Silver-containing powder, method for producing the same, conductive paste using the same, and plastic substrate

A technology of silver powder and conductivity, which is applied in the fields of silver-containing powder and its preparation method, conductive paste using it and plastic substrates, which can solve the problem of poor adhesion, inability to provide universal and simple conductive paste, High surface energy, excellent storage stability, and excellent reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0124] Hereinafter, although an Example is given and this invention is demonstrated in more detail, this invention is not limited to these Examples. In addition, unless otherwise specified, "%" means "mass %".

[0125] In the following examples, the instruments used are as follows.

[0126] 1 H-NMR: manufactured by JEOL Ltd., AL300, 300Hz

[0127] Particle size measurement: FPAR-1000 manufactured by Otsuka Electronics Co., Ltd.

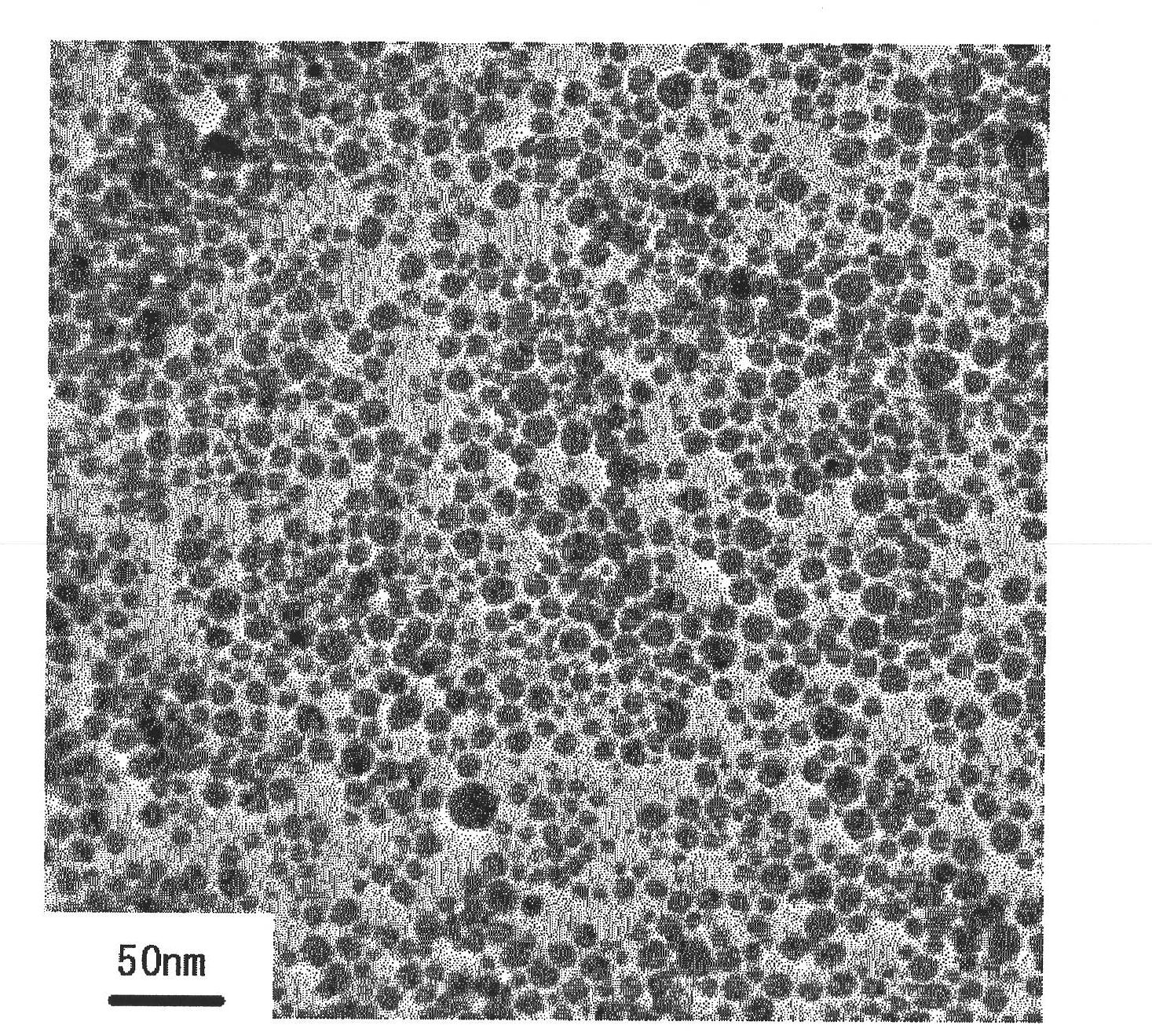

[0128] TEM observation: manufactured by JEOL Ltd., JEM-2200FS

[0129] TGA measurement: manufactured by SII NANOTECHNOLOGY INC., TG / DTA6300

[0130] Plasma absorption spectrum: UV-3500 manufactured by Hitachi, Ltd.

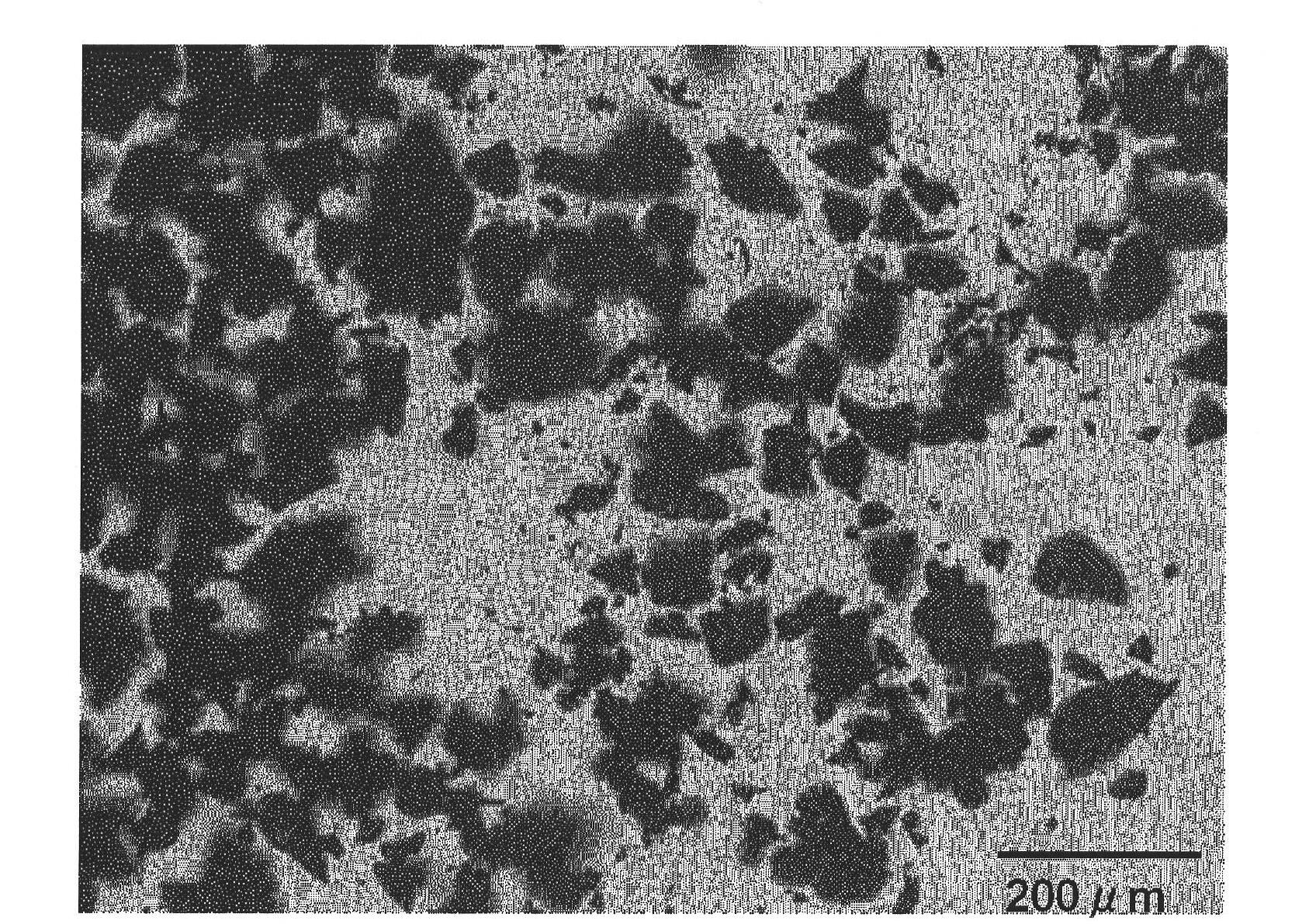

[0131] Optical microscope: Fluorescence microscope BX60, manufactured by Olympus Optical Industries, Ltd.

[0132] Light scattering digital dust meter: REX Co., Ltd., M-3423

[0133] Volume resistivity: manufactured by Mitsubishi Chemical Corporation, low resistivity meter Loresta EP

[0134] DSC measurement: DSC7200 manufactured ...

Synthetic example 1

[0135] Synthesis Example 1 [Synthesis Example of Compound (X-1)]

[0136] In a nitrogen atmosphere, in a mixed solution of 20.0 g (10.0 mmol) of methoxypolyethylene glycol [Mn=2,000], 8.0 g (100.0 mmol) of pyridine, and 20 ml of chloroform, dropwise added methoxypolyethylene glycol [Mn=2,000] over 30 minutes while stirring on ice A chloroform (30 ml) solution containing 9.6 g (50.0 mmol) of p-toluenesulfonyl chloride was obtained. After completion of the dropwise addition, stirring was further performed at a bath temperature of 40° C. for 4 hours. After completion of the reaction, 50 ml of chloroform was added to dilute the reaction liquid. Next, it was washed successively with 100 ml of 5% aqueous hydrochloric acid solution, 100 ml of saturated aqueous sodium bicarbonate solution, and 100 ml of saturated saline solution, dried over magnesium sulfate, filtered, and concentrated under reduced pressure. The obtained solid was washed several times with hexane, filtered, and dri...

Embodiment 1

[0151] 10.0 g of silver oxide was added to 138.8 g of an aqueous solution using 0.592 g of the compound (X-1) obtained in Synthesis Example 1, and stirred at 25° C. for 30 minutes. Next, 46.0 g of dimethylethanolamine was gradually added with stirring. As a result, the reaction solution turned dark red and slightly exothermic, and was left to stand in this state and stirred at 25° C. for 30 minutes. Then, 15.2 g of a 10% ascorbic acid aqueous solution was gradually added with stirring. This temperature was maintained and stirring was continued for a further 20 hours, resulting in a dark red dispersion.

[0152] The obtained dispersion was sampled, and the peak of the plasmon absorption spectrum was confirmed at 400 nm by the visible absorption spectrum measurement of the 10-fold dilution liquid, and the formation of silver nanoparticles was confirmed. In addition, spherical silver nanoparticles were confirmed by TEM measurement. And when the silver content in the solid was m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com