Method for preparing ZSM-5 zeolite/clay composite catalytic material without amine

A technology of ZSM-5 and catalytic materials, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of polluting the environment and increasing the cost of zeolite preparation, and achieve low preparation cost and tight combination , the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

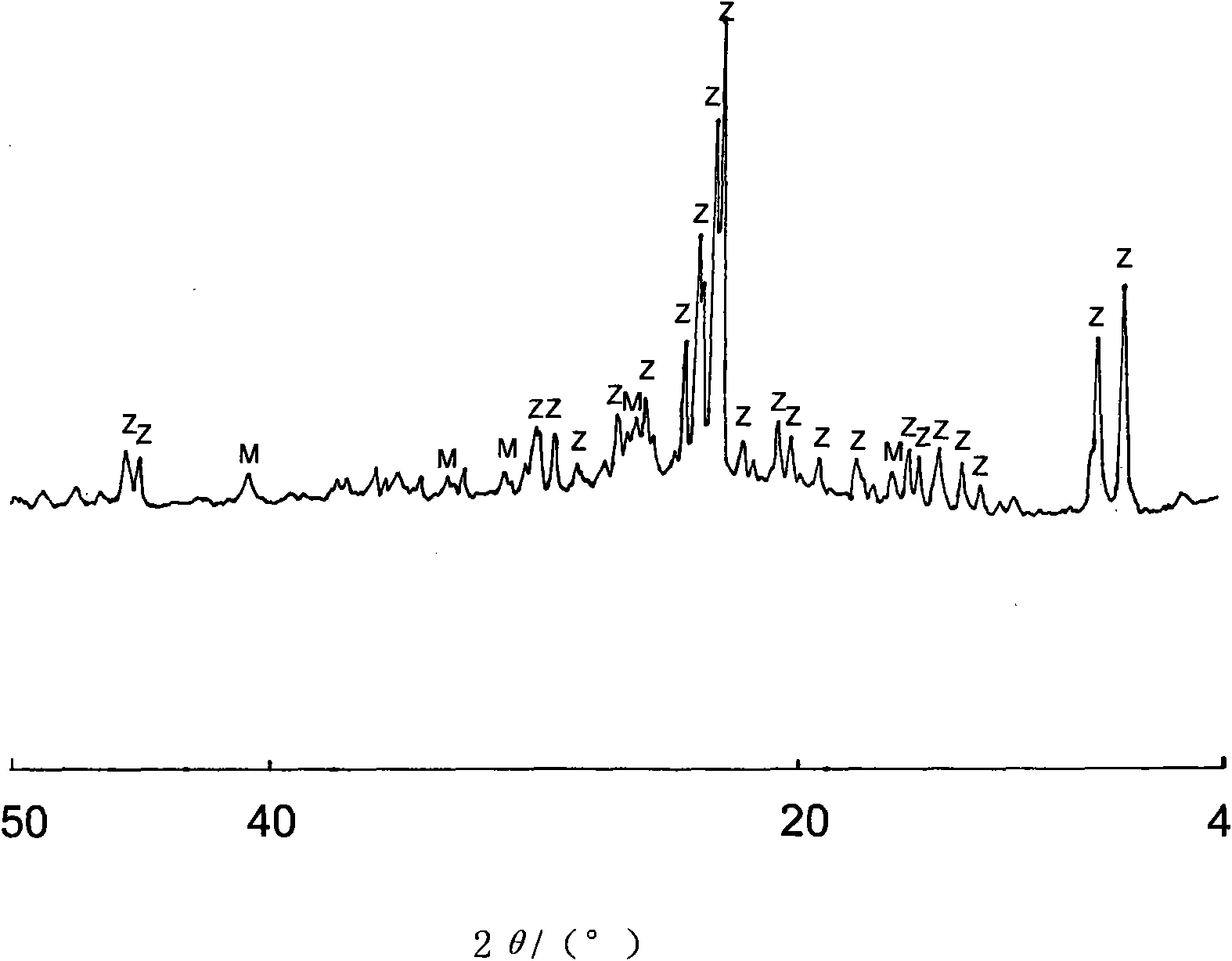

[0041] 2700g (dry basis) of hydrated kaolin and 180g of ZSM-5 zeolite were added with water to make a slurry with a solid content of 35%, and 143g of sodium silicate was added as a dispersant for spray molding to obtain 2500g of spray microspheres. The sprayed microspheres were calcined in a muffle furnace at 960°C for 3h to obtain the calcined microspheres A0. After mixing 12g of microspheres A0, 51mL of water glass, 0.6g of ZSM-5 zeolite, 16mL of 3M sulfuric acid and 120mL of water, the mixture was transferred into a stainless steel tank with a polytetrafluoroethylene liner, sealed, and placed at 150°C for crystallization. After 80 hours, filtered, washed and dried, the ZSM-5 zeolite composite material A1 of the present invention was obtained. The ZSM-5 content was determined to be 38% by weight by X-ray diffraction method.

Embodiment 2

[0043] The calcined microspheres A0 12g obtained in Example 1, 51mL water glass, 2g commercial solid silicon oxide (solid content 97%), 16mL 3M sulfuric acid and 120mL water were mixed, after mixing evenly, the mixture was transferred into a tank equipped with polytetrafluoroethylene. In a lined stainless steel tank, seal, stand at 150° C. for 96 hours for crystallization, filter, wash, and dry to obtain composite material A2 of the present invention containing 53% ZSM-5 zeolite.

Embodiment 3

[0045] 100g (dry basis) montmorillonite, 7g ZSM-5 zeolite, 2g sodium hydroxide, 2g sodium pyrophosphate, and 50g water were mixed, ground and mixed in a ball mill for 0.5h, and then extruded by an extruder. Drying at 120°C for 3h, followed by sintering in a muffle furnace at 1000°C for 2h to obtain a roasted strip B0. After mixing 8g of roasted bar B0, 26mL of water glass, 0.26g of ZSM-5 zeolite, 2.4g of NaCl, 7mL of 3M nitric acid and 80mL of water, the mixture was transferred into a stainless steel tank equipped with a polytetrafluoroethylene liner, sealed, Stand at 140°C for 24 hours for crystallization, then raise the temperature to 180°C for 48 hours, filter, wash, and dry to obtain the ZSM-5 zeolite composite material B1 of the present invention. Contains 45% ZSM-5 by X-ray diffraction method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear index | aaaaa | aaaaa |

| Wear index | aaaaa | aaaaa |

| Wear index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap