Soy protein / emulsion polymerization high polymer nano composite material, and preparation and use thereof

A nanocomposite material and soybean protein technology, applied in the field of polymers and nanomaterials, can solve the problems of difficult biodegradation, poor biocompatibility, and increased cost, and achieve good mechanical properties, enhanced environmental protection, enhanced water resistance and The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Soybean protein isolate is pre-dissolved in water to obtain a 35% soybean protein aqueous solution by weight. After stirring for 10 minutes, add styrene and emulsifier sodium lauryl sulfate to control the weight ratio of styrene and sodium lauryl sulfate It is 9:1. After stirring at high speed for 40 minutes, the temperature was raised to 90°C to form a well-dispersed emulsion. Then, add potassium persulfate to the emulsion, the initiator is 8.5‰ of the weight of styrene monomer, react at 90°C for 4 hours, cool the emulsion at room temperature, pour it into a glass container after vacuum defoaming, and dry it in vacuum After casting at 50° C. in the box for 24 hours, a transparent protein and polystyrene composite nanoplastic was obtained.

Embodiment 2

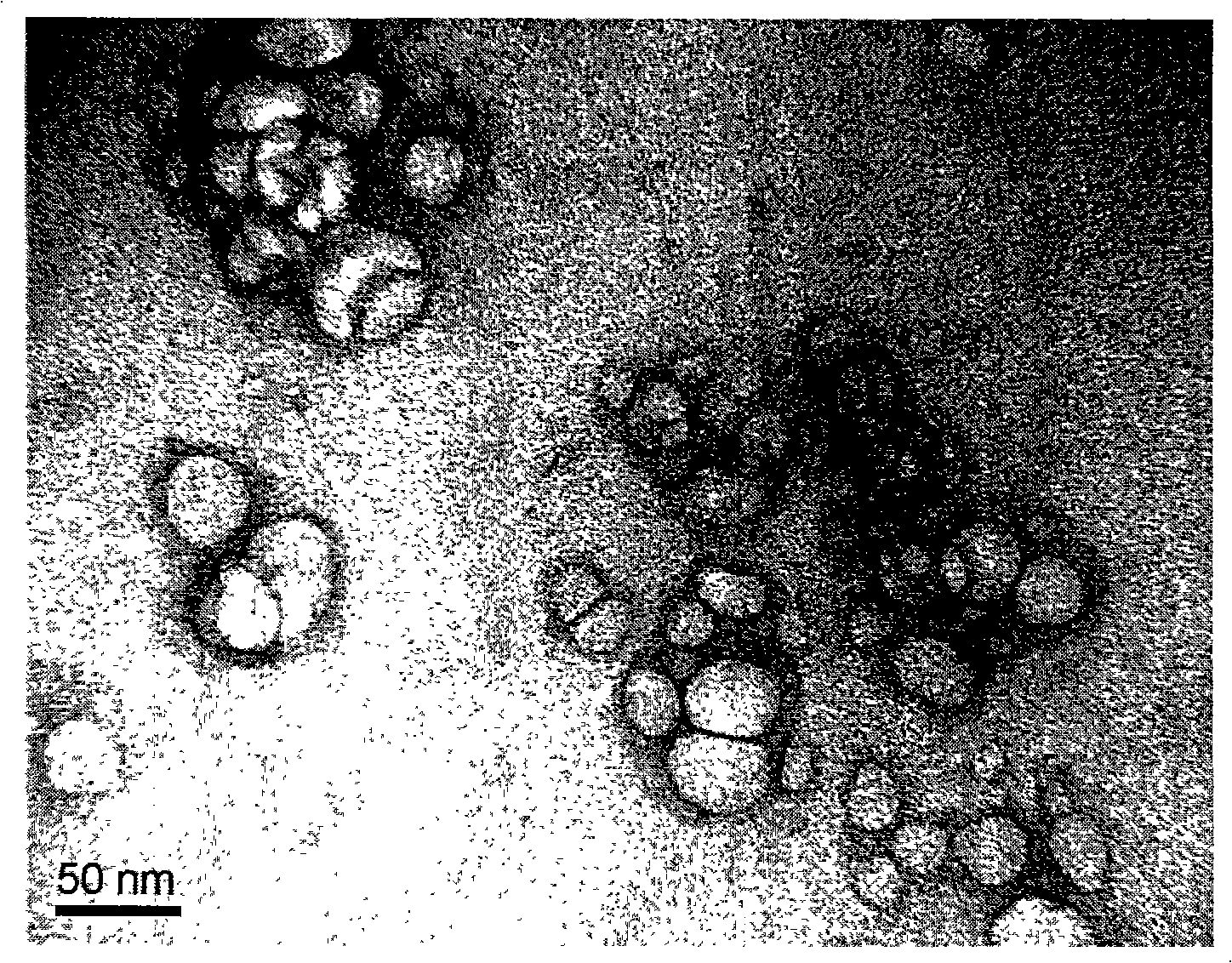

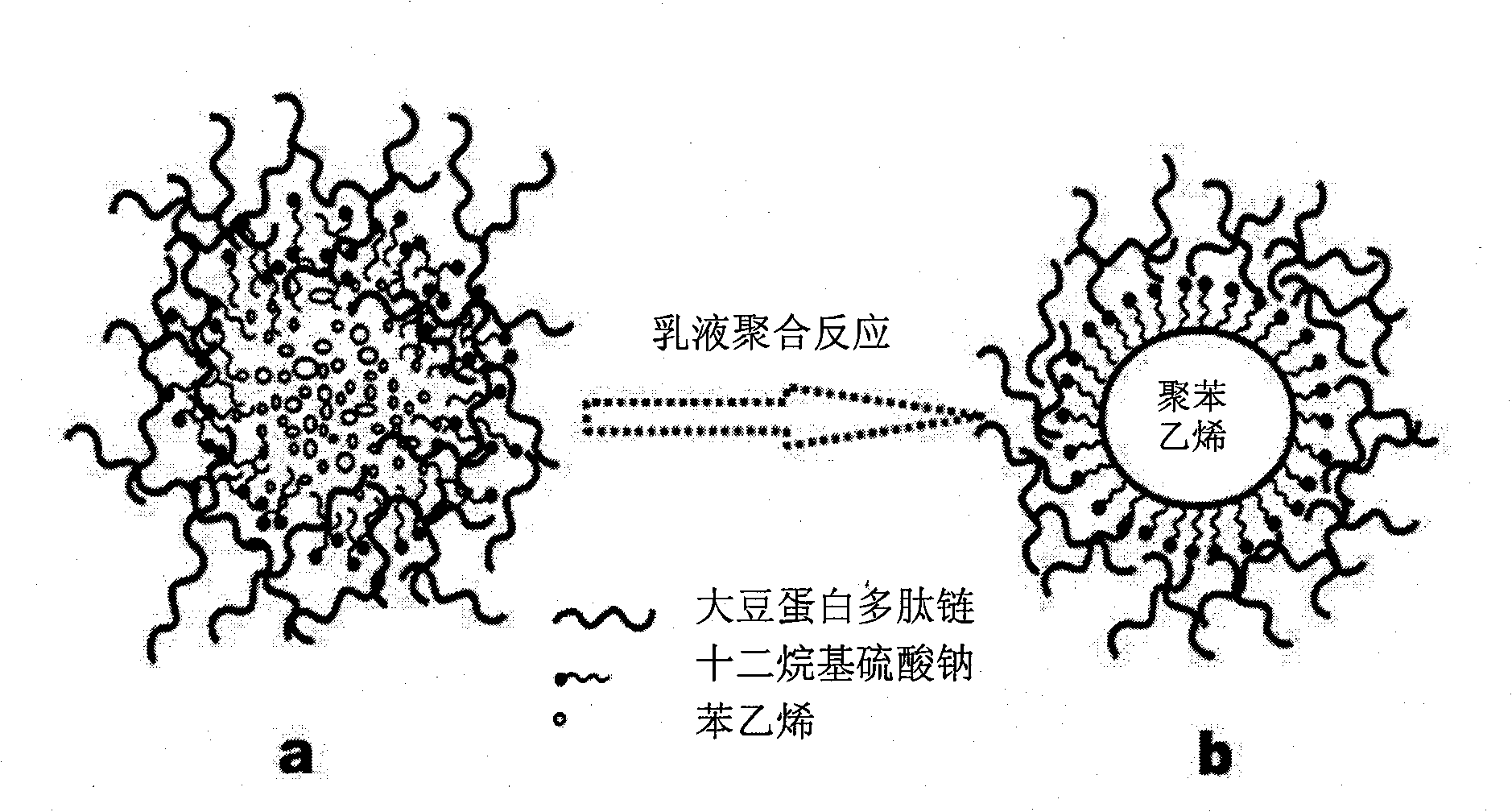

[0044] Soybean protein is pre-dissolved in water to obtain a 50% soybean protein aqueous solution by weight. After stirring for 40 minutes, add styrene and emulsifier sodium dodecylbenzenesulfonate to control the concentration of styrene and dodecylbenzenesulfonate. The sodium weight ratio is 4:1. After stirring at high speed for 50 minutes, the temperature was raised to 50°C to form a well-dispersed emulsion. Then, add sodium persulfate to the emulsion, the initiator is 5.5‰ of the weight of styrene monomer, react at 60°C for 10 hours, cool the emulsion at room temperature, pour it into a glass container after vacuum defoaming, and dry it in vacuum After casting at 80°C in the box for 48 hours, a transparent protein and polystyrene composite nanoplastic was obtained, and its scanning electron microscope photo is as follows: figure 1 As shown, the transmission electron microscope pictures are shown as figure 2 shown. Its formation diagram see image 3 .

Embodiment 3

[0046] Soybean protein is pre-dissolved in water to obtain a 16% by weight soybean protein aqueous solution. After stirring for 30 minutes, styrene and emulsifier sodium laurate are added to control the weight ratio of styrene and sodium laurate to 8:1. After stirring at high speed for 1 hour, the temperature was raised to 70° C., and after stirring was continued for 50 minutes, a well-dispersed emulsion was formed. Then, potassium persulfate was added to the emulsion, the initiator was 6.5‰ of the weight of styrene monomer, and after reacting at 70°C for 10 hours, the emulsion was cooled at room temperature, vacuum defoamed, and the protein / polystyrene mixed emulsion was concentrated to 90% of the solid content is put into a single-screw extruder for extrusion molding, and the temperature of the segments of the screw is adjusted to 80° C., 120° C., and 150° C. to obtain nanocomposite plastics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com