Metal master mold for electroforming and use thereof

A metal and master mold technology, applied in electroforming, electrolysis process, etc., can solve problems such as waste, environmental pollution, violent reaction, etc., and achieve the effect of easy removal and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

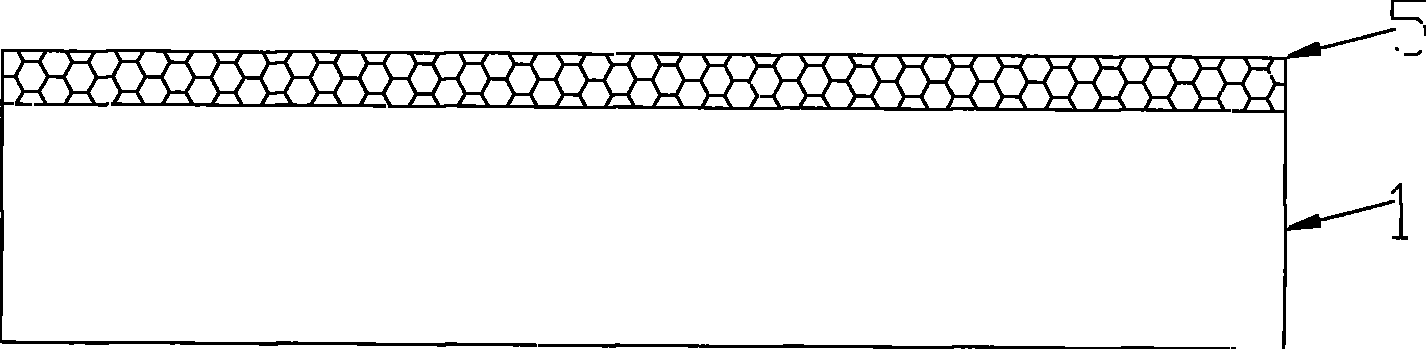

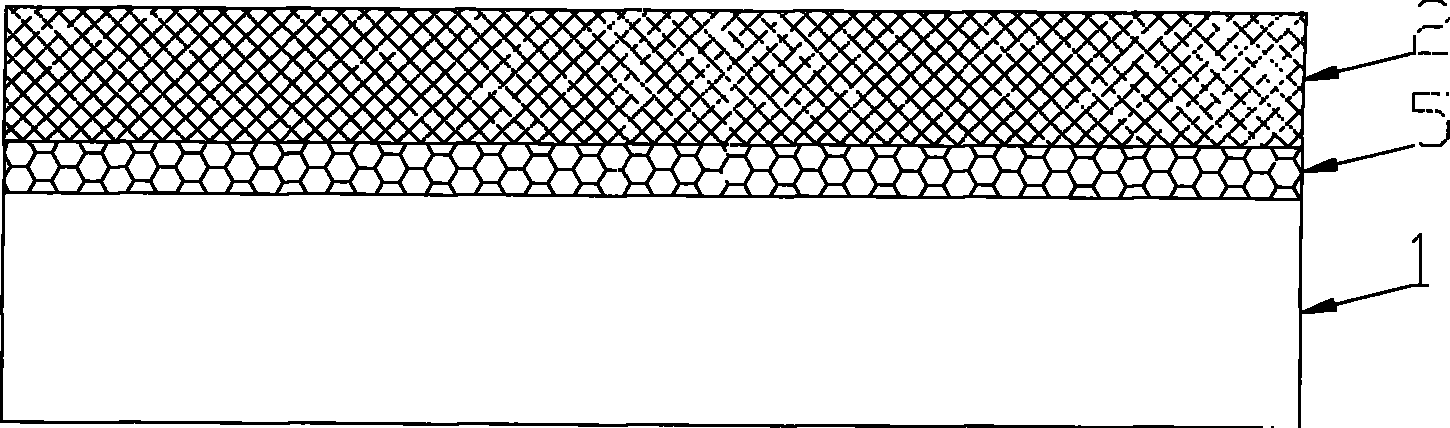

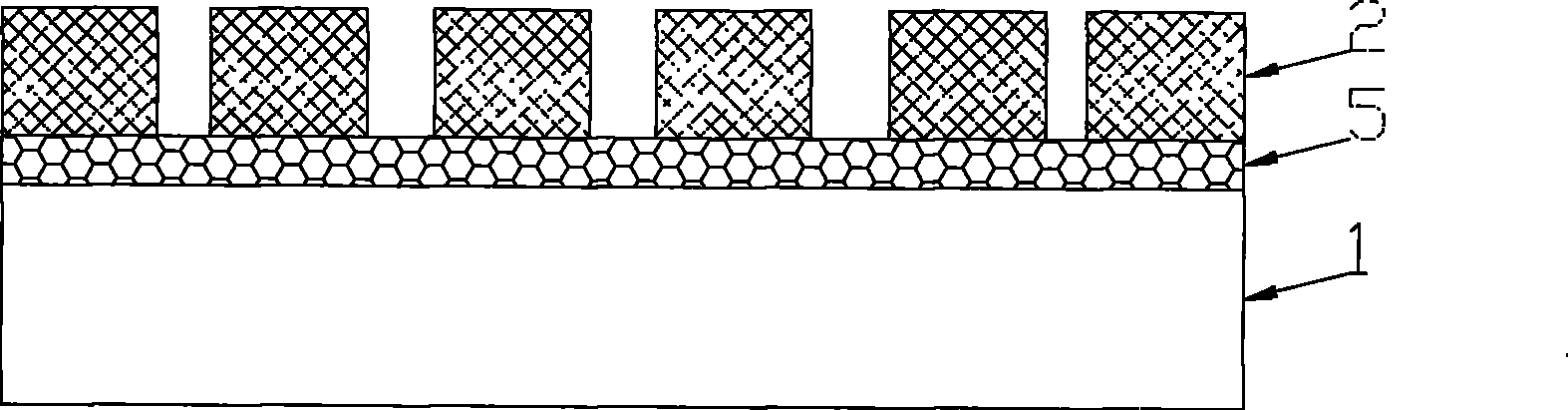

[0039] Example 1. Preparation of a metal master mold for electroforming of a metal hot-pressing mold for a microfluidic chip

[0040] 1. Making a low melting point metal layer

[0041]Deposit 100 on the single crystal silicon wafer 1 Thick titanium, the titanium layer is used as an adhesion layer, and the preparation method is as follows: use a DZS-500 electron beam evaporation coating machine to evaporate 100 For thick titanium, the set parameters are: vacuum degree 9×10 -5 Pa, filament voltage 73V, filament current 0.55A, beam current 53mA; then make a metal indium layer with a thickness of 2 microns, and the indium layer is used as the low melting point metal layer 5 to form figure 1 The structure shown, the metal indium layer preparation method is as follows: using DZS-500 electron beam evaporation coating machine, 100 Metal indium is evaporated on the thick titanium layer, and the set parameters are: vacuum degree 9×10 -5 Pa, filament voltage 80V, filament current ...

Embodiment 2

[0055] Example 2, Preparation of a metal master mold for electroforming of a metal hot-press mold for a microfluidic chip

[0056] 1. Making a low melting point metal layer

[0057] Deposit 100 on the single crystal silicon wafer 1 Thick titanium, the titanium layer is used as an adhesion layer, and the preparation method is as follows: use a DZS-500 electron beam evaporation coating machine to evaporate 100 For thick titanium, the set parameters are: vacuum degree 9×10 -5 Pa, filament voltage 73V, filament current 0.55A, beam current 53mA; then make a metal indium layer with a thickness of 2 microns, and the indium layer is used as the low melting point metal layer 5 to form figure 1 The structure shown, the metal indium layer preparation method is as follows: using DZS-500 electron beam evaporation coating machine, 100 Metal indium is evaporated on the thick titanium layer, and the set parameters are: vacuum degree 9×10 -5 Pa, filament voltage 80V, filament current 0....

Embodiment 3

[0078] Example 3. Preparation of a metal master mold for electroforming of a metal hot-pressing mold for a microfluidic chip

[0079] 1. Making the organic thin film layer

[0080] Put the monocrystalline silicon wafer on the coating machine, and spin-coat BN303 cyclized rubber negative photoresist produced by Beijing Institute of Chemical Reagents, at a speed of 3000rpm, for 30 seconds, and spin-coat to produce a cyclized rubber negative photoresist with a thickness of 1 micron. Resist layer 6, forming Figure 14 structure shown.

[0081] 2. Making a low melting point metal layer

[0082] in having Figure 14 100 Thick titanium, the titanium layer is used as an adhesion layer, and the preparation method of the titanium layer is as follows: use a DZS-500 electron beam evaporation coating machine to evaporate 100 For thick titanium, the set parameters are: vacuum degree 9×10 -5 Pa, filament voltage 73V, filament current 0.55A, beam current 53mA; then make a metal indium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com