Polylactic acid electrospinning fibre immobilized laccase and preparation thereof

A technology of immobilizing laccase and electrospun fiber, which is applied in the field of environmental enzyme catalysis, can solve problems such as unstable properties, water body separation, complex processing, etc., to maintain activity and stability, efficient adsorption and immobilization, and less environmental conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the polylactic acid electrospun fiber immobilized laccase comprises two steps: the synthesis of the carrier and the immobilization of the laccase;

[0025] The synthesis steps of the carrier include:

[0026] 1) Dissolve polylactic acid (racemic) particles with a molecular weight of 100,000 in dichloromethane, add a hydrophilic block copolymer surfactant, mix evenly and stir for more than 1 hour to obtain a polylactic acid / block copolymer mixture Solution, wherein the amount of the block copolymer is 5% to 10% of the weight of the polylactic acid;

[0027] 2) The high-voltage electrospinning equipment consists of a high-voltage power supply, a spinneret and a negative plate. The mixed gel obtained in 1) was introduced into a high-voltage electrospinning device. Adjust the power supply voltage to 12-15 kV, the distance between the spinneret and the negative plate is 10 cm, and adjust the spinneret to obtain stable and continuous spraying.

[...

Embodiment 1

[0043] 1.2 g of racemic polylactic acid was dissolved in 10 g of methylene chloride to form a 10.7 g / g methylene chloride solution. Add 0.06 g of F108 block copolymer surfactant and keep stirring until completely dissolved. Introduce a high-voltage electrospinning device to be spun. Adjust the voltage of the high-voltage power supply to 14 kV, and the distance between the spinneret and the plate is 10 cm to obtain a stable and continuous jet flow. The negative plate is covered with aluminum foil to collect fibrous products. After 2 hours, when the fiber membrane reaches a certain thickness, stop spinning. The resulting fiber membrane was irradiated under an infrared lamp for 30 minutes to completely volatilize the dichloromethane. The fiber membrane was rinsed three times with deionized water to remove the residual hydrophilic block copolymer on the surface. The obtained fiber film is dried at 40 degrees for subsequent use. That is, the electrostatic spinning polylactic a...

Embodiment 2

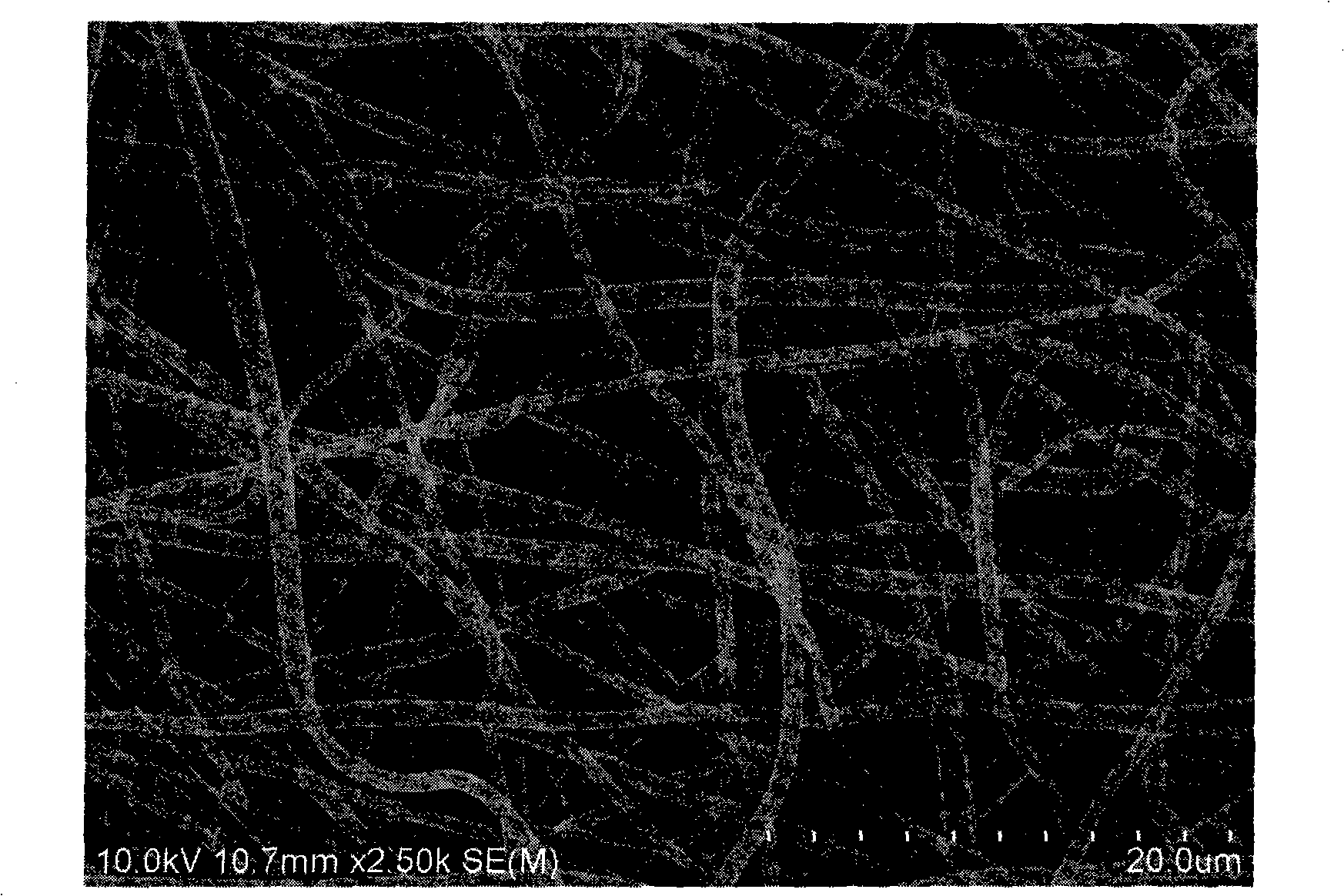

[0046] 1.3 g of racemic polylactic acid was dissolved in 10 g of methylene chloride to form a 11.5 g / g methylene chloride solution. Add 0.1 g of F108 block copolymer surfactant and stir until completely dissolved. The voltage of the high-voltage power supply was adjusted to 12 kV, and the distance between the spinneret and the plate was 10 cm to obtain a stable and continuous jet flow. After 2 hours, when the fiber membrane reaches a certain thickness, stop spinning. Irradiate under infrared light for 30 minutes to completely volatilize dichloromethane. The fiber membrane was rinsed three times with deionized water to remove the residual hydrophilic block copolymer on the surface. The obtained fiber film is dried at 40 degrees for subsequent use. The specific surface area of this sample was 43 m2 / g. The morphology of the fiber was characterized under a scanning electron microscope. The average diameter of the fiber was about 500 nanometers, and the overall shape was comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com