Catalyst modified by proton conductor and using conductive polymer as carrier and preparation method thereof

A conductive polymer, catalyst technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of unfavorable three-phase reaction zone, poor electrochemical stability, Problems such as harsh electrochemical environment of fuel cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

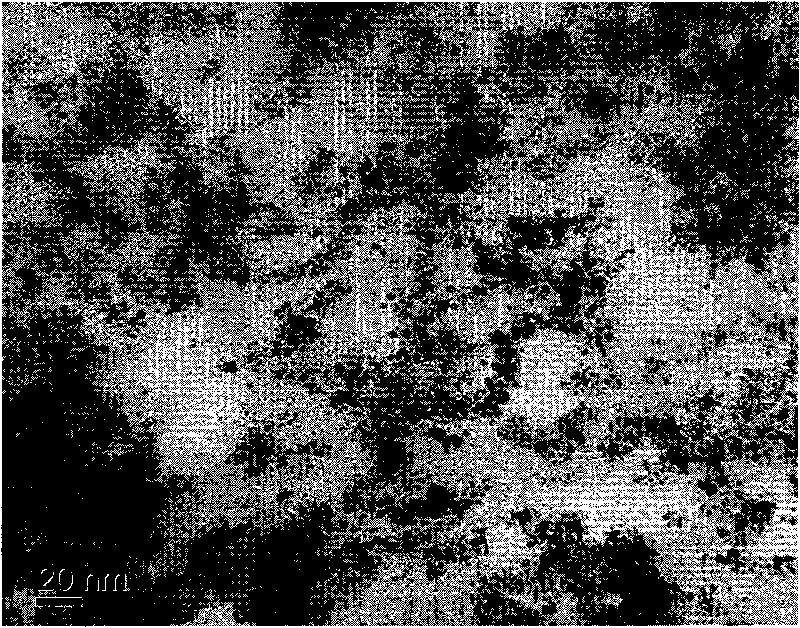

[0025] Take 5ml Nafion (5wt%) solution and add it to the mixed solution of 200ml ethanol and water, the mass ratio of absolute ethanol and water is 2:1, after stirring for 5-10min, add 5g / L H 2 PtCl 6 60ml continue to stir, adjust PH=10 with NaOH, under N 2 Stir fully under protection and keep heating at reflux at 80-100°C, the solution gradually turns from light yellow to black, and finally turns dark black to obtain Nafion-modified Pt colloid; after cooling, add 1g of 90wt% aniline solution to the Pt colloid, continue Stir for 2 to 3 hours; add 1 g of ammonium persulfate and 20 ml of hydrochloric acid solution with a concentration of 1 mol / L, stir at 0°C for 8 hours, then add 0.05 g of conductive carbon black (XC-72R, produced by Cabot, USA), and mix , filtration, and alcohol washing to prepare a catalyst modified by proton conductor Nafion and using conductive polyaniline as a carrier. Among them, the Pt particle size is ≤5nm, the average particle size is 2.9nm, and the d...

Embodiment 2

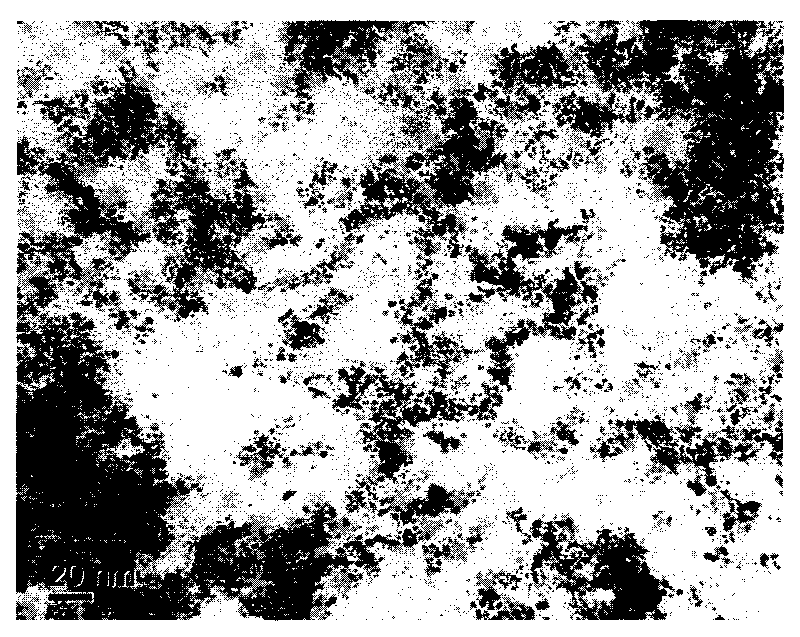

[0027] Take 8ml of sulfonated polyphenylene sulfide (10wt%) solution and add it to the mixed solution of 150ml of isopropanol and water, the mass ratio of isopropanol and water is 3:1, after stirring for 20min, add 4g / L of H 2 PtCl 6 60ml, 4g / L RuCl 3 60ml, continue to stir, adjust PH=11 with NaOH, in N 2Stir fully under protection and keep heating at reflux at 90-100°C to prepare PtRu colloid modified by sulfonated polyphenylene sulfide; after cooling, add 1.3g of 90wt% aniline solution to the PtRu colloid and continue stirring for 3 hours; add dichromic acid Potassium 2g and concentration are 20ml of the hydrochloric acid solution of 1mol / L, stir at 5 ℃ for 7 hours, then add 0.13g of conductive carbon black (BP-2000, produced by U.S. Cabot Company), through mixing, filtering and alcohol washing, the prepared A proton conductor sulfonated polyphenylene sulfide modified catalyst supported by conductive polyaniline. Among them, the average particle size of PtRu is 4.3nm, and...

Embodiment 3

[0029] Take 4.5ml of sulfonated polybenzimidazole (6wt%) solution and add it to the mixed solution of 250ml methanol and water, the mass ratio of methanol and water is 100:1, after stirring for 5-10min, add 5g / L H 2 PtCl 6 80ml, 5g / L SnCl 3 50ml continue to stir, adjust PH=10 with NaOH, in N 2 Stir fully under protection and keep heating at reflux at 80-100°C to prepare sulfonated polybenzimidazole-modified PtSn colloid; after cooling, add 1 g of 95wt% pyrrole solution to the PtSn colloid and continue stirring for 2-3 hours; add persulfuric acid 0.5g of sodium and 25ml of perchloric acid with a concentration of 2mol / L were stirred at 10°C for 6 hours, then 0.20g of conductive carbon black (XC-72R, produced by U.S. Cabot Corporation) was added, mixed, filtered, and washed with alcohol to prepare A catalyst modified by proton conductor sulfonated polybenzimidazole and supported by conductive polypyrrole was obtained. Among them, the average particle size of PtSn is 4.1nm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com