Device for microwave plasma based low-energy ion implantation on internal surface of metal round pipe with small pipe diameter

A technology of microwave plasma and low-energy ions, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of limitation, large variation range of ion sheath, waste of device power, etc., and achieve cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

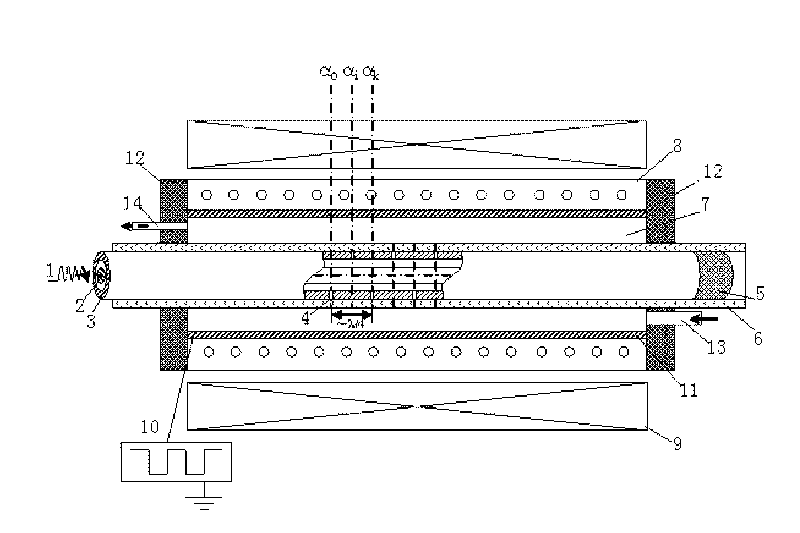

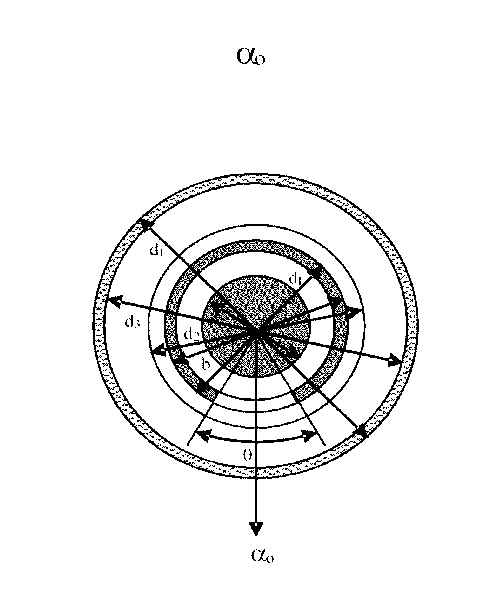

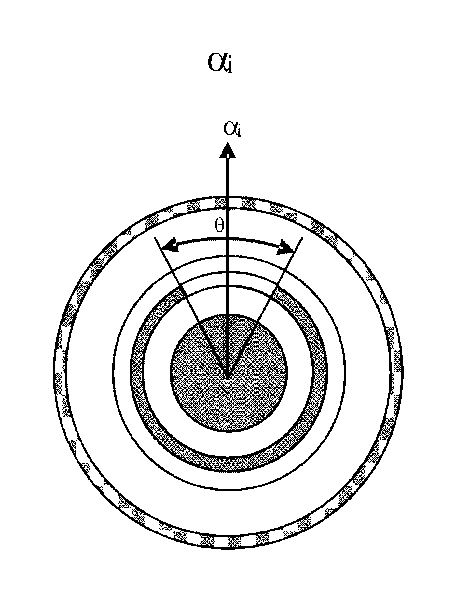

[0039] A machinery factory requires the manufacture of a microwave plasma-based low-energy ion implantation device for the inner surface of a small-diameter metal circular tube, and performs plasma-based low-energy nitrogen ion implantation on the inner surface of an austenitic stainless steel pipe with an inner diameter of 10mm, a wall thickness of 1mm, and a length of 200mm. Its specific process parameters are as follows:

[0040] The microwave source power is 2000W, the outer diameter of the microwave coaxial waveguide inner conductor 2 of the linear ECR microwave plasma source is 3mm, the inner diameter of the coaxial waveguide outer conductor 3 is 7mm, and there are Nk=13 slot radiation antennas with a slot width of 0.2mm. Xiang Zhangjiao q=30

[0041] The working pressure of nitrogen in the vacuum chamber 7 reaches 1?0 -2 Pa, apply pulse negative bias voltage -0.5kV to the austenitic stainless steel pipe fittings, the temperature of the austenitic stainless steel pipe f...

Embodiment 2

[0043] A steel factory requires the manufacture of a microwave plasma-based low-energy ion implantation device for the inner surface of a small-diameter metal circular tube. The inner surface of a titanium alloy pipe with an inner diameter of 20 mm, a wall thickness of 1 mm, and a length of 300 mm is treated with plasma-based low-energy nitrogen ion implantation. The process parameters are as follows:

[0044] The microwave source power is 3000W, the outer diameter of the microwave coaxial waveguide inner conductor 2 of the linear ECR microwave plasma source is 3mm, the inner diameter of the coaxial waveguide outer conductor 3 is 7mm, and there are Nk=28 slot radiation antennas with a slot width of 0.2mm. Xiang Zhangjiao q=60

[0045] The working pressure of nitrogen in the vacuum chamber 7 reaches 5×10 -2 Pa, apply a pulse negative bias of -3kV to the titanium alloy pipe fittings, the temperature of the processed titanium alloy pipe fittings reaches the process temperature o...

Embodiment 3

[0047] A machine tool factory requires the manufacture of a microwave plasma-based low-energy ion implantation device for the inner surface of a small-diameter metal circular tube, and performs plasma-based low-energy nitrogen ion implantation on the inner surface of a martensitic stainless steel pipe with an inner diameter of 50mm, a wall thickness of 5mm, and a length of 500mm. Its specific process parameters are as follows:

[0048] The power of the microwave source is 5000W, the outer diameter of the inner conductor 2 of the microwave coaxial waveguide of the linear ECR microwave plasma source is 7mm, the inner diameter of the outer conductor 3 of the coaxial waveguide is 16mm, and there are Nk=46 slot radiation antennas with a slot width of 0.3mm. Xiang Zhangjiao q=120

[0049] The nitrogen working pressure of the vacuum chamber 7 reaches 3×10 -2 Pa, apply pulse negative bias voltage -2kV to the martensitic stainless steel pipe fittings, make the temperature of the marte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com