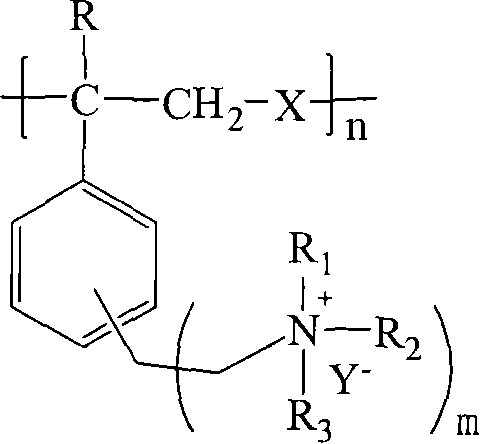

Styrene or substituted styrene polymer type quaternary ammonium salt antistat or bacterial agent and preparation method thereof

A technology of styrene polymers and styrene homopolymers, which is applied in botany equipment and methods, fungicides, biocides, etc., and can solve the problems of insufficient resin compatibility, high price, and insufficient resin coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

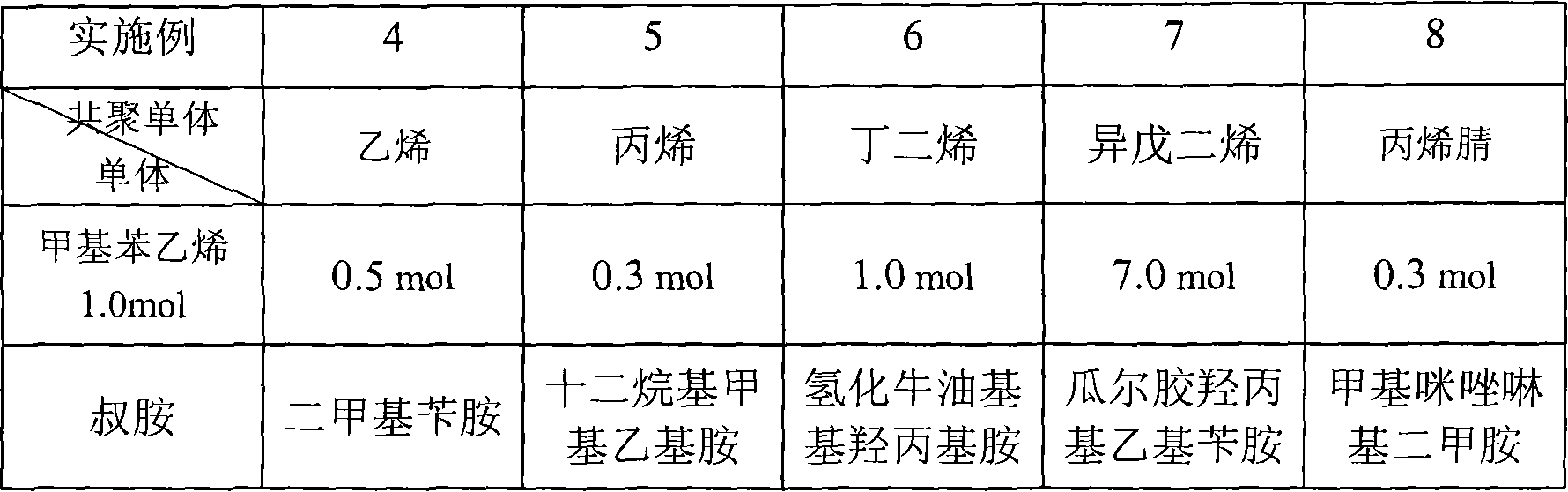

Examples

Embodiment 1

[0025] Embodiment 1, the preparation of poly α-methyl (-2 (4)-α-chloroethyl) styrene dimethyl cetyl ammonium linear polymer

[0026] Take a dry polymer tube, equipped with a single-hole rubber stopper, a dry short glass tube and a piece of dry rubber tube, connect it to an anhydrous and oxygen-free operating system, vacuumize, and fill with argon gas three times to remove the test tube. medium air. Then turn on the argon system, cool the polymerization tube to 0°C with an ice bath, and inject 9ml of anhydrous cyclohexane, 4.0g of dry α-methylstyrene and 5.4ml of n-butyl lithium ( 2.8M) solution, shake well, the solution turns orange red, after stirring for 30min, add a small amount of methanol to terminate the reaction, the color disappears immediately. The reaction solution was added dropwise to 30ml of methanol, and a white precipitate was formed immediately, which was filtered, washed with methanol and dried to obtain 3.7g of white poly-α-methylstyrene with a yield of 92%....

Embodiment 2

[0029] Embodiment 2, the preparation of poly-2(4)-chloroethylstyrene diethyldodecyl ammonium linear polymer

[0030] Add 650ml of dichloroethane to a 2L three-neck flask equipped with a stirrer, a separatory funnel with a calcium chloride drying tube, and a reflux condenser connected to an absorption gas device, and then add 36g of benzoyl peroxide while stirring and 200 g of styrene, heated to 60° C. for about 5 hours to obtain a polystyrene polymer solution. The temperature was lowered to 30° C., and 26 g of aluminum trichloride was added into the reaction flask. Then slowly feed 44g of ethylene oxide, and pass through in about 5 hours. 80ml of 5% dilute hydrochloric acid was added to the reaction mixture for hydrolysis, and after the water layer was separated, the organic layer was washed three times with a small amount of water and dried with anhydrous sodium sulfate. Add the dried organic phase into a 2L container with a stirring and hydrogen bromide gas absorbing devic...

Embodiment 3

[0031] Embodiment 3, the preparation of poly-alpha-ethyl (-2 (4)-chloroethyl) styrene-acrylonitrile trimethylammonium linear block copolymer

[0032] Take a dry polymer tube, match it with a single-hole rubber stopper, a short glass tube and a section of rubber tube, connect it to an anhydrous and anaerobic operating system, evacuate it, and fill it with argon three times to remove the air in the test tube. Then turn on the argon system, cool the polymerization tube to 5°C with an ice bath, inject 5ml of anhydrous cyclohexane, 1.5g of dry ethyl styrene and 1.5ml of n-butyl lithium (2.8M ) solution, shake well, the solution turns orange red, after stirring for 30 minutes, inject 1.0 g of dry acrylonitrile from the rubber tube with a syringe, stir for 15 minutes after the addition, and add a small amount of methanol to terminate the reaction. The color fades away instantly. The reaction liquid was added dropwise to 30ml of methanol, and a white precipitate was formed immediatel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com