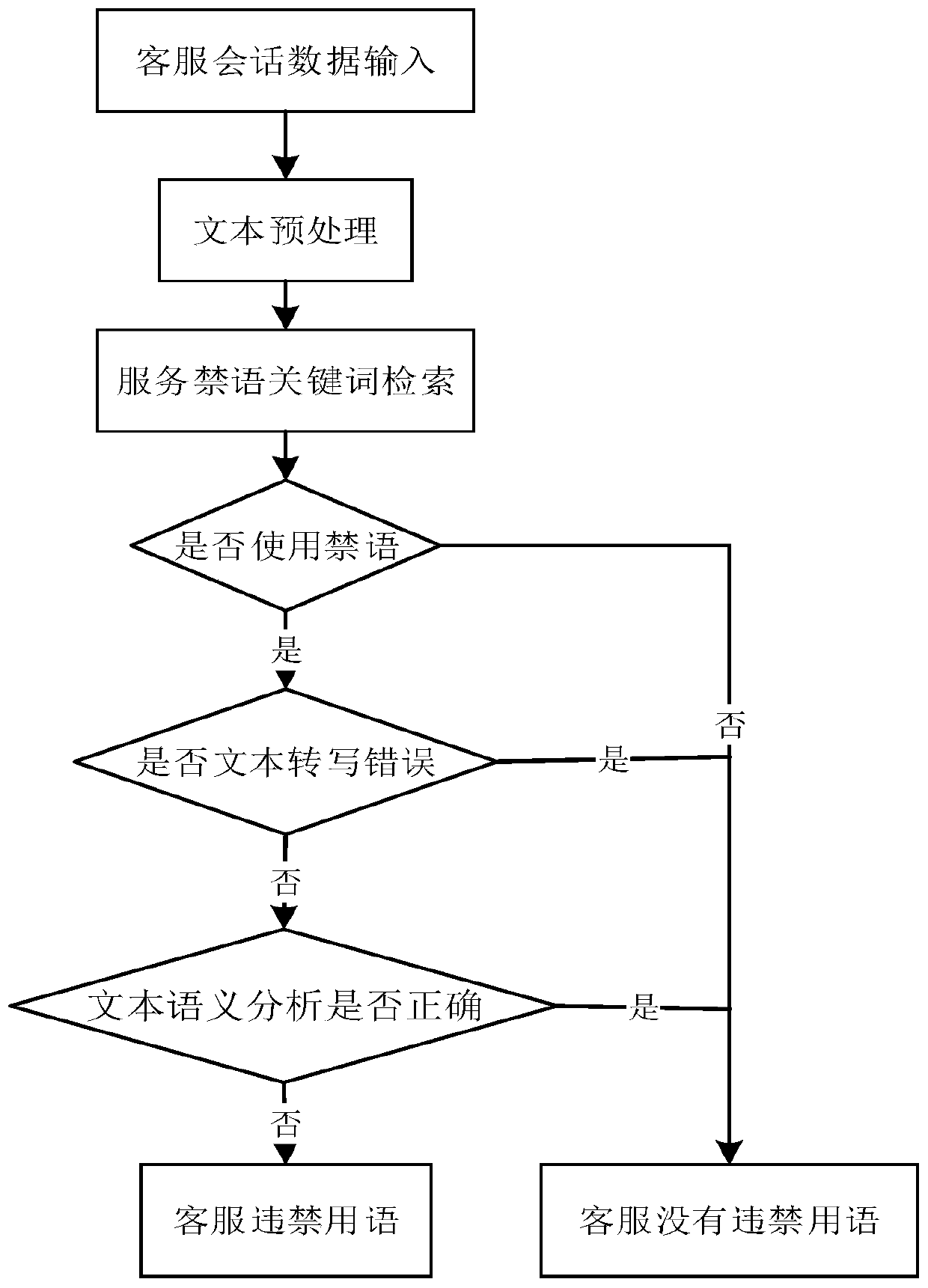

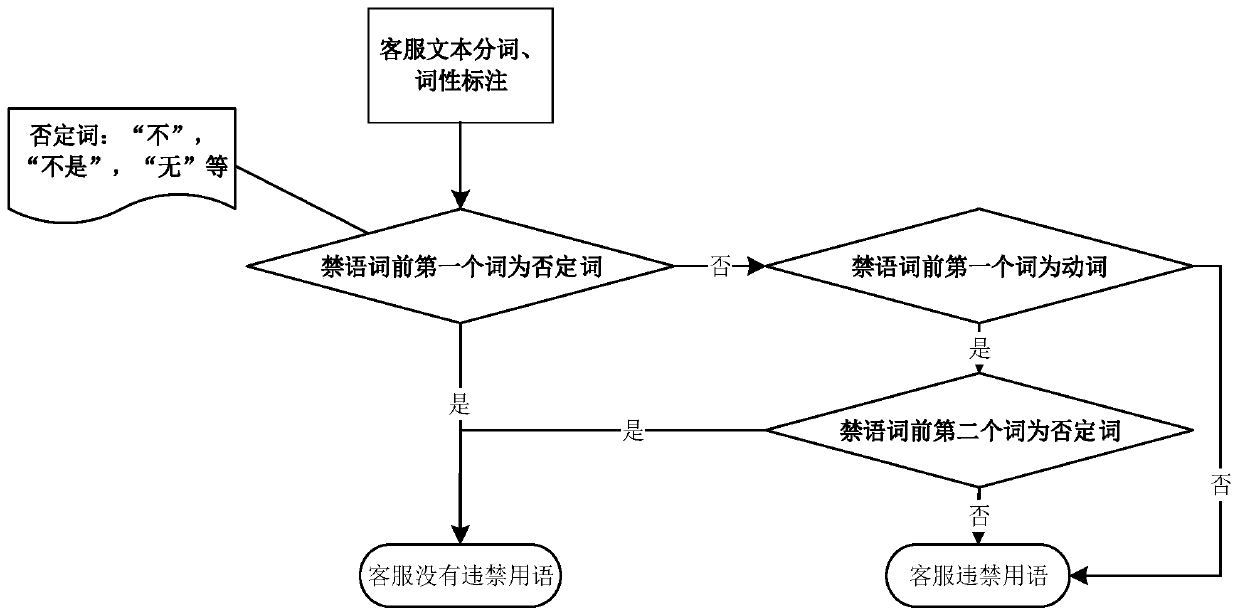

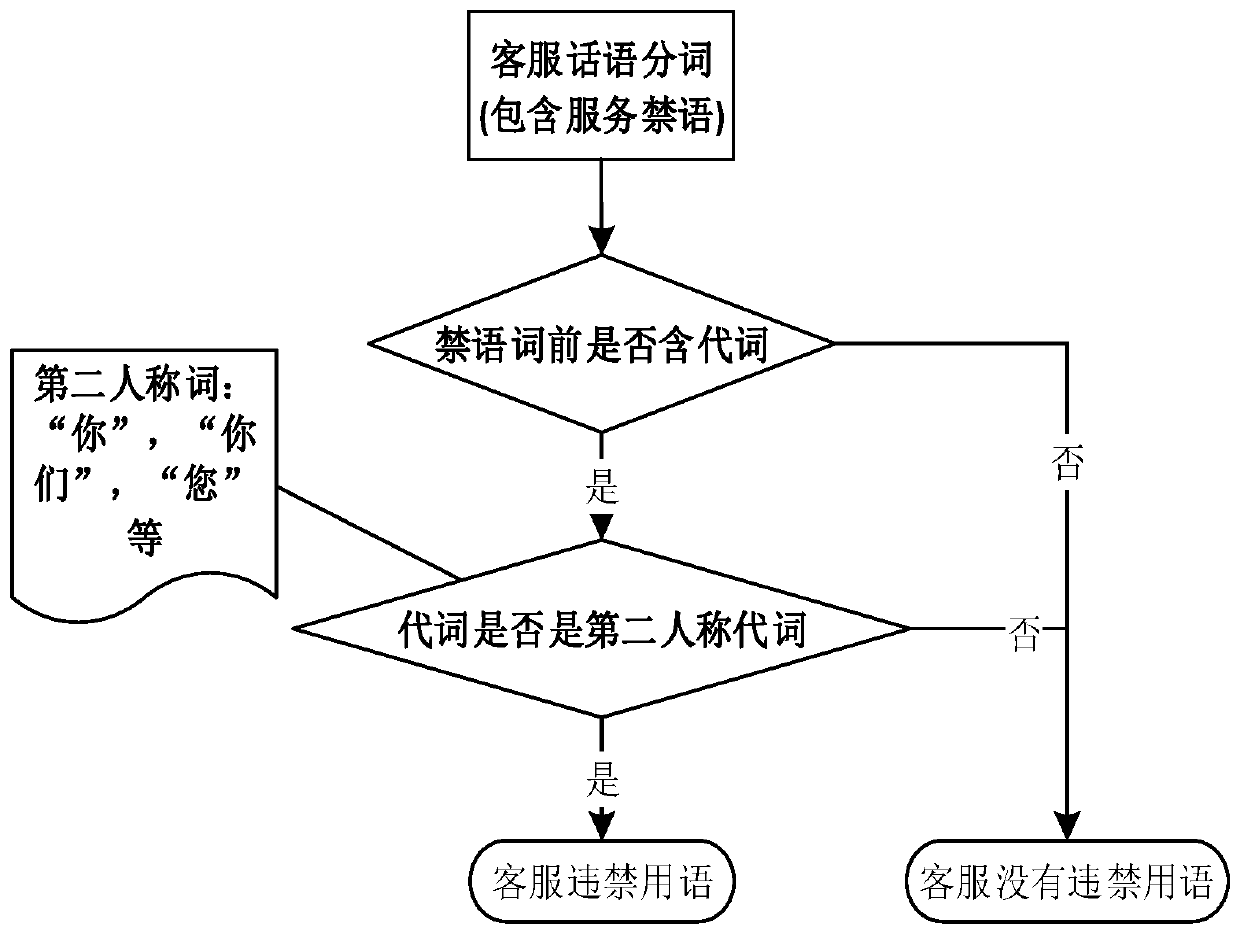

Identification method and system for intelligent quality inspection of service forbidden words

The invention relates to a natural language processing technology, in particular to an identification method and system for intelligent quality inspection of service forbidden words, and the method comprises: performing text transcription and text preprocessing, i.e., carrying out the letter capital and lower-case conversion and part-of-speech tagging of text data of customer service; performing keyword retrieval; performing text transcription error identification, i.e., judging whether text transcription is reasonable or wrong according to historical customer service session text data; performing text semantic analysis, i.e., analyzing semanteme of the text in the customer service session content hitting the service forbidden word keyword to obtain an identification result of whether thesupport staff uses forbidden words or not ; and filtering an identification result that the support staff does not use forbidden words to obtain a final inspection result. The context of the keywordsin the text and historical session text data are combined in the text analysis process, and the accuracy of quality inspection is improved through rule matching.

Owner:GUANGZHOU BAILING DATA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com