Flunarizine hydrochloride pills and preparation method thereof

A technology of flunarizine hydrochloride and dropping pills, which is applied in the fields of pill delivery, pharmaceutical formulations, medical preparations containing active ingredients, etc. It can solve the problem of difficulty in controlling pill roundness due to differences in pill weight, low dissolution rate and dissolution rate , affect flunarizine hydrochloride and other issues, and achieve the effects of controllable pellet weight difference and pellet roundness, fast absorption and distribution, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

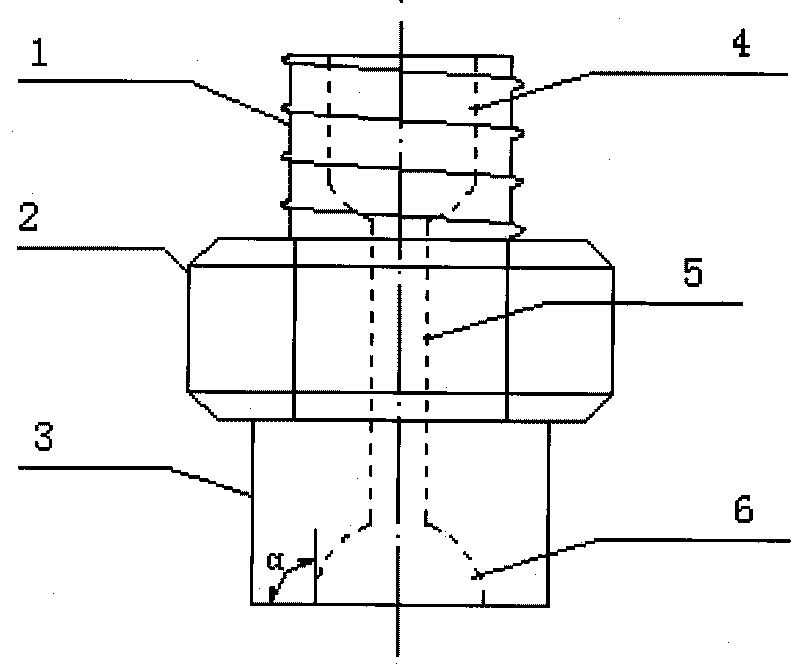

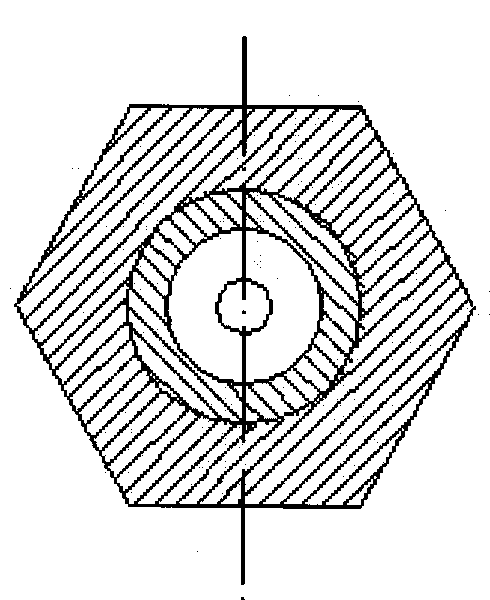

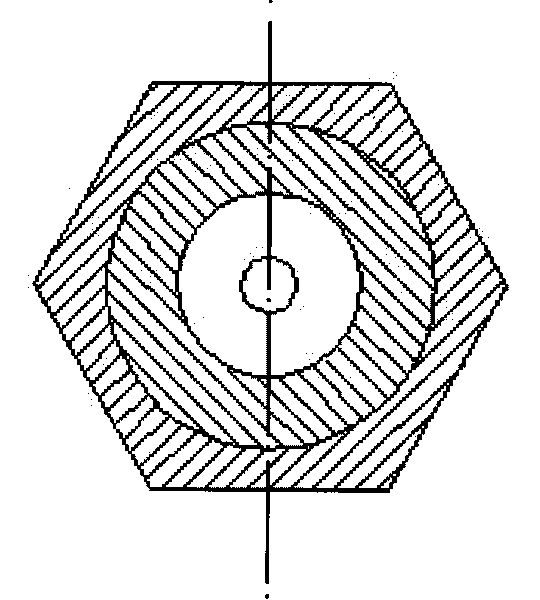

Image

Examples

Embodiment 1

[0040] Flunarizine Hydrochloride 1.5g

[0041] Macrogol 4000 18g

[0042] Macrogol 6000 3.5g

[0043] —————————————

[0044] drops made of 1000 capsules

[0045] Preparation

[0046] Weigh and pulverize flunarizine hydrochloride raw material according to the prescription ratio, pass through an 80-mesh sieve, mix evenly with polyethylene glycol 4000 and polyethylene glycol 6000 bases, heat and melt, and stir well; Diameter cylindrical concave nozzle dripper drop system, use a drop pill forming machine to form pellets, use 50℃~-10℃ dimethyl silicone oil coolant gradient cooling, drop into pellets, deoil, and screen out the appropriate size Dropping pills, packaged, ready to use.

Embodiment 2

[0048] Flunarizine Hydrochloride 1.5g

[0049] Macrogol 4000 18g

[0050] Macrogol 6000 3.5g

[0051] ———————————

[0052] drops made of 1000 capsules

[0053] Preparation

[0054] Weigh and pulverize flunarizine hydrochloride raw material according to the prescription ratio, pass through an 80-mesh sieve, mix evenly with polyethylene glycol 4000 and polyethylene glycol 6000 bases, heat and melt, and stir well; Diameter cylindrical concave nozzle dripper drop system, use drop pill forming machine to form pills, use 50℃~-10℃ liquid paraffin coolant gradient cooling, drip into pills, deoil, and screen out suitable size drop pills , packaged, ready to serve.

Embodiment 3

[0056] Flunarizine Hydrochloride 1.5g

[0057] Macrogol 4000 18g

[0058] Macrogol 6000 3.5g

[0059] ———————————

[0060] drops made of 1000 capsules

[0061] Preparation

[0062] Weigh and pulverize flunarizine hydrochloride raw material according to the prescription ratio, pass through an 80-mesh sieve, mix evenly with polyethylene glycol 4000 and polyethylene glycol 6000 bases, heat and melt, and stir well; Diameter cylindrical concave nozzle dripper drop system, use drop pill forming machine to form pills, use 50℃~-10℃ vegetable oil coolant gradient cooling, drop into pills, deoil, and screen out the appropriate size of dropping pills, Pack and serve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com