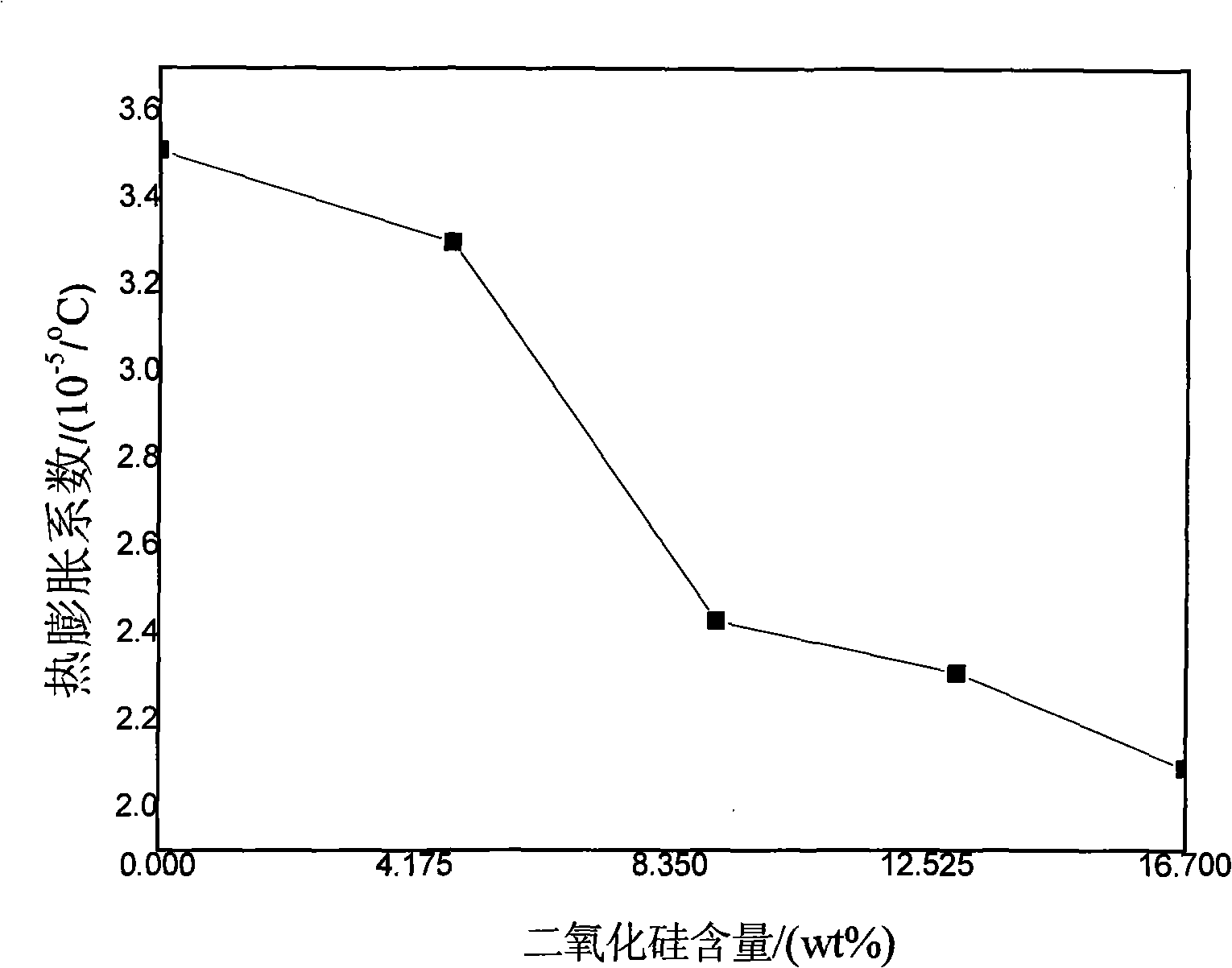

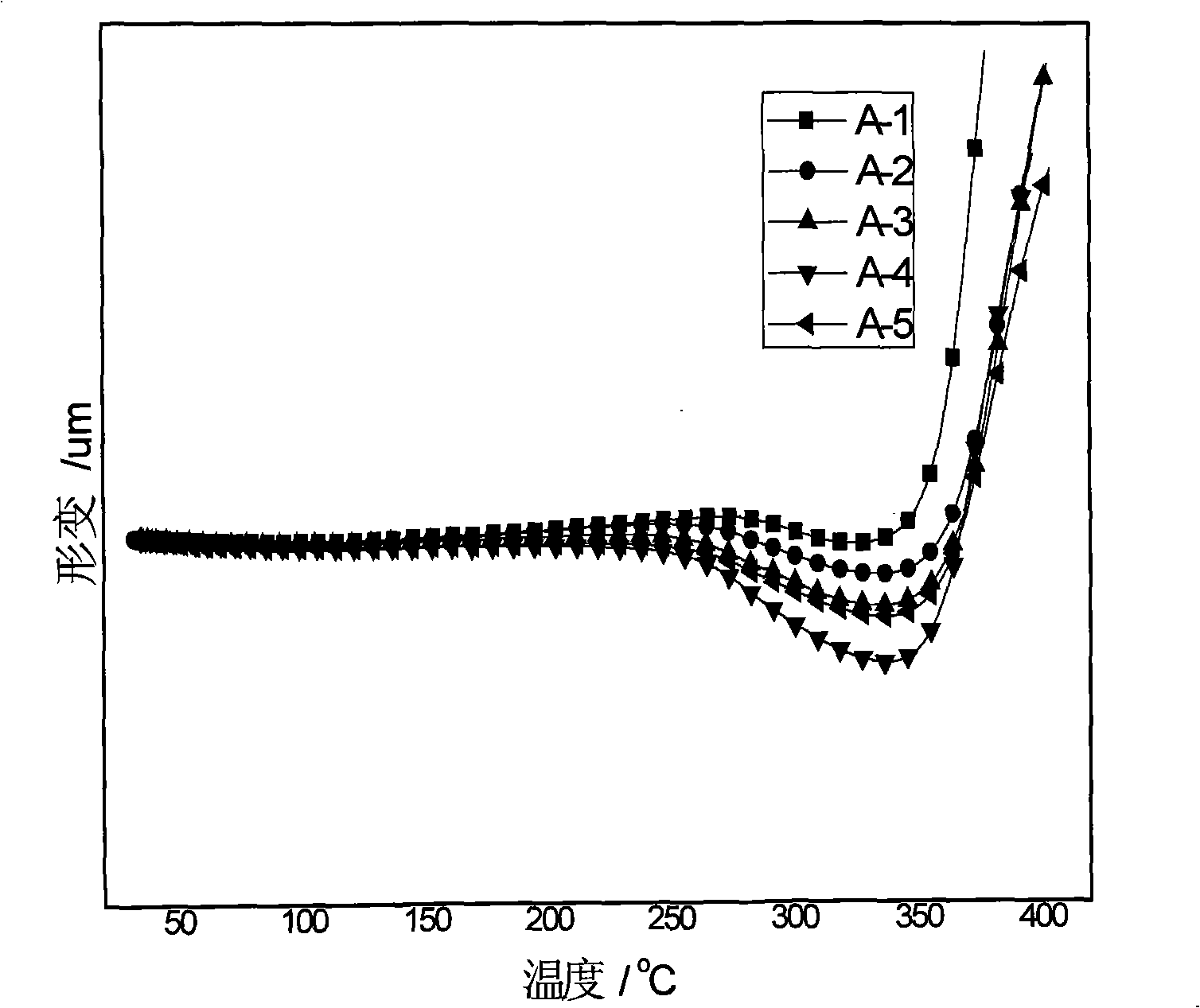

Preparation of high modulus, low thermal expansion coefficient polyimide hybridization film

A low thermal expansion coefficient and polyimide technology, which is applied in the field of low thermal expansion polyimide hybrid film to prepare high modulus, can solve the problem of long operation time, and achieve the goal of increasing the density and increasing the amount of doping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 3.5897g of 4,4'-diaminodiphenyl ether (ODA), dissolve it in 42.5000g of N,N'-dimethylacetamide (DMAc) solvent, stir evenly at room temperature, and then add the equimolar amount of ODA in batches The amount of dianhydride monomer pyromellitic anhydride (PMDA) is a total of 3.9103g, continue to stir, along with the continuous dissolving of dianhydride monomer, the viscosity of polymer also constantly increases, continue to stir at normal temperature after monomer is all dissolved After 4 hours, a PAA solution with a solid content (mass fraction) of 15% was prepared.

[0032] Add 1.3002g tetraethyl orthosilicate (TEOS) to PAA solution, 0.1123gH 2 O, 0.3743g catalyst glacial acetic acid (HAc) and 0.075g coupling agent (KH550), stirring continuously for 4h to form a homogeneous phase, complete the sol reaction and form SiO 2 PAA / SiO with a mass percentage of 4.76% 2 hybrid solution.

[0033] PAA / SiO 2 The solution was dip-coated on a glass plate, placed in a vacuu...

Embodiment 2

[0035] Weigh 1.8837g m-phenylenediamine, dissolve in 42.5000g N,N'-dimethylacetamide (DMAc) solvent, stir evenly at normal temperature, then add the dianhydride monomer 3 in an equimolar amount to ODA in batches , a total of 5.6163g of 3,4,4-benzophenone tetra-acid dianhydride (BTDA), continue to stir, along with the continuous dissolution of the dianhydride monomer, the viscosity of the polymer is also constantly increasing, after all the monomers are dissolved, continue to Stir at room temperature for 3.5 h to prepare a PAA solution with a solid content (mass fraction) of 15%.

[0036] Add 1.3002g tetraethyl orthosilicate (TEOS) to PAA solution, 0.1123gH 2 O, 0.3743g catalyst glacial acetic acid (HAc) and 0.075g coupling agent (KH560), stirring continuously for 4h to form a homogeneous phase, complete the sol reaction and form SiO 2 PAA / SiO with a mass percentage of 4.76% 2 hybrid solution.

[0037] PAA / SiO 2 The solution was dip-coated on a glass plate, placed in a vacu...

Embodiment 6

[0039] Weigh 2.8737g of 4,4'-diaminodiphenyl ether (ODA), dissolve it in 42.2500g of N,N'-dimethylacetamide (DMAc) solvent, stir evenly at room temperature, then add in batches with ODA, etc. The molar amount of dianhydride monomer 3,3,4,4-benzophenonetetraacid dianhydride (BTDA) is a total of 4.6263g, continue to stir, along with the continuous dissolving of dianhydride monomer, the viscosity of polymer also constantly increases After all the monomers are dissolved, continue to stir at room temperature for 3.5 hours to obtain a PAA solution with a solid content (mass fraction) of 15.5%.

[0040] Add 2.6004g tetraethyl orthosilicate (TEOS) to PAA solution, 0.2247gH 2 O, 0.7486g catalyst glacial acetic acid (HAc) and 0.075g coupling agent (KH560), stirring continuously for 4.5h to form a homogeneous phase, complete the sol reaction and form SiO 2 9.1% by mass of PAA / SiO 2 hybrid solution.

[0041] PAA / SiO 2 The solution was dip-coated on a glass plate, placed in a vacuum ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com