Synthesis method of 2-thiophene acetylchloride

A technology of thiophene acetyl chloride and a synthesis method, which is applied in the field of preparation of 2-thiophene acetyl chloride, can solve the problems of cumbersome reaction steps, high cost, unsuitable for industrialized production and the like, and achieves high product purity, simple and convenient operation, and easy-to-obtain raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

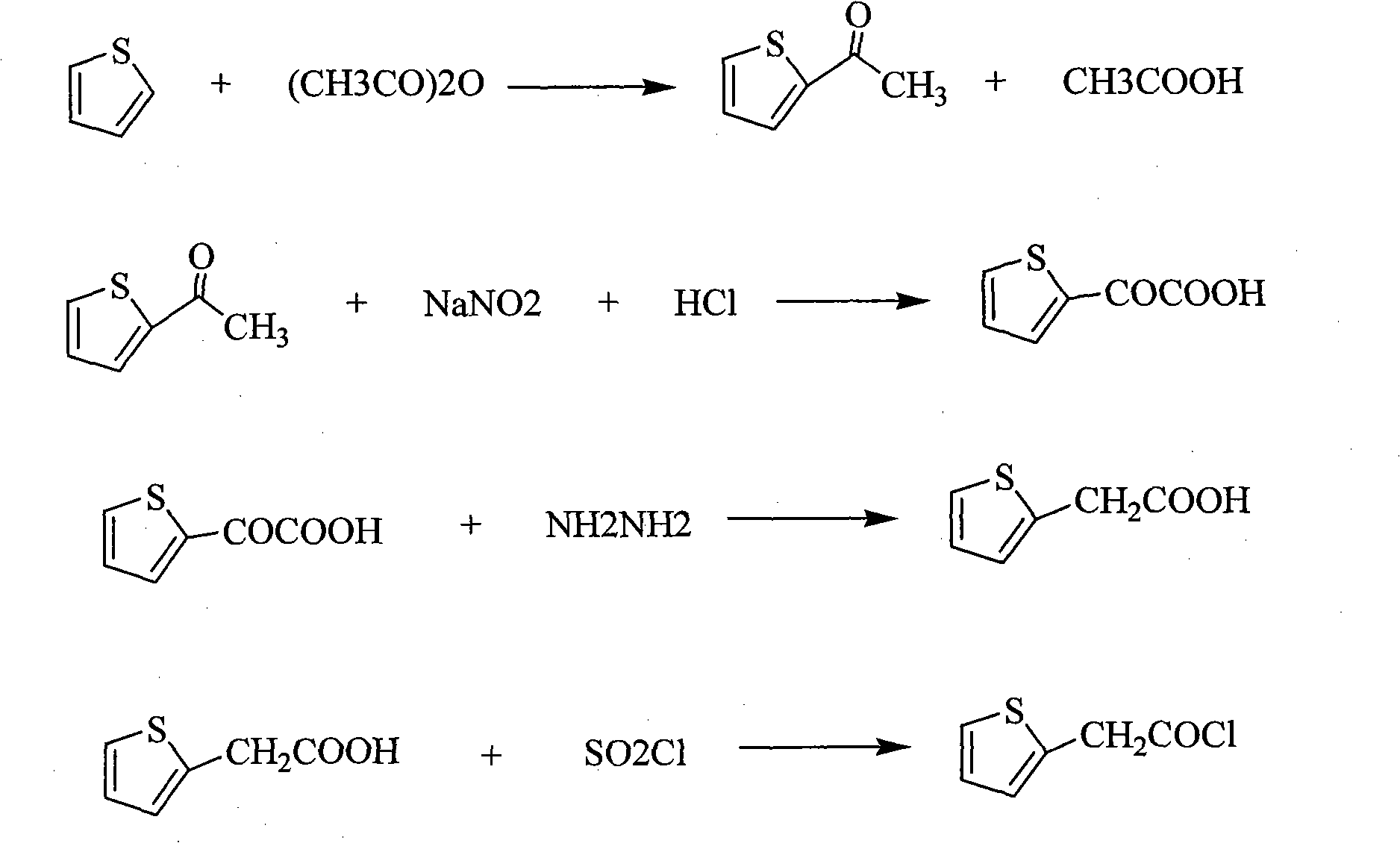

[0030] Example 1. A kind of synthetic method of 2-thiophene acetyl chloride, its step is as follows:

[0031] (1) Preparation of 2-acetylthiophene: in the presence of a catalyst, thiophene and acylating agent were heated and reacted in an organic solvent for 3 hours, the molar ratio of thiophene and acylating agent was 1: 1.0, and the reaction temperature was 65° C. Collect 102 DEG C (15mmHg) fractions by vacuum distillation to obtain 2-acetylthiophene; the acylating agent is acetic acid; the catalyst used is concentrated phosphoric acid; the organic solvent is ethylene dichloride;

[0032] (2) Preparation of 2-thiophene glyoxylic acid: in the presence of catalyst, get 2-acetylthiophene and carry out heating reaction in the mixed solution of sodium nitrite and hydrochloric acid, the weight ratio of 2-acetylthiophene, sodium nitrite and hydrochloric acid is 1:1.5:10, the reaction temperature is 65°C, cool down after the reaction, adjust the pH to 2, extract with organic solven...

Embodiment 2

[0035] Example 2. A kind of synthetic method of 2-thiophene acetyl chloride, its step is as follows:

[0036] (1) Preparation of 2-acetylthiophene: in the presence of a catalyst, thiophene and acylating agent were heated and reacted in an organic solvent for 10 hours, the molar ratio of thiophene and acylating agent was 1: 1.8, and the reaction temperature was 95° C. Collect 105 DEG C (15mmHg) fractions by vacuum distillation to obtain 2-acetylthiophene; the acylating agent is acetyl chloride; the catalyst used is molecular sieve; the organic solvent is tetrachloroethylene;

[0037] (2) Preparation of 2-thiophene glyoxylic acid: in the presence of catalyst, get 2-acetylthiophene and carry out heating reaction in the mixed solution of sodium nitrite and hydrochloric acid, the weight ratio of 2-acetylthiophene, sodium nitrite and hydrochloric acid is 1:5.0:15, the reaction temperature is 95°C, cool down after the reaction, adjust the pH to 3, extract with organic solvent to rem...

Embodiment 3

[0040] Example 3. A kind of synthetic method of 2-thiophene acetyl chloride, its step is as follows:

[0041] (1) Preparation of 2-acetylthiophene: in the presence of a catalyst, thiophene and acylating agent were heated and reacted in an organic solvent for 6 hours, the molar ratio of thiophene and acylating agent was 1: 1.2, and the reaction temperature was 85° C. Vacuum distillation collects fractions at 103°C (15mmHg) to obtain 2-acetylthiophene; the acylating agent is acetic anhydride; the catalyst used is trifluoromethanesulfonate; the organic solvent is N,N-dimethylformaldehyde amides;

[0042] (2) Preparation of 2-thiophene glyoxylic acid: in the presence of catalyst, get 2-acetylthiophene and carry out heating reaction in the mixed solution of sodium nitrite and hydrochloric acid, the weight ratio of 2-acetylthiophene, sodium nitrite and hydrochloric acid is 1:3:13, the reaction temperature is 85°C, cool down after the reaction, adjust the pH to 3, extract with orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com