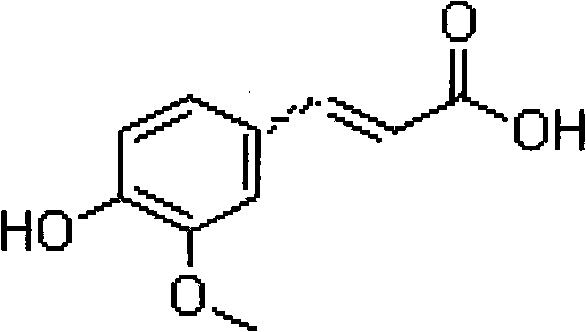

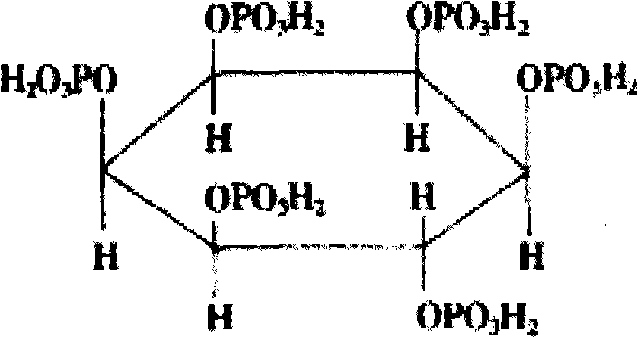

Technology for preparing ferulic acid and phytic acid from rice bran

A ferulic acid and phytic acid technology, applied in the separation/purification of carboxylic acid compounds, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc., can solve the problem of difficult control of the replacement end point and high calcium and magnesium content , heating and other issues, to achieve the effect of easy continuous production, low protein content and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Crush the rice bran through a 20-mesh sieve, put 100kg of rice bran into an extraction tank, add 600L of calcium hydroxide aqueous solution with a pH of 12 and 75g of vitamin C, heat and dynamically soak for 1.5 hours, extract twice, and combine the two filtrates to obtain 1150L of filtrate and filter residue.

[0046] Pass the filtrate through the 724-type cation exchange resin, collect the infusion solution and concentrate under reduced pressure, and mix n-hexane-ethyl acetate-ethanol-water with a volume ratio of 5:3:5:1 in the separatory funnel, shake well Leave to stand for stratification, get the upper phase as the stationary phase, and the lower phase mobile phase, dissolve 200 mg of the concentrated solution with 40 ml of the upper and lower phase mixed solution of 1:1 to separate, collect the ferulic acid component peak, and freeze-dry to obtain the ferulic acid Ferulic acid solid.

[0047] Add 400L of pH2 aqueous solution adjusted to the filter residue with hy...

Embodiment 2

[0049] Grind the rice bran through a 40-mesh sieve, put 200kg of rice bran into the extraction tank, add 1400L of calcium hydroxide aqueous solution with a pH of 13 and 150g of vitamin C, heat and dynamically soak for 1 hour, extract twice, and combine the two filtrates to obtain 2700L of filtrate and filter residue.

[0050]Pass the filtrate through 732-type cation exchange resin, collect the infusion solution and concentrate under reduced pressure, mix n-hexane-acetone-ethanol-water with a volume ratio of 6:3:7:1 in a separatory funnel, shake well and let stand Layering, the upper phase is taken as the stationary phase, and the lower phase mobile phase is separated by dissolving 200 mg of the concentrated solution in 40 ml of the upper and lower phase mixed solution of 1: 1, collecting the ferulic acid component peak, and freeze-drying to obtain ferulic acid The solid content is above 98%.

[0051] Add 1000L of pH3 aqueous solution to the filter residue adjusted with sulfur...

Embodiment 3

[0053] Crush the rice bran through a 60-mesh sieve, put 400kg of rice bran into an extraction tank, add 3000L of calcium hydroxide aqueous solution with a pH of 11 and 300g of vitamin C, heat and dynamically soak for 1 hour, extract twice, and combine the two filtrates to obtain 5500L of filtrate and filter residue.

[0054] Pass the filtrate through 724-type cation exchange resin, collect the infusion solution and concentrate, mix n-hexane-ethyl acetate-ethanol-water with a volume ratio of 5:4:8:1 in a separatory funnel, shake well and let stand Layering, the upper phase is taken as the stationary phase, and the lower phase mobile phase is separated by dissolving 200 mg of the concentrated solution in 40 ml of the upper and lower phase mixed solution of 1: 1, collecting the ferulic acid component peak, and freeze-drying to obtain ferulic acid The solid content is above 98%.

[0055] Add 2200L of pH3 aqueous solution to the filter residue adjusted with hydrochloric acid, soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com