Method for producing efficient composite microbial preparation by livestock and poultry liquid dung

A technology of compound microbial agent and livestock and poultry manure, which is applied in the field of environmental microbiology and agricultural science, can solve the problems of livestock and poultry manure polluting the environment, and achieve the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

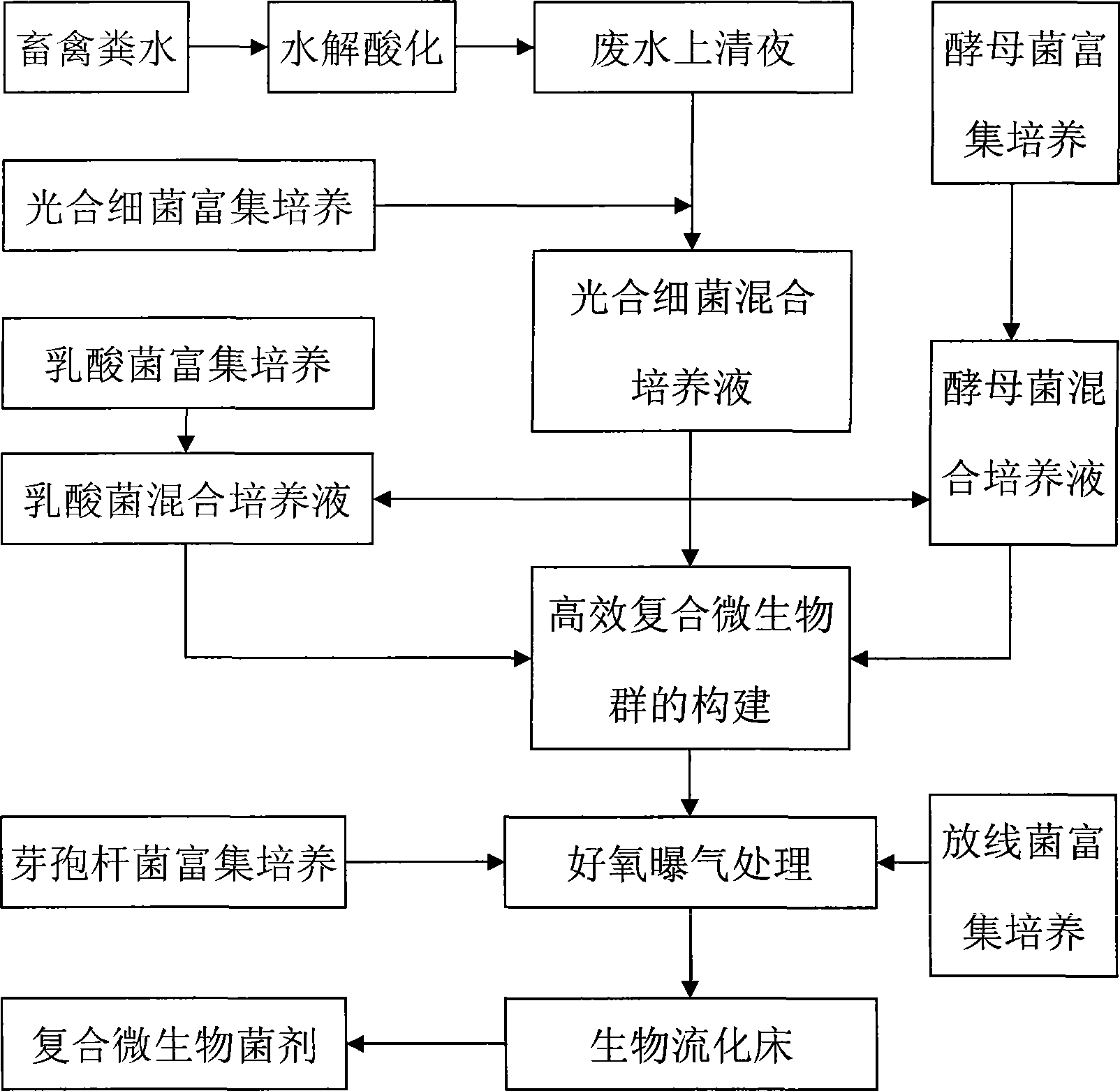

Image

Examples

Embodiment 1

[0042] Step 1: Aseptically inoculate Rhodopseudomonas palustris and Rhodobacter sphaeroides in 1L of photosynthetic bacteria enrichment medium, mix and culture at 3000Lux, 27°C for 7 days, and expand the culture under the same conditions 1000 kilograms of photosynthetic bacteria liquid, spare;

[0043] Step 2: Aseptically inoculate Lactobacillus plantarum, Lactobacillus casei and Lactobacillus fermentum in 1L MRS medium, mix and cultivate at 27°C for 36 hours, and then expand and cultivate 100 kg of lactic acid bacteria liquid under the same conditions ,spare;

[0044] Step 3: Aseptically inoculate brewer's yeast, Candida tropicalis and Candida utilis in 1L of PDA medium, mix and culture at 27°C for 48 hours, and expand and culture 100 kg of yeast under the same conditions Bacteria solution, spare;

[0045] Step 4: Aseptically inoculate Bacillus subtilis, Bacillus megaterium and Bacillus colioids in 1L of beef extract peptone medium, mix and culture at 37°C for 24 hours, and...

Embodiment 2

[0054] Step 1: Aseptically inoculate Rhodopseudomonas palustris and Rhodobacter sphaeroides in 1L of photosynthetic bacteria enrichment medium, mix and culture at 3000Lux, 27°C for 7 days, and expand the culture under the same conditions 2000 kilograms of photosynthetic bacteria liquid, spare;

[0055] Step 2: Aseptically inoculate Lactobacillus plantarum, Lactobacillus casei and Lactobacillus fermentum in 1L MRS medium, mix and culture at 27°C for 36 hours, and then expand and cultivate 200 kg of lactic acid bacteria liquid under the same conditions ,spare;

[0056] Step 3: Aseptically inoculate brewer's yeast, Candida tropicalis and Candida utilis in 1L of PDA medium, mix and culture at 27°C for 48 hours, and expand and cultivate 200 kg of yeast under the same conditions Bacteria solution, spare;

[0057] Step 4: Aseptically inoculate Bacillus subtilis, Bacillus megaterium and Bacillus colioids in 1L beef extract peptone medium, mix and culture at 37°C for 24 hours, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com