Nickelous chloride assisted synthesis method of fuel cell catalyst carrier ordered mesoporous carbon

A catalyst carrier, fuel cell technology, applied in catalyst carriers, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low loading rate, weakened electrocatalytic performance of Pt nanoparticles, and difficulty in dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0019] Specific embodiment two (comparative example):

[0020] (1) Dissolve 1.0 g of surfactant F127 in 10.0 g of absolute ethanol, and stir to form a transparent solution. Without adding nickel chloride solution, stirring was continued at 40°C for 1h. Slowly add 2.08g tetraethyl orthosilicate and 2.5g ethanol solution (20%) of phenolic resin dropwise, stir for 2h to make it evenly mixed.

[0021] (2) Transfer the mixture to a flat-bottomed evaporating dish, evaporate the solvent at room temperature (25°C) for 5-8 hours, put it in a vacuum drying oven at 100°C for thermal polymerization for 24 hours, and form a soft film.

[0022] (3) Carbonization is carried out in an atmosphere tube furnace with nitrogen gas flow. Insulate at 900°C for 2 hours, and the heating rate is strictly controlled at 1°C·min -1 , that is, ordered mesoporous carbon-silicon oxide composites.

[0023] (4) Soak the carbonized and ground sample with a mixed solution of NaOH, ethanol and water (mass rat...

specific Embodiment 3

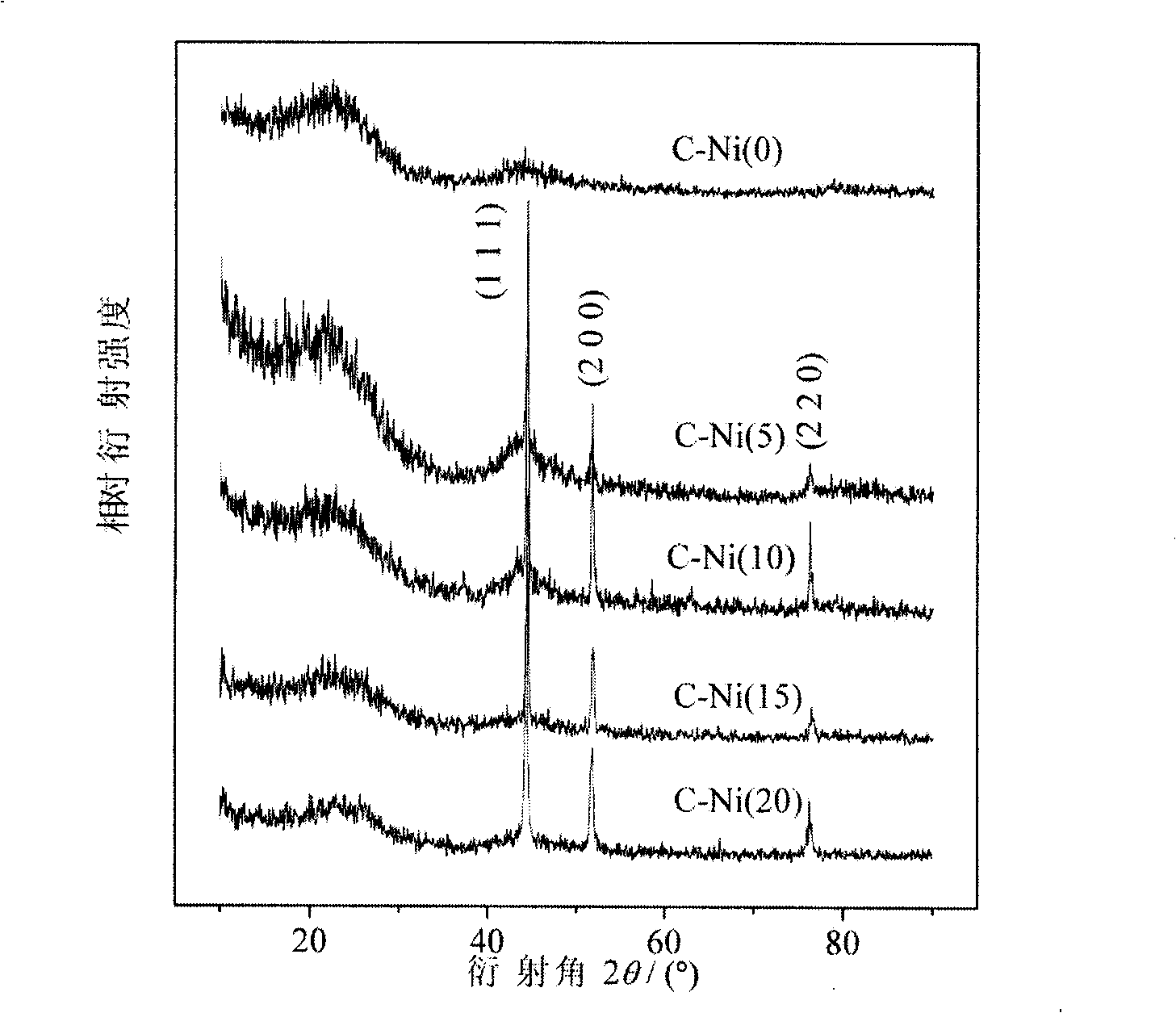

[0027] (1) Add nickel chloride solution on the basis of soft template self-assembly method. Namely: Dissolve 1.0 g of template agent F127 in 10.0 g of absolute ethanol and stir to form a transparent solution. Add 4.0mL, 0.2mol·L -1 Nickel chloride solution was stirred at 40°C for 1 h. Slowly add 2.08g tetraethyl orthosilicate and 2.5g ethanol solution (20%) of phenolic resin dropwise, stir for 2h to make it evenly mixed.

[0028] (2) Transfer the mixture to a flat-bottomed evaporating dish, evaporate the solvent at room temperature (25°C) for 5-8 hours, put it in a vacuum drying oven at 100°C for thermal polymerization for 24 hours, and form a soft film.

[0029] (3) Carbonization is carried out in an atmosphere tube furnace with nitrogen gas flow. Insulate at 900°C for 2 hours, and the heating rate is strictly controlled at 1°C·min -1 , that is, ordered mesoporous carbon-silicon oxide composites.

[0030] (4) Soak the carbonized and ground sample with a mixed solution of...

specific Embodiment 4

[0034] (1) Add palladium chloride solution on the basis of soft template self-assembly method. Namely: Dissolve 1.0 g of template agent F127 in 10.0 g of absolute ethanol and stir to form a transparent solution. Add 2.0mL, 0.2mol·L -1 The palladium chloride solution was continuously stirred at 40°C for 1h. Slowly add 2.08g tetraethyl orthosilicate and 2.5g ethanol solution (20%) of phenolic resin dropwise, stir for 2h to make it evenly mixed.

[0035] (2) Transfer the mixture to a flat-bottomed evaporating dish, evaporate the solvent at room temperature (25°C) for 5-8 hours, put it in a vacuum drying oven at 100°C for thermal polymerization for 24 hours, and form a soft film.

[0036] (3) Carbonization is carried out in an atmosphere tube furnace with nitrogen gas flow. Insulate at 900°C for 2 hours, and the heating rate is strictly controlled at 1°C·min -1 , that is, ordered mesoporous carbon-silicon oxide composites.

[0037] (4) Soak the carbonized and ground sample wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com