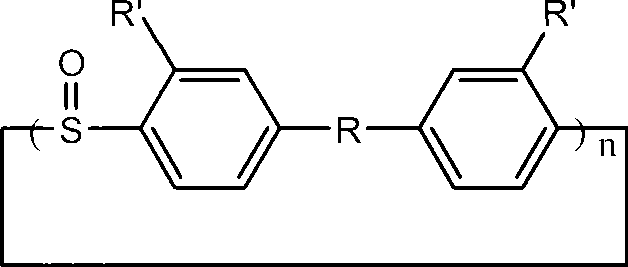

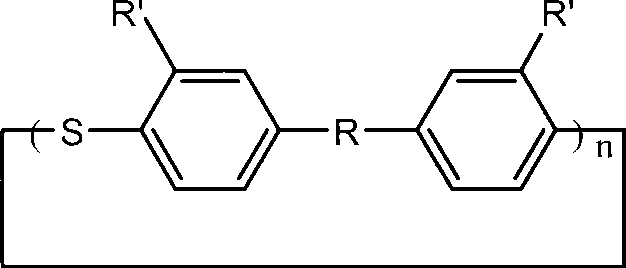

Macrocyclic aryl thioether ether sulfone oligomer and preparation method thereof

A technology of oligomer and polysulfoxide, which is applied in the field of synthesis and preparation of aromatic cyclic polysulfoxide oligomer, can solve the problem of high cost and achieve the effects of low cost, wide sources and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

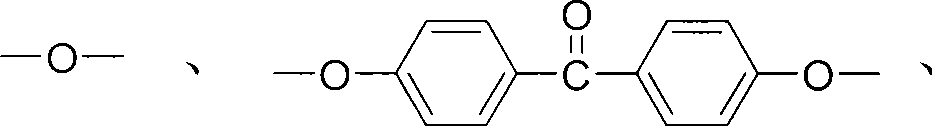

[0043] Example 1 Preparation of polyether ketone ether sulfoxide cyclic oligomer

[0044] Place 6.68g (0.05mol) of anhydrous aluminum trichloride and 500mL of carbon disulfide in a 1000mL three-neck flask with a nitrogen inlet, a spherical condenser connected to a calcium chloride drying tube and a gas absorption device at the top. 2.3821 g (0.02 mol) of thionyl chloride and 7.3258 g (0.02 mol) of 4,4'-phenoxybenzophenone were dissolved in 80 mL of carbon disulfide. Dry nitrogen gas was introduced, and the solution was slowly and uniformly dropped into the three-necked flask within 8 hours under room temperature and vigorous stirring. After the dropwise addition was completed, the stirring was continued for 3 hours, and 150 mL of 0.1M dilute hydrochloric acid was added to terminate the reaction. After the organic phase was obtained by liquid separation, it was washed three times with 100 mL of distilled water to remove the catalyst. Under the protection of nitrogen, it was co...

Embodiment 2

[0045] Example 2 Preparation of Polyetherethersulfoxide Cyclic Oligomer

[0046] The reaction monomer 5.2442g (0.02mol) triphenyl ether was substituted for 4,4'-phenoxybenzophenone, and other monomer feed ratios, reaction conditions and processing steps were the same as in Example 1 to obtain light yellow powder with a yield of was 76%. The main signal peaks of the laser mass spectrogram of the product are located at: m / z=617.2, 925.3, 1233.8, 1541.8, 1850.0, 2158.3, respectively corresponding to the protonated molecular ions of the dimer to the heptamer of the cyclic oligomer peaks, indicating that the product is composed of a series of cyclic oligomers with different degrees of polymerization.

Embodiment 3

[0047] Example 3 Preparation of methyl polyether ketone ether sulfoxide cyclic oligomer

[0048] The reaction monomer 7.8820g (0.02mol) 4,4'-(3-methyl)phenoxy-benzophenone is replaced by 4,4'-phenoxybenzophenone, other monomer feed ratios and reaction conditions are the same as The processing steps were the same as in Example 1 to obtain a cyclic oligomer with a yield of 90%. The main signal peaks of the laser mass spectrogram of the product are located at: m / z=881.4, 1321.6, 1761.8, 2201.8, 2641.9, 3082.4, 3522.3, respectively corresponding to the protonation of the dimer to the octamer of the cyclic oligomer Molecular ion peaks, indicating that the product is composed of a series of cyclic oligomers with different degrees of polymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com