Conductive polyaniline composite electrode material and preparation method thereof

A conductive polyaniline and composite electrode technology, applied in the direction of non-metallic conductors, organic material conductors, etc., can solve the problems of no patent application for inventions, and achieve the effects of long service life, high yield, and good electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

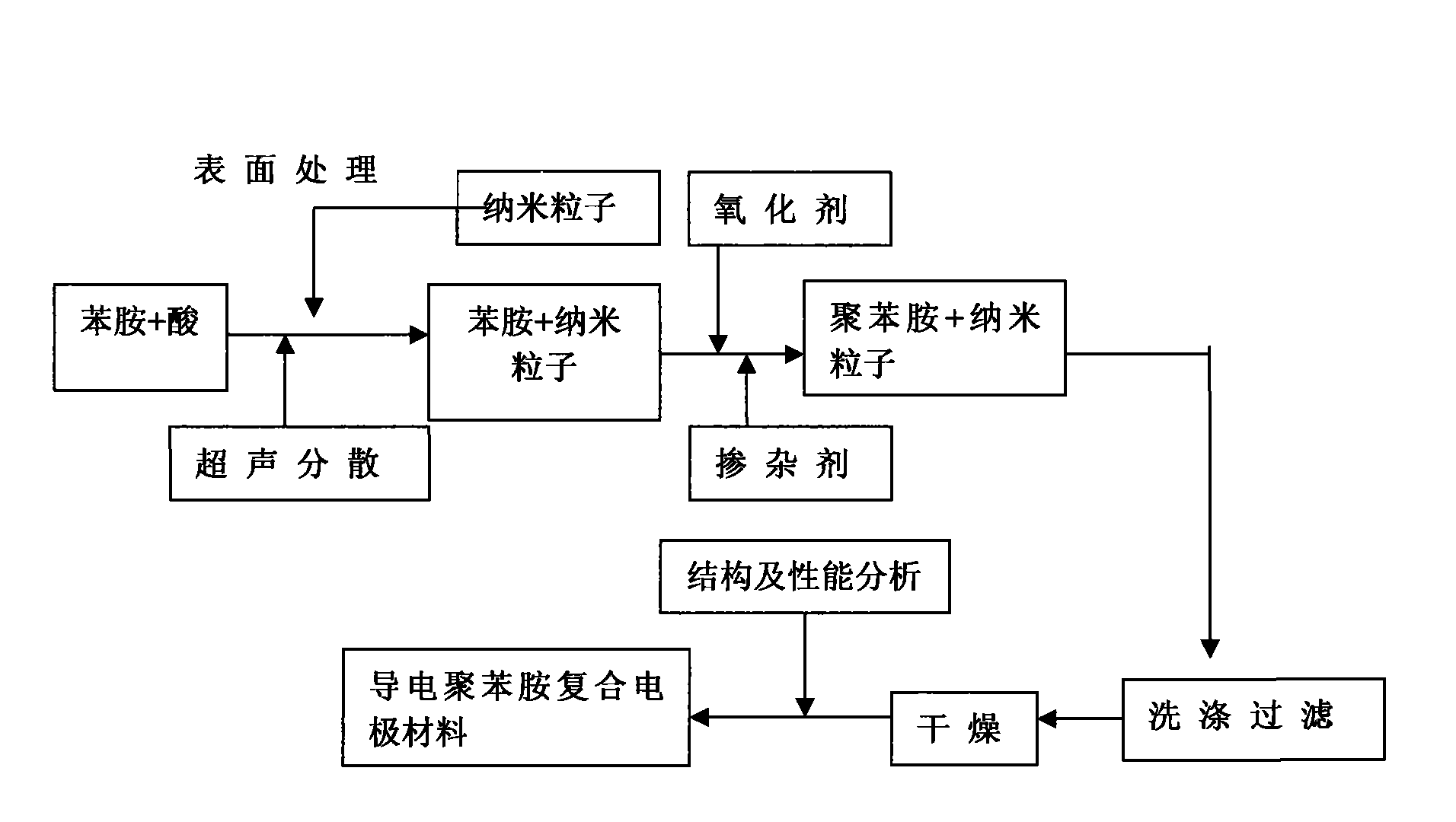

Method used

Image

Examples

Embodiment 1

[0015] Process and steps in the present embodiment are as follows:

[0016] (1) First, modify the nano-titanium dioxide. Take 0.05mol of nano-titanium dioxide and put it in 1000ml of concentrated mixed acid. The concentrated mixed acid is a mixed acid of concentrated nitric acid and sulfuric acid. The volume ratio of the two is: HNO 3 :H 2 SO 4 =1:1.5, heating and refluxing at 80°C for 8 hours, then filtering and washing with distilled water until neutral, drying, and finally high-speed ball milling for 4 hours to obtain modified nano-titanium dioxide. Since the nano-titanium dioxide itself has a phenomenon of coagulation, which is not conducive to industrial application, after treatment, it can be dispersed relatively uniformly and the degree of dispersion can be improved.

[0017] (2) Get 0.025mol of above-mentioned modified nano titanium dioxide and join in 100mL hydrochloric acid solution, the concentration of hydrochloric acid is 0.5mol / L, add 0.0005mol surfactant sodiu...

Embodiment 2

[0021] Process and steps in the present embodiment are as follows:

[0022] (1) First, modify nano-cerium oxide, put 0.05mol of nano-cerium oxide in 1000ml of concentrated mixed acid, the concentrated mixed acid is a mixed acid of concentrated nitric acid and sulfuric acid, the volume ratio of the two is: HNO 3 :H 2 SO 4 = 1:2, heat and reflux at 90°C for 10 hours, then filter and wash with distilled water until neutral, dry, and finally undergo high-speed ball milling for 6 hours to obtain modified nano-ceria. Since the nano-cerium dioxide itself has the phenomenon of coagulation, which is not conducive to industrial application, after treatment, it is dispersed relatively uniformly and the degree of dispersion is improved.

[0023](2) Get 0.02mol of the above-mentioned modified nano-cerium dioxide and join in 100mL sulfuric acid solution, the concentration of sulfuric acid is 1mol / L, then add 0.001mol surfactant polyethylene glycol, carry out ultrasonic dispersion for 3 ho...

Embodiment 3

[0027] Process and steps in the present embodiment are as follows:

[0028] (1) First, modify the nano-manganese dioxide, take 0.05mol of nano-manganese dioxide and put it in 1000ml of concentrated mixed acid. The concentrated mixed acid is a mixed acid of concentrated nitric acid and sulfuric acid. The volume ratio of the two is: HNO 3 :H 2 SO 4 = 1:3, heated and refluxed at 100°C for 14 hours, then filtered and washed with distilled water until neutral, dried, and finally subjected to high-speed ball milling for 8 hours to obtain modified nano manganese dioxide. Since the nano-manganese dioxide itself has a phenomenon of aggregation, which is not conducive to industrial application, after treatment, it can be dispersed relatively uniformly, and the degree of dispersion is improved.

[0029] (2) Get 0.01mol above-mentioned modified nano manganese dioxide and join in 65mL phosphoric acid solution, the concentration of phosphoric acid is 2.5mol / L, then add 0.0015mol surfactan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com