Multilevel pore channel SAPO-11 molecular sieve and synthetic method of hydrocarbon isomerization catalyst

A SAPO-11, synthesis method technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of single pore channel, small external surface area, poor selectivity of double-branched and multi-branched chains, etc. Achieve the effect of increasing pore volume and pore size, increasing specific surface area, and increasing selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 HP-SAPO-11-1

[0036] Mix 13.6g of phosphoric acid (AR, 85%) and 45g of deionized water in a water bath at 35°C, add 9g of pseudo-boehmite and 3.9g of tetraethyl orthosilicate (AR, 99%), and place in a water bath at 35°C After 2h of medium magnetic stirring, add 1.27g ethylene group didodecyl dimethyl ammonium bromide [C 12 h 25 N + (CH 3 ) 2 -C 2 h 4 -N + (CH 3 ) 2 C 12 h 25 ]2Br - , the amount added is the same as the aluminum source (pseudoboehmite, as Al 2 o 3 The molar ratio of the mixture) is 3:100, after continuing to stir in a water bath at 35° C. for 2 hours, slowly add 7.9 g of di-n-propylamine (AR, 99%), and stir for 2 hours until a mixed solution (sol) is formed;

[0037] Put the mixed solution into a polytetrafluoroethylene high-pressure reactor, crystallize it in an oven at 185°C for 28 hours, then perform centrifugation, wash the solid product with deionized water to pH = 7-8, and then cool it at 120°C Dry for 6 hours to obtain th...

Embodiment 2

[0043] Example 2 HP-SAPO-11-2

[0044] The 1.27g ethylene group double dodecyl dimethyl ammonium bromide of embodiment 1 is changed into 2.5g double dodecyl polyoxyethylene ether triquaternary ammonium chloride [(C n h 2n+1 ) 2 -N + -[(EO) 5 -O-C 2 h 4 -N + (CH 3 ) 2 C 2 h 5 ] 2 ]3Cl - , the molar ratio of the added amount to the aluminum source was 3:100, and the rest of the components and synthesis conditions were the same as in Example 1 to prepare a multi-stage porous SAPO-11 molecular sieve (HP-SAPO-11-2).

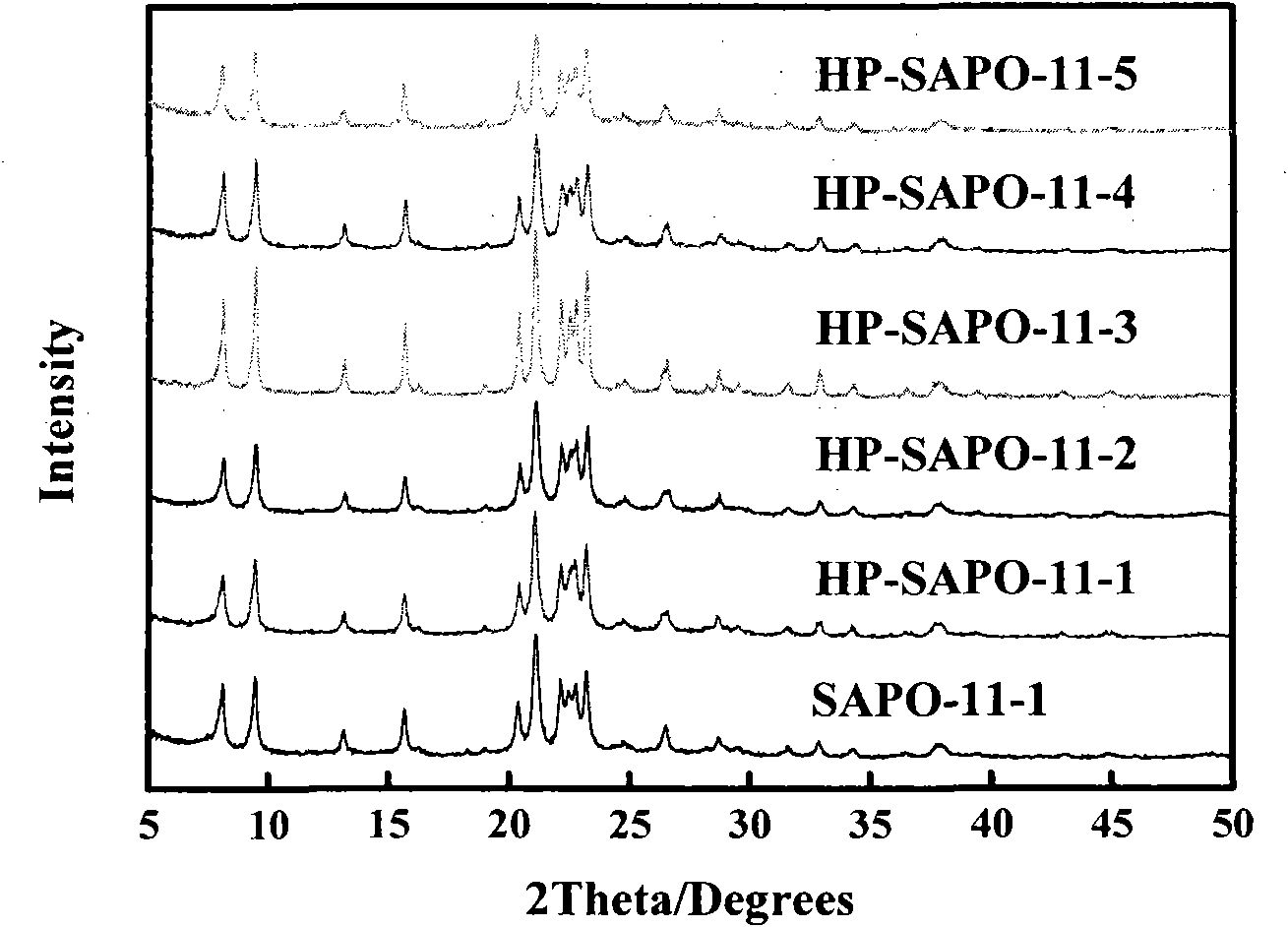

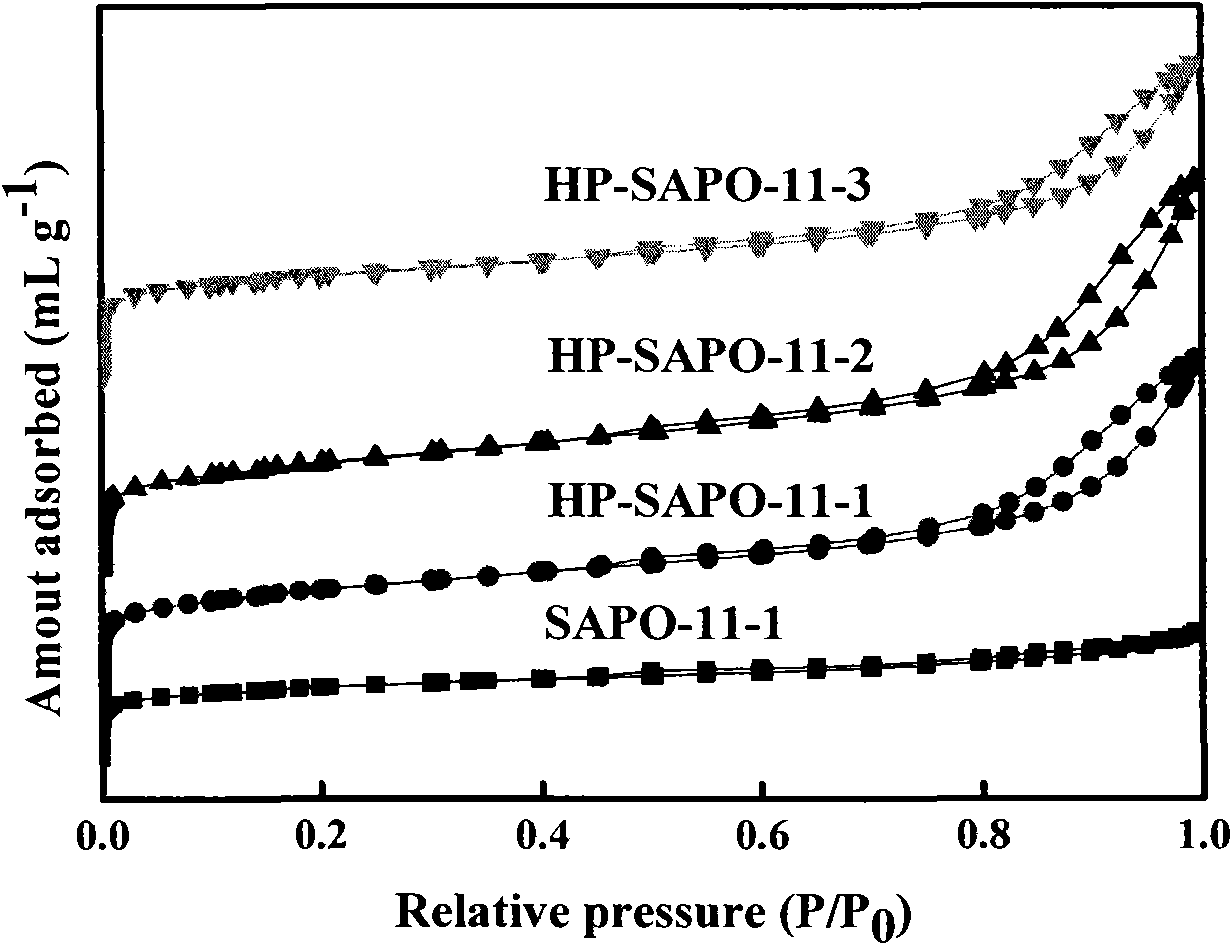

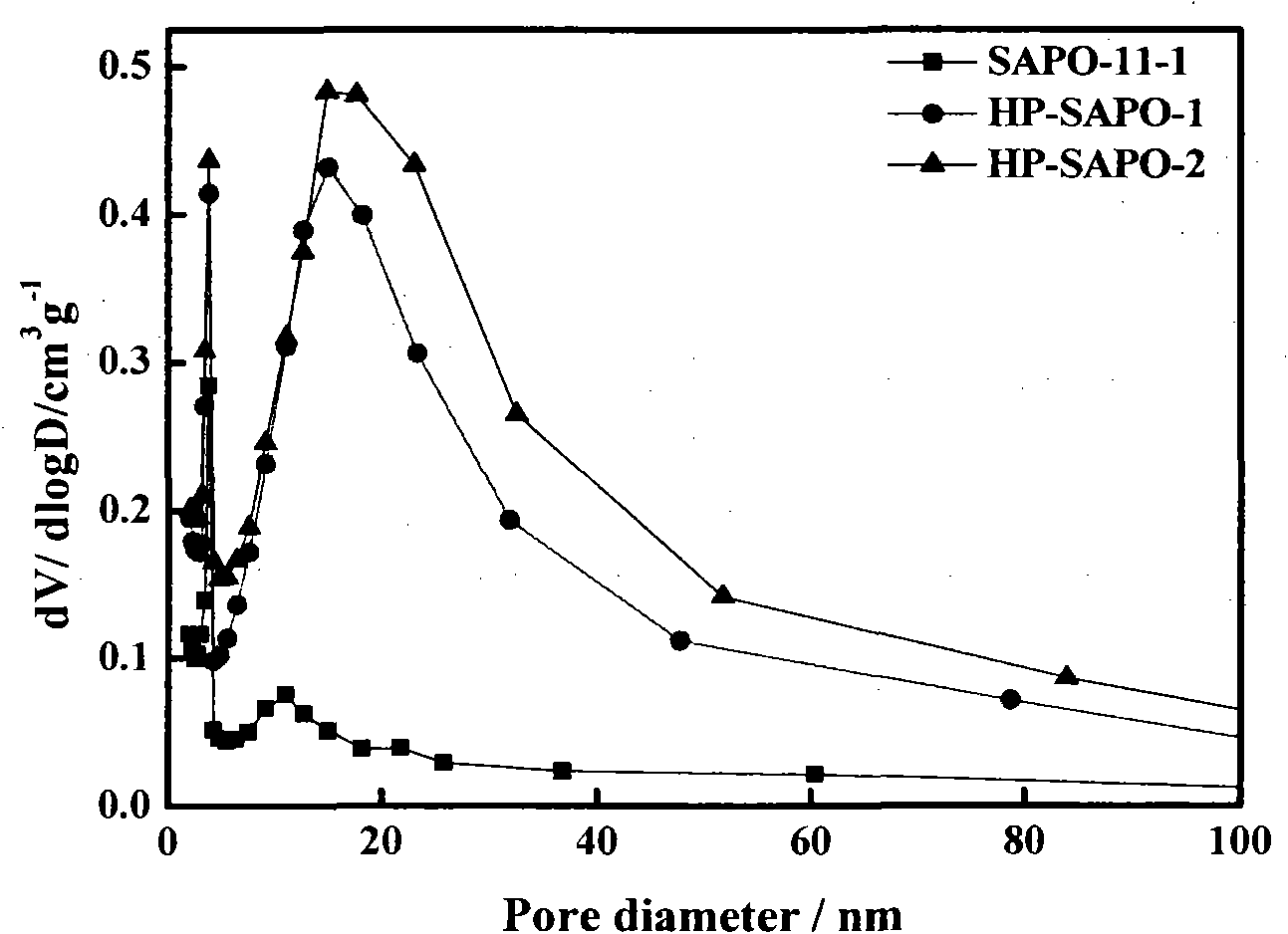

[0045] The XRD characterization results of the obtained HP-SAPO-11-2 molecular sieve are shown in figure 1 , the pore structure data are shown in Table 1, the nitrogen adsorption and desorption distribution data are as follows figure 2 As shown, the pore structure distribution is as image 3 shown.

Embodiment 3

[0046] Example 3 HP-SAPO-11-3

[0047] The 1.27g ethylene group didodecyl dimethyl ammonium bromide in embodiment 1 is changed into 5g polymer polyquaternary ammonium salt PCD (polymerization degree is 16, and molecular weight is about 8000), add-on and aluminum source The molar ratio of the compound was 3:100, and the rest of the components and synthesis conditions were the same as in Example 1 to prepare a multi-stage pore SAPO-11 molecular sieve (HP-SAPO-11-3).

[0048] The XRD characterization results of the obtained HP-SAPO-11-3 molecular sieve are shown in figure 1 , the pore structure data are shown in Table 1, and the nitrogen adsorption and desorption results are as follows figure 2 shown.

[0049] Table 1 The pore structure parameters of the SAPO-11 molecular sieves synthesized in Examples 1-3 and Comparative Example 1

[0050]

[0051] It can be seen from Table 1 that adding different types of quaternary ammonium salts during the synthesis of SAPO-11 molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com