Composite latex of organic silicon resin and acrylic ester polymers, and preparation method thereof

A technology of acrylate and composite latex, which is applied in the field of composite latex of silicone resin and acrylate polymer and its preparation. Complicated reaction steps and other problems, to achieve the effect of mild conditions, simple operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

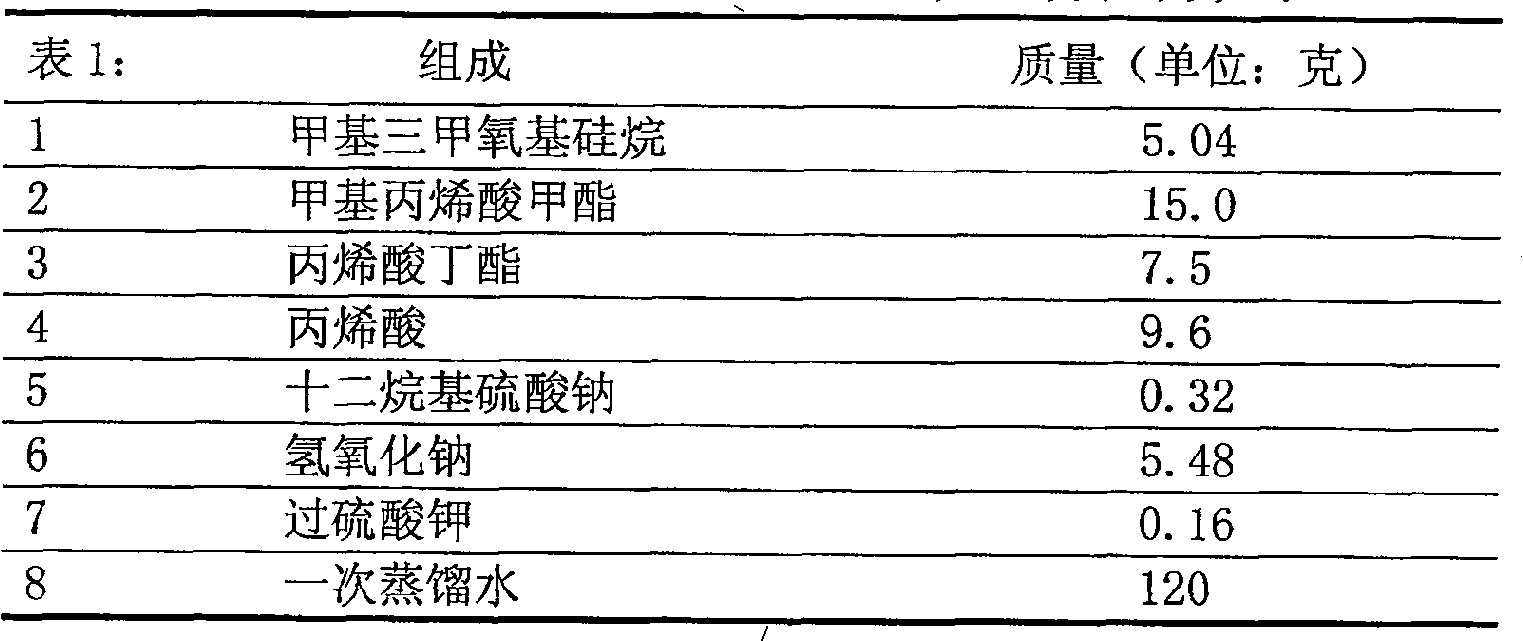

[0034] The organosiloxane uses methyltrimethoxysilane, and its component formula is shown in Table 1.

[0035]

[0036] (1) Preparation of silicone resin: in a three-necked flask with a condensing device and a stirring device, add methyltrimethoxysilane, methyl methacrylate, butyl acrylate, acrylic acid and metered water (2.0 grams), React at a temperature of 20° C. for 30 hours to prepare a silicone resin acrylate solution.

[0037] (2) Pre-emulsification process: Sodium lauryl sulfate is dissolved in 5 grams of water, joins in the acrylate solution of methyltrimethoxysilane resin that step (1) makes, high-speed stirring (1000r / min) 1.0 hour to prepare a pre-emulsion. Sodium hydroxide was dissolved in 108 grams of water, and was slowly added dropwise to the pre-emulsion with a constant pressure funnel, and the drop was completed in 0.5 hours. During the dropping process, high-speed stirring was maintained to prepare the pre-emulsion.

[0038](3) Polymerization reaction:...

Embodiment 2

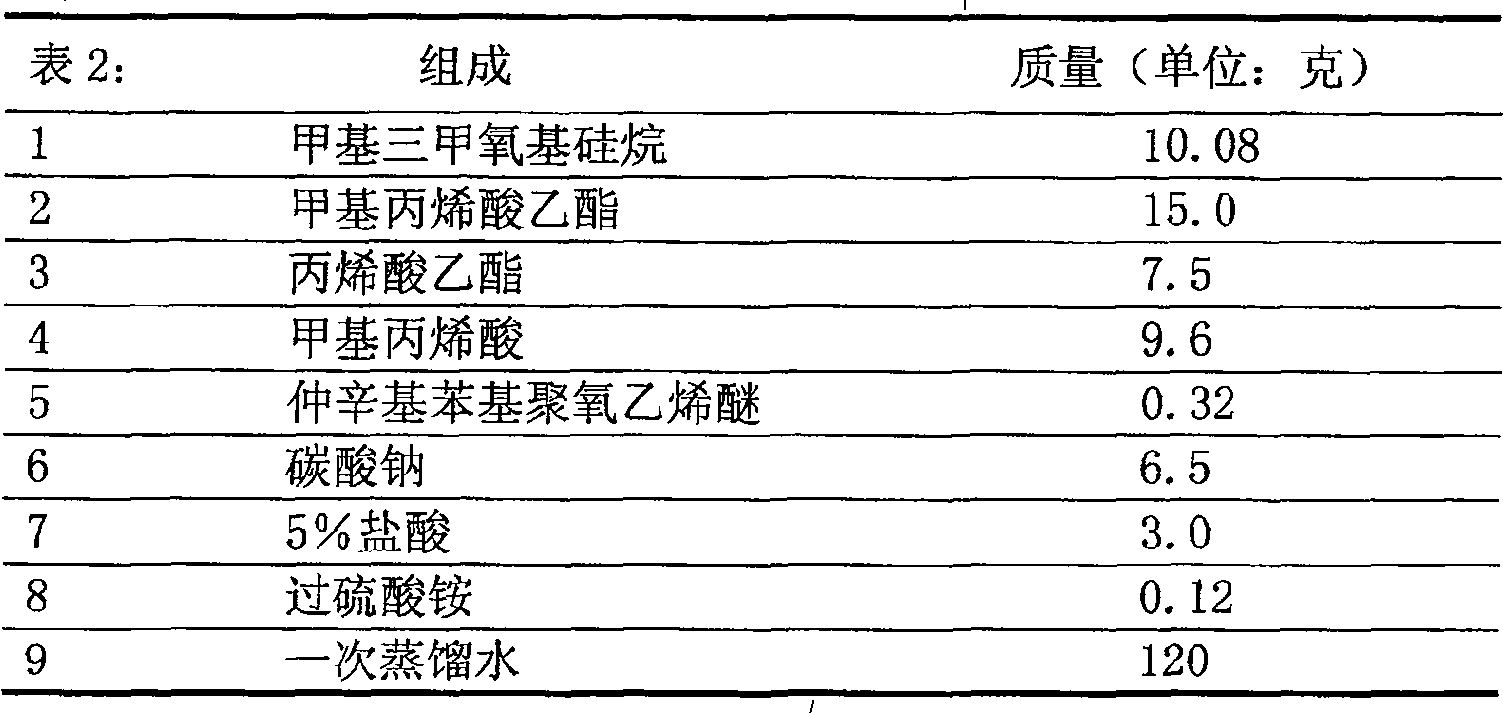

[0040] The organosiloxane adopts methyltrimethoxysilane, but the dosage is larger than [Example 1], and its composition is shown in Table 2.

[0041]

[0042] (1) Preparation of silicone resin: In a three-necked flask with a condensing device and a stirring device, add 3.0 grams of methyltrimethoxysilane, ethyl methacrylate, ethyl acrylate, methacrylic acid and 5% hydrochloric acid , and reacted at a temperature of 45°C for 10 hours to obtain a silicone resin acrylate solution.

[0043] (2) Pre-emulsification process: Dissolve OP-10 in 10 grams of water, add it to the acrylate solution of organosiloxane resin prepared in step (1), and stir at a high speed (1000r / min) at 50°C for 10 minutes to prepare Get a pre-emulsion. Sodium carbonate was dissolved in 102 grams of water, and was slowly added dropwise to the pre-emulsion with a constant pressure funnel, and the drop was completed in 0.5 hours. During the dropping process, high-speed stirring was maintained to prepare the ...

Embodiment 3

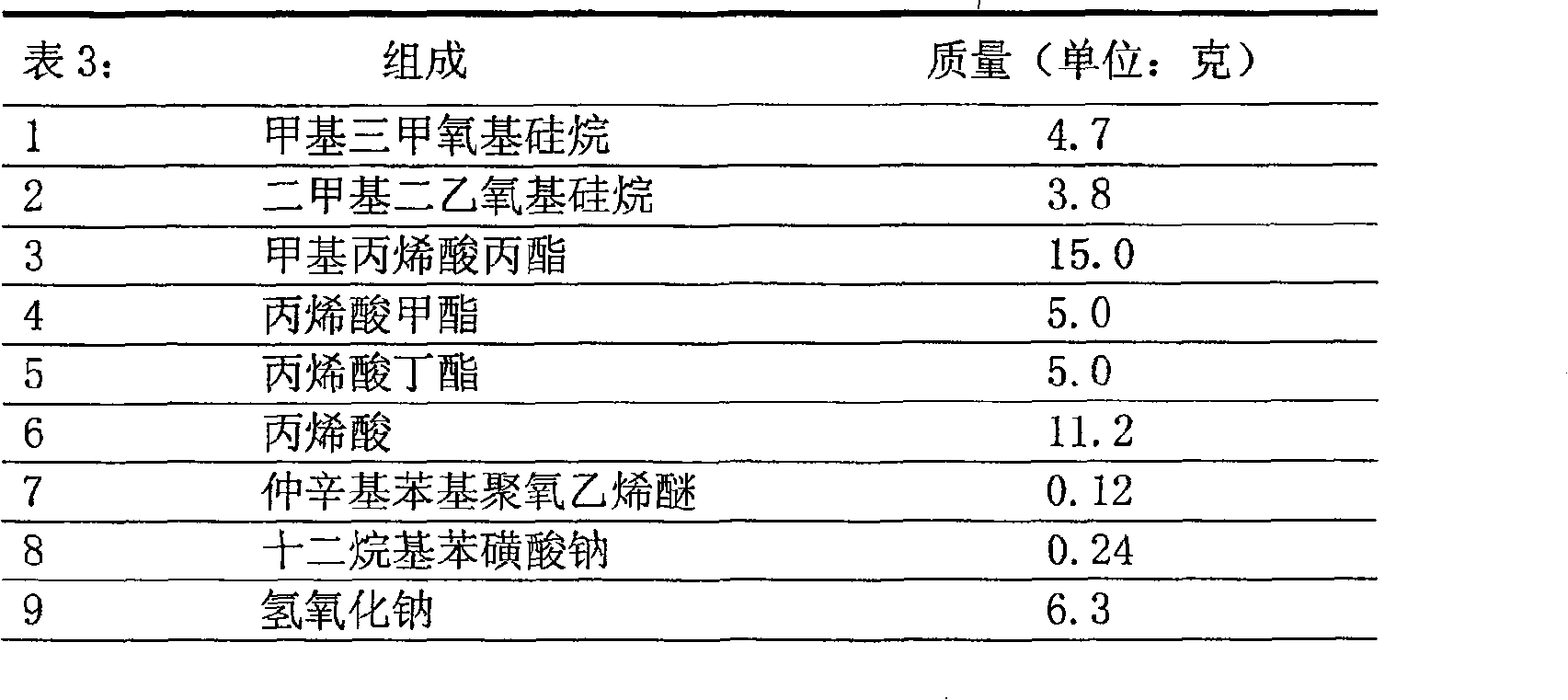

[0046] The organosiloxane is a mixture of methyltrimethoxysilane and dimethyldiethoxysilane. Its group distribution is shown in Table 3.

[0047]

[0048]

[0049] (1) Preparation of silicone resin: In a three-necked flask with a condensing device and a stirring device, add methyltrimethoxysilane, dimethyldiethoxysilane, propyl methacrylate, methyl acrylate, acrylic acid Butyl ester, acrylic acid and metered water (3.0 g) were reacted at a temperature of 45° C. for 10 hours to prepare a silicone resin acrylate solution.

[0050] (2) Pre-emulsification process: Dissolve OP-10 and sodium dodecylbenzene sulfonate in 12 grams of water, add to the acrylate solution of organosiloxane resin prepared in step (1), and heat at a high speed at 50°C Stir (1000r / min) for 30 minutes to prepare a pre-emulsion. Sodium hydroxide was dissolved in 97 grams of water, and slowly added dropwise to the pre-emulsion with a constant pressure funnel, and the dripping was completed in 0.5 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com