Solid electrolytic capacitor

A technology of solid electrolysis and solid electrolyte, applied in the direction of solid electrolytic capacitors, electrolytic capacitors, capacitors, etc., can solve the problems of cracks, thinning, and narrowing of the conductive path in the dielectric layer, and achieve the effect of small leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

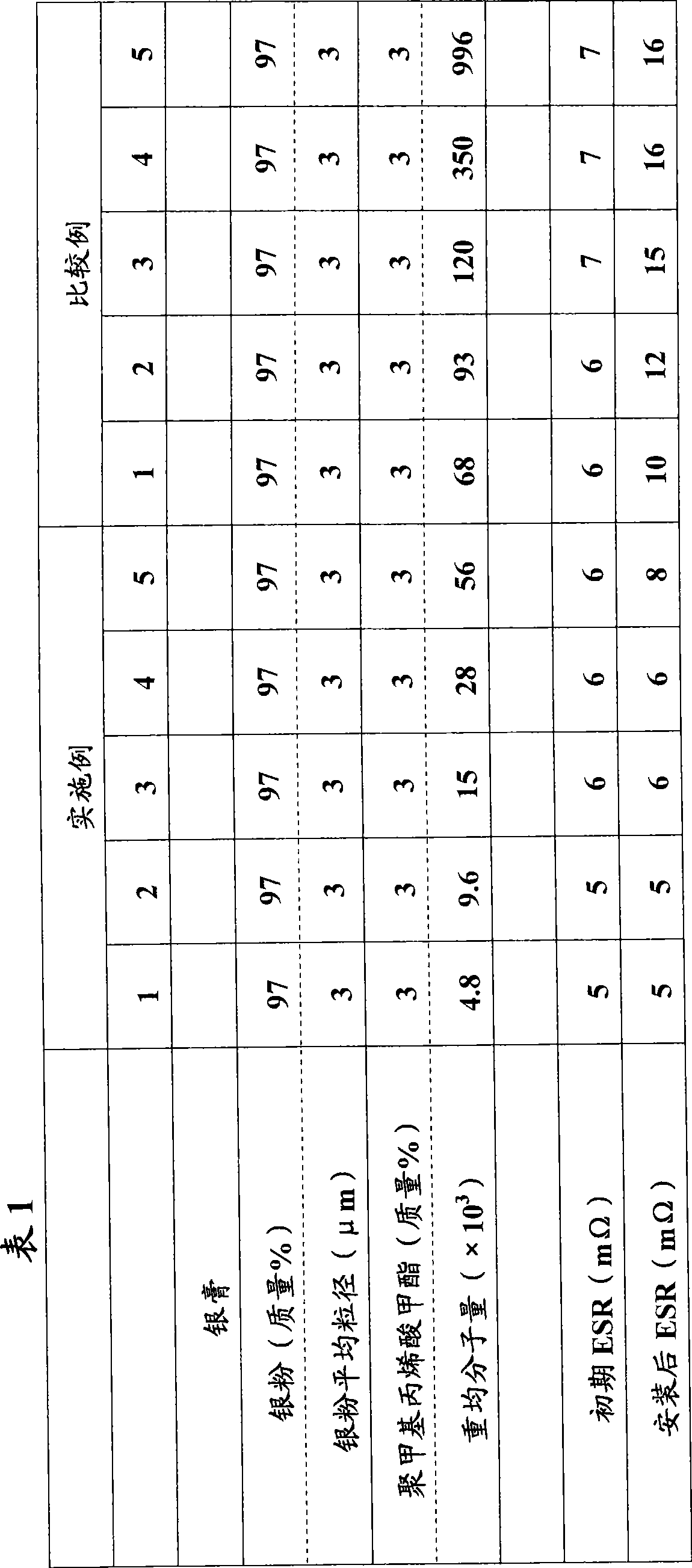

Embodiment 1~5 and comparative example 1~5

[0077] 24.1 mg of tantalum powder and a Φ0.40mm tantalum lead (length 13mm) were molded together, and fired at 1325°C for 20 minutes under vacuum to obtain a CV (product of capacitance and chemical conversion voltage) of 160000μF·V / g , Density is 6.3g / cm 3 , A sintered body with a size of 1.0mm×1.2mm×3.4mm. A tantalum lead of 3.0 mm was buried parallel to the longitudinal direction of the 3.4 mm dimension of the sintered body, and the tantalum lead protruding from the sintered body by 10 mm became an anode part.

[0078] The sintered body was immersed in 1% anthraquinonesulfonic acid aqueous solution at 65°C except for a part of the lead wire, and a voltage of 9V was applied between the sintered body (anode) and the tantalum plate electrode (cathode), and a chemical conversion treatment was performed for 400 minutes. Formed on the surface of the sintered body containing Ta 2 o 5 dielectric layer. A semiconductor (solid electrolyte) layer made of polypyrrole containing naph...

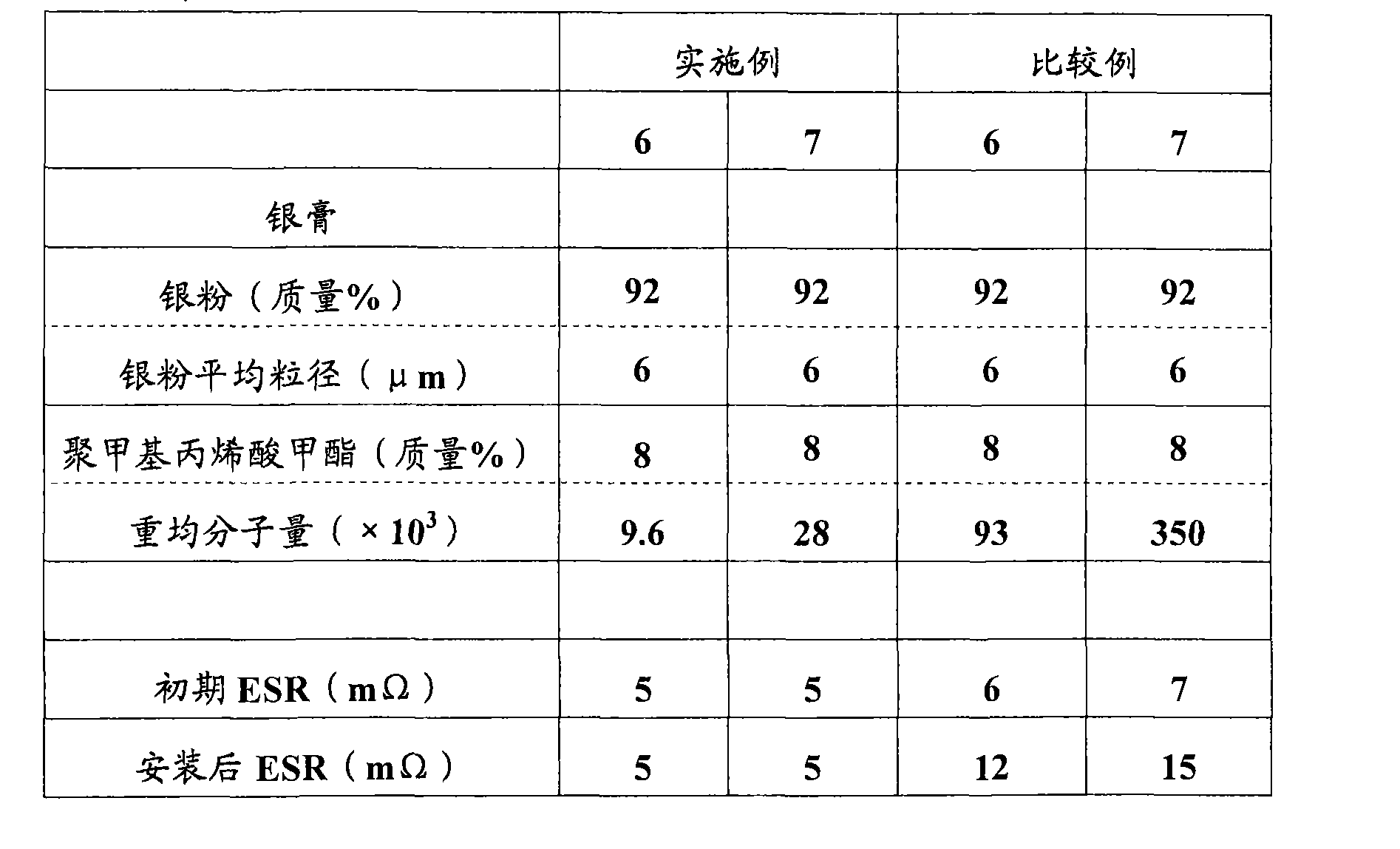

Embodiment 6~7 and comparative example 6~7

[0083] Niobium primary powder (average particle size 0.31 μm) pulverized by utilizing the hydrogen embrittlement of niobium ingot was granulated to obtain niobium powder with an average particle size of 140 μm (because it is a fine powder, the surface is naturally oxidized and contains 9600 ppm oxygen as a whole). Next, by standing in a nitrogen atmosphere at 450°C and then in argon at 700°C, a partially nitrided niobium powder (CV: 285,000 μF·V / g) with a nitrided amount of 9000 ppm was obtained. The partly nitrided niobium powder is molded together with a Φ0.38mm niobium lead (length 13.5mm), and fired at 1260°C to produce multiple pieces with a size of 1.0mm×1.5mm×4.4mm (mass 22.1mg , The niobium lead is buried inside the sintered body with 3.5mm and protrudes 10mm to the outside) of the sintered body.

[0084] Next, the sintered body was immersed in an aqueous solution containing 5% ammonium benzoate and 1% toluenesulfonic acid, and chemical conversion was performed at 20V ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com