Method for preparing functional textile of nano materials

A technology for nanomaterials and textiles, applied in the field of nanomaterial preparation and textile functional finishing, can solve the problems of easy agglomeration and poor binding force, and achieve the effects of simple process, avoidance of agglomeration and less waste water discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The specific steps of the technical solution of this embodiment are as follows:

[0029] Dissolve the soluble metal salt zinc chloride in water to form a solution with a concentration of 0.1M, use 0.3M urea as a precipitant, and no chemical reaction occurs at room temperature (20-30°C); then put 5g of cotton fabric in the above solution through Padding treatment, control liquid retention rate to 90%, the fabric after padding treatment is treated at 150° C. for 2 minutes in a baking machine, and then treated in high-temperature and high-pressure hot water for 30 minutes to obtain nano-zinc oxide on cotton cloth.

[0030] The main reaction equation is as follows:

[0031]

[0032]

[0033]

[0034]

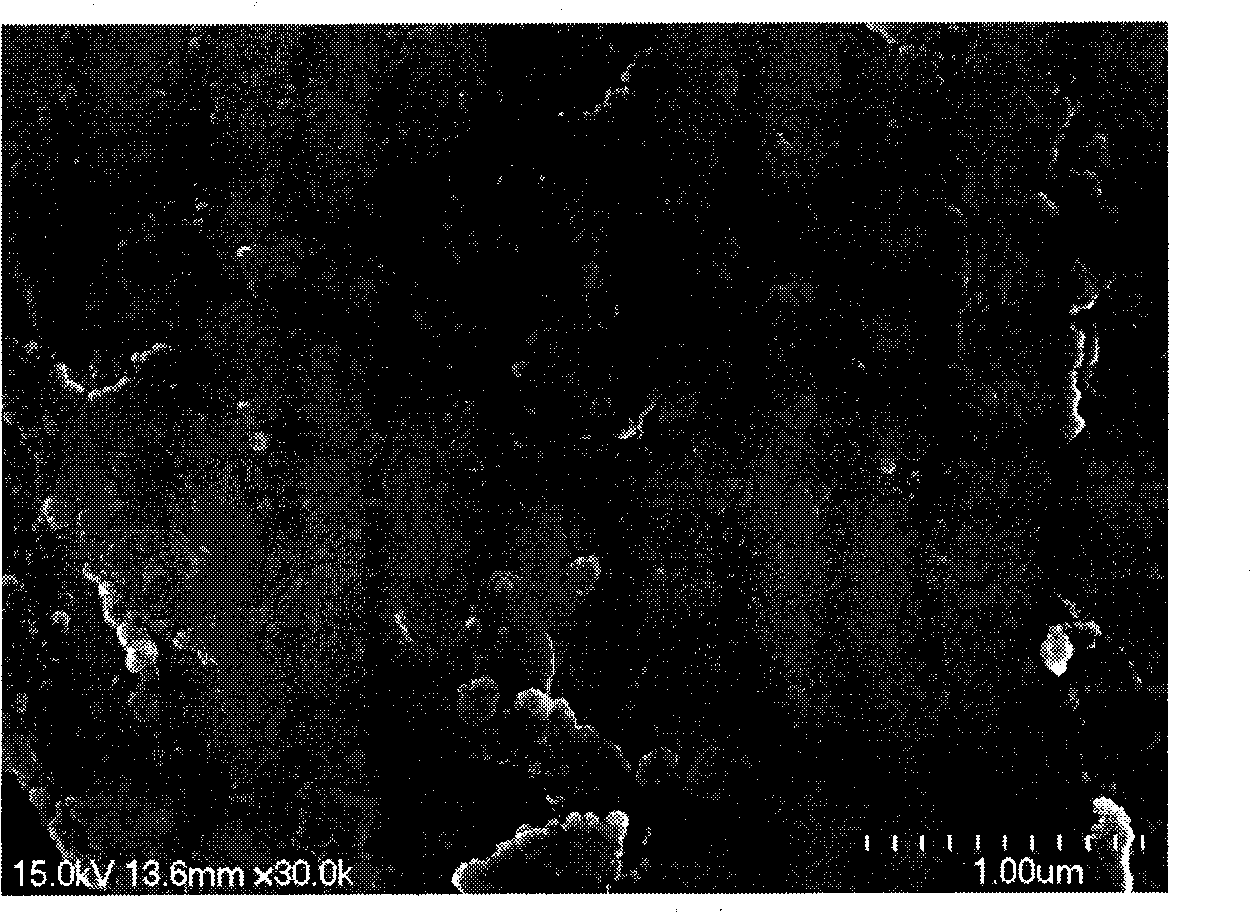

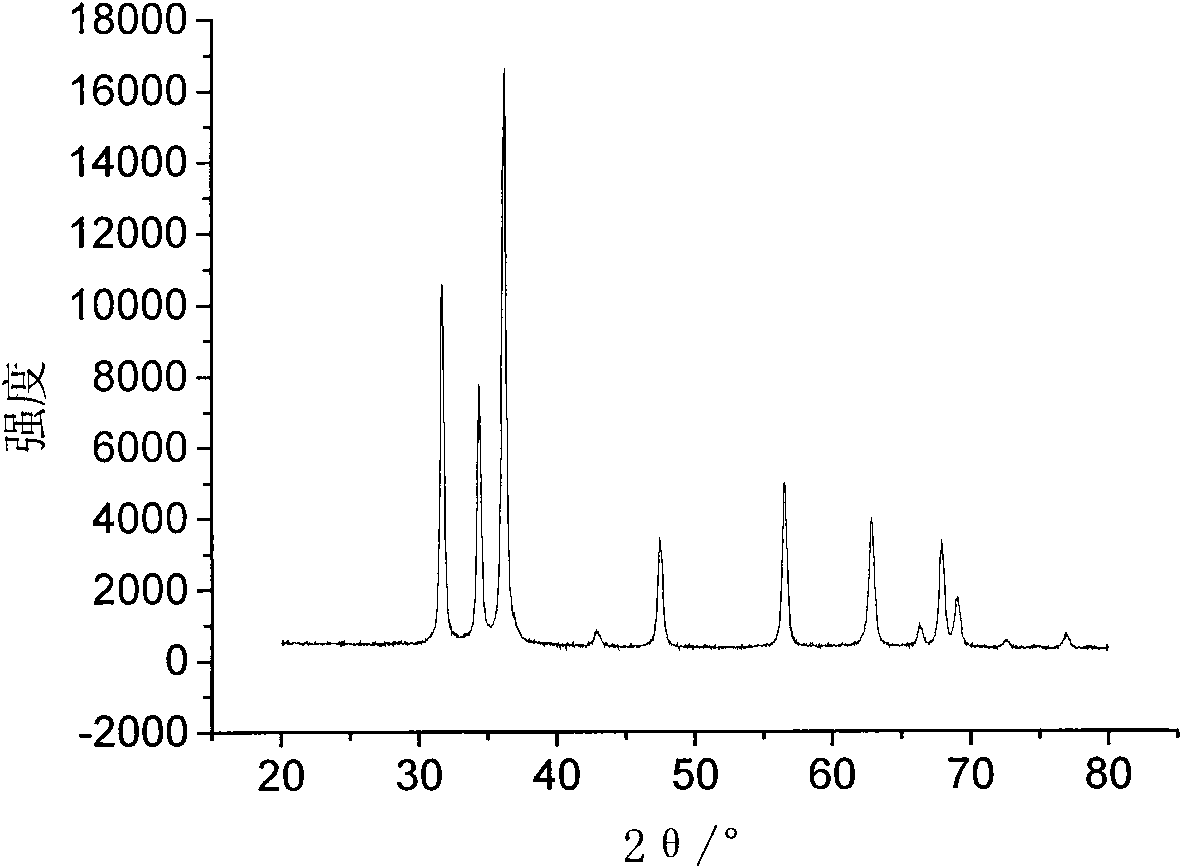

[0035] See attached figure 1 , which is a scanning electron microscope image of in-situ synthesized nano-zinc oxide on cotton fabric prepared according to the technical scheme of this embodiment. Depend on figure 1 It can be seen that the diameter of the nano-z...

Embodiment 2

[0038] Soluble metal salt SnCl 2 .2H 2 O is dissolved in water to form a solution with a concentration of 0.15M, and a small amount of acetic acid is added to make the pH of the solution 4-5 to prevent SnCl 2 .2H 2 O hydrolysis, then add 0.4M precipitant thioacetamide and 0.05M complexing agent polyvinylpyrrolidone, 5g silk fabric is dehydrated after 30 minutes with 0.1M calcium chloride solution, and then in the above water dispersion system After padding treatment, the liquid retention rate is controlled at 120%. The fabric after padding treatment is treated at 140°C for 1min in a steamer, and then treated at 40°C for 20min in a solution containing 10g / L of softener. , black-brown nano-tin sulfide is obtained on the silk fabric, and the color of the silk is reddish black. The test results show that the silk has good UV resistance.

[0039] The main reaction equation is as follows:

[0040]

[0041]

Embodiment 3

[0043] AlCl 3 .6H 2 O and Al(NO 3 ) 3 .9H 2 O was dissolved in water at a molar ratio of 3:1 to form a solution with a concentration of 0.3M, and then 0.9M of precipitating agent thiourea, 0.05M of complexing agent polyvinylpyrrolidone and 0.1M of ammonium oxalate were added to form a water dispersion system . Treat 5g of ultra-fine polyester fabric in the hydrophilic agent for a certain period of time, then soak it in the above-mentioned water dispersion system, treat it in a high-temperature and high-pressure dyeing machine for 60 minutes, and then go through a rolling treatment to control the liquid retention rate to 70%. After the padding treatment The polyester fabric is treated at 170°C for 1 min in a heat setting machine, and flake nano-aluminum hydroxide is obtained on the polyester fabric. The test results show that the silk has good flame-retardant properties.

[0044] The reaction equation is as follows:

[0045]

[0046]

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com