Large power super capacitor power battery

A technology for power batteries and supercapacitors, applied in capacitor electrodes, capacitors, electrolytic capacitors, etc., can solve the problems of high cost, expensive supercapacitors, troublesome preparation of titanium dioxide dielectric layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

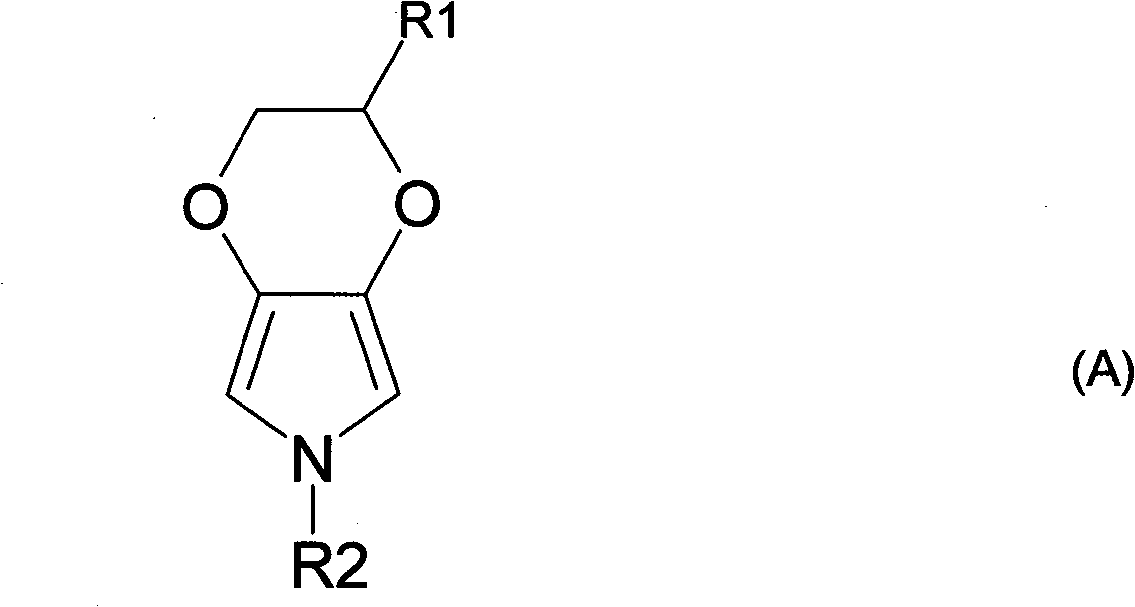

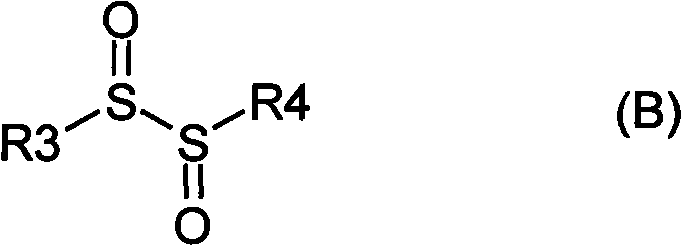

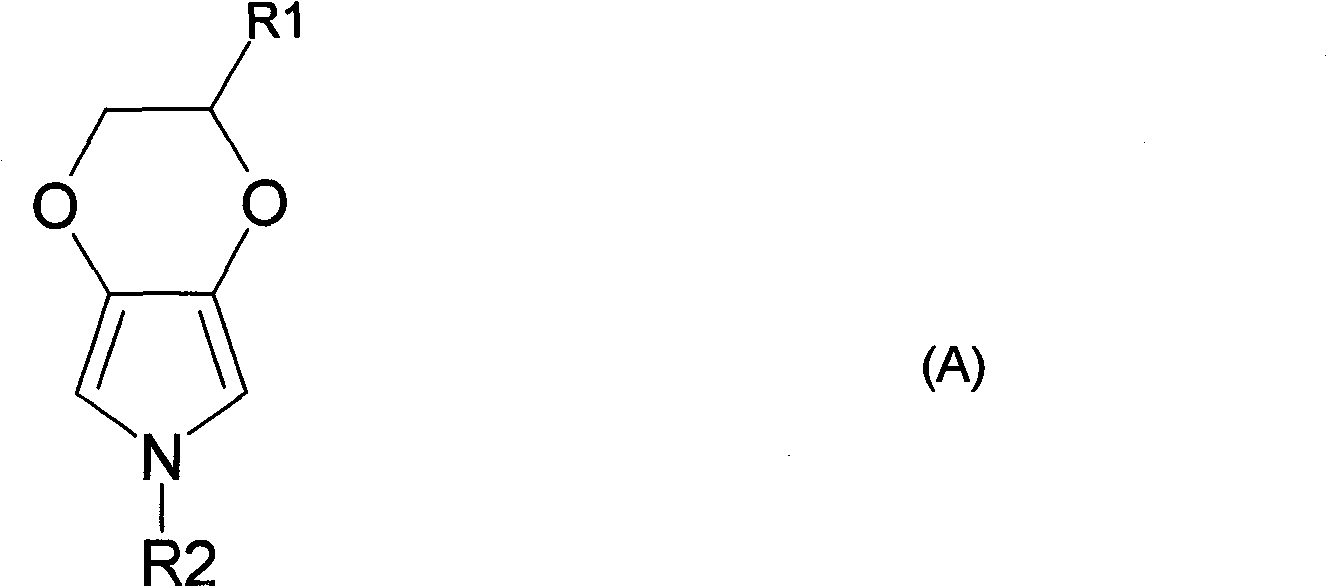

[0052] 20*20cm thicker than 0.2mm of 60 / 40 in a piece of titanium aluminum 2 Except for one corner, 95% of the titanium-aluminum alloy foil is immersed in 10% hydrochloric acid, and kept at room temperature for 6-8 hours of corrosion reaction until no bubbles are generated. Then the corroded porous skeleton titanium foil was washed with water and dried. Then heated at 1000° C. for 2 hours under the condition of oxygenation, and formed a rutile titanium dioxide oxide film with a thickness of about 500 nm on the inner surface of the pores of the porous skeleton titanium foil. After cooling to room temperature, immerse in the mixture of N-methyl-3,4-ethylenedioxypyrrole and dibenzyl sulfoxide, and heat to 80 degrees to initiate N-methyl 3,4-ethylene Dioxypyrrole is polymerized in bulk and covered on the surface of the titanium dioxide oxide film to form a conductive polymer cathode.

[0053] Detection capacitance C=1.33F. Breakdown voltage: 865V

Embodiment 2

[0055] 20*20cm thick in a piece of titanium aluminum ratio 0.2mm of 50 / 50 2 Except for one corner, 95% of the titanium-aluminum alloy foil is immersed in 10% hydrochloric acid, and kept at room temperature for 6-8 hours of corrosion reaction until no bubbles are generated. Then the corroded porous skeleton titanium foil was washed with water and dried. Then heated at 1000° C. for 2 hours under the condition of oxygenation, and formed a rutile titanium dioxide oxide film with a thickness of about 500 nm on the inner surface of the pores of the porous skeleton titanium foil. After cooling to room temperature, immerse in the mixture of N-methyl-3,4-ethylenedioxypyrrole and dibenzyl sulfoxide, and heat to 80 degrees to initiate N-methyl-3,4-ethylene The base dioxypyrrole is bulk polymerized and covered on the surface of the titanium dioxide oxide film to form a conductive polymer cathode.

[0056] Detection capacitance C=1.41F. Breakdown voltage: 780V

Embodiment 3

[0058] 20*20cm thicker than 0.2mm of 70 / 30 in a piece of titanium aluminum 2 Except for one corner, 95% of the titanium-aluminum alloy foil is immersed in 10% hydrochloric acid, and kept at room temperature for 6-8 hours of corrosion reaction until no bubbles are generated. Then the corroded porous skeleton titanium foil was washed with water and dried. Then heated at 1000° C. for 2 hours under the condition of oxygenation, and formed a rutile titanium dioxide oxide film with a thickness of about 500 nm on the inner surface of the pores of the porous skeleton titanium foil. After cooling to room temperature, immerse in the mixture of N-methyl-3,4-ethylenedioxypyrrole and dibenzyl sulfoxide, and heat to 80 degrees to initiate N-methyl-3,4-ethylene The base dioxypyrrole is bulk polymerized and covered on the surface of the titanium dioxide oxide film to form a conductive polymer cathode.

[0059] Detection capacitance C=1.06F. Breakdown voltage: 930V

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com