Cellulomonas fimi DA 8 bacterial strain as well as acquiring method and application thereof

A technology of cellulomonas and bacterial strains, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve the problems of unrealized industrialization, no report on the application of hemp fiber colloid decomposition, etc., and shorten the degumming cycle , Improve the combing output rate, and the effect of not being easily polluted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Screening and Obtaining of Flax Degumming Strains

[0058] (1) Sampling rotting seaweed from the Zhoushan sea area of the East China Sea, first put the seaweed and the enrichment medium at a ratio of 1g: 20ml in the enrichment medium and culture it at room temperature for 30 days, then take 0.1ml of the enrichment medium and apply it to the separation medium Culture medium, static culture at 37°C for 1 to 4 days, obtained from the wild-type degumming dominant strain;

[0059] Among them, the formula of the enrichment medium is: 5 g of flax powder, 200 ml of sterile water, and the pH is natural; the formula of the separation medium is: 5 g of flax powder, (NH 4 ) 2 SO 4 5g, K 2 HPO 4 1g, MgSO 4 0.5g, KCl 0.5g, FeSO 4 0.01, 20g agar, 1000mL water, adjust the pH to 9 with NaOH;

[0060] (2) Inoculate 4 loops of the bacterial strain obtained in step (1) into pectin nutrient medium (petri dish diameter 10cm), cultivate at 28°C for 72h, after the formation of col...

Embodiment 2

[0079]In order to enable the strain to maintain a stable high-yielding characteristic, beef extract peptone medium is used as the slant preservation medium. The raw materials and preparation methods of the medium are: 0.5g beef extract, 1g peptone, and 0.5g sodium chloride (pH7.4-7.6) , add water to 100ml constant volume, culture overnight at 37°C 200rpm, add 100ml of freezing buffer; among them, the freezing buffer consists of 0.0627g of potassium dihydrogen phosphate, 0.0177g of dipotassium hydrogen phosphate, 0.0588g of sodium citrate, sulfuric acid heptahydrate Magnesium 0.02645g, glycerin 10ml, add water to volume to 100ml; divide nutrient broth medium (beef extract 0.3g, peptone 1g, sodium chloride 0.5g, add water to 100ml volume, pH7.4-7.6) In 250mL containers, 50mL in each container, after sealing and bandaging, sterilize at 121°C for 20min; after cooling, insert the bacteria loop cultured on a slant for 24h, and shake the flask at a speed of 200r / min and a temperature ...

Embodiment 3

[0089] The flax degumming process is as follows:

[0090] Put 5g of the original flax stem into a 250ml conical flask, divide the flax flax and the fermented bacteria liquid into the conical flask at a bath ratio of 1:20, the liquid volume is 100ml, degumming in a shaker at 40°C and 200rpm for 1 day , 2 days and 4 days; when the degumming time is up, remove the degumming solution, boil in a boiling water bath for 5 minutes, rinse with tap water several times to remove bacteria on the linen, and stop degumming.

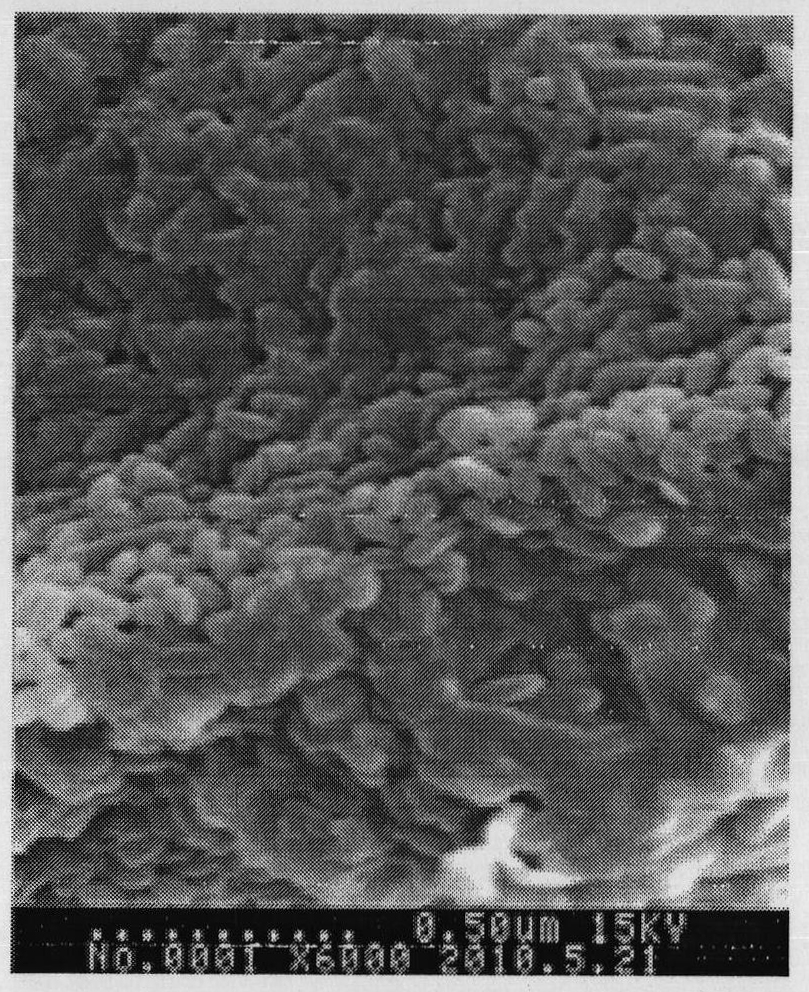

[0091] Through the observation of degummed flax, it was found that the flax fibers were obviously dispersed after 1 day, and the color of the fermentation broth became dark and turbid; after 2 days of degumming, the original bundled flax was completely dispersed into fibers, and the fermentation broth was obviously thickened; after 4 days of degumming, the degumming rate of flax reached more than 90 percent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com