II type collagen hyaloplasm acid compound sponge bracket and use thereof

A technology of hyaluronic acid and composite sponge, which is applied in the field of biomedicine, can solve the problems of high collagen concentration and high production cost, and achieve the effect of good performance, maintaining mechanical properties and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Embodiment, the preparation of type II collagen hyaluronic acid composite sponge scaffold of the present invention

[0040] 1. Preparation of high-purity type II collagen [Reference: Li Siming, Ye Chunting, etc., Preparation and detection of high-purity porcine cartilage type II collagen, Journal of Biomedical Engineering, 2001, 18(4)592-594]:

[0041] Material:

[0042] Fresh pig articular cartilage: obtained from the limb articular cartilage of freshly slaughtered pigs in the slaughterhouse

[0043] Guanidine hydrochloride: Farco 500g / bottle

[0044] Pepsin: Sigma 100g / bottle

[0045] The rest are domestic analytical reagents.

[0046] method:

[0047] Cut the hyaline cartilage from freshly slaughtered pig limb joints, cut into thin slices, degrease, mash, and homogenate, then stir with 10 times the volume of 4M (pH7.5) guanidine hydrochloride for 24 hours, and centrifuge; the sediment diameter is fully washed , Weigh the precipitated cartilage particles with a w...

experiment example 1

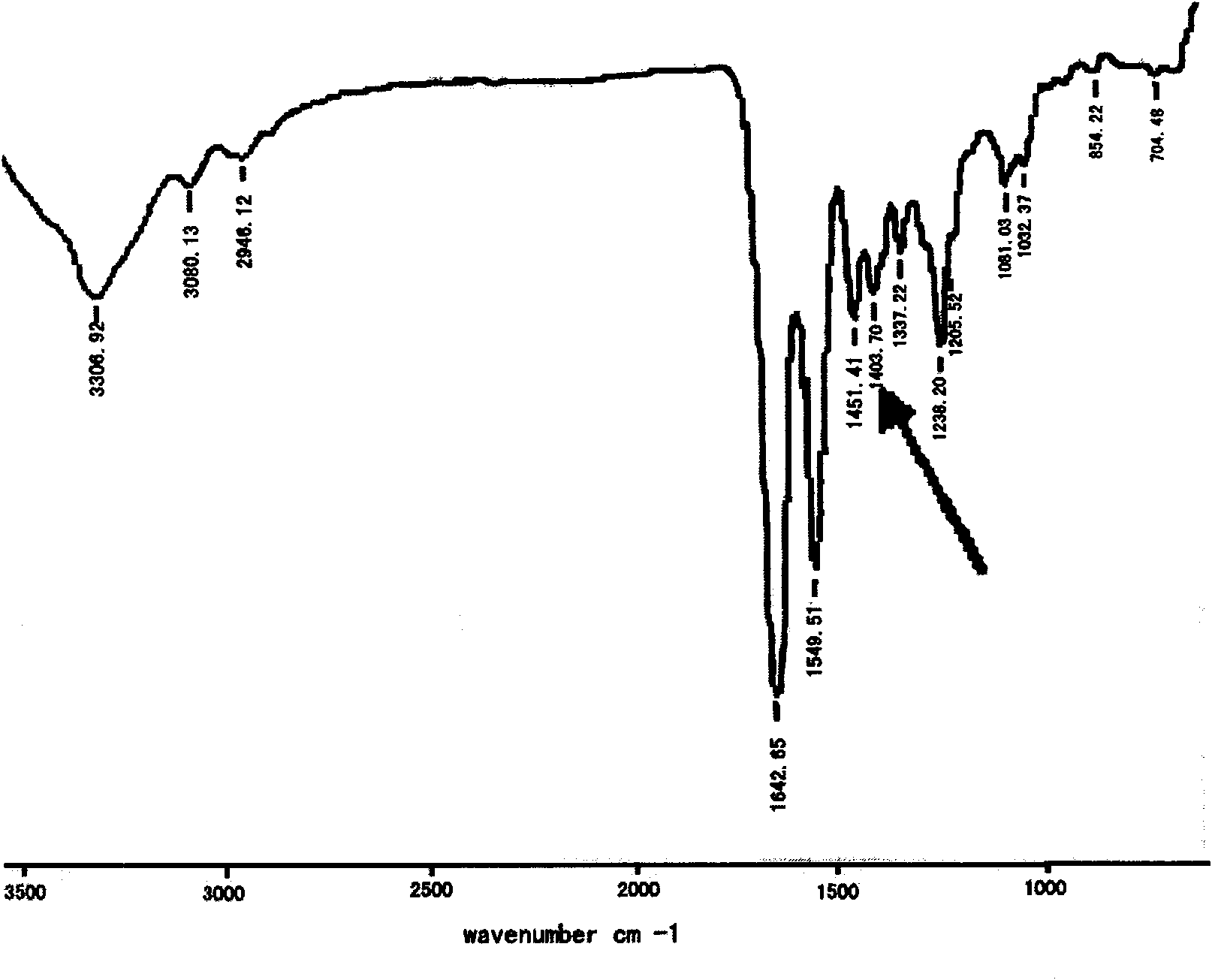

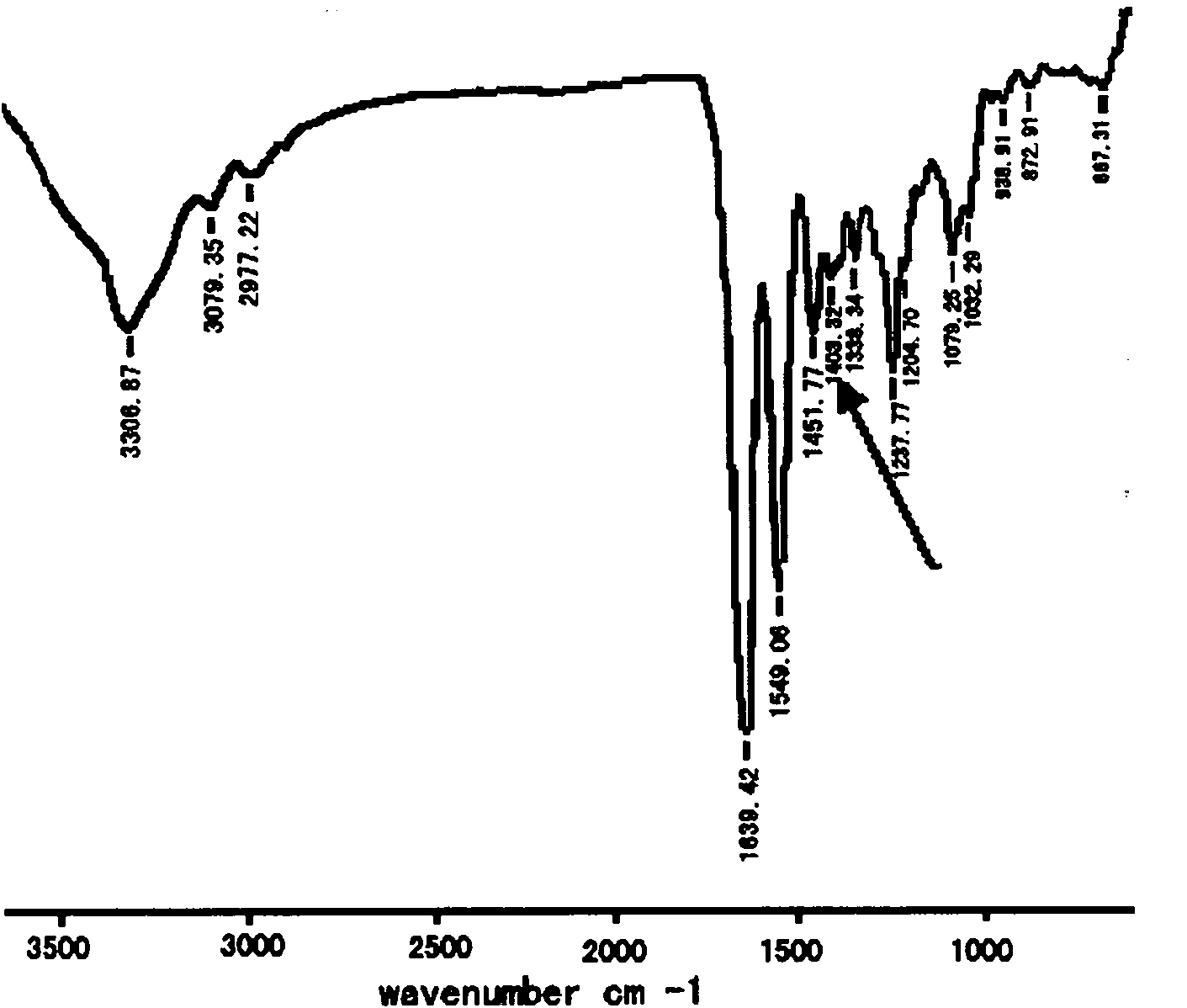

[0058] Experimental Example 1: Infrared Spectroscopy (FTIR) Analysis

[0059] The type II collagen hyaluronic acid composite sponge scaffold material of the present invention is compared with the type I collagen hyaluronic acid composite sponge material reported in the literature, and is measured by an infrared spectrometer (Spectrum one, Perkin-Elmer, USA).

[0060] Compared with the FTIR spectrogram, the present invention adopts the partial homogenization method to obtain the type II collagen hyaluronic acid composite sponge scaffold, and the traditional full homogenization method to obtain the type I collagen hyaluronic acid composite sponge. -1 The characteristic absorption peaks of hyaluronic acid appear in both of them, which proves that the two homogenization methods can prepare composite sponges with two characteristics of collagen and hyaluronic acid. The results are as follows: Figure 3a and Figure 3b shown.

experiment example 2

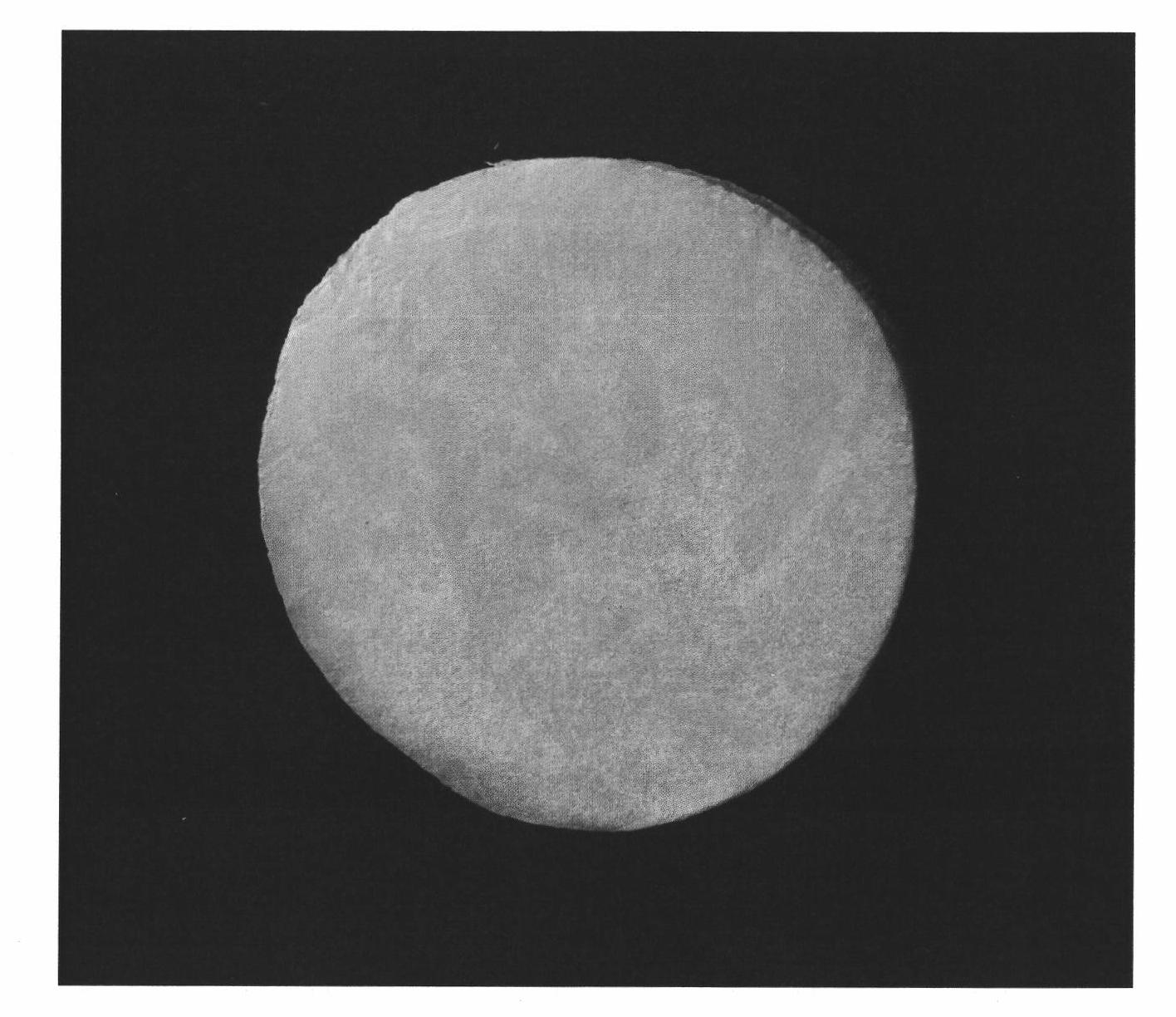

[0061] Experimental Example 2: Pore Size Detection of Type II Collagen Hyaluronic Acid Composite Sponge Scaffold

[0062] The type II collagen hyaluronic acid composite sponge support material of the present invention is compared with the type I collagen hyaluronic acid composite sponge reported in the literature and the type II collagen hyaluronic acid material prepared by the existing full homogenization method. The results are shown in Table 1

[0063] Collagen autofluorescence layered scanning was carried out on two kinds of collagen sponges by laser confocal microscope, the excitation wavelength was 488nm, the emission wavelength was 520nm, and the measurement was carried out with the limit of autofluorescence signal intensity to determine the pore size of the sponge material; using CLSM image analysis system Carry out operation and analysis, and then use SPSS13.0 software package to make statistics on the data.

[0064] The result is as Figure 2a and Figure 2b and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com