Method for producing low-carbon alkene by catalytic pyrolysis of biomass

A technology of catalytic cracking and low-carbon olefins, which is applied in the production of bulk chemicals, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of not providing catalysts and achieve high olefin yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] In the preparation method of the macroporous catalyst of the present invention, the spray drying is a prior art, and there is no special requirement, for example, the temperature of the tail gas of the spray drying is 100°C-300°C. The preparation method may also include the steps of roasting, washing and drying. The methods of roasting, drying and washing are prior art, without special requirements, for example, the roasting temperature is 300°C-700°C, and the drying temperature is 100°C-300°C; washing with deionized water until the content of sodium oxide in the catalyst is less than More than 0.5% by weight.

[0018] In the catalytic cracking method provided by the present invention, the biomass is preferably one or more of the organic oxygen-containing compounds with a long-chain carbon number of 10-24, and the organic oxygen-containing compounds are saturated, monounsaturated, One or more of polyunsaturated fatty acids and fatty acid compounds, said fatty acid comp...

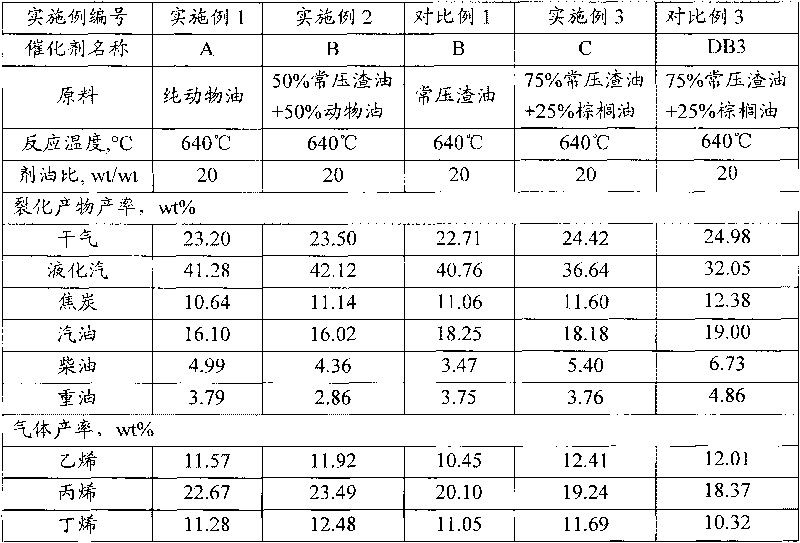

Embodiment 1

[0024] Catalyst preparation: 20Kg decationized water and 20.1Kg pseudoboehmite (industrial product of Shandong Aluminum Plant, solid content 63% by weight) were mixed, beaten, and its pH value was adjusted to 3 with hydrochloric acid; 72.6Kg decationized water was mixed with 28.4 Kg hallowed kaolin (industrial product of Suzhou porcelain clay company, solid content 72.3% by weight) mixes, beats for 5 minutes, then adds potassium borate 2.0Kg (analytical pure), beats for 15 minutes; The above-mentioned two kinds of slurries are mixed, stirred, at 65 ℃ for static aging for 1.5 hours, keep the pH value of 2-4 (adjusted with hydrochloric acid) during aging, then lower the temperature to 55 ℃, add 13.0Kg aluminum sol (produced by Qilu Petrochemical Catalyst Factory, Al 2 o 3 content is 21.7% by weight), stirred for 40 minutes, and added 33.0Kg of molecular sieve slurry (which contained 0.5kg of REHY zeolite, 11.0Kg of ZRP zeolite; RE in REHY zeolite 2 o 3 The content is 8% by wei...

Embodiment 2

[0028] Catalyst preparation: 20Kg decationized water and 18.2Kg pseudoboehmite (industrial product of Shandong Aluminum Plant, solid content 63% by weight) were mixed and beaten, and its pH value was adjusted to 3 with hydrochloric acid; 72.6Kg decationized water was mixed with 32.1Kg Halloysite (industrial product of Suzhou China Clay Company, solid content 72.3% by weight) was mixed and beaten for 5 minutes, then 5Kg of potassium sulfate (industrial grade, content 98% by weight) was added and beaten for 15 minutes. The above two slurries were mixed, stirred evenly, left to age at 65°C for 1.5 hours, and the pH value was kept at 3-4, then the temperature was lowered to 55°C, and 14Kg of aluminum sol (product of Qilu Petrochemical Catalyst Factory, Al 2 o 3 Content is 21.7% by weight), stirred for 40 minutes, added molecular sieve slurry 25.0Kg (containing REHY zeolite 2.5kg, ZRP zeolite 6.5Kg, beta zeolite 2.5 kilograms, REHY zeolite is the same as embodiment 1, ZRP zeolite i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com