Method for preparing alpha-alkamine using alpha-aminoacid as raw material and used catalyst and preparation of catalyst

A catalyst, amino alcohol technology, applied in the preparation of organic compounds, preparation of amino hydroxyl compounds, catalysts for physical/chemical processes, etc., can solve the problems of low single-pass conversion rate, long production cycle, long reaction time, etc., to shorten the reaction time. The steps, the production process are simple, and the raw material utilization rate is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

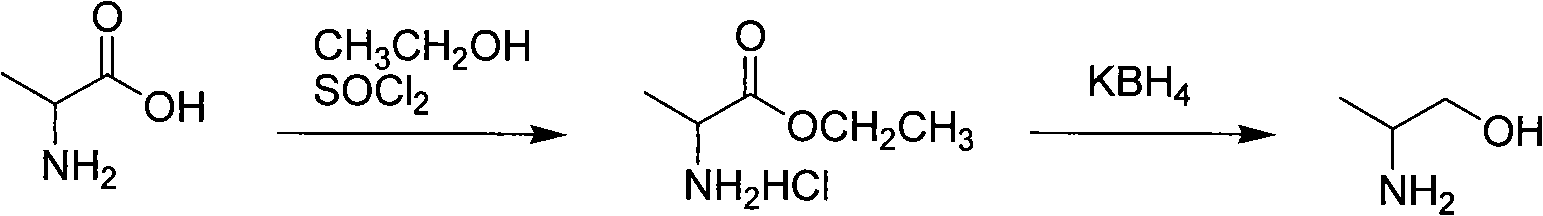

[0042] 100 grams of commercially available high-strength coconut shell activated carbon was heated at 80° C. for 3 hours with 2000 milliliters of 10% nitric acid solution, and filtered to obtain filter cake 1. The filter cake 1 was added to 2000 ml of 10% aqueous sodium hydroxide solution, stirred and washed, and filtered to obtain the filter cake 2. Filter cake 2 was added to 2000 ml of 10% nitric acid solution, stirred and washed, and filtered to obtain filter cake 3. The filter cake 3 is washed with deionized water until the effluent is free of nitrate. Take 0.6 g of CuCl 2 and 1 g FeCl 2 ·6H 2 O, dissolve with 10 ml of 31% hydrochloric acid and 2000 ml of water, under stirring, disperse the aforementioned pretreated activated carbon evenly in it to obtain a suspension, keep stirring at 80°C for 4 hours, and evaporate the suspension at 100-150°C to dryness, and then calcined at 450°C to obtain a modified carrier. 8.2 g RuCl 3 and 1.67 g PdCl 2 Dissolve with 40 millil...

Embodiment 2

[0044] In a 1-liter autoclave, put 500ml of water, 60 grams of DL-2-alanine, and 1 gram of the catalyst prepared in Example 1, start stirring, adjust the pH of the solution to 3.5, replace hydrogen twice, and pass hydrogen to 160°C, pressure 6MPa, keep for 8 hours, during the process, hydrogen is fed intermittently, keep the pressure at 6MPa. After the reaction was completed, filter, and use the filter cake (catalyst) mechanically; the filtrate was distilled and separated to obtain 42.0 g of DL-2-aminopropanol, with a GC analysis content of 99.8% and a product yield of 83.1%.

Embodiment 3

[0046] In a 1-liter autoclave, put 500ml of water, 60 grams of DL-2-alanine, and 1 gram of the catalyst prepared in Example 1, adjust the pH of the solution to 4.5, start stirring, replace hydrogen twice, and pass hydrogen to 170°C, pressure 7MPa, keep it for 8 hours, during the process, hydrogen gas is fed intermittently, keep the pressure at 7MPa. After the reaction was completed, filter, and use the filter cake (catalyst) mechanically; the filtrate was distilled and separated to obtain 43.0 g of DL-2-aminopropanol, with a GC analysis content of 99.6% and a product yield of 85.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com