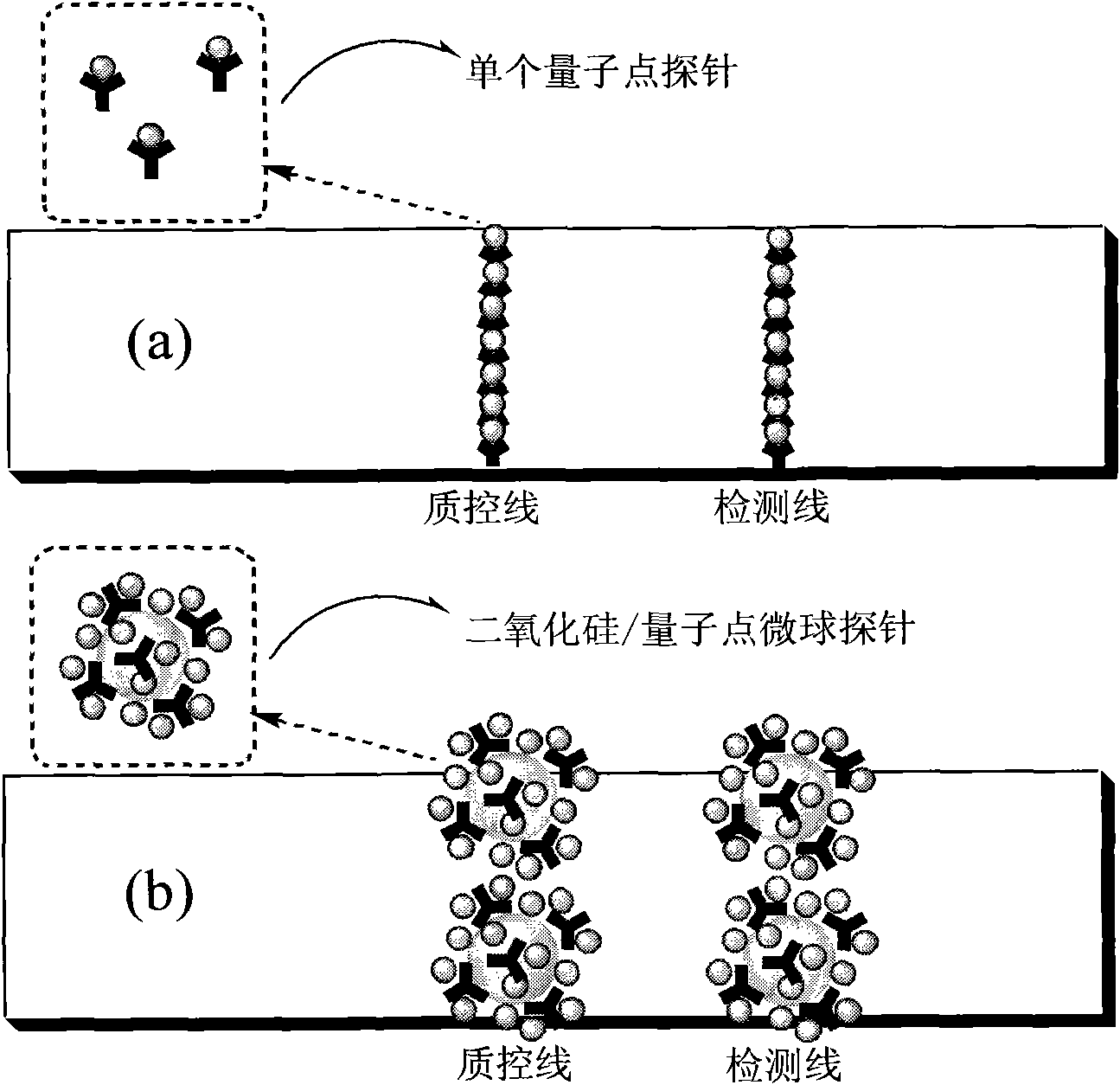

Rapid detection method employing ultrasensitive quantum dot microsphere immunity-chromatograph test paper strips

A technology of immunochromatography and detection method, which is applied in the field of detection, can solve the problems of strict detection limit, quenching of fluorescence intensity, unobtainable and other problems, and achieve the effect of simple detection method, improved sensitivity and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

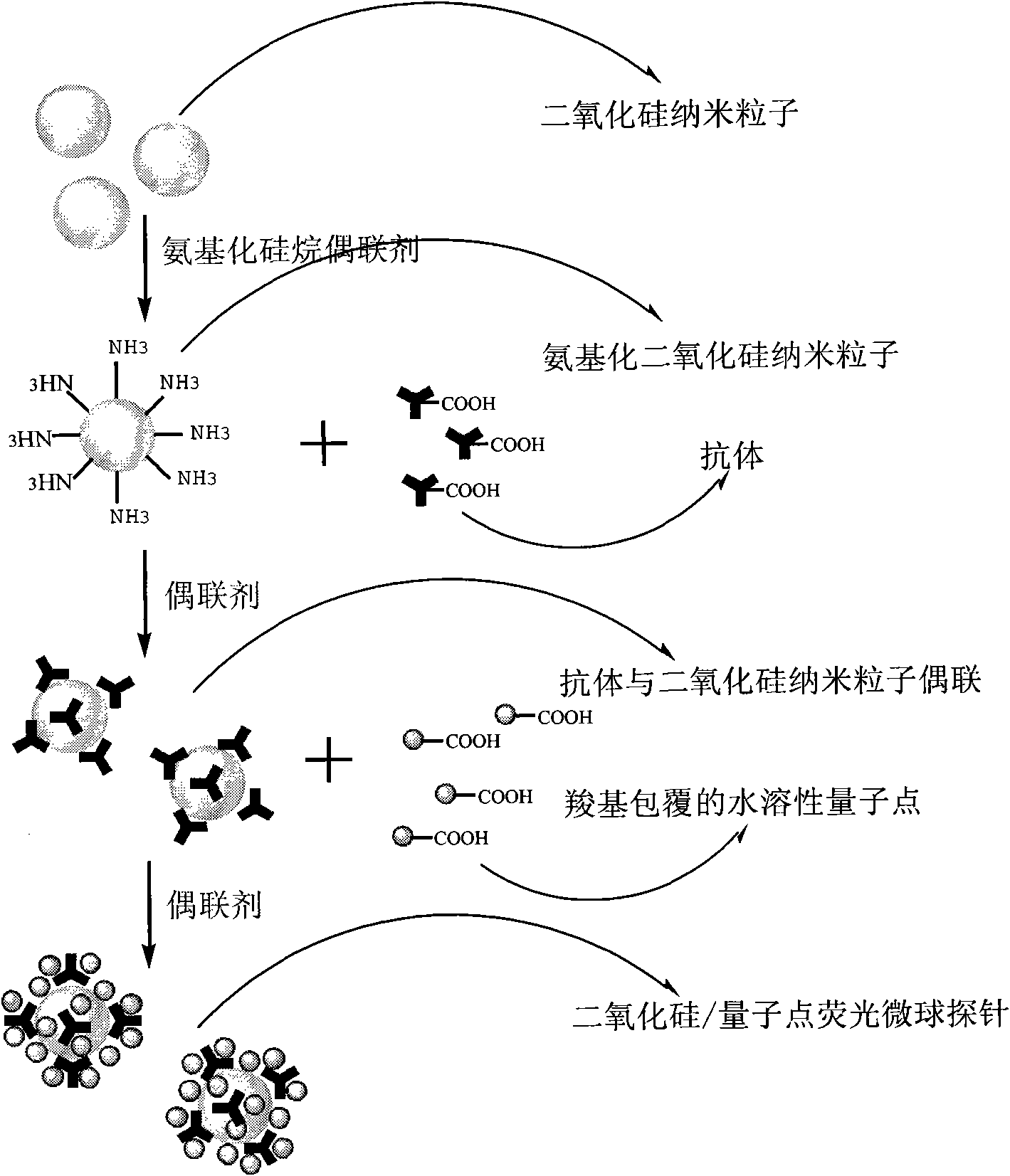

Embodiment 1

[0055] Preparation of aminated silica: Weigh 8.85ml Triton X-100, 37.5ml cyclohexane, 9ml n-hexanol and an appropriate amount of water to form an inverse microemulsion system, respectively add 0.5ml TEOS and 0.3ml ammonia water under magnetic stirring, After reacting for 24 hours, 0.1ml APTES and 0.05ml THPMP were added to continue the reaction for 12 hours, acetone was demulsified, purified by high-speed centrifugation and dried. Characterized by field emission scanning electron microscopy, the particle size is 115nm.

[0056] Aqueous phase synthesis of CdTe quantum dots: 2×10 in nitrogen saturated 244mL -2 mol / LCdCl 2 2.5H 2 O solution (114.2 mg) was added with 104.4 uL of mercaptopropionic acid, and the pH of the solution was adjusted to about 9.2 with 1 mol / L NaOH. Inject freshly prepared NaHTe. Under vigorous stirring, deoxidize with N2 for 20 minutes, then quickly add the above-mentioned newly prepared sodium telluride hydride solution into the reaction system, and f...

Embodiment 2

[0061] Preparation of aminated silica: In the ethanol / water mixed system, add 2ml tetraethyl orthosilicate and 2ml ammonia water, stir magnetically for 12 hours to obtain silica nanoparticles, remove impurities by high-speed centrifugation, and add 1ml of APTES was refluxed at 90°C for 12 hours to obtain aminated silica nanoparticles with a particle size of 231nm.

[0062] Synthesis of CdTe / ZnSe quantum dots: Synthesize oil-soluble CdTe / CdSe core-shell quantum dots in a high-temperature organic phase, and then use MPA for ligand exchange to transfer the oil-soluble quantum dots to the water phase. Water-soluble CdTe / CdSe quantum dots coated with carboxyl groups are obtained.

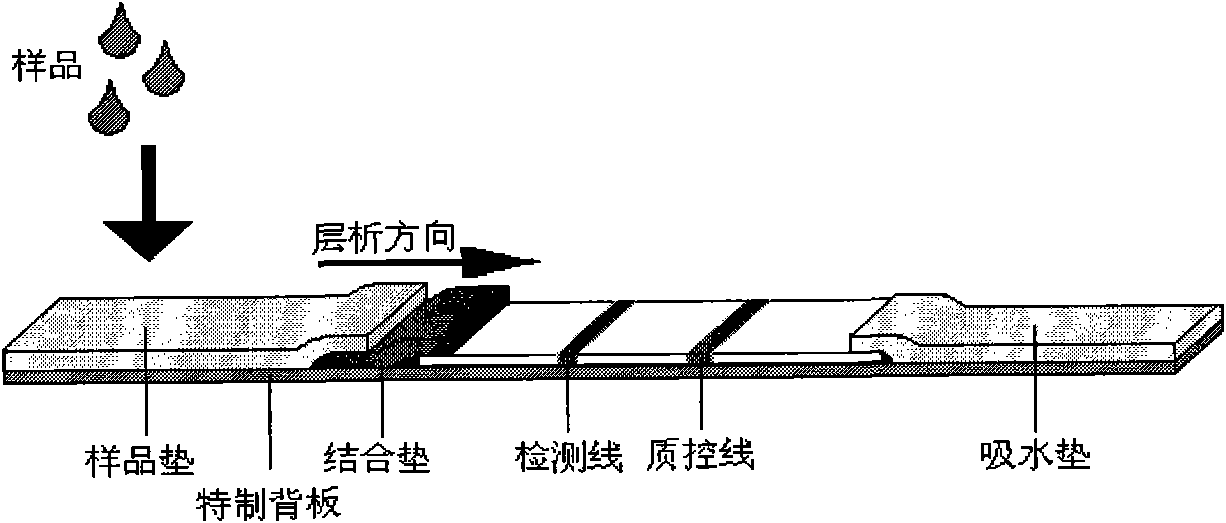

[0063] The green anti-penicillin monoclonal antibody silica / quantum dot microsphere probe and the red anti-chloramphenicol monoclonal antibody silica / quantum dot microsphere probe were prepared according to the method in Example 1. Spray on the binding pads respectively, and arrange the two binding pads...

Embodiment 3

[0066] The preparation of aminated silica nanoparticles and water-soluble quantum dots is the same as in Example 1.

[0067] According to the method of Example 1, the silica / red quantum dot microsphere probe coupled with anti-alpha-fetoprotein monoclonal antibody was prepared.

[0068] On the special backboard, paste NC film (with the goat anti-mouse quality control line and the anti-alpha-fetoprotein polyclonal antibody detection line drawn with a film-drawing instrument), water-absorbing pads, and secondary antibodies sprayed with anti-alpha-fetoprotein monoclonal antibody. The bonding pad of the silicon oxide / red quantum dot microsphere probe, the sample pad, and then cut into 4mm wide strips with a strip cutter.

[0069] In semi-quantitative testing, if a red line appears on the test line, it is positive, otherwise it is negative. If the quality control line does not show red, the test is invalid.

[0070]For quantitative detection, prepare a series of alpha-fetoprotein s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com