Preparation method for three-dimensional ordered foramen magnum titanium oxygen 'lithium ion screen'

A three-dimensional ordered, lithium-ion technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of failure and low adsorption capacity, and achieve the effect of strengthening internal diffusion capacity, high adsorption capacity and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment:

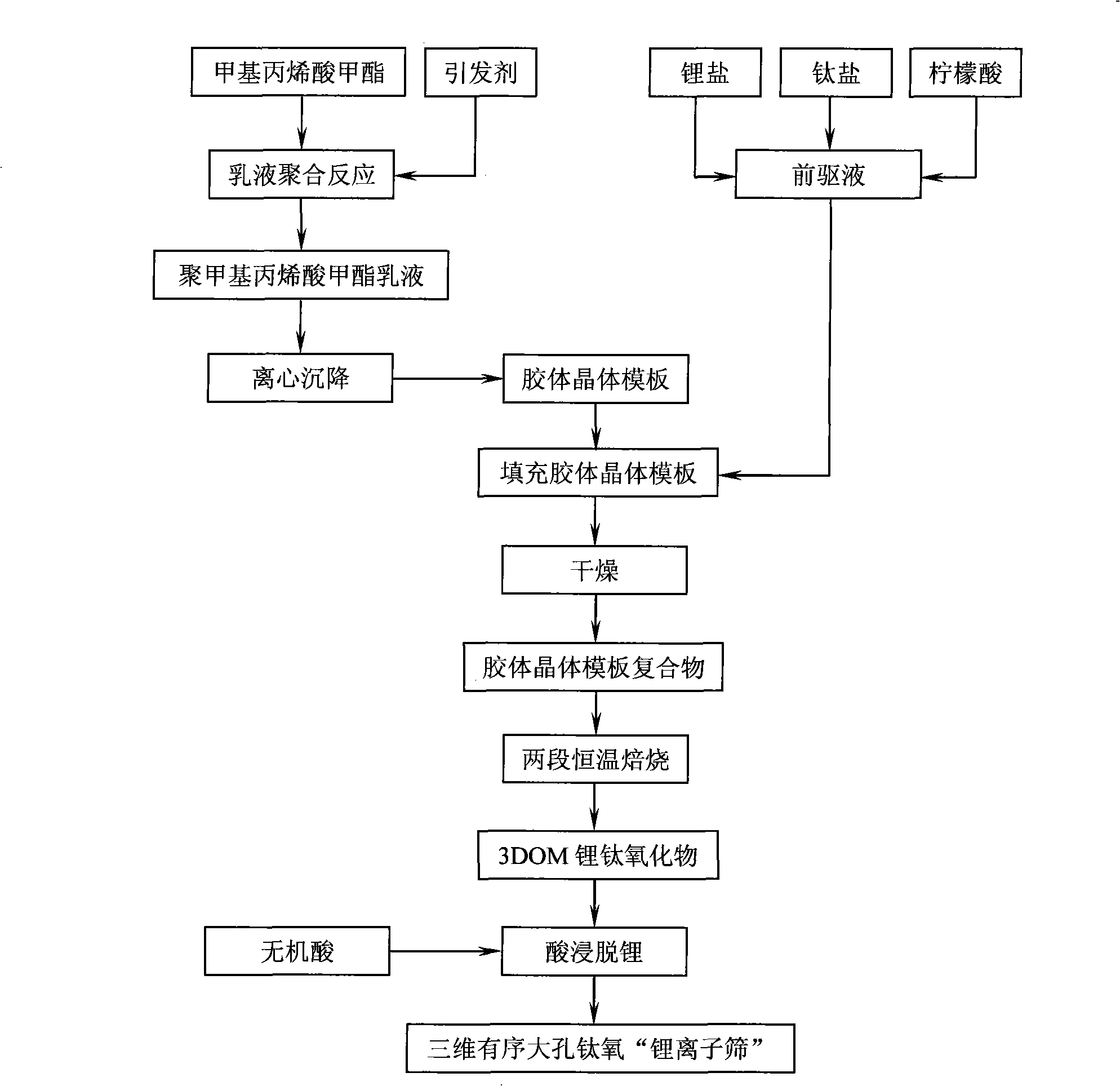

[0017] The flow chart of the preparation process of three-dimensional ordered macroporous titania "lithium ion sieve" is as follows figure 1 shown.

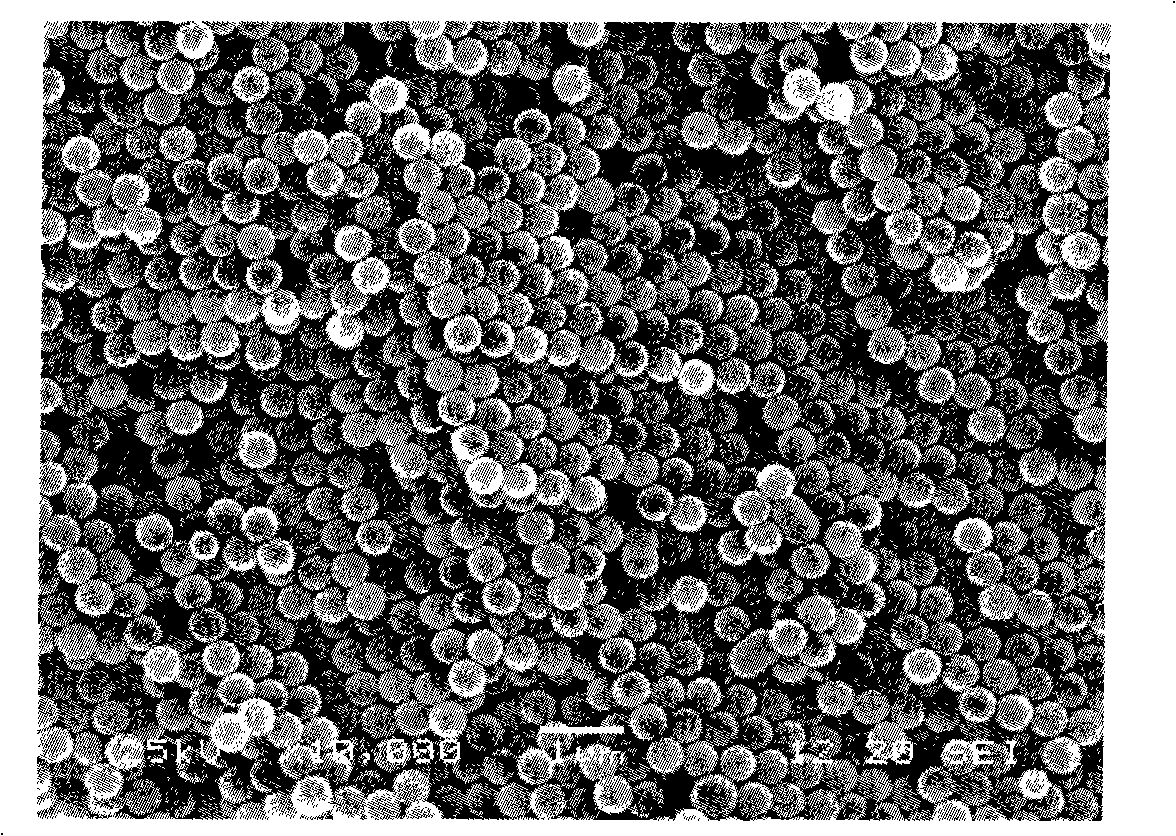

[0018] Add methyl methacrylate and distilled water into a three-necked flask at a volume ratio of 1:10, and add K at 70°C and a stirring speed of 300r / min 2 S 2 o 8 The in situ polymerization reaction of the initiator lasted for 2 hours; the directional arrangement of the microemulsion spheres was realized by the centrifugal sedimentation method, and the colloidal crystal template was obtained, such as figure 2 Shown; Accurately weigh analytically pure lithium acetate (CH 3 COOLi·2H 2 O) 2.0056g, oxalic acid (H 2 C 2 o 4 2H 2 O) 5.7406g, citric acid (C 6 h 8 o 7 ·H 2 O) 2.3934g, accurately measure 2.2780mol / L titanium dioxychloride (TiOCl 2 ) solution 10.00ml, concentrated ammonia water (NH 3 ·H 2 (0) 8.60ml, made into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com