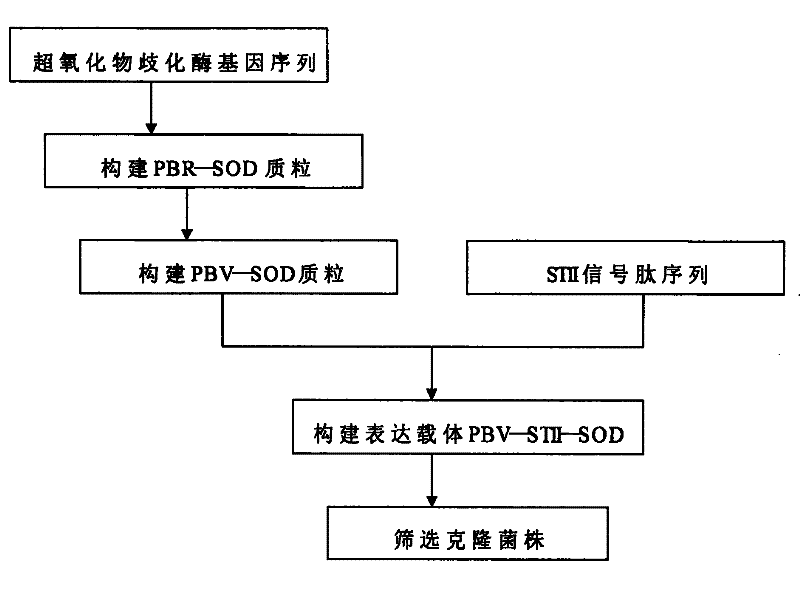

Technique for producing gene rHu(Cu/Zn-SOD) with one-step method

A technology of superoxide dismutase and gene recombination, applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of difficult industrial mass production, complicated extraction process, and limited source of raw materials, and achieve low unit cost and no cost. Effects of exogenous pollution and no virus residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] This method is implemented and applied in a 100L fermenter.

[0041] 1. Preparation of seed solution

[0042] 1) Take a frozen engineered bacteria (PBV / STII / SOD), use an inoculation loop to take a small amount of strains, draw a line on an LB plate, and culture at 30°C for 24 hours.

[0043] 2) Pick a single colony and inoculate it into an LB medium test tube (LB culture solution: 56g of peptone, 28g of yeast powder, 56g of NaCl, 5.6L of fixed solution) and sterilize it, then add a small amount of ampicillin, and put it in a constant temperature shaker for cultivation at 30°C. 170 rpm for 10-24 hours, OD 600 When it is 0.4-0.6, it is connected to the fermenter.

[0044] 2. Fermentation tank culture

[0045] 1) Fermentation broth adopts improved M 9 Medium (M 9 Preparation of medium: 800g peptone, 500g yeast powder, NaHPO 4 320g, KH 2 PO 4 110g, NaCl 100g, NH4Cl70g, MgSO 4 13.4g, CaCl 2 0.5g, CuSo 4 10g, ZnSo 4 0.5g, glucose 600g. )

[0046] 2) After the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com