Method for preparing nitrous oxides selectivity reduction catalyst on metal alloy carrier

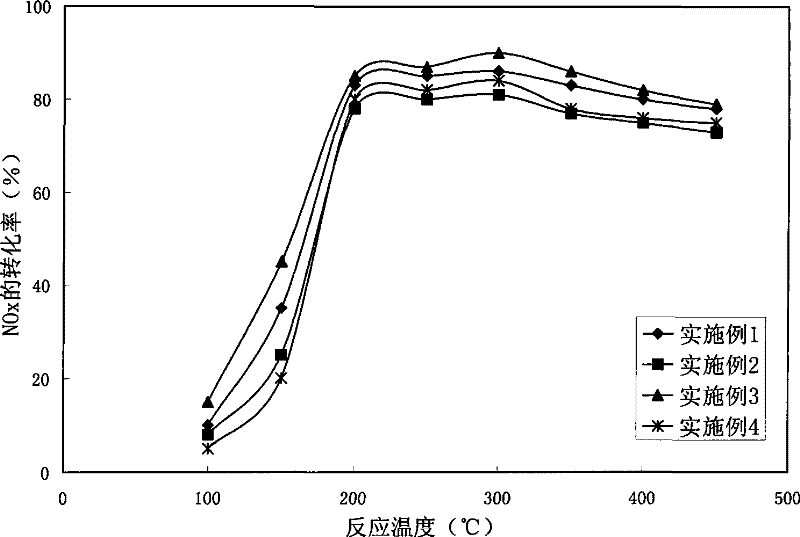

A metal alloy, nitrogen oxide technology, applied in the field of nitrogen oxide selective reduction catalyst, can solve the problems of high light-off temperature and poor purification effect, and achieve low light-off temperature, high conversion efficiency, high and low temperature light-off characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Mix ammonia water with a mass concentration of 25%, hydrogen peroxide with a mass concentration of 30%, and deionized water at a volume ratio of 1:2:6, completely immerse the metal alloy carrier in the mixed solution, ultrasonically clean for 1 hour, and then dry ; then the mass concentration is 35% hydrochloric acid, mass concentration is 30% hydrogen peroxide and deionized water are mixed in a volume ratio of 1: 2: 6, the carrier is completely immersed in the mixed solution, the pickling time is 5 minutes, and then Drying; immerse the pickled metal alloy carrier completely in deionized water, and ultrasonically clean it for 1 hour to remove residual acid ions on the surface, and then dry; finally, completely immerse the above metal alloy carrier in absolute ethanol, and ultrasonically clean 1 hour, then dry. Burn at 800°C for 2 hours and cool at room temperature.

[0040] The nitrates of each substance in the sol-gel solution and distilled water are prepared into a m...

Embodiment 2

[0043] Mix ammonia water with a mass concentration of 25%, hydrogen peroxide with a mass concentration of 30%, and deionized water at a volume ratio of 1:2:6, completely immerse the metal alloy carrier in the mixed solution, ultrasonically clean for 1 hour, and then dry ; then the mass concentration is 35% hydrochloric acid, mass concentration is 30% hydrogen peroxide and deionized water are mixed in a volume ratio of 1: 2: 6, the carrier is completely immersed in the mixed solution, the pickling time is 5 minutes, and then Drying; immerse the pickled metal alloy carrier completely in deionized water, and ultrasonically clean it for 1 hour to remove residual acid ions on the surface, and then dry; finally, completely immerse the above metal alloy carrier in absolute ethanol, and ultrasonically clean 1 hour, then dry. Burn at 900°C for 2 hours and cool at room temperature.

[0044] The nitrates of each substance in the sol-gel solution and distilled water are prepared into a m...

Embodiment 3

[0047] Mix ammonia water with a mass concentration of 25%, hydrogen peroxide with a mass concentration of 30%, and deionized water at a volume ratio of 1:2:6, completely immerse the metal alloy carrier in the mixed solution, ultrasonically clean for 1 hour, and then dry ; then the mass concentration is 35% hydrochloric acid, mass concentration is 30% hydrogen peroxide and deionized water are mixed in a volume ratio of 1: 2: 6, the carrier is completely immersed in the mixed solution, the pickling time is 5 minutes, and then Drying; immerse the pickled metal alloy carrier completely in deionized water, and ultrasonically clean it for 1 hour to remove residual acid ions on the surface, and then dry; finally, completely immerse the above metal alloy carrier in absolute ethanol, and ultrasonically clean 1 hour, then dry. Burn at 900°C for 1 hour and cool at room temperature.

[0048] The nitrates of each substance in the sol-gel solution and distilled water are prepared into a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com