Preparation of zinc oxide nano-wire array

A technology of zinc oxide nanowires and arrays, applied in the field of preparation of zinc oxide nanowire arrays, can solve problems such as zinc anodic oxidation research, and achieve the effects of easy large-scale synthesis, simple equipment and steps, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment directly carries out anodic oxidation with zinc sheet as anode, comprises the following steps:

[0036] 1) Electrolyte preparation: prepare 500 milliliters of sodium bicarbonate aqueous solution with a concentration of 15 mmol / L, add 50 milliliters of alcohol, then fully stir to make it dissolve and mix evenly, so that the obtained solution is used as the electrolyte;

[0037] 2) Zinc sheet pretreatment: ultrasonically clean the zinc sheet with absolute alcohol and acetone in sequence, dry it, and use it as an anode for anodic oxidation after electrochemical polishing;

[0038]3) Anodizing of zinc flakes: Install the pretreated zinc flakes on the sample holder so that one side is exposed to the solution, and the other side is connected to the positive electrode. The counter electrode (cathode) uses a 7cm×5cm graphite plate; then DH1720 - Type 2 DC constant voltage source anodized for 4 hours at a working voltage of 10V;

[0039] 4) Annealing trea...

Embodiment 2

[0044] This example adopts the same preparation method as that of Example 1, except that the anode is not subjected to electrochemical polishing treatment before anodic oxidation.

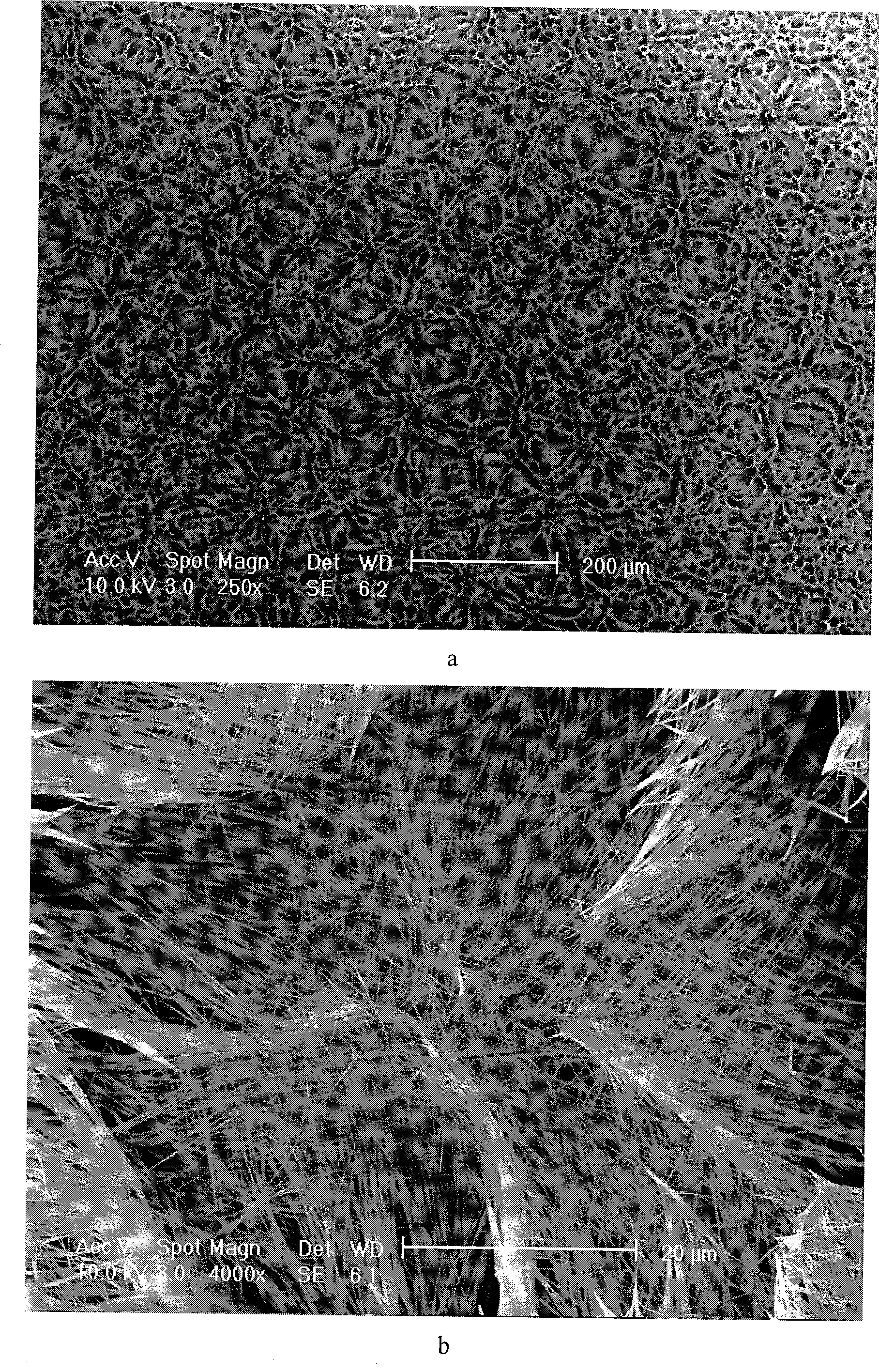

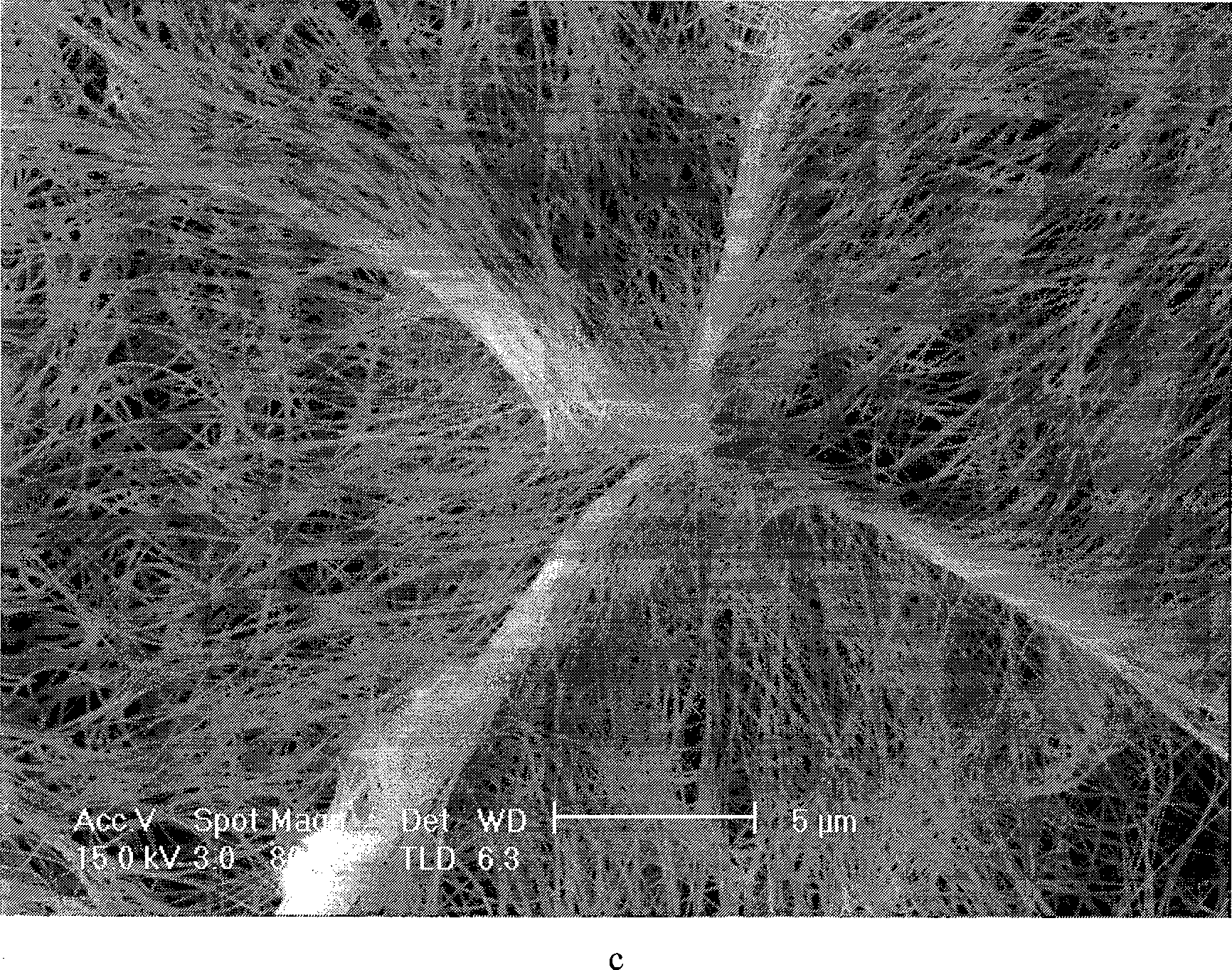

[0045] Depend on Figure 5 It can be seen that the product of Example 1 is relatively dense, while the product of Example 2 is relatively sparse. It can be seen that the electrochemical polishing treatment before anodizing has a significant impact on the compactness of the final product.

Embodiment 3

[0047] This embodiment adopts the same preparation method as in Example 1, the difference is that the anode adopts ITO (or FTO) glass with magnetron sputtering galvanized (or electrochemically deposited zinc), and the required zinc oxide nanowire array can also be obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com