Preparation method and application of redox graphene

A graphene and oxide stone technology is applied in the field of preparation of reduced graphene oxide to achieve the effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

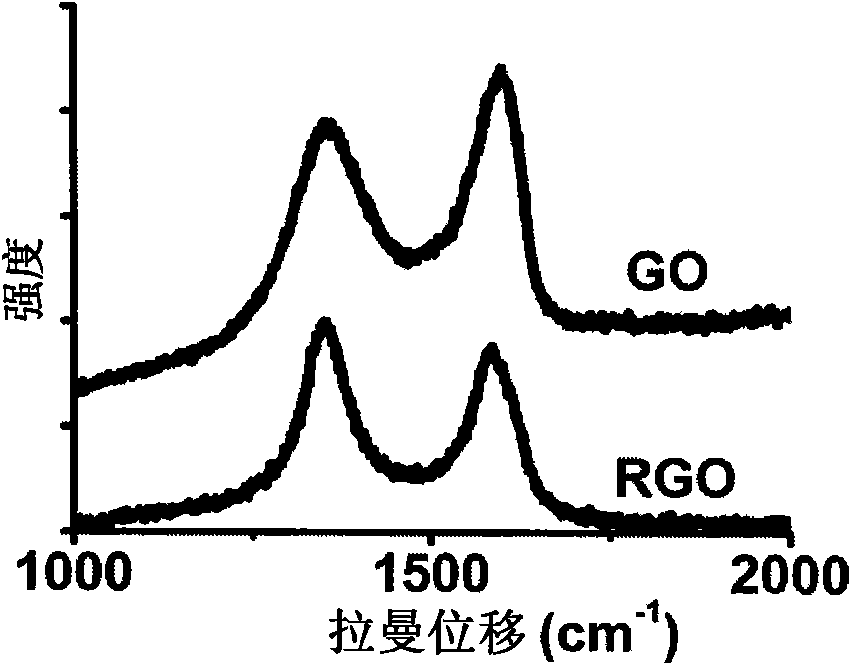

[0034] Embodiment 1, repair graphene oxide

[0035] 1) Preparation of graphene oxide (GO) aqueous solution:

[0036] Graphene oxide was prepared by exfoliating graphite (purity, 99wt%) with an average particle size of 20 μm by the modified Hummers method. Add 1g of graphite to the solution containing 0.5g NaNO 3 23ml of sulfuric acid solution. Slowly add 3 g of potassium permanganate dropwise into the above mixed solution under vigorous stirring in an ice-water bath below 10°C. Stirring was continued for 5 days after the ice-water bath was removed. Add ultrapure water to the above slurry product, continue stirring for 30 min, and then add 125 ml (3 wt %) of hydrogen peroxide. After repeated precipitation, filtration, and centrifugation, the bright brown mixture was purified until no sulfate in the upper layer solution was detected with saturated barium chloride solution, and then graphene oxide was obtained by filtration. The obtained graphene oxide is dispersed in water ...

Embodiment 2

[0047] Embodiment 2, repairing graphene oxide and its application as electrode material in photoelectric response devices

[0048] The preparation of graphene oxide solution is as embodiment 1;

[0049] The preparation of graphene oxide (GO) film sample is as embodiment 1;

[0050] The method of vacuum thermal deposition of gold film on the graphene oxide film is as in Example 1, the difference is that the model is G75, the distance between the gap electrodes is 20 μm to 50 μm, the edge width of the copper mesh is 280 to 300 μm, and the diameter is 3mm. The copper mesh is a mask, such as Figure 5 shown;

[0051] The method of electron injection repairing graphene oxide film is as embodiment 1:

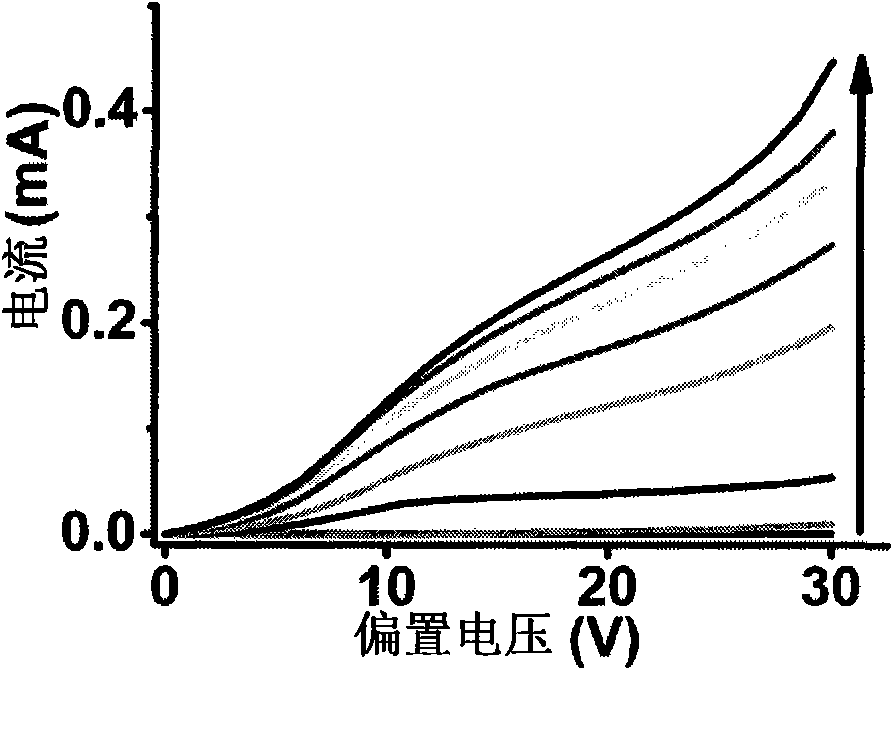

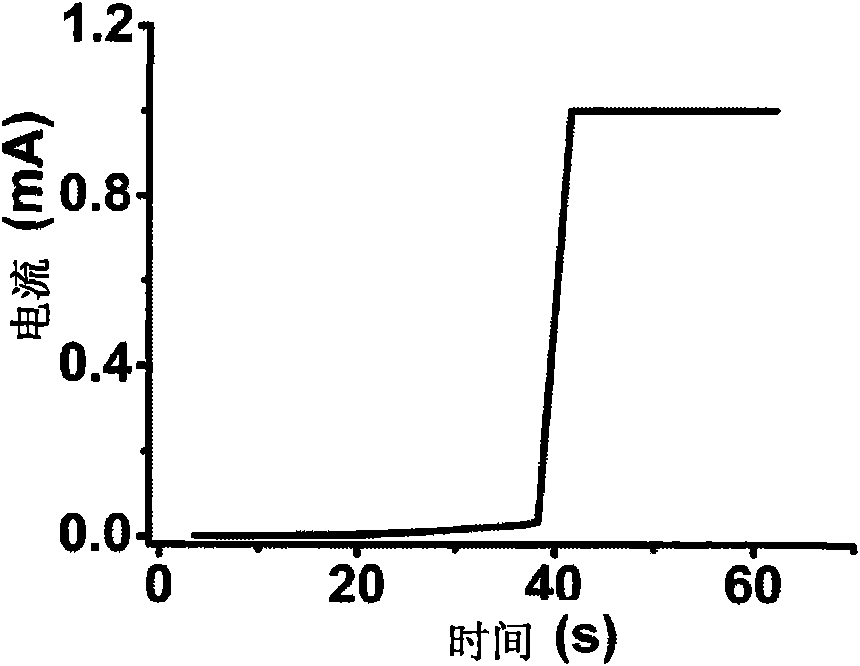

[0052] When the distance between the gap electrodes is 20 μm to 50 μm, in situ electron injection repairing of the graphene oxide film can be achieved by energizing at a voltage of 30 V for a certain period of time (20-600 s).

[0053] When the distance between the gap electrodes ...

Embodiment 3

[0060] Embodiment 3, the application of repairing graphene oxide as an electrode material in a photoelectric response device

[0061] The preparation of graphene oxide aqueous solution is as embodiment 1;

[0062] Preparation of graphene oxide (GO) film samples: Use a micro-injector to pipette 500 μl of graphene oxide aqueous solution with a concentration of 3 mg / ml and drop it on a hydrophilic glass slide, let it dry naturally, and obtain a thickness of 100 μl. - 300nm graphene oxide film. Store in a clean environment at room temperature.

[0063] The method of vacuum thermal deposition of gold film on the graphene oxide film is the same as that in Example 1, except that an aluminum foil with a width of 0.5-2 mm is used as a mask.

[0064] The method for repairing graphene oxide film by electron injection is as in Example 1, the difference is that because the width of the gap electrode is 0.5-2mm, it needs to be energized at 180V for a long time (20min) to realize in-situ e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com