Method for Preparing black zinc oxide and application of black zinc oxide

A technology of zinc oxide and metal flakes, applied in the direction of zinc oxide/zinc hydroxide, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve low synthesis cost, simple operation steps, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

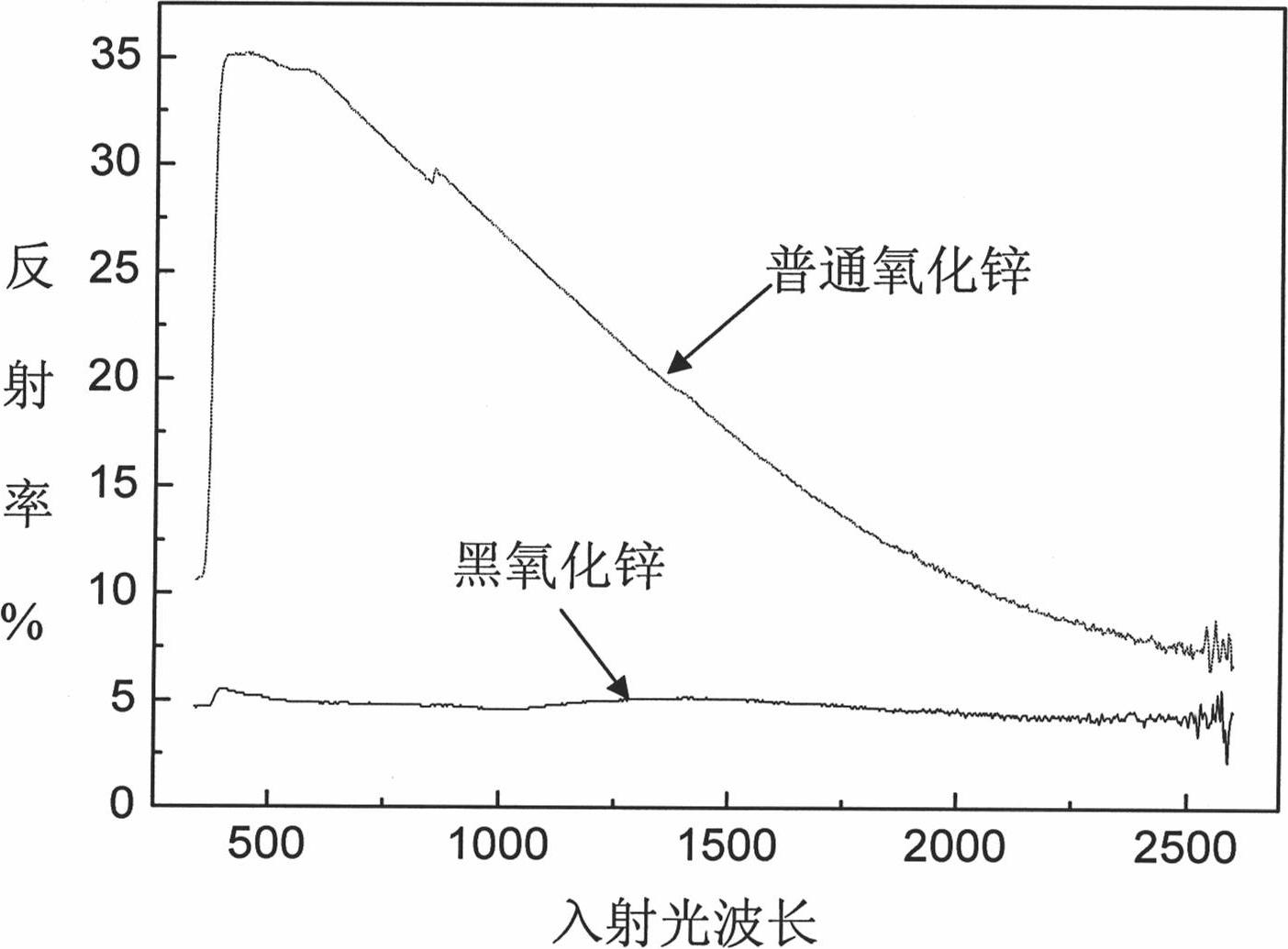

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) get the zinc metal flakes with a purity of 90%, and use deionized water and absolute ethanol to ultrasonically clean it for 25 minutes for subsequent use;

[0029] (2) Inject the deionized water of its volume 40% in the reactor prepared by organic polymer, add sodium chloride and make solution with deionized water in the reactor, this solution chloride ion concentration is 0.01mol / L, drop Add acid or alkali to adjust the pH of the solution to 3;

[0030] (3) The reaction vessel of step 2 is placed in a muffle furnace for heating, allowing the zinc metal sheet to react in the reactor, the heating temperature is 80° C., and black zinc oxide is formed on the surface of the zinc metal sheet after heating for 100 hours;

[0031] (4) The reaction vessel in step 3 is naturally cooled to room temperature, and then the zinc metal sheet is taken out through cleaning and naturally dried to obtain black zinc oxide attached to the zinc metal sheet.

Embodiment 2

[0033] (1) Get the zinc metal flakes with a purity of 100%, and ultrasonically clean them with deionized water and absolute ethanol for 40 minutes for subsequent use;

[0034] (2) Inject the deionized water of its volume 95% in the reactor of noble metal, add sodium-chlor, potassium chloride and make solution with deionized water in the reactor, this solution chloride ion concentration is 1mol / L, drops Add acid or alkali to adjust the pH of the solution to 14;

[0035] (3) Add hydrogen peroxide to the reactor in step 2, place the reactor in a resistance furnace, and heat it to allow the zinc metal sheet to react in the reactor. The heating temperature is 240 ° C. After heating for 1 hour, the surface of the zinc metal sheet forms black zinc oxide;

[0036] (4) Put the reactor in step 3 into cold water to rapidly cool to room temperature, take out the zinc metal sheet, ultrasonically clean it with deionized water and absolute ethanol, then heat and dry to obtain the black zinc...

Embodiment 3

[0038] (1) get the zinc metal flakes with a purity of 95%, and ultrasonically clean them with deionized water and absolute ethanol for 30 minutes for subsequent use;

[0039] (2) Inject the deionized water of volume 85% in the reactor, add potassium chloride and make solution with deionized water in the reactor, this solution chloride ion concentration is 0.2mol / L, drip acid or alkali, adjust The pH value of the solution is 8;

[0040] (3) The reactor in step 2 is placed in an oven for heating, allowing the zinc metal sheet to react in the reactor, the heating temperature is 150° C., and black zinc oxide is formed on the surface of the zinc metal sheet after heating for 30 hours;

[0041] (4) The reactor in step 3 is put into cold water and rapidly cooled to room temperature, then the zinc metal sheet is taken out, ultrasonically cleaned with deionized water and absolute ethanol, dried naturally or heated and dried to obtain the zinc metal sheet attached Black Zinc Oxide.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com