Multilayer-film negative pole shoe and making method thereof

A technology of negative pole piece and multi-layer film, applied in the field of multi-layer film negative pole piece for lithium ion battery and its production, can solve the problem of charge and discharge capacity, cycle life current density, characteristic limitation of discharge battery, environmental pollution and complicated process and other problems, to achieve the effect of improving battery safety performance, reducing costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

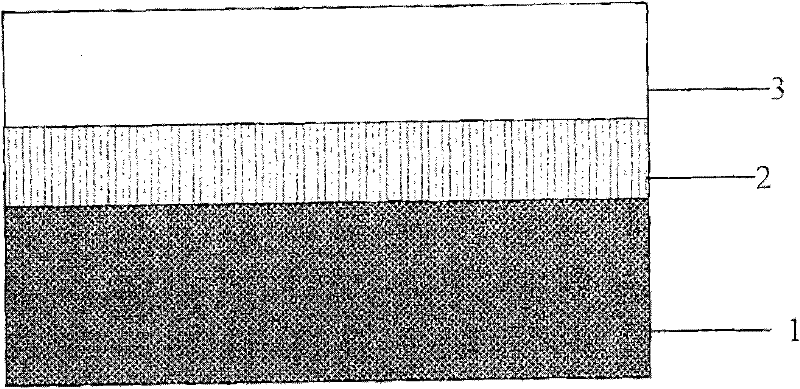

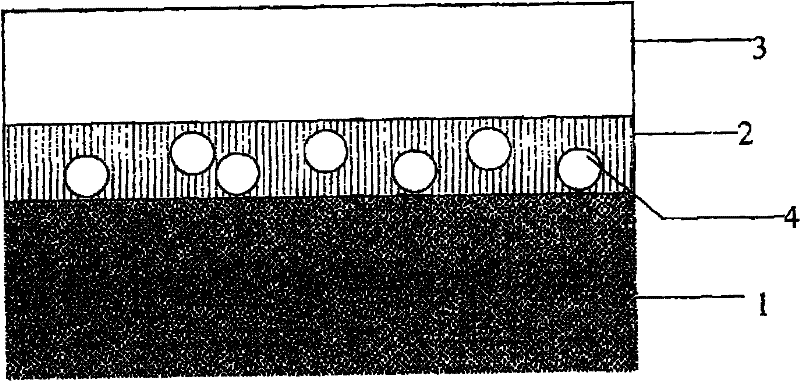

[0033] Using DC magnetron sputtering technology, using crystalline silicon-aluminum sputtering target as a target, a Si-Al composite film 2 is deposited on a copper foil 1 with a thickness of 15 μm (see figure 2 ), forming a semi-finished product with a negative electrode material layer. The sputtering power of the target is 500W, the flow rate of the gas Ar is 58sccm, and the thickness of the obtained composite film layer is 10 μm, wherein the atomic ratio of Si:Al is 100:50.

[0034] Preparation of polymer coating: polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) is used as binder, butanone and butanol are used as solvents, ethylene carbonate is used as plasticizer, and silicon dioxide is used as oxide particles . The oxide particles are dissolved in butanol, the volume ratio of butanone and butanol is 3:1, and the content of silicon dioxide is 10% of the weight of polyvinylidene fluoride-hexafluoropropylene. Add the oxide particles and plasticizer dissolved in buta...

Embodiment 2

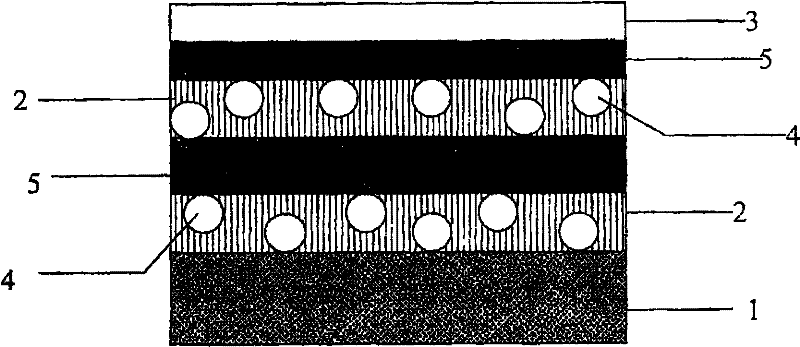

[0037] Using radio frequency magnetron sputtering technology, using crystalline silicon-aluminum sputtering target and graphite target as target materials, 5 μm Si-Al composite film layer 2, 1 μm carbon layer 5, 5 μm copper foil 1 are sequentially deposited on the copper foil 1 with a thickness of 15 μm. Si-Al composite film layer 2, carbon layer 5 of 1 μm (see image 3 ), forming a semi-finished product with a negative electrode material layer. When depositing the Si-Al composite film layer 2, the sputtering power of the Si-Al target is 500W, the flow rate of the gas Ar is 58sccm, wherein the atomic ratio of Si:Al is 100:50; when depositing the carbon layer, the sputtering power is 400W , the gas Ar flow rate is 36 sccm.

[0038] Preparation of the polymer coating: polyethylene is selected as a binder, dimethyl sulfoxide and tetrahydrofuran are used as solvents, ethylene carbonate is used as a plasticizer, and titanium dioxide is selected as oxide particles. The oxide parti...

Embodiment 3

[0041] Using radio frequency magnetron sputtering technology, using crystalline silicon-tin sputtering target and graphite target as target materials, 5 μm Si-Sn composite thin film layer 2, 5 μm carbon layer 5, and 5 μm copper foil 1 are sequentially deposited on the copper foil 1 with a thickness of 15 μm. Si-Sn composite film layer 2, carbon layer 5 of 1 μm (see image 3 ), forming a semi-finished product with a negative electrode material layer. When depositing the Si-Sn composite film layer 2, the sputtering power of the Si-Sn target is 850W, the flow rate of the gas Ar is 52sccm, wherein the atomic ratio of Si:Sn is 100:25; when depositing the carbon layer, the sputtering power is 400W , the gas Ar flow rate is 36 sccm.

[0042]Preparation of the polymer coating: polymethyl methacrylate is selected as a binder, acetone and methanol are used as solvents, propylene carbonate is used as a plasticizer, and oxide particles are selected from aluminum oxide. The oxide particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com