Method for preparing immobilized enzyme by taking bacterial cellulose bead/membrane as vector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Pick 1 ring single colony from the acetic acid bacteria slant and inoculate in 100mL sterile seed medium, described seed medium comprises (mass percentage): glucose 2.0%, yeast powder 0.5%, tryptone 0.5%, Na 2 HPO 4 12H 2 O0.27%, 0.115% citric acid, pH5.0, cultured at 30°C, 130rpm for 12h. The seed solution was inserted into a 500mL Erlenmeyer flask containing 300mL sterile fermentation medium with a 6% inoculum amount. Described fermentation medium comprises (mass percentage): glucose 2.0%, yeast powder 0.5%, tryptone 0.3%, Na 2 HPO 4 12H 2 O 0.27%, citric acid 0.115%, pH 5.0; 30°C, 110rpm after culturing for 72 hours, many bacterial cellulose pellets were formed in the medium. After decanting the culture medium, take out the cellulose pellets, rinse them repeatedly with deionized water to remove the culture medium and impurities on the surface of the pellets, then soak the pellets in 0.1% NaOH solution, and treat them at 80°C for 60 minutes to remove the cellulos...

Embodiment 2

[0077] Preparation of Bacterial Cellulose Membrane Block Carrier

[0078] Pick 1 ring single colony from the activated slant strain and inoculate it in 100mL sterile seed culture medium. After cultivating for 12h under the condition of 100-200rpm at 30°C, the described seed culture medium comprises (mass percentage): Mannitol 2.5%, yeast powder 0.5%, tryptone 0.5%, pH5.0. The liquid seed is transferred to the fermentation medium with 4-10% inoculation amount, and the fermentation medium comprises (mass percentage): mannitol 2.5%, yeast powder 0.5%, tryptone 0.3%, pH5.0; 25 -30°C, culture statically for 5-14 days, decant, and collect the bacterial cellulose membrane. Treat the bacterial cellulose membrane collected by fermentation with 0.1% NaOH in a water bath at 80°C until the membrane is milky white and translucent, rinse with deionized water for 3-5 times, collect, and neutralize the remaining residue in the membrane with 0.1% acetic acid Lye, let it stand overnight, rins...

Embodiment 3

[0081] Preparation of immobilized laccase (simple adsorption immobilization)

[0082] Add pH 5.0, enzyme activity unit, 10mL laccase enzyme solution of 1000U / L to a 50mL beaker, add 0.2g freeze-dried bacterial cellulose membrane block and make it submerged, shake slightly for 3-5min, at 4°C After 24 hours of adsorption, the bacterial cellulose membrane was taken out, rinsed 1-2 times with 200 mM acetic acid-sodium acetate buffer solution, pH 5.2, and the moisture on the surface of the membrane was blotted, and stored in a refrigerator at 4°C for later use.

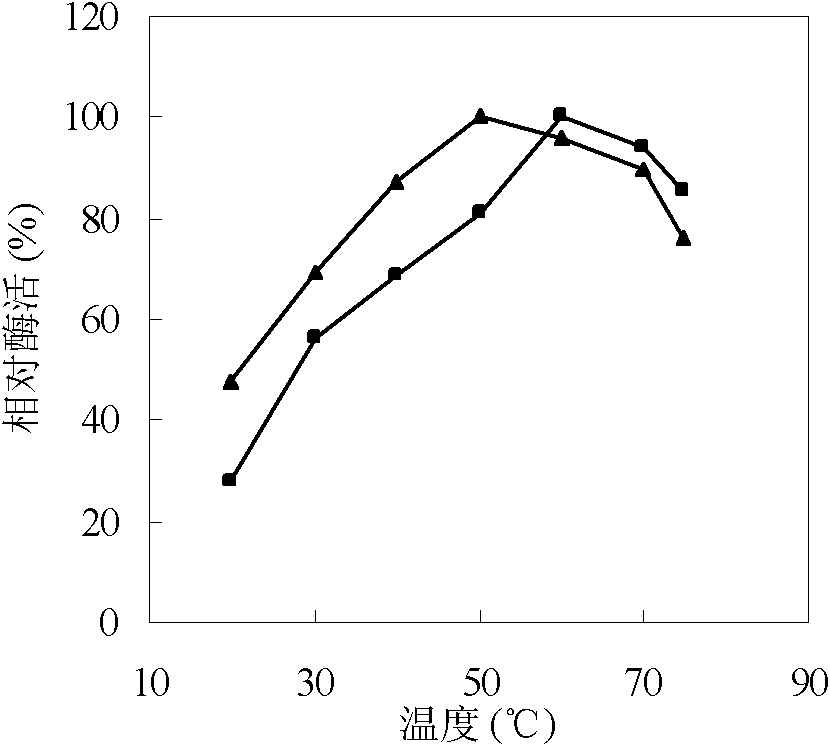

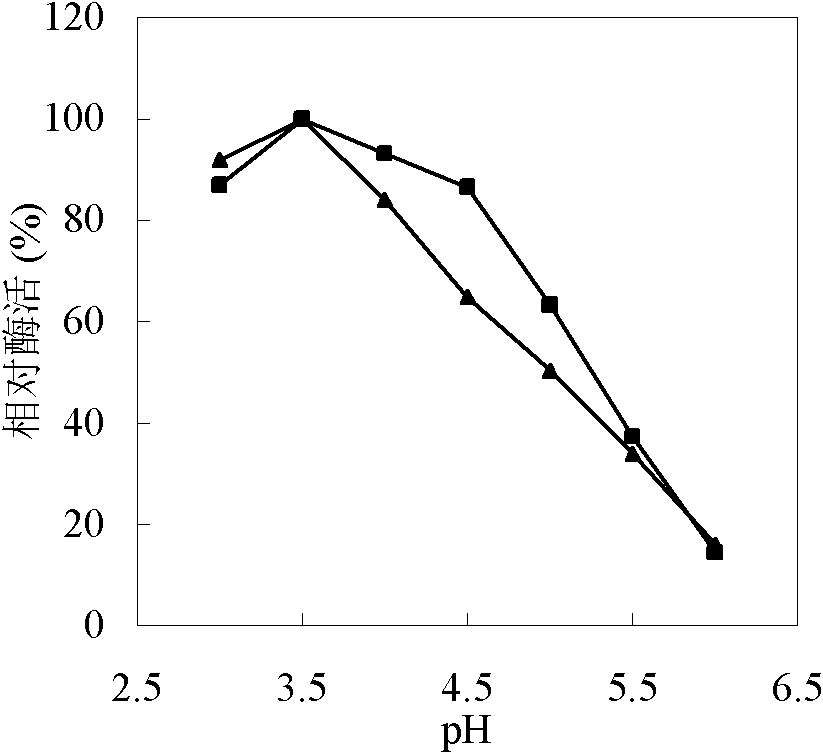

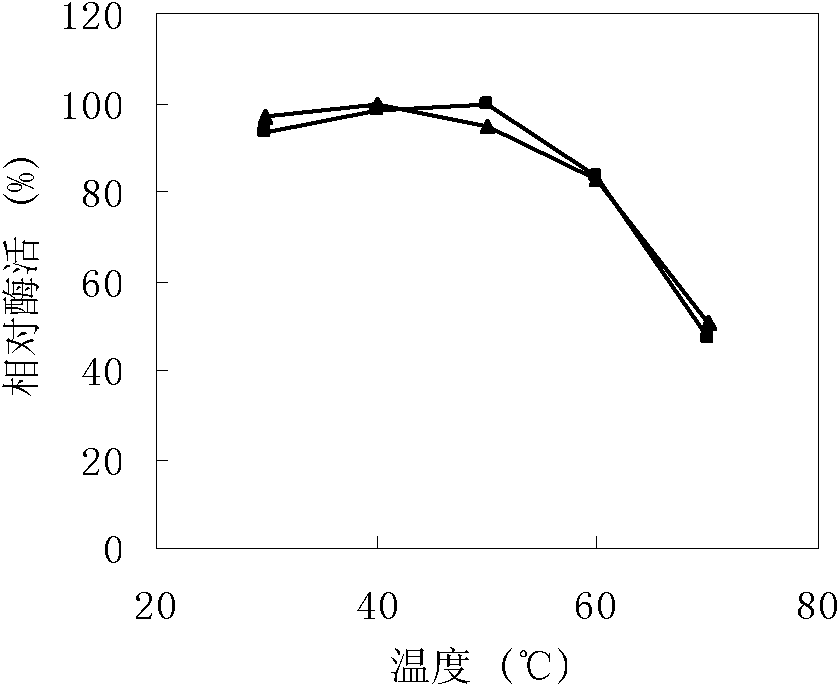

[0083] Compared with the free enzyme, the immobilized enzyme has the following characteristics: from Figure 6-10 The change of relative enzyme activity (in the same group of experiments, the highest enzyme activity is 100%, compared with the activities of other immobilized enzymes or free enzymes, expressed as a percentage) shows that the optimum reaction temperature of immobilized enzymes is 60°C, which is 10°C higher t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com