Method for realizing gallium nitride ELD vertical structure using metal bounding process

A technology of light-emitting diodes and metal bonding, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low product yield and difficulty in obtaining high-quality alloy layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

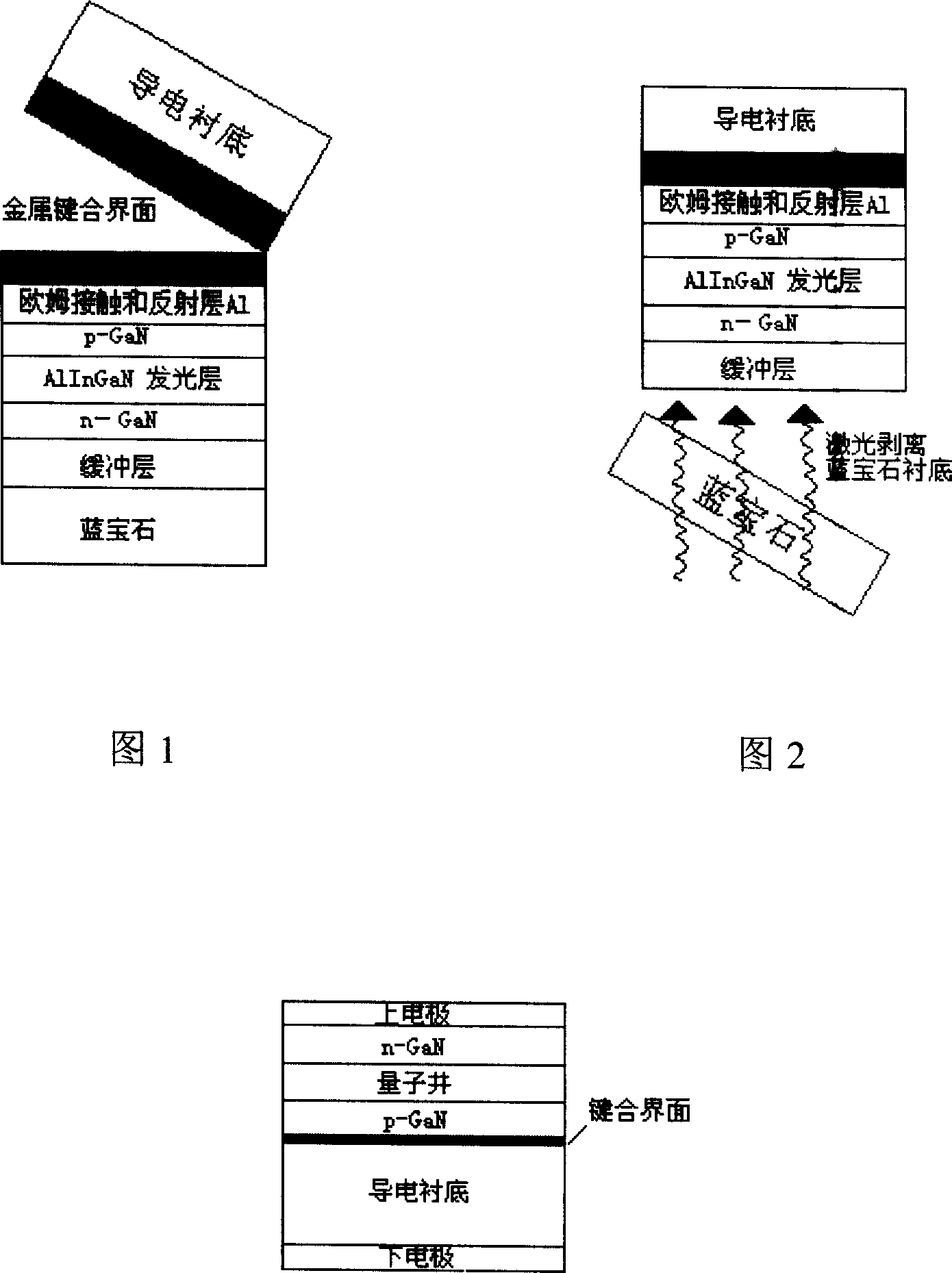

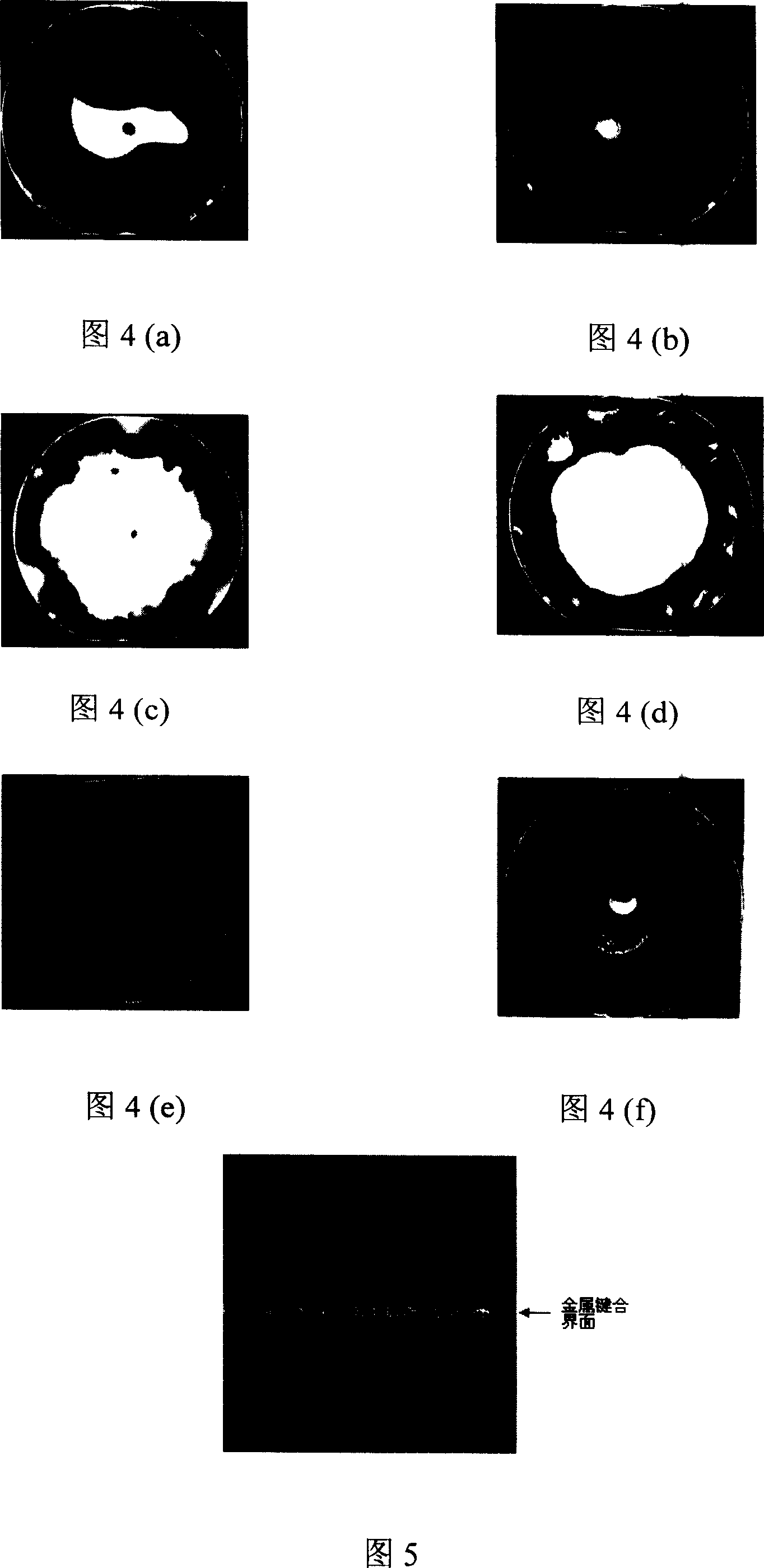

[0022] MOCVD sequentially epitaxy GaN buffer layer, n-type GaN, light-emitting quantum well layer (AlInGaN), p-type GaN on the sapphire substrate

[0023] 2. Thermally evaporate or sputter the metal layer Ni / Au / Al on the p-type gallium nitride layer as the ohmic contact and reflective layer, the thickness of Ni layer and Au layer is 100 Ȧ, and the thickness of Al layer is 1500 Ȧ.

[0024] 3. Thermal evaporation or sputtering of Cr / Au on the reflective layer and on the Si substrate as a bonding interface layer, and the Cr layer as an adhesion layer enables the Au layer to be closely connected to the silicon wafer and prevents the reaction between Au and the substrate Si. Generally, a silicon wafer with good surface flatness is used as the substrate, so that better bonding quality can be obtained when the Au layer is very thin. Generally, the thickness of the Au layer in Au-Au diffusion bonding is about 0.5μ (too thin or too thick metal layer will lead to a decrease in surface f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com