Method for preparing carbon nitride tube-polyaniline-gold composite material and application method thereof

A composite material, carbon nitrogen tube technology, applied in the direction of material electrochemical variables, etc., to achieve the effects of easy availability of raw materials, high sensitivity, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1. Preparation of carbon nitrogen tube / polyaniline nanocomposite

[0024] Carbonitride tubes and their acidification treatment were synthesized according to literature methods [see: Chen H, Yang Y, Hu Z, Huo K F, Ma Y W and Chen Y 2006 J.Phys.Chem.B 110 16422]. Acidified carbon nitrogen tube (2mg / mg) 5mL was dissolved in 1% polydiallyldimethylammonium chloride (PDDA) in 10mL NaCl (0.5M) aqueous solution, stirred for 20 minutes, washed with water, and then dissolved in 1% polystyrene sodium sulfonate (PSS) in 10 mL NaCl (0.5 M) aqueous solution, stirred for 20 minutes, washed with water, separated and dissolved in 1 mol / L HCl solution, added 10 μL of aniline monomer, stirred for 30 minutes , add 5 mL of 1 mol / L hydrochloric acid solution containing 24.38 mg oxidant ammonium persulfate, react for 24 hours, wash with water, centrifuge, and dry to obtain carbon nitrogen tube / polyaniline.

Embodiment 2

[0025] Embodiment 2. Preparation of carbon nitrogen tube / polyaniline / gold nanocomposite

[0026] The carbon nitrogen tube / polyaniline is dispersed in the gold colloid, and the gold colloid is synthesized according to the literature method [Yan W, Feng X M, Chen X J, Hou W H and Zhu J-J 2008 Biosens.Bioelectron.23 925], and the carbon nitrogen tube / polyaniline is obtained / gold nanocomposites.

Embodiment 3

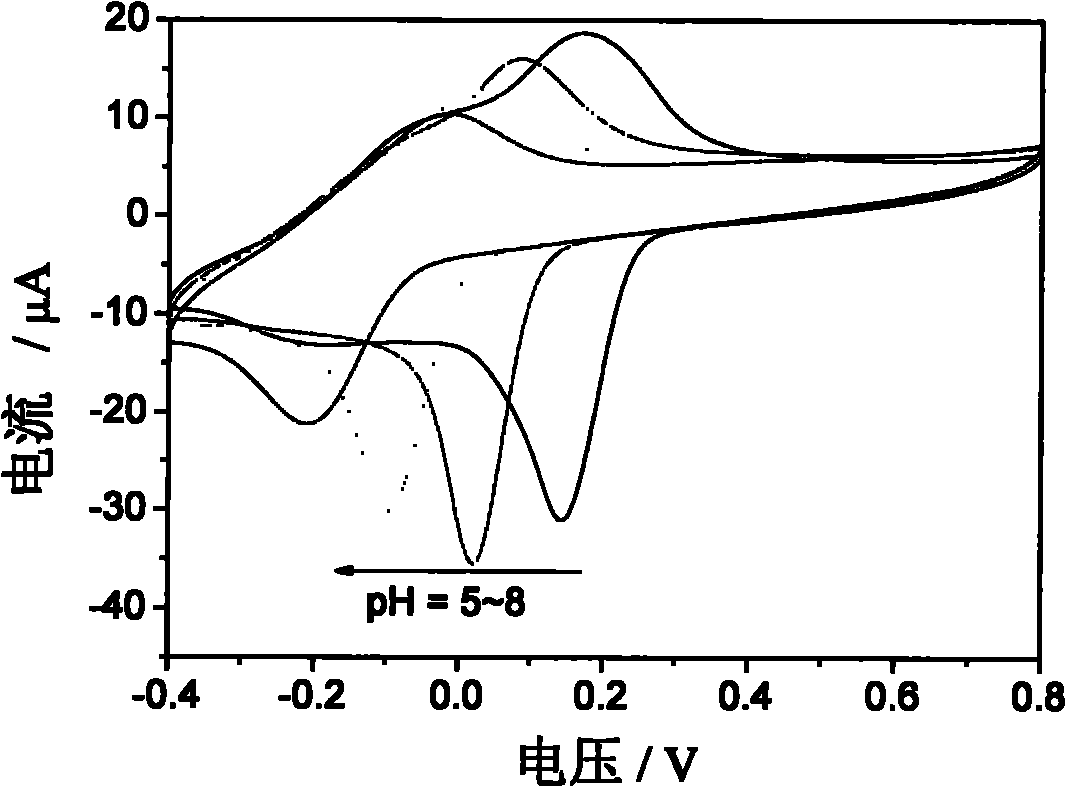

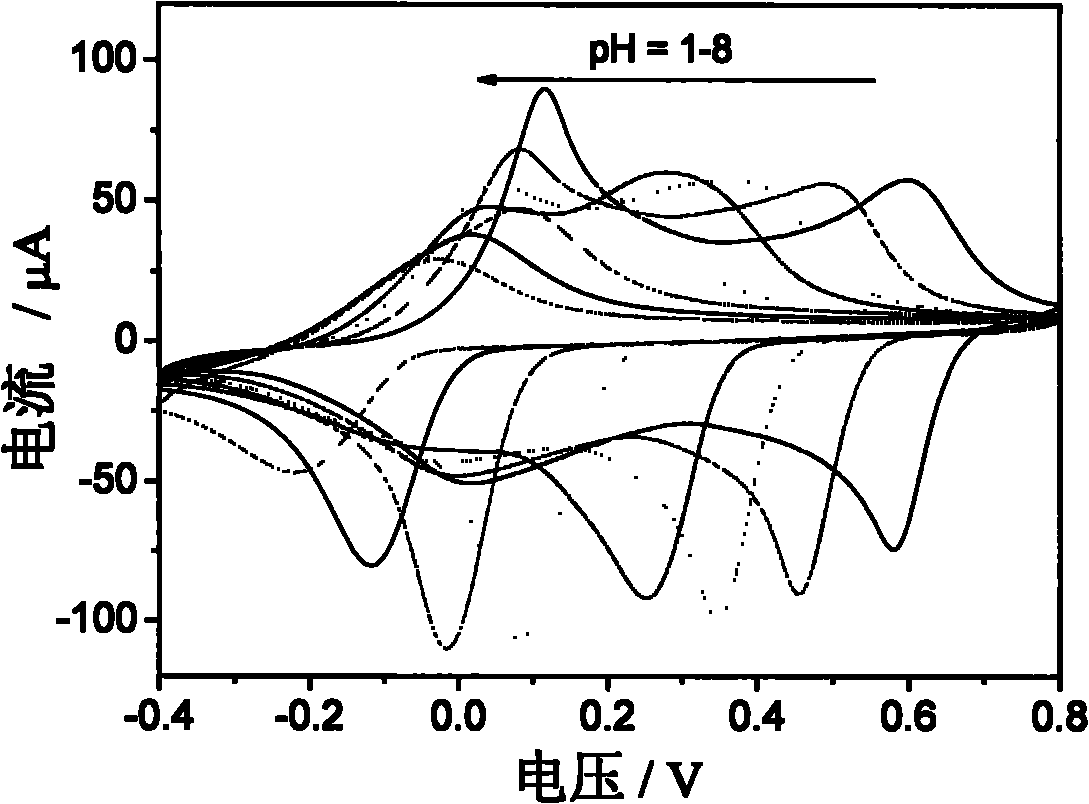

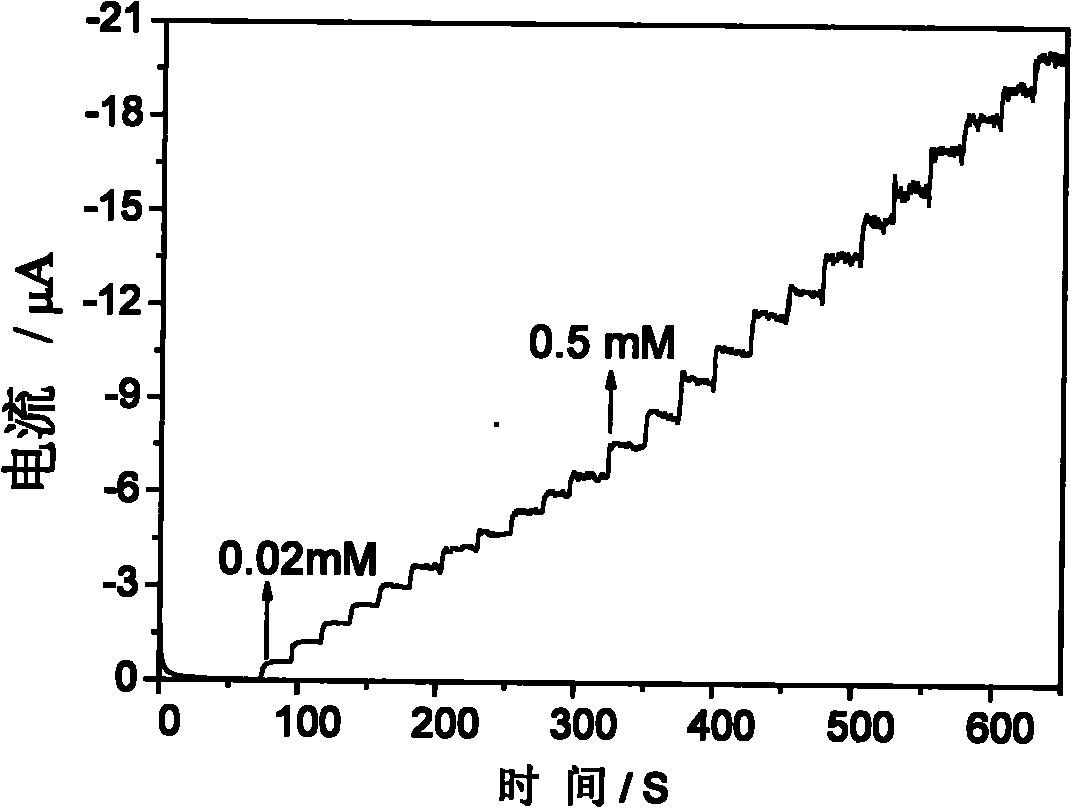

[0027] Embodiment 3. Electrochemical activity test of carbon nitrogen tube / polyaniline and carbon nitrogen tube / polyaniline / gold nanocomposite

[0028] The carbon nitrogen tube / polyaniline and carbon nitrogen tube / polyaniline / gold modified electrodes are in the phosphate buffer solution with pH from 1 to 8 in the electrolyte, the potential window is -0.4-0.8v, and the sweep speed is 100mV / s In the case of cyclic voltammetry test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com