Electrostatic enamel powder and preparation method thereof

A production method and enamel technology, which is applied in the field of electrostatic enamel powder and its production, can solve the problems of inability to spray electrostatic dry powder and poor stability of enamel, and achieve the effects of excellent spraying quality, process saving and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

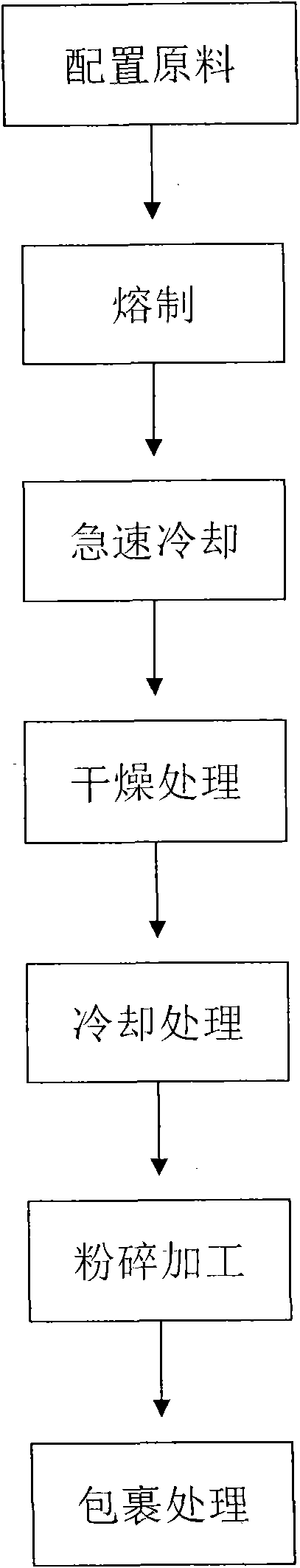

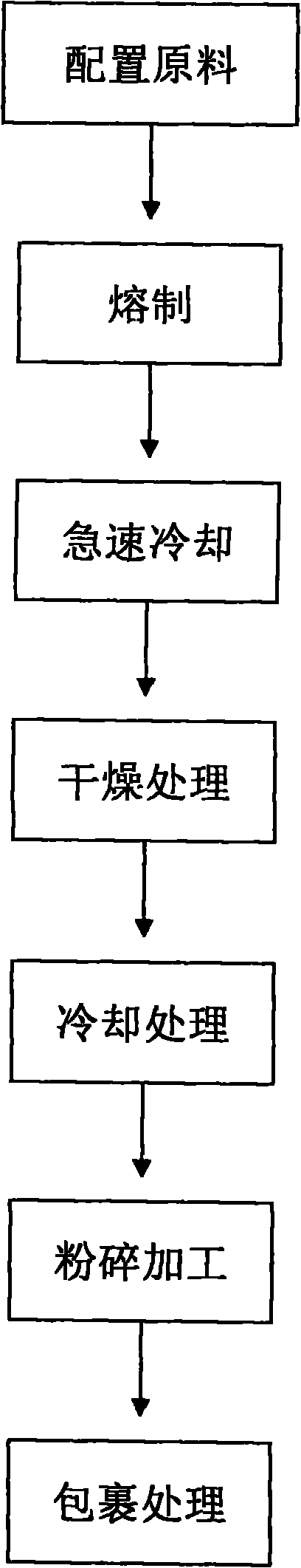

[0038] See figure 1 , the preparation method of electrostatic enamel powder in the present embodiment comprises the following steps:

[0039] 1. Prepare raw materials according to the following ingredients and weight ratio:

[0040] A. Quartz 45%;

[0041] B. Borax 18%;

[0042] C. Adhesive 5%;

[0043] D. Flux 32%;

[0044] The flux described therein includes: albite feldspar, potassium feldspar, calcium fluoride, sodium fluorosilicate, and the weight ratio of each component in the enamel powder raw material is: albite feldspar is 8%; potassium feldspar 4% %, calcium fluoride 9%, sodium fluorosilicate 11%. The adhesive is one of nickel oxide, cobalt oxide and manganese oxide. In this embodiment, nickel oxide is used.

[0045] Among the above raw materials, the main component of quartz is silicon dioxide. Its physical and chemical properties are very stable mineral resources. In the present invention, it is the main material for making enamel powder.

[0046] Borax i...

Embodiment 2

[0066] Embodiment two, this is a preferred embodiment of the present invention, and the difference from the above-described embodiment is: the raw material type and weight proportion of electrostatic enamel powder in the present invention are:

[0067] A. Quartz 50.1%;

[0068] B. Borax 12.47%;

[0069] C. Adhesive 5.6%;

[0070] D. The composition of the flux, that is, the weight ratio is: 10.87% of albite feldspar; 5.15% of potassium feldspar, 7.3% of calcium fluoride, and 8.51% of sodium fluorosilicate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap