Spherical ordered mesoporous silicon oxide substrate chromatograph stationary phase and preparation

A technology of mesoporous silica and chromatographic stationary phase, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of narrow particle size distribution, increased mass transfer resistance, disordered arrangement, etc., and achieve uniform particle size distribution, high The effect of specific surface area and orderly arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Synthesis of spherical mesoporous silica matrix

[0030] Dissolve 5.0g of P123 and 4.51g of KCl in 120ml of water, then add 13.3ml of sulfuric acid, stir the solution for 30min, add 4.32g of TMB, stir vigorously for 30min, add 8.90g of TEOS dropwise, stir vigorously for 30min, then turn to Put it into a polytetrafluoroethylene bottle and let it stand at 308K for 24h, then transfer to 373K for aging for 48h. The solid product was filtered and washed successively with deionized water, methanol, acetone, and water, and air-dried at room temperature. After air-drying, the product was heated at 873K (the heating rate was 1Kmin -1 ) calcined for 8 hours (cooling rate 10Kmin -1 ) to obtain a mesoporous silica matrix.

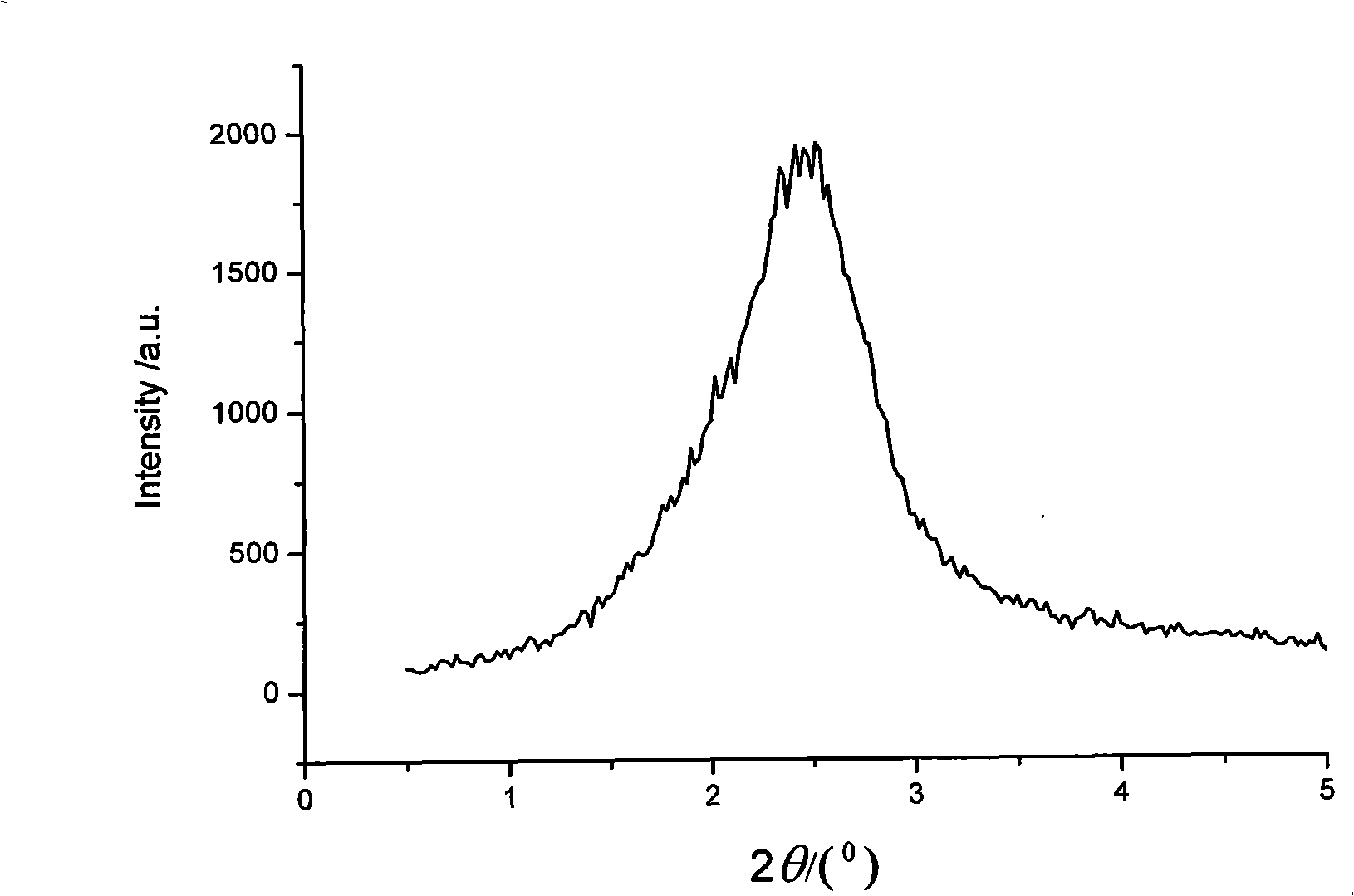

[0031] The specific surface area of the obtained sample measured by the ASAP2020 specific surface pore size measuring instrument is 582.99m 2 / g, the X-ray diffraction pattern of the obtained sample is shown in figure 1 .

[0032] 2) Synthesis of bond...

Embodiment 2

[0035] 1) Synthesis of spherical mesoporous silica matrix

[0036] Dissolve 4.0g of P123 and 3.04g of KCl in 120ml of water, then add 20ml of hydrochloric acid, stir the solution for 30min, add 3.0g of TMB, stir vigorously for 30min, add 8.5g of TEOS dropwise, stir vigorously for 30min, then turn to Put it into a polytetrafluoroethylene bottle and let it stand at 308K for 24h, then transfer to 373K for aging for 24h. The solid product was filtered and washed successively with deionized water, methanol, acetone, and water, and air-dried at room temperature. After air-drying, the product was heated at 823K (the heating rate was 1Kmin -1 ) calcined for 6 hours (cooling rate 10Kmin -1 ) to obtain a mesoporous silica matrix.

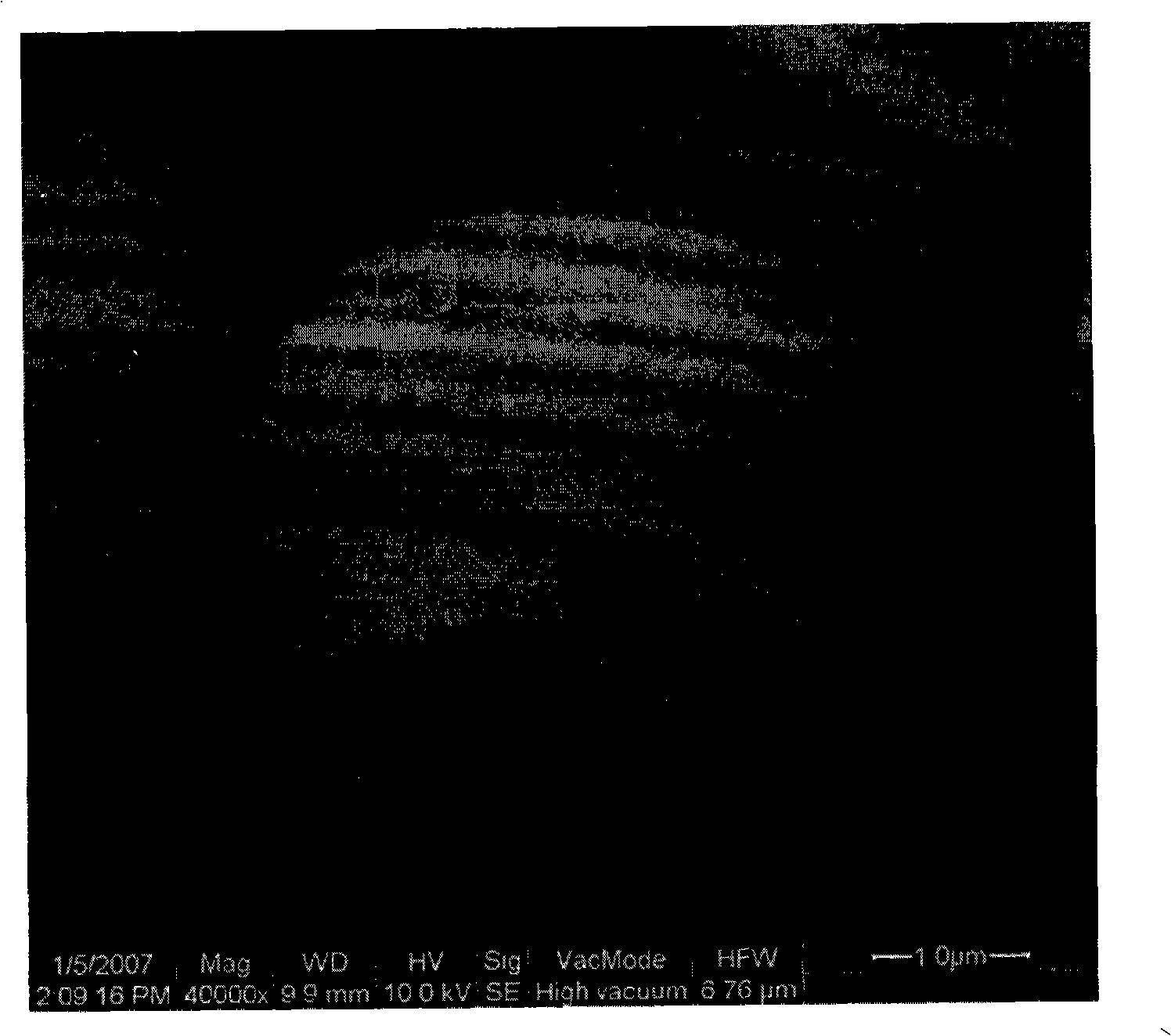

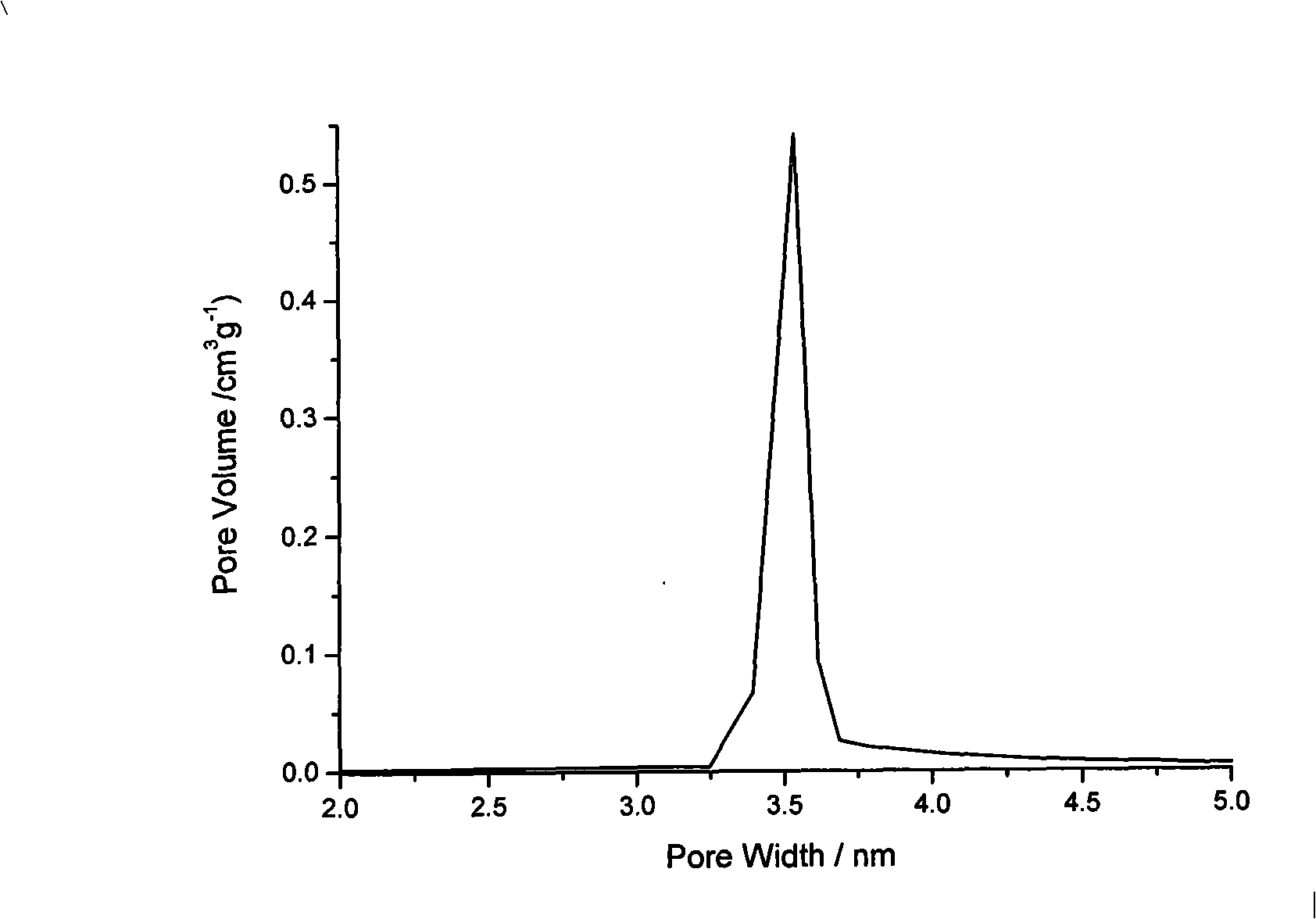

[0037] The scanning electron microscope and pore size distribution diagram of the obtained sample are shown in figure 2 and image 3 .

[0038] 2) Synthesis of bonded stationary phase

[0039]Weigh 3.0 g of β-cyclodextrin, recrystallize three times wi...

Embodiment 3

[0041] 1) Synthesis of spherical mesoporous silica matrix

[0042] Dissolve 10g of P123 and 6.02g of KCl in 150ml of water, add 20ml of hydrochloric acid, when the solution is stirred and clarified, add 5.5g of 1,3,5-trimethylbenzene (TMB), stir vigorously for 30 minutes, then add dropwise Tetraethyl orthosilicate 8.5g, then vigorously stirred for 30 minutes, then transferred to a polytetrafluoroethylene bottle at 308K for 24 to 48 hours, and then transferred to 373K for aging for 24 hours. The solid product was filtered and washed successively with deionized water, methanol, acetone, and water, and air-dried at room temperature. After air-drying, the product was calcined at 873K for 8 hours to obtain a spherical mesoporous silica matrix product.

[0043] The specific surface area of the obtained sample measured by the ASAP2020 specific surface pore size tester is 815.82m 2 / g, the pore size distribution diagram of the obtained sample is shown in Figure 4

[0044] 2) Sy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com