System for purifying flue gas and recovering sulfur and technique

A technology for flue gas purification and sulfur recovery, which is applied in the fields of chemical process technology and equipment, air purification and environmental protection equipment, and can solve the problem of limited height, large-scale and flue gas processing capacity, centripetal motion, centrifugal motion is not clear, heat energy recovery and utilization Incomplete functions, etc., to achieve the effect of integrated utilization and recovery of thermal energy, stable and fast transportation, and saving equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

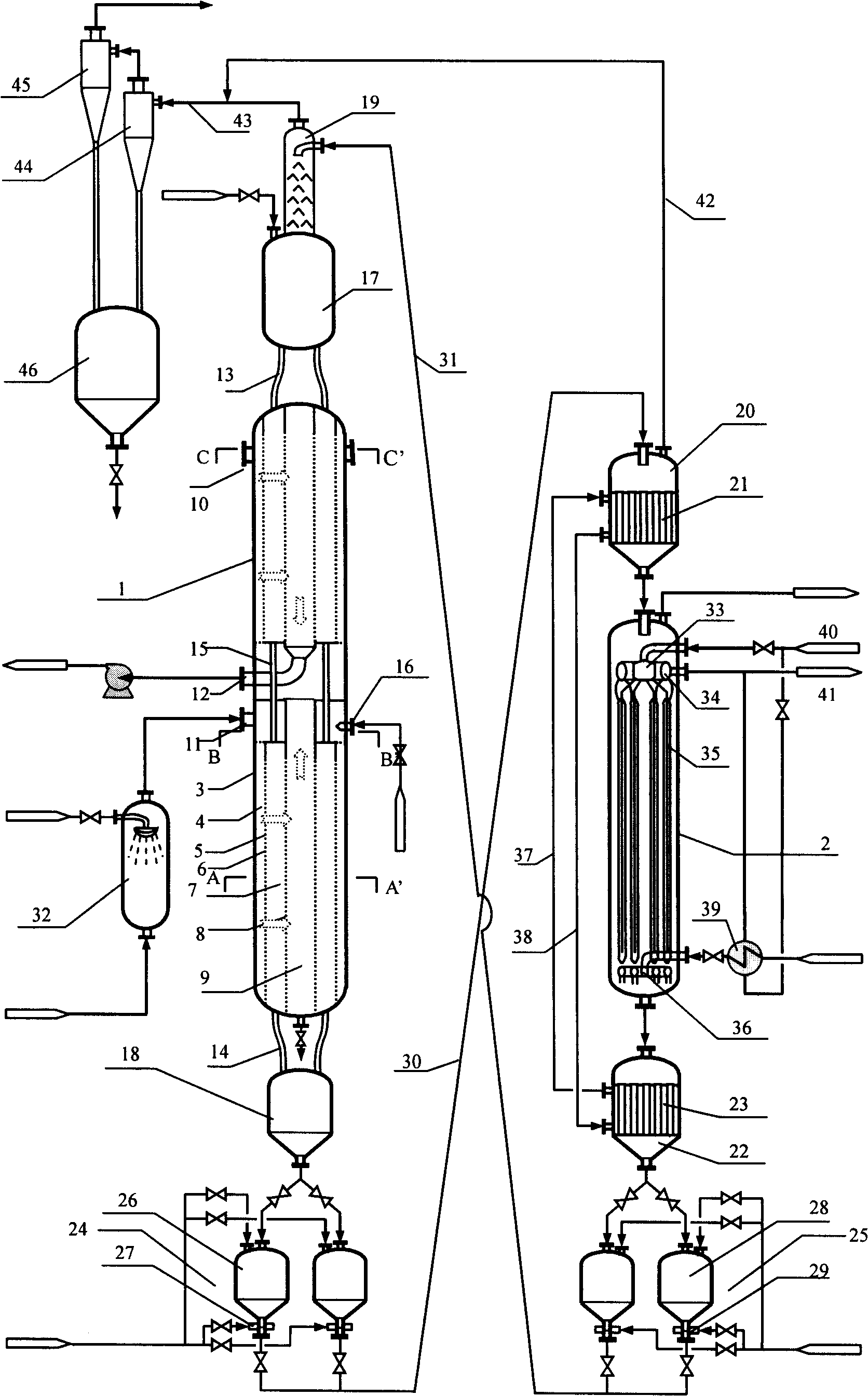

[0064] (10) Example 1: SO 2 Removal and purification and sulfur recovery

[0065] In this example, the flue gas purification and sulfur recovery system is designed to be used on a single-unit 600MW supercritical coal-fired unit in a coal-fired power plant. The flue gas volume of the coal-fired unit is 1.8×10 6 m 3 / h, the designed flue gas volume is 2.0×10 6 m 3 / h, single adsorber 1 treatment, design flue gas space velocity 1000h -1 . SO in flue gas components 2 The content is 1000-4000ppm, NO x The content is 200-800ppm, the adsorption temperature is 120-150°C, and the desorption temperature is 350-450°C; the adsorbent used is ZL50 columnar desulfurization and denitrification activated carbon with a diameter of 5mm produced by Shanxi Xinhua Environmental Protection (Chemical) Co., Ltd., or a 10mm diameter activated carbon ZL100 columnar desulfurization and denitrification activated carbon. The upper and lower sections of the single adsorber 1 are equivalent to the tr...

Embodiment 2

[0068] (11) Example 2: Broad-spectrum purification of sulfur and nitrogen double depletion and sulfur recovery

[0069] In this example, the flue gas purification and sulfur recovery system is designed to be used on a single-unit 600MW supercritical coal-fired unit in a coal-fired power plant. The flue gas volume of the coal-fired unit is 1.8×10 6 m 3 / h, the designed flue gas volume is 2.0×10 6 m 3 / h, single adsorber 1 treatment, SO in flue gas components 2 The content is 1000-4000ppm, NO xThe content is 200-800ppm, CO 2 The gas content is about 13%, and it also contains some toxic heavy metal ions such as mercury and cadmium, which are harmful smoke and dust. Design two working conditions: Working condition 1 is flue gas air velocity 1000h -1 At this time, the adsorption temperature, desorption temperature, design parameters and activated carbon loading are the same as in Example 1; working condition 2 is flue gas space velocity 500h -1 , At this time, the adsorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com